HANSEO HS-1000FS User manual

- 1 -

Manual

HS-1000FS

Hydraulic detachable multi-purpose vehicle

「 Please read in advance for your safety」

HANSEO PRECISION INDUSTRY CO.,LTD

A/S Tel +82 41) 529 3065

Fax +82 41) 529-3005

In order to use the machine safely and efficiently, be sure to read this manual

thoroughly before use.

(If it is lost, it must be purchased separately. Be careful with storage.)

The product warranty is written in this manual. The appearance and specifications

of the product are subject to change without prior notice for product improvement.

- 2 -

1. Safety work

2. Name of each part

3. Handling and operation of each part

1) Prevention and control equipment

2) GX-100A high pressure pump

3) high pressure hose reel

4) high pressure hose

5) hydraulic oil

4. Operation steps

1) engine operation

2) Ventilation part operation

3) side nozzle

4) outrigger

5) reel hose

5. Inspection and maintenance

1) Inspection of each part

2) Inspection before starting the engine

3) Inspection after engine start

4) Maintenance tips

6. First aid measures

7. Vehicle inspection

3

10

11

13

16

17

18

19

19

20

20

21

22

23

25

26

27

29

- CONTENT -

We sincerely thank you for always using

Hanseo Precision Co., Ltd.

In order to use it safely and efficiently, please

read the instruction manual to the end before

use, and fully understand the precautions

before use, the characteristics of the machine,

and how to use it.

- 3 -

1. Safety work

Failure to observe the precautions described here may result in

injury, accidents, or damage to machinery, including death. Before

driving, read these precautions and the markings attached to the

machine carefully, and follow these instructions to ensure safe and

comfortable work.

※ Be sure to observe the mark below as it is a particularly

important item for safety.

① If you do not follow danger it indicates that you will be killed or

seriously injured.

② If you do not follow warning here is a risk of death or serious

injury

③ If you do not follow caution it indicates that there is a risk of

injury.

① ② ③

1) Manual

Be sure to read the user manual.

Be sure to read the instruction manual before use, and

Please read the operation method and precautions.

Also, in actual work, it is flat and has a wide view.

Practice the operation method in a good place.

Incorrect usage will cause accidents.

- 4 -

When lending a machine to another person, explain how to

handle it.

When lending or transferring the machine to a person other than the

user, give this instruction manual together, explain how to use it, and

instruct them to read the instruction manual.

Incorrect usage will cause accidents.

2) Worker's condition

These symptoms and these people do not drive.

Those who fall under the following items should not drive or work.

◦ When you are unable to concentrate on your work due to overwork,

illness, the influence of drugs, or other reasons.

◦ When drinking alcohol. ◦ When you are pregnant.

◦ People under the age of 18.

◦ People who do not know how to operate and use the machine

3) Work clothes

Dress appropriately for the job.

When working, wear clothes suitable for the job.

Too loose clothes. Clothes that are uncomfortable to use such as

fluffy clothes, headbands, and shawls

Be careful to prohibit it.

◦ Wearing a long sleeve top

◦ Wear long pants

◦ Wear a helmet or work hat

◦ Wear shoes that do not slip well

◦ Wear a protective mask for safety

Failure to observe the above may interfere with machine operation,

- 5 -

get caught in a rotating object, or slip and fall.

4) Machine modification

No mechanical modification

Modification of the machine is strictly prohibited. Do not modify.

When replacing parts for consumables or repairs, be sure to use our

genuine parts.

Please purchase and use.

Failure to do so can lead to death or damage to the machine.

5) Inspection

Covers must be attached.

Covers removed for inspection and cleaning must be attached intact.

Also, replace deformed covers.

Failure to do so may result in a winding accident or safety hazard.

Even minor failures are repaired and used.

If an abnormal sound or strange smell occurs during work,

immediately stop the engine, check each part, and contact the store

where you purchased the product or the A/S department of the head

office. Repair even minor failures before use. Failure to do so will

lead to malfunction.

Check and clean.

Before using the machine, be sure to inspect and clean it. Also,

regular inspections must be followed to ensure safe and long-term

use of the machine.

- 6 -

When inspecting and cleaning each part, fix the wheels in a flat, hard

place, stop the engine, and run. Failure to do so may lead to

accidents, injuries, breakdowns and overturns.y lead to accidents,

injuries, breakdowns and overturns.

Inspection and cleaning should be performed after the

overheated part has cooled down.

Check and clean after the engine body, muffler, and overheated parts

of the rotating material have sufficiently cooled down. Failure to do

so may result in burns.

