2

Table of

Contents

Dear

Customer

Thank you for choosing a Hanna Instruments product.

Please read this instruction manual carefully before using this instrument. This

manual will provide you with the necessary information for correct use of this

instrument, as well as a precise idea of its versatility.

If you need additional technical information, do not hesitate to e-mail us at

representative near you at www.hannainst.com.

All rights are reserved. Reproduction in whole or in part is prohibited without the

written consent of the copyright owner, Hanna Instruments Inc., Woonsocket,

Rhode Island, 02895 , USA

Included...............................................................................................................................................3

Safety Measures..............................................................................................................................3

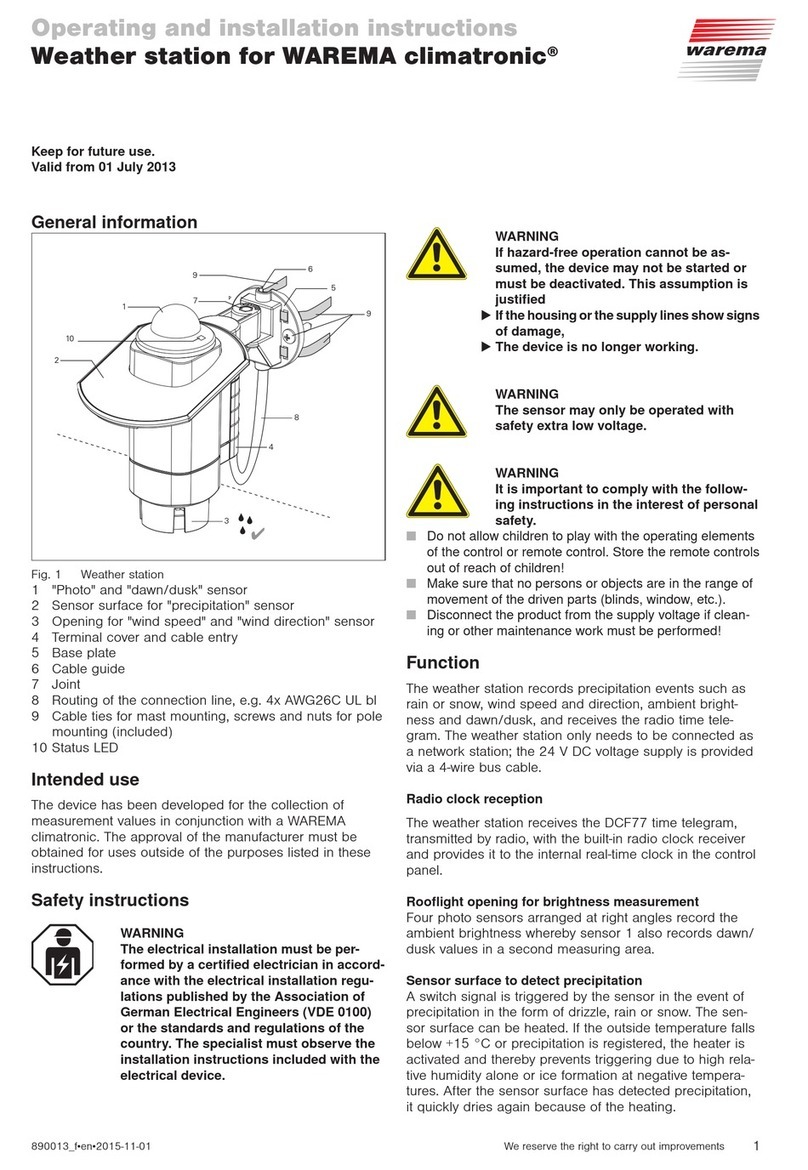

Description.........................................................................................................................................4

