Haojue HJ110-2 User manual

HJ110-2/2A

95500H51121H000

https://www.motomanuals.net/

https://www.motomanuals.net/

FOREWORD

This manual contains an introductory description

on HJ110-2/2A and procedures for their

inspection/maintenance and overhaul of their

main components. Other information considered

as generally known is not included.

Apprentice mechanics and do it yourself

mechanics will also find this an extremely useful

repair guide.

HAOJUE

JIANGMEN DACHANGJIANG GROUP CO.,LTD.

October, 2008

This manual provides you with more informa-

tion about your motorcycle and ensures users

best and quickest service.

This manual is for those adequately informed

and skilled in the maintenance of HAOJUE

motorcycle. If you are not well-informed and

skilled in this respect, you should not attempt

to effect maintenance and repair only by the

help of this manual.

This manual contain up-to-date information at

the time of its issue. There might be minor

discrepancies between your motorcycle and

this manual as a result of modifications made

after the publication of this manual.

Please contact your nearest authorized

HAOJUE motorcycle dealer.

*

*

*

https://www.motomanuals.net/

1

1-1

1-1

1-2

1-2

1-2

1-3

............................

...................................

.....................

...............................

..............................

..........................

GENERAL INFORMATION

CONTENTS

WARNING/CAUTION/NOTE

GENERALPRECAUTIONS

SERIALNUMBER LOCATIONS

FUELAND OILRECOMMENDATIONS

BREAK-IN PROCEDURE

SPECIFICATIONS

1

https://www.motomanuals.net/

Controlling torque

Near data indicates specified torque

OIL

A

S

M

No.4

1322

1342

BF

V

A

TOOL

Oil filling

Use engine oil unless otherwise stated

SUPER SILICONE GREASE

SYMBOLS

The following symbols illustrate necessary information of directions and servicing.

Symbol Item Symbol Item

SUPER GREASE “A”

MOLYPASTE

BOND No.4

THREAD LOCK BOND “1322”

THREAD LOCK BOND “1342”

Filling or using brake fluid

Measuring the current

Using special tool

Measure the voltage

Measure the resistance

https://www.motomanuals.net/

WARNING

GENERALINFORMATION

WARNING/CAUTION/NOTE

Please read this manual and follow its instructions carefully. To emphasize special information, the symbol and the

words WARNING,CAUTION and NOTE have special meanings. Pay special attention to the messages highlighted by

these signal words.

Personal safety of the rider is involved, and disregard of the information could result in injury.

For the protection of the motorcycle, the instructions and rule must be highly strictly adhered to.

NOTE:

Advice to facilitate the repair of the motorcycle is given under this heading.caIculate

Please note, however, that the contained in this manual cannot possibly cover all

potential hazards relating to the servicing, or lack of servicing of the motorcycle. In addition to the WARNING and

CAUTION stated, you must use good judgment and basic mechanical safety principles. If you are unsure about how to

perform a particular service operation, ask a more experienced mechanic for advice.

WARNINGS and CAUTIONS

GENERAL PRECAUTION

●

●

Proper service and repair procedures are important for the safety of the servicing mechanic, the safety and the

reliability of the motorcycle.

When 2 or more persons perform work in cooperation, pay attention to safety of each other.

When it is necessary to run the engine indoors, make sure that exhaust gas is forced outdoor.

When working with toxic or flammable materials, make sure that the area you work in is well-ventilated and that

you follow all of the material manufacturer's instructions.

Never use fuel as a cleaning solvent.

To avoid getting burned, do not touch the engine, engine oil and muffler until they have cooled.

After servicing the fuel, oil, muffler or brake system, check all hoses and fittings related to the system for leaks.

●

●

●

●

●

●If parts replacement is necessary, replace the parts with the HAOJUE GENUINE PARTs or their equivalent.

When removing parts that are to be reused, keep them arranged in an orderly manner so that they may be

reinstalled in the proper order and orientation.

Be sure to use special tools when instructed.

Make sure that all parts used in reassembly are clean. Lubricate them when specified.

lubricant, bond, or sealant.

When performing service to electrical parts, if the service procedures not required to use the battery power,

disconnect the positive pole.

When removing the battery, disconnect the negative wire first and then the positive wire.

When reconnecting the battery, connect the positive wire first and then the negative wire, and place the pole

cover on the positive pole.

ightening cylinder head and crankcase bolts and nuts, tighten the larger sizes first.

Always tighten the bolts and nuts diagonally from the inside working out.

Whenever you remove oil seals, gaskets, packing, O-rings, lock washers, cotter pins, circlips, and certain

other parts as specified, be sure to replace them with the new ones.Also, before installing these new parts, be

sure to remove any left over material from the mating surfaces.