After use, be sure to clean it on the same day.

When washing with water, be sure to wipe off the moisture and apply

machine oil or grease to the friction area to prevent rust. Also, start

the engine to remove any water that has accumulated in the fan

cover.

Failure to do so may lead to machine breakdown or accidents due to

rust.

6) Fuel

No fire when refueling.

No fire when fuel is being supplied or when

fuel is next to it. Do not smoke or get

close to flames. Failure to do so will ignite

the fuel and lead to fire. Be sure to use

unleaded gasoline for automobiles as fuel,

and do not use leaded gasoline, fake gasoline, or denatured gasoline.

It adversely affects each part of the engine and leads to engine

trouble or breakdown.

- 7 -

Refueling and refueling are performed after the engine has

cooled down.

Never open the fuel cap, refuel or refuel while the engine is running

or when the engine is hot.

Failure to comply will lead to fire.

Watch out for fuel leaks.

Because the fuel hose is made of rubber, it may be damaged by UV

rays, etc. If the hose breaks, fuel leakage will occur, so be sure to

check. If damage is noticeable, contact the agency or head office A/S

to exchange for genuine parts. Failure to comply will lead to fire.

Check or change engine oil and hydraulic oil regularly.

There is no breakdown when you need to change engine oil

regularly. In addition, regular cleaning of the air cleaner must be

observed. Oil should be lubricated up to the appropriate line shown in

the figure.

7) Sealed indoor

Pay attention to the exhaust

gas of the engine.

The exhaust gases from the engine are harmful. Do not start the

engine in an enclosed indoor space. The engine is used outdoors with

good ventilation. Specially when starting indoors, provide adequate

ventilation. Failure to observe this will lead to poisoning by exhaust

gas, leading to death

- 8 -

8) Attention when working

Pay attention to obstacles in all directions when working.

When working, pay attention to obstacles (slope, cliff topography) in

all directions.

Failure to do so may result in serious accidents, resulting in death,

injury, or machine breakdown.

Damage occurs.

Remove foreign substances around the engine.

Before use, check the engine cooling fan, air intake port, air cleaner

air intake port, and muffler for foreign substances such as garbage.

Failure to do so can lead to engine trouble, overheating, and fire.

Do not put your hand on the belt

rotating part.

Do not put your hand while driving.

Failure to do so can lead to disability

accidents such as hand amputation or death.

Do not put your hand inside the cover.

There is a rotating object inside the belt cover. Do not put your

hands or feet in the gap.

Failure to do so will lead to injury.

Do not panic and respond in an emergency.

- 9 -

Incorrect usage is the cause of an accident. If you do not understand

how to operate with great care and know how to operate without

embarrassment, you will not be able to make appropriate judgments

in an emergency, and risk avoidance is impossible. This can lead to

deaths, injuries and machine breakdowns.

When starting the engine, be sure to check the surrounding safety.

Before starting the engine, check the safety of people and objects

around you and make sure that all switches are “OFF”.

Failure to comply will lead to unexpected accidents such as runaway.

No sudden start, sudden stop, or sudden turn

When rotating in uneven areas, slow down sufficiently.

Failure to do so can lead to fall or fall and damage to the machine.

Park on flat ground.

When leaving the machine, the engine will stop on a level, sturdy

surface. Parking on a slope is dangerous, so avoid dangerous places

as much as possible.

Failure to do so will cause the machine to move and lead to an

accident.

8) Caution on the slope

Driving on a slope is at a low speed.

- 10 -

When driving on a slope, or when preventing or preventing

quarantine, reduce the speed sufficiently.

Failure to do so may lead to a fall, fall or damage to the machine.

On slopes, do not put a full amount of fuel in the fuel

tank.

When using the machine on a slope, fuel may overflow, so use it

without full fuel (two-thirds is appropriate). Failure to do so will

cause fuel to overflow and lead to a fire accident.

8) Storage

The machine is stored indoors.

When storing the machine for a long period, be sure to store it

indoors, and if it is stored outdoors, cover it to prevent rain. (Short

term storage)

Long-term exposure to UV rays shortens the life of the machine.