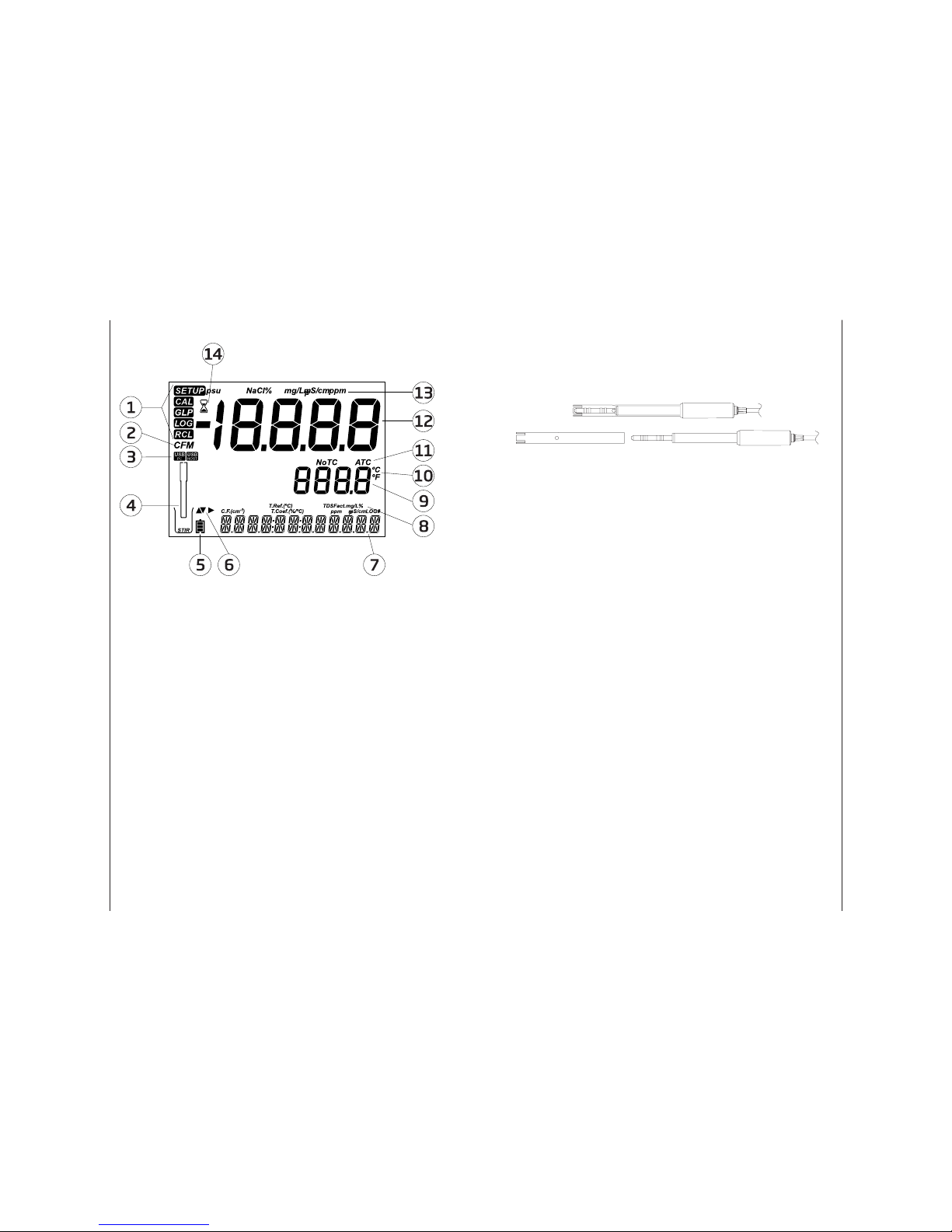

Diagram ..........................................................................................................................................4-8

Product Diagram..................................................................................................................................................................4-5

Probe Diagram.......................................................................................................................................................................... 6

Keypad Function.......................................................................................................................................................................7

Guide to Indicators.................................................................................................................................................................. 8

