!2009 > D 1.6 TCI-U > !

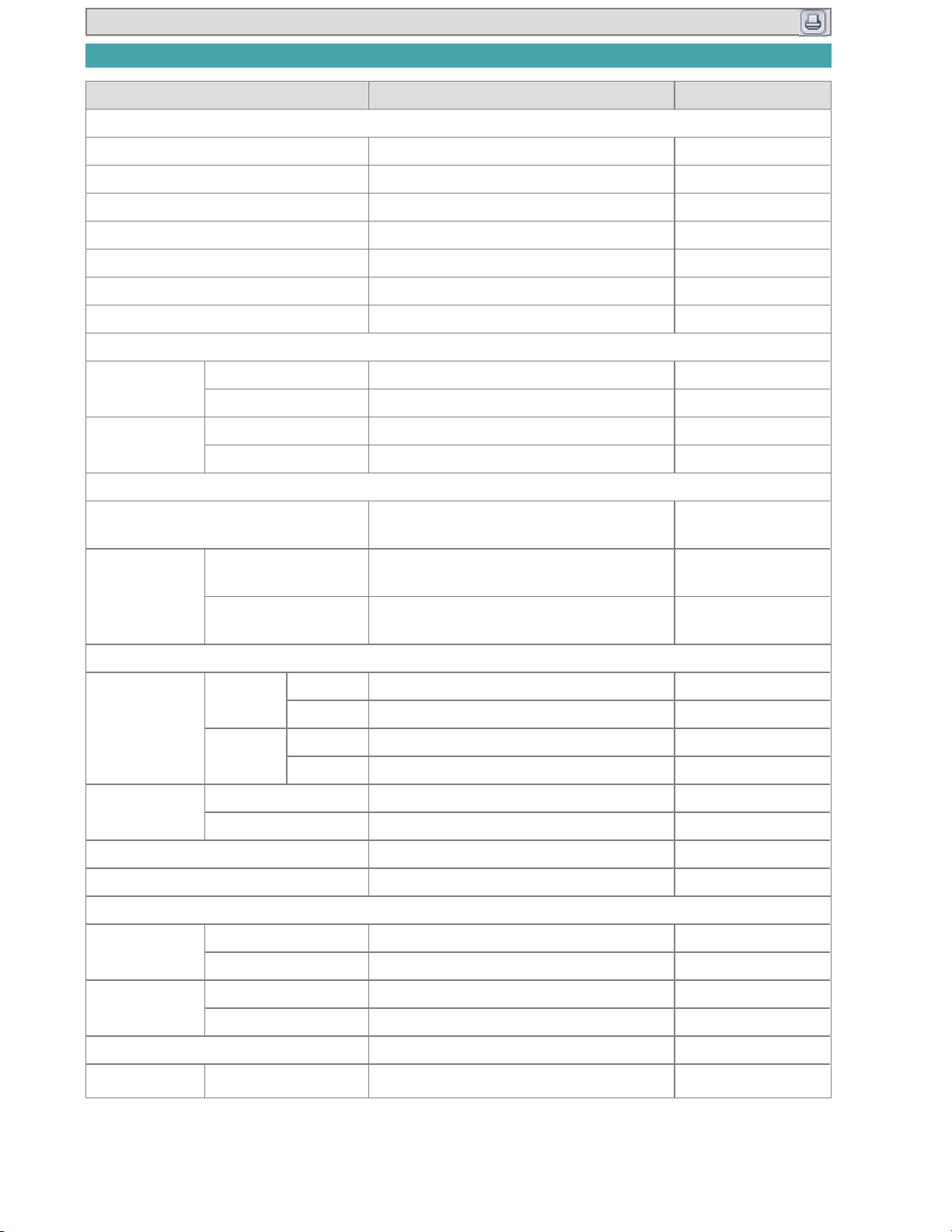

TROUBLESHOOTING

Symptom Suspect area Remedy

"#$%#&!'%()%*&!+%,-

./#0*'.1!%#,&*#.1

10+&*!&#$%#&!#0%(&(2

300(&!0*!%'4*04&*15!%#(,.11&6!&#$%#&!)15+-&&12 7&4.%*!0*!*&41.8&!,-&!)15+-&&1!.(

*&9:%*&62

;0*#!4%(,0#!*%#$(2

<=%1!80#(:'4,%0#!'.5!0*!'.5!#0,!8.:(&!,-&

&#$%#&!,0!'%()%*&2>

?#(4&8,!,-&!851%#6&*!)0*!.!10((!0)