- 11 -

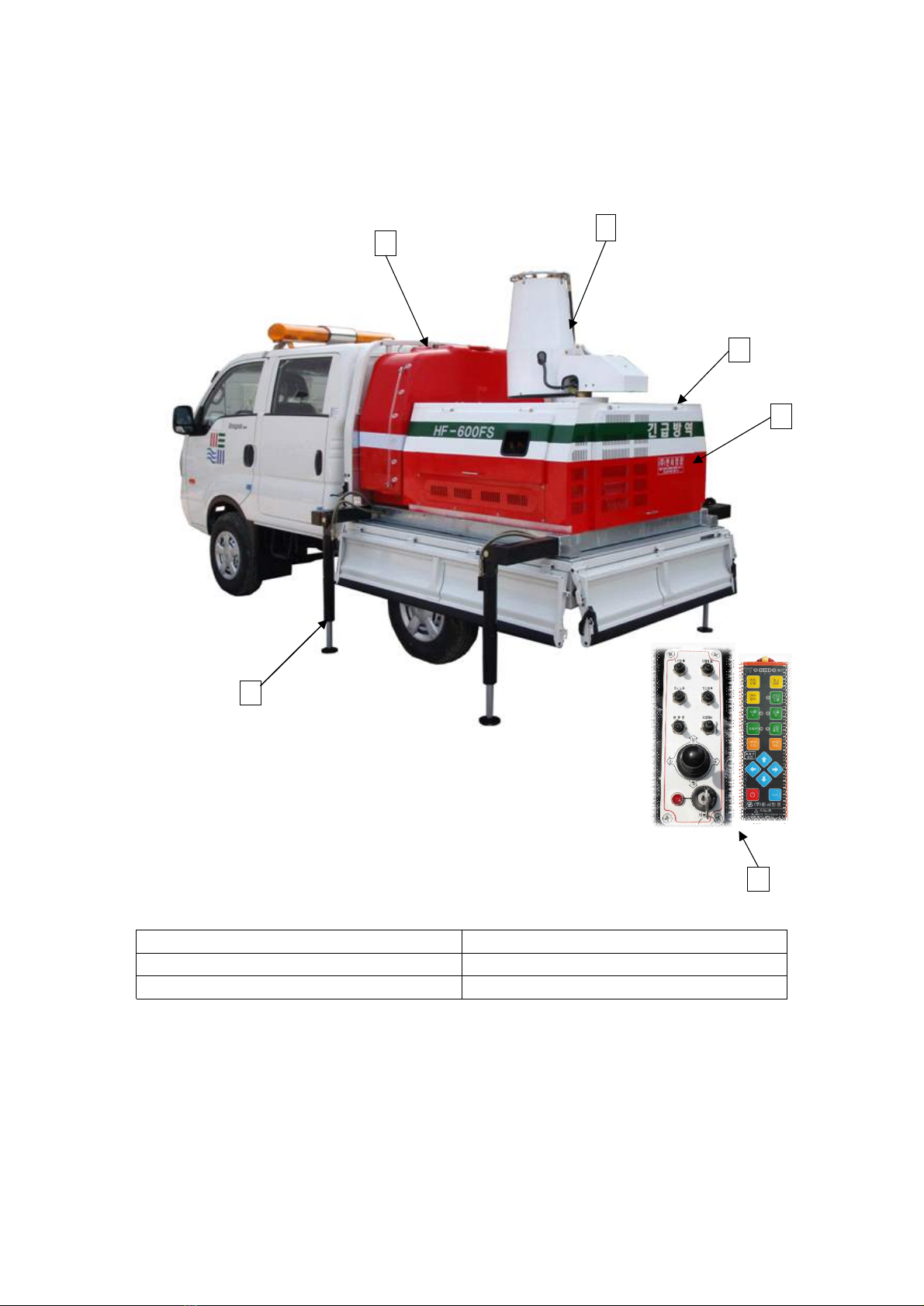

① Outrigger

④ Engine room

② Water tank

⑤ Door

③ Fan

⑥ Remote control

2. Name of each part

1

2

4

3

6

5

- 12 -

3. Handling and operation of each part

1) Prevention and control equipment

(1) Water tank

-The water tank is made of special FRP (synthetic resin), so it can

be used permanently due to its strong impact and corrosion

resistance.

-In the water tank, a strainer and a stirrer were installed to enable

the control work.

-It can be used practically as it is equipped with a 1000ℓ water tank.

(2) Fan

-Long-distance control is possible by spraying fine chemicals in the

strong wind generated by the variable axial fan.

-The object is shaken by the influence of the wind, and the chemical

is evenly applied to the front and back, so it is more effective than

general control.

-Up, down, left and right directions can be easily operated with a

wired remote control.

(3) Filter (filter)

-It is installed in the suction port of GX-100A (high pressure pump)

to filter out foreign substances, thus preventing malfunction and

malfunction of the pump.