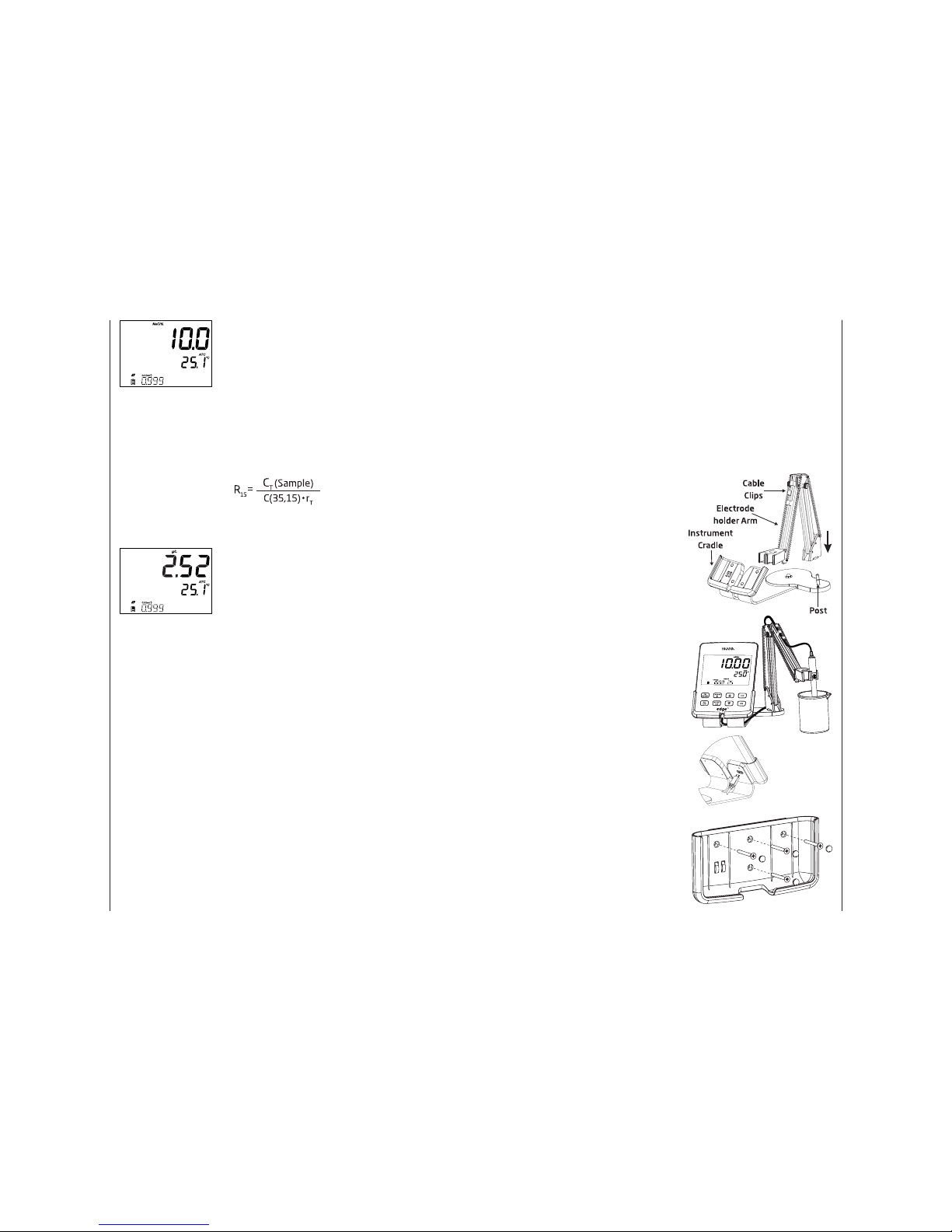

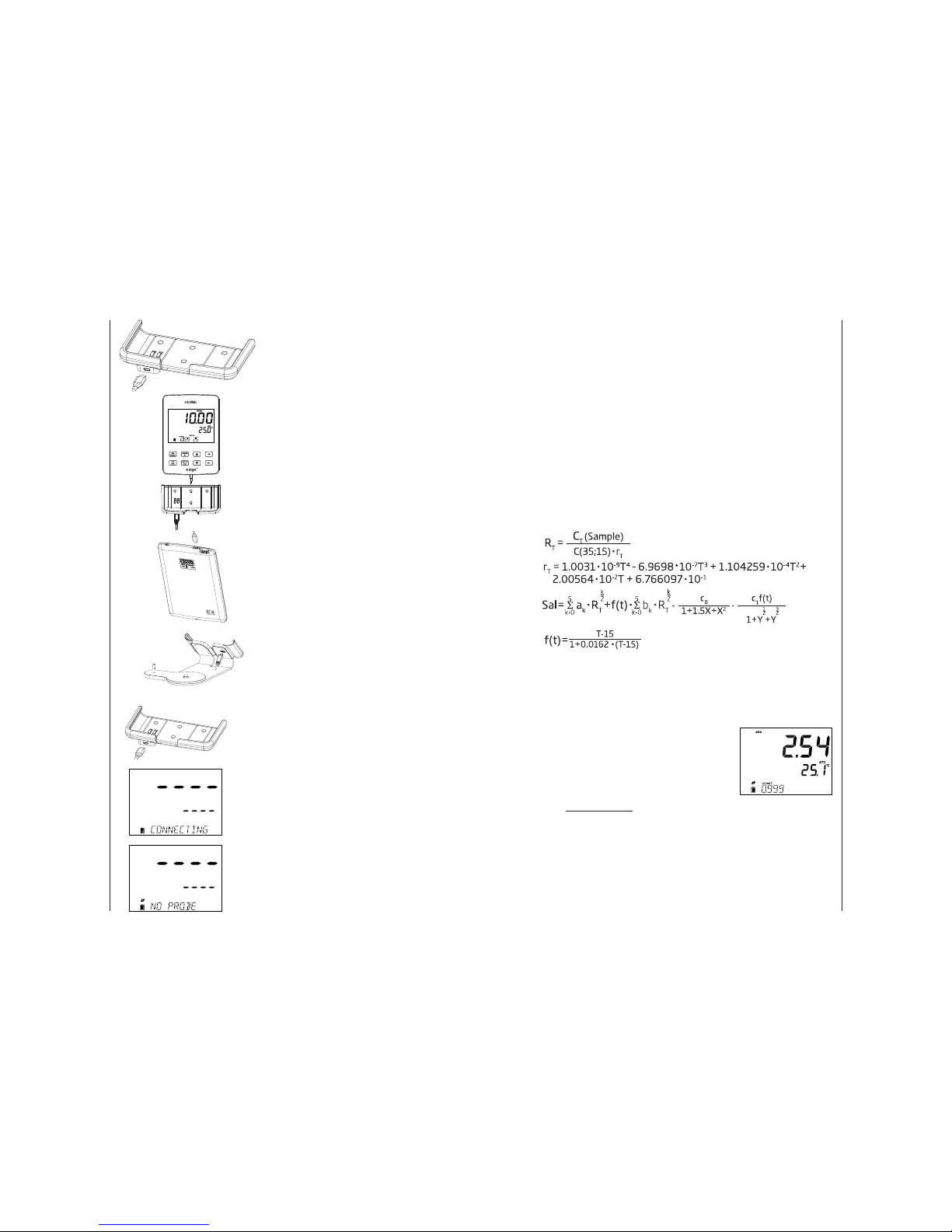

Setup/Installation....................................................................................................................9-19

Setting Up edgeEC ®......................................................................................................................................................... 9-10

Electrode & Probe Connections ...................................................................................................................................... 10

General Setup...................................................................................................................................................................11-12

Basic Mode ............................................................................................................................................................................... 13