80'4*&((%0#2

7&4.%*!0*!*&41.8&!.(!*&9:%*&62

;0*#!8*.#@(-.),!,-*:(,!/&.*%#$(2 7&41.8&!,-&!8*.#@(-.),!.#6!/&.*%#$(

.(!*&9:%*&62

"#$%#&!'%()%*&!+%,-

./#0*'.1!A.1A&!,*.%#

#0%(&2

B,:8@!A.1A&(2

<C.*/0#!/:%16:4!0#!,-&!A.1A&!(,&'!8.#!8.:(&

,-&!A.1A&!#0,!,0!810(&!4*04&*152>

7&4.%*!0*!*&41.8&!.(!*&9:%*&62

"D8&((%A&!+0*#!0*!'%(E.1%$#&6!,%'%#$!8-.%#2 7&41.8&!,-&!,%'%#$!8-.%#!.#6

(4*08@&,!.(!*&9:%*&62

;0*#!8.'(-.),!10/&(2 7&41.8&!,-&!8.'(-.),!.#6!A.1A&

1%),&*(2

"#$%#&!'%()%*&!+%,-

8001.#,!80#(:'4,%0#

FG.:1,5!851%#6&*!-&.6!$.(@&,!.#6H0*!8*.8@%#$

0*!0,-&*!6.'.$&!,0!,-&!851%#6&*!-&.6!.#6

&#$%#&!/108@!8001%#$!(5(,&'2

F C001.#,!80#(:'4,%0#!'.5!0*!'.5!#0,!8.:(&

,-&!&#$%#&!,0!0A&*-&.,2

F ?#(4&8,!,-&!851%#6&*!-&.6!.#6

&#$%#&!/108@!)0*!6.'.$&!,0!,-&

8001.#,!4.((.$&(!.#6H0*!.!).:1,5

-&.6!$.(@&,2

F 7&4.%*!0*!*&41.8&!.(!*&9:%*&62

"#$%#&!'%()%*&!+%,-

&D8&((%A&!0%1

80#(:'4,%0#

;0*#!A.1A&(I!A.1A&!$:%6&(!.#6H0*!A.1A&!(,&'!0%1

(&.1(2 7&4.%*!0*!*&41.8&!.(!*&9:%*&62

;0*#!4%(,0#!*%#$(2

<=%1!80#(:'4,%0#!'.5!0*!'.5!#0,!8.:(&!,-&

&#$%#&!,0!'%()%*&>

?#(4&8,!,-&!851%#6&*!)0*!.!10((!0)

80'4*&((%0#

7&4.%*!0*!*&41.8&!.(!*&9:%*&62

"#$%#&!#0%(&!0#

(,.*,E:4I!/:,!0#15

1.(,%#$!.!)&+

(&80#6(2

?#80**&8,!0%1!A%(80(%,52 J*.%#!,-&!0%12

7&)%11!+%,-!,-&!80**&8,!A%(80(%,5!0%12

;0*#!8*.#@(-.),!,-*:(,!/&.*%#$2 ?#(4&8,!,-&!,-*:(,!/&.*%#$!.#6

8*.#@(-.),2

7&4.%*!0*!*&41.8&!.(!*&9:%*&62

K44&*!&#$%#&!#0%(&I

*&$.*61&((!0)!&#$%#&

(4&&62

30+!0%1!4*&((:*&2 7&4.%*!0*!*&41.8&!.(!*&9:%*&62

L*0@&#!A.1A&!(4*%#$2 7&41.8&!,-&!A.1A&!(4*%#$2

;0*#!0*!6%*,5!A.1A&!1%),&*(2 7&41.8&!,-&!A.1A&!1%),&*(2

B,*&,8-&6!0*!/*0@&#!,%'%#$!8-.%#!.#6H0*

6.'.$&6!(4*08@&,!,&&,-2

7&41.8&!,-&!,%'%#$!8-.%#!.#6

(4*08@&,(2

;0*#!,%'%#$!8-.%#!,&#(%0#&*I!%)!.441%8./1&2 7&41.8&!,-&!,%'%#$!8-.%#!,&#(%0#&*

.(!*&9:%*&62

;0*#!8.'(-.),!10/&(2 ?#(4&8,!,-&!8.'(-.),!10/&(2

7&41.8&!,-&!8.'(-.),!.#6!A.1A&

1%),&*(!.(!*&9:%*&62

;0*#!A.1A&!$:%6&(!0*!A.1A&!(,&'(2 ?#(4&8,!,-&!A.1A&(!.#6!A.1A&!$:%6&(I

,-&#!*&4.%*!.(!*&9:%*&62