(4) beacon

-In case of an emergency, warning lights and sirens are used to

inform the vehicle that it is an emergency vehicle, and can be used

for vehicle broadcasting in normal times.

(5) rear camera

-This vehicle is equipped with a rear camera so that you can see the

external situation from the inside of the vehicle, and you can work

with the air vents while looking at the rear camera monitor.

(6) Wired remote control

-The user convenience has been improved by making it possible to

operate the engine and manipulate the air vents inside the vehicle

during prevention.

- 13 -

(7) Pump room

-It protects key parts and equipment of the vehicle, keeps the user's

safety when operating the machine, and prevents outsiders from

approaching, freezing in winter, and the inflow of foreign substances.

-It is designed to allow easy inspection and maintenance with a

structure that opens three sides.

(8) Main instrument panel

-The instrument panel is installed so that the same functions as the

wired remote control installed inside the vehicle can be performed

from the rear of the vehicle for convenience.

-The main switch and the fuse box are concentrated in one place,

making it easy to manage and troubleshoot.

(9) Drain

-It is a device that discharges water remaining in the tank. It is

attached to the rear of the vehicle, and the drain valve uses a 2" ball

valve to prevent residual water from remaining in the tank and pipes,

so it is effective in preventing freeze in winter.

(10) Outrigger

-It can be used as a general vehicle in normal times and as a forest

fire/prevention vehicle in emergency situations.

-The hydraulic pump is located in the pump room, and it is easily

used by operating the switch.