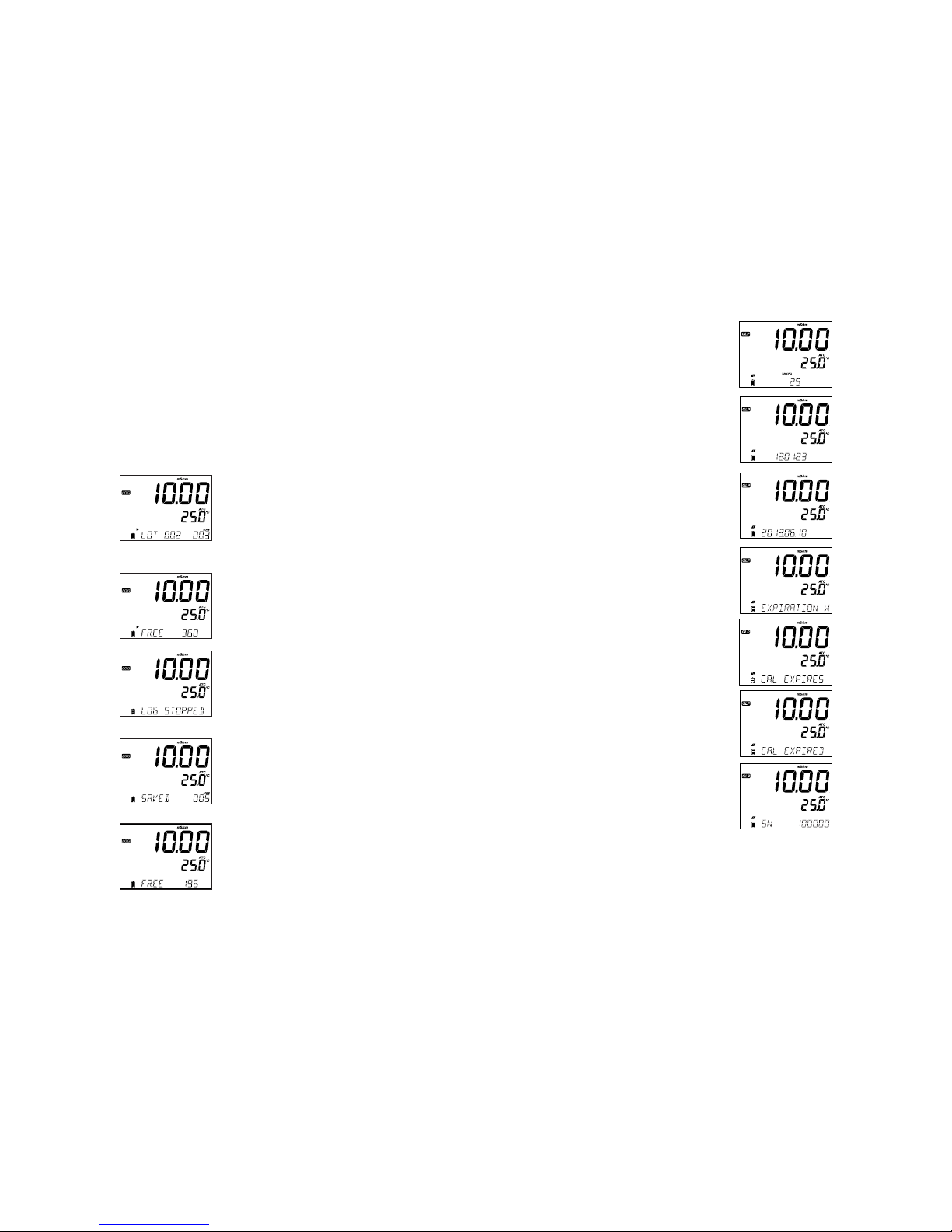

Logging Function ........................................................................................................................................................... 13-15

Viewing Logged Data................................................................................................................................................... 15-17

PC & Storage Interface.................................................................................................................................................18-19

Operational Guide .................................................................................................................20-32

Basic vs Standard EC Mode ...............................................................................................................................................20