Never reuse a circlip. When installing a new circlip, take care not to expend the end gap larger than required to

slip the circlip over the shaft.After installing a circlip, always ensure that it is completely seated in its groove and

securely fitted.

Do not use self-lock nuts a few times over.

Use a torque wrench to tighten fasteners to the specified torque, and wipe off grease or oil if a thread is

with them.

After reassembly, check parts for tightness and proper operation.

●

●

●

●

●

●

●

●

●

●

●

●

Use the specified

When t

smeared

NOTE:

●

●To protect environment, do not unlawfully dispose of used engine oil and other fluids, batteries and tires.

To protect Earth's natural resources, properly dispose of the used motorcycle and parts.

1-1

CAUTION

WARNING

CAUTION

https://www.motomanuals.net/

GENERALINFORMATION

1

2

SERIAL NUMBER LOCATIONS

The V.I.N (Vehicle Identification Number) is

stamped on the chassis rear under the saddle.

The engine serial number is located on the

lower of the left crankcase.

①

②

These numbers are required especially for

registering the motorcycle and ordering the spare

parts.

ENGINE OIL

SAE

20W/50

10W/50

10W/30

20W

10W

40

30

C

F

-20

-4

-10

14

0

32

10

50

20

68

30

86

40

104

Temp.

BREAK-IN PROCEDURE

During the manufacture only the best ossible

are used and all machined parts are

finished to a very high standard

allow the moving part to “BREAK-IN”

subjecting the engine to maximum

stresses s the care and restraint

exercised during its early life The general rules

are as follows:

p

materials ,itisstill

necessary to

before . The future performance and reliability

of the engine depend on .

●

●

●

1-2

The break-in mileage is 500 km.

The throttle must not be opened to the full during

the new motorcycle's break-in period. Throttle

opening should be limited to 3/4 of its maximum,

while violent acceleration should be avoided.

Do not maintain constant engine speed for an

extended time period during any portion of the

break-in. Try to vary the throttle position.

≦

FUEL AND OIL

RECOMMENDATIONS

FUEL

Use fuel with an octane number of 90-97

(Research method), preferably unleaded.

NOTE:

Unleaded fuel will extend spark plug life.

Be sure that the motorcycle engine oil you use

comes underAPI classification of SF or SG and its

viscosity rating is SAE 10W-40. If SAE 10W-40

engine oil is not available, select the oil viscosity

according to the following chart:

https://www.motomanuals.net/

...........................................

..........................................

...........................................

..........................................

............................................

.......................................

1909 mm HJ110-2) 1906 mm(HJ110-2A)

677 mm(HJ110-2) 676 mm(HJ110-2A)

1088 mm(HJ110-2) 1085 mm(HJ110-2A)

1218 mm(HJ110-2) 1202 mm(HJ110-2A)

120 mm

104 kg(HJ110-2) 106 kg(HJ110-2A)

(

Four-stroke, air-cooled, OHC

1

52.4 mm

49.5 mm

107 ml

9.1:1

VM type PZ26S

Polyurethane foam element

Electric starter with kick starter

Pressure splash

Wet automatic centrifugal type

Reciprocalshift(driving), cyclic shift(parking)

4-speed gear transmission

4.059

2.571

2.833

1.705

1.238

0.958

428, 100 links

..................................................

.....................................

..................................................

.................................................

....................................

......................................

.............................................

........................................

......................................

.............................................

.................................................

.......................................

......................................

.........................................

..........................................

........................................

.........................................

.........................................

.........................................

............................................