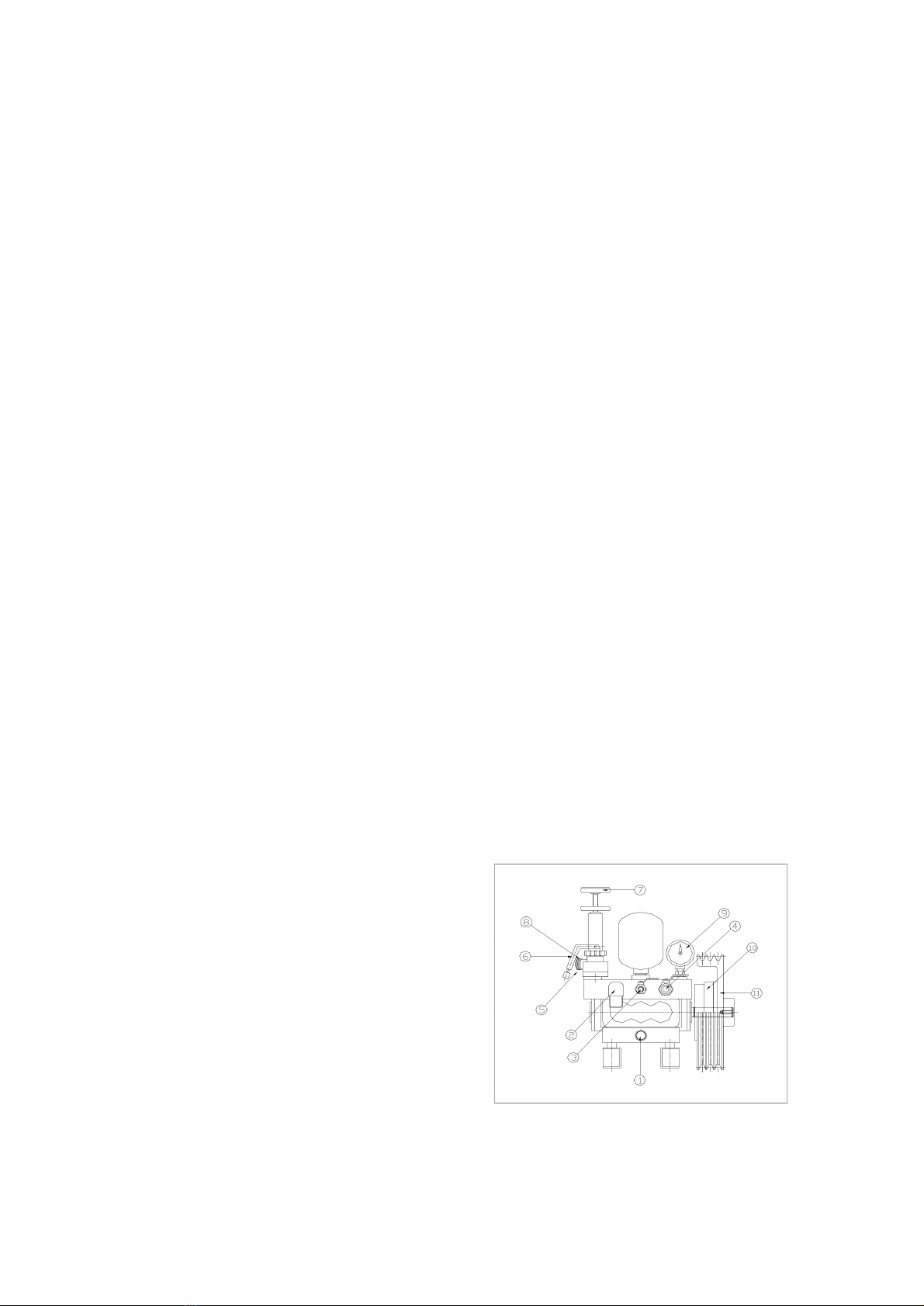

2) GX-100A high pressure pump

(1) Turn on the ignition key mounted

on the instrument panel and wired

remote control to turn on the

power. In this state, when the high

pressure pump switch is turned

on, the electronic clutch operates

to transmit power to the high

pressure pump, and the pump

operates.

- 14 -

1. To prevent safety accidents, avoid access when pulleys or belts

are rotating.

2. For repair and inspection, be sure to turn off the engine and cut

off the power before repairing on a level surface for safety.

1. Before turning on the pump switch, check the safety,

interference, and direction of valves, hoses and nozzles before use.

2. Be sure to turn off the pump switch and turn off the ignition

key after finishing the work to prevent discharge.

Check

1. Before using the high pressure pump, check the belt tension

and wear conditions, and check the oil in the crankcase before

use.

-If the belt tension is loose, use a tension adjusting bolt to adjust

the tension. If the belt is severely worn, the belt must be

◆ Fire extinguishing and control work through hose reel ◆

1. Water sucked through the suction hose is discharged through the

pump. At this time, you can open and close the valve according to

the purpose of use.

-When using a hose reel, close other valves and open and use only

the valve connected to the hose reel.

-There are 3 discharge valves, the left valve is directed to the side

nozzle, the middle valve is connected to the manifold connected to

the hose reel and the air outlet, and the right valve is assembled

with quick coupling.

-Quick coupling is an extra valve that is normally used by

connecting it to the compressor, and it is a valve that can be sprayed

by connecting a hose occasionally.

- 15 -

1. If the pump is idle for more than 2-3 minutes without inhaling

water, the piston and V-packing will wear out, resulting in poor

pump performance and failure.

2. Spraying through a hose reel is appropriate if it is set at

40~45kg/㎠.

3. Adjust the pressure of the pump with the pump running and all

valves closed. If you close the valve after setting the pressure

while spraying water, the pressure applied to the pump rises

rapidly, causing an overload to the pump, causing a malfunction.

replaced.

-If there is insufficient oil in the crankcase oil gland, it is safe to

add oil.

2. Unscrew the high-pressure hose wrapped around the reel, install

the spray device (nozzle), and open the valve to spray water.

3. A pressure regulator (regulator) is attached to the GX-100A

high-pressure pump to adjust the pressure and instantly remove

the pressure in case of an emergency.

-The pressure control device is pressurized when locked using bolt

⑦, and decompressed when released, so it can be easily adjusted

while looking at the pressure gauge.

-If the product is used under excessive pressure (50kg/㎠ or more),

the belt and the electronic clutch may slip, causing abrasion and

failure. In addition, overloading occurs on the entire machine, which

can cause breakdowns and shorten machine life.

4. If a sudden abnormality occurs in the pump or the pump pressure

is too high, raise the handle ⑥ upward and check. At this time, the

water sucked into the pump returns naturally to the tank through

the water hose. (No pressure)

- 16 -

Please be sure to check.

※ In winter, drain water from the tank, etc., and run idle for 20 to

30 seconds to drain the water remaining in the pump and piping to

prevent freezing.

1. Disinfectant not only harms the human body, but can also harm

humans, especially keep it out of reach of children or the elderly.

2. This equipment uses wind to control, and pesticides are often

blown in unintended directions according to the flow of the wind.

3. Never spray directly on people or livestock.

4. Please note that the act of discharging pesticides remaining in

the tank after work is prohibited in rivers, rivers, or water

sources.

◆ How to use the pump for quarantine work. ◆

1. Check the scale marked on the medicine tank and dilute the

chemical solution to be sprayed referring to the medicine dilution

table.