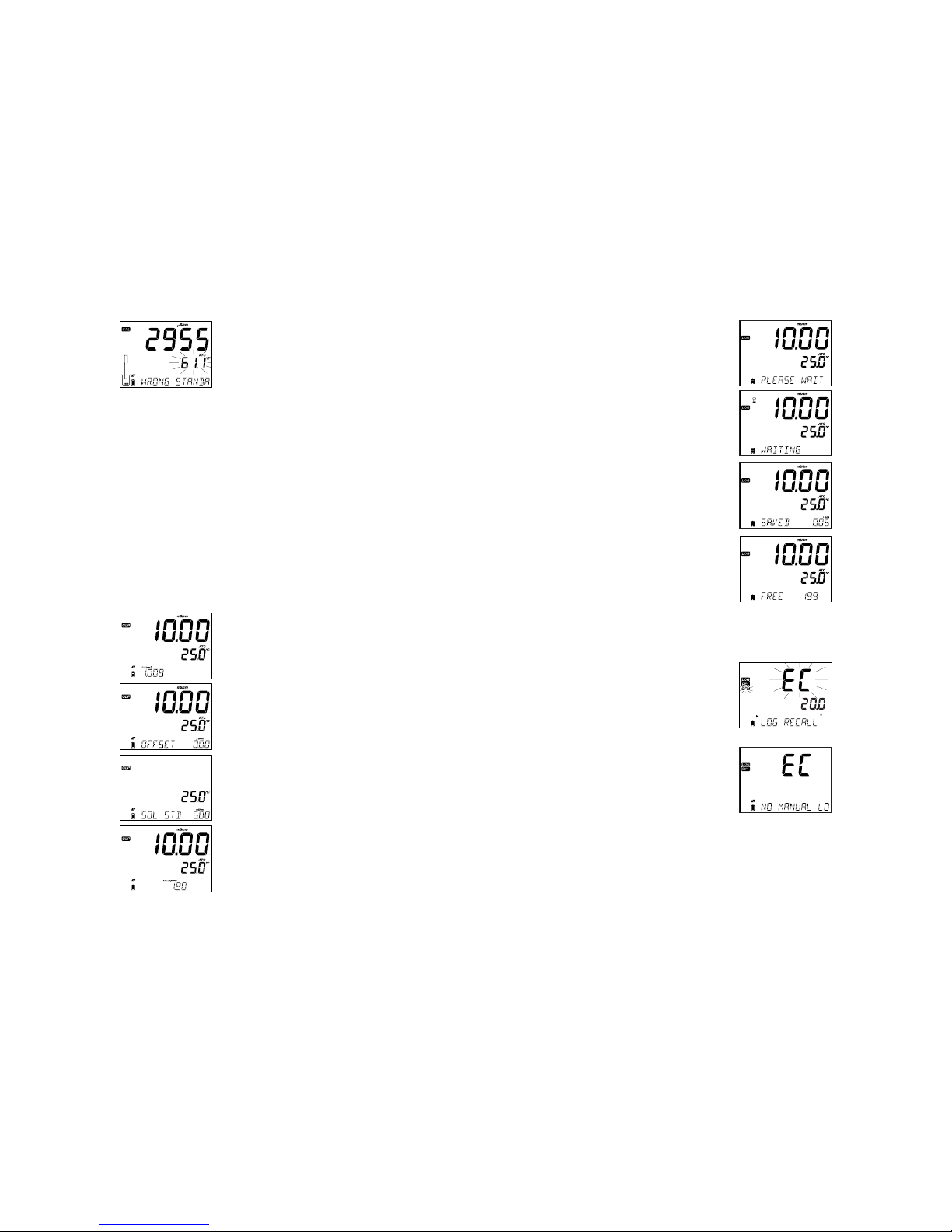

EC Meter Conguration............................................................................................................................................... 20-23

EC/TDS Calibration........................................................................................................................................................ 23-24

NaCl % Calibration ...............................................................................................................................................................25

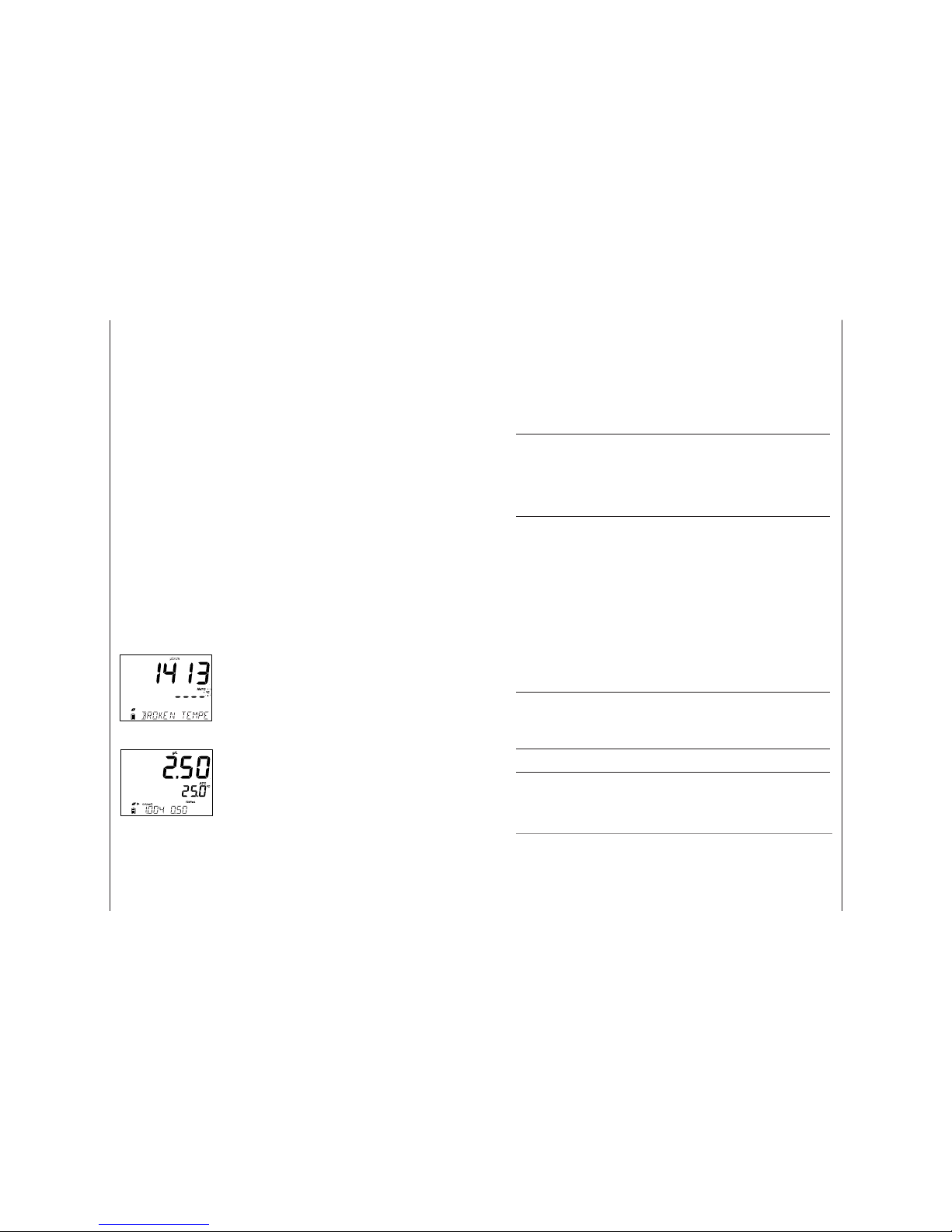

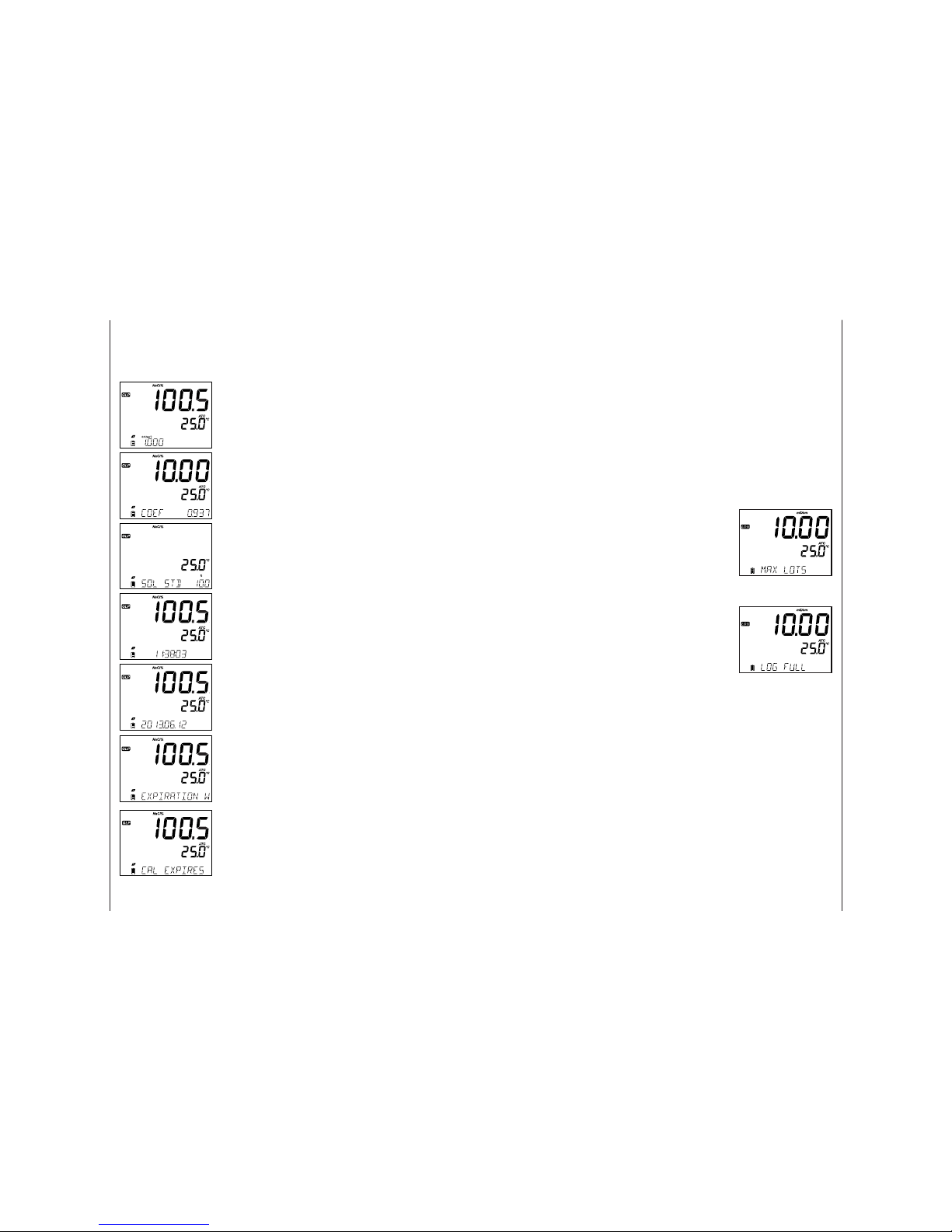

Calibration Messages................................................................................................................................................... 25-26