2. Please perform spraying work when there is no special weather

change.

3. When controlling, the pump pressure is about 20kg/㎠.

4. After cleaning work, wash the tank and pump with clean water to

prevent corrosion and damage caused by disinfectants.

3) High pressure hose reel

(1) The automatic reel installed inside the engine room has an inner

diameter 13mm hose 150m wound around it, and when using it,

pull out the fixing pin on the side. When winding the hose, turn

on the switch located at the bottom of the reel to automatically

wind it.

(2) It is designed to automatically wind the hose by connecting the

- 17 -

-When unwinding and winding the hose, it is safe to use it when

the pump is stopped and there is no pressure in the hose.

power through the D.C motor and the electronic clutch and turning

on the switch.

(3) For safety, the power unit is designed to automatically slip when

a certain force is applied to protect workers, hoses and

equipment.

4) High pressure hose

(1) High pressure hose is a hose manufactured by our company to be

used at high pressure (100kg/㎠ or more).

(2) The hose is fastened with a special quick coupling, so it is easy

to attach and detach, and it can be connected and disconnected

without tools.

(3) For the convenience of use, it is composed of multi-stage nodes

(100m, 50m) so that it can be used properly according to the

conditions of use, and if the hose breaks, it is possible to use it by

connecting another hose immediately.

5) hydraulic oil

(1) Temperature rise

Hydraulic oil generates heat due to pipe resistance or the action of

relief valves. Excessive heat not only degrades efficiency, but also

promotes oil deterioration due to an increase in the temperature of

the hydraulic oil, which may lead to malfunctions that are liable to

leak in the hydraulic system. Therefore, it should be avoided that

hydraulic oil becomes abnormally high temperature due to overload,

cavitation, direct sunlight from the sun, and access to hot objects. In

general, the temperature of hydraulic oil suitable for operation is

30~80°C, the limit operating temperature range is 80~100°C, and

- 18 -

higher temperatures are in the dangerous range.

(2) Against foreign matter, air, and moisture

Hydraulic equipment is composed of a combination of precise

rotational parts, perturbation parts, tight contact parts, and minute

gaps, so if foreign substances are mixed, the function will

immediately deteriorate or become inoperative. In addition, when the

mixing ratio of air is high and the temperature is high, oxidation of

oil is promoted due to the catalytic action of metals and moisture.

Moisture mixing can cause corrosion, and it can also cause wear and

tear as it emulsifies and slows lubrication.

(3) Hydraulic oil and filter replacement

If the oil ages, its color and viscosity will deform and it will not

function properly. Replace it every 200 hours.

- 19 -

① Engine operation

- Start the vanguard engine from the main board (instrument

panel) or remote control.

- While using the pump, use the RPM control switch on the main

board to adjust the output.

- After use, be sure to turn off the engine in reverse order.

② Ventilation part operation

- Turn on the engine from the remote control and set it to an

appropriate RPM. (Use the remote control for the air vent)

Turn on the blower fan, spray nozzle and high pressure pump

switch on the remote control.

Use the joystick to adjust the direction of the air outlet. -Turn off

the engine in reverse order after use.

4. Operation steps

- 20 -

It is safe to attach and detach on a flat surface.

When the operation is over, be sure to take the key inserted

into the main board (instrument panel) to avoid safety accidents.

Check the cylinder, hydraulic pump and hydraulic hose for leaks.

④ Outrigger

A. When separating the vehicle and the special features, loosen

the bolts fastened to the vehicle and the special features, pull out

the outriggers (hydraulic cylinders) on both sides to a position

where there is no vehicle interference, and make the outriggers

face toward the ground.

B. Connect the power by rotating the hydraulic pump by inserting

the power supply key.

When separating and fastening from the vehicle using an outrigger,

operate the manual valve alternately between the front and the

rear so that the machine is kept horizontal. Be especially careful

as there is a risk of overturning. There is no risk of overturning

when the joint between the machine and the vehicle is tightened

with bolts.

C. Use the manual valve located inside the engine part on the left

side of the base to gradually rise so that the vehicle and the

control unit are completely separated

D. When the vehicle and the features are completely separated,

you can slowly advance the vehicle and exit.

E. When the vehicle exits, keep the special equipment level

gradually and lower it to store it safely.

③ Side nozzle

-Turn on the engine from the remote control and set it to an

appropriate

RPM.

Turn on the side nozzle and high pressure pump switch on the

remote control.

-Turn off the engine in reverse order after use.

Table of contents