EC/TDS GLP Information ............................................................................................................................................ 26-27

NaCl % GLP Information.............................................................................................................................................28-29

EC/TDS Measurements............................................................................................................................................... 29-30

Salinity Measurements................................................................................................................................................30-32

Maintenance............................................................................................................................33-34

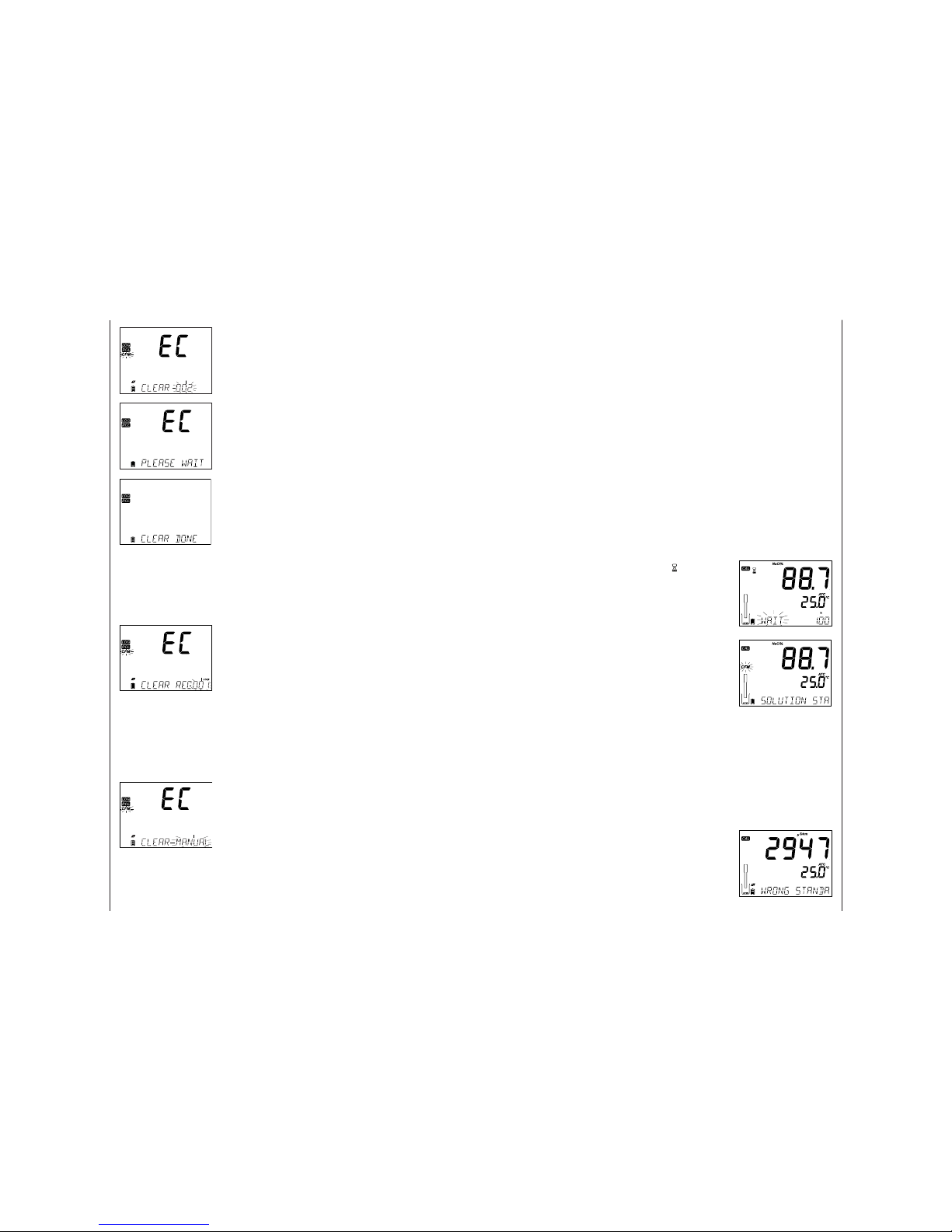

EC Probe Maintenance........................................................................................................................................................33

Troubleshooting Guide .......................................................................................................................................................34

Specications .........................................................................................................................35-36

Accessories ..................................................................................................................................... 37

Warranty ..........................................................................................................................................38