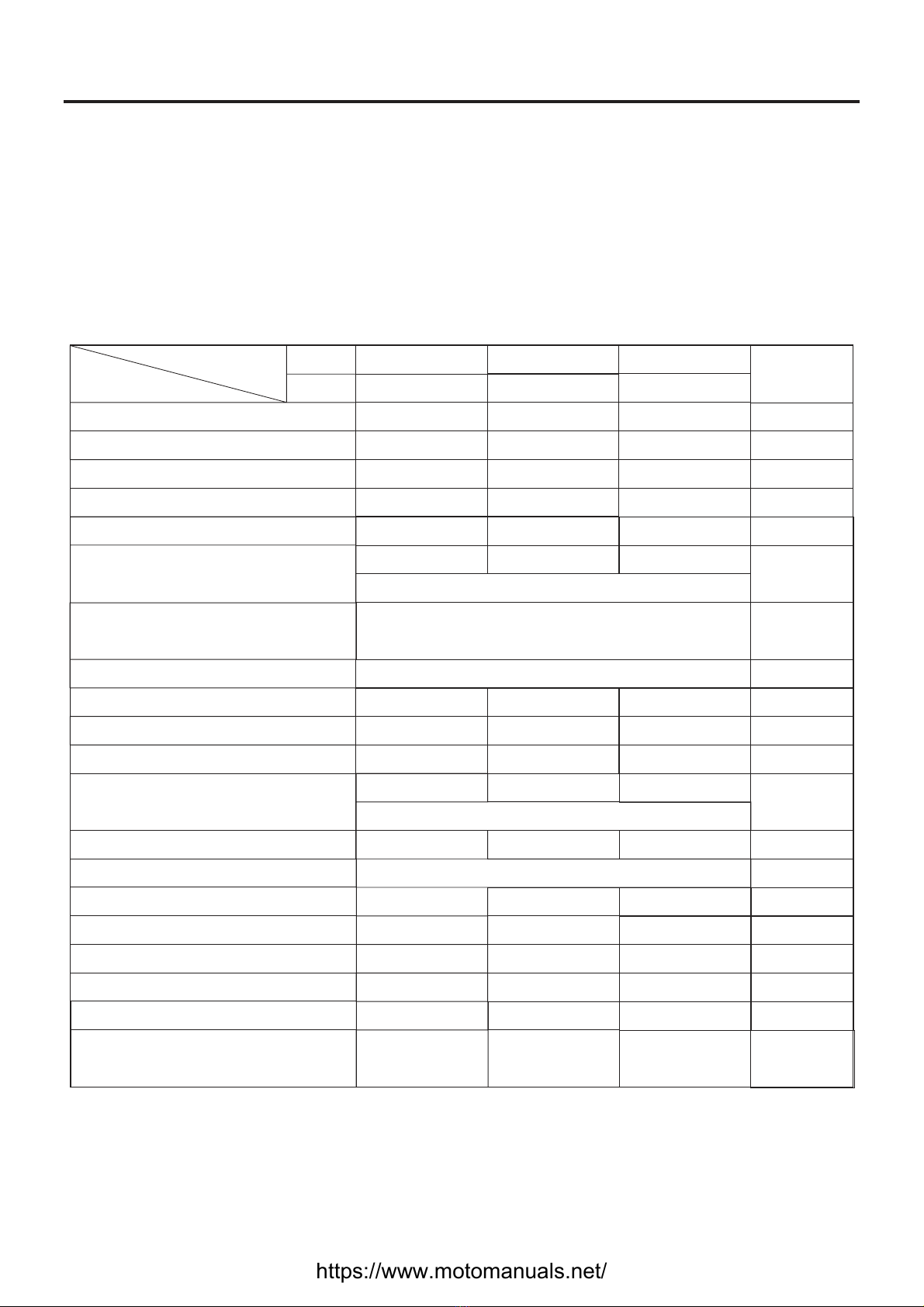

SPECIFICATIONS

DIMENSIONS AND CURB WEIGHT

Overall length

Overall width

Overall height

Wheelbase

Ground clearance

Curb weight

ENGINE

Type

Number of cylinders

Bore

Stroke

Piston displacement

Compression ratio

Carburetor

Air cleaner

Starting system

Lubrication system

TRANSMISSION

Clutch

Transmission

Gearshift pattern

Primary reduction

Final reduction

Gear ratios, low

2nd

3rd

4th

Drive chain

GENERALINFORMATION

1-3

https://www.motomanuals.net/

DC-CDI

15° B.T.D.C. below 1500r/min and

30° B.T.D.C. above 5000r/min

TORCHA7RC or NHSP LDA7RTC

12V 5Ah

15A

12V, 35W/35W

12V, 5W/21W

12V, 21W (front) 12V,21W(rear) (HJ110-2)

12V, 21W (front 12V,16W(rear) (HJ110-2A)

12V, 5W

12V, 2W×5

12V, 2W

12V, 2W

12V, 2W×2

)

...........................................

.........................................

.............................................

................................................

..................................................

................................

........................................

..............................................

.........................................

...........................................

...................................

.............................

................................

..................................................

................................................

.......................................

............................................

..........................................

..........................................

.......................................

.......................................

.........................................

............................................

ELECTRICAL

Ignition type

Ignition timing

Spark plug

Battery

Fuse

Headlight

Tail/Brake light

Turn signal light

Position light

Gear position indicator light

Dashboard panel light

High beam indicator light

Turn signal indicator light

CHASSIS

Front suspension

Rear suspension

Steering angle

Caster

Trail

Turning diameter

Front brake

Rear brake

Front tire size

Rear tire size

Telescopic, coil spring, oil dampened

Swing arm, oil dampened

coil spring 5-way adjustable

42°

27°

93 mm

3.7 m

Internal expanding

2.50-17-4PR

2.75-17-4PR

coil spring,

Internal expanding

CAPACITIES

Fuel tank including reserve

Engine oil

Front absorber oil

4.7 L

900 ml

57 ml

GENERALINFORMATION

1-4

..............................

.............................................

.....................................

*These specifications are subject to change without notice.

https://www.motomanuals.net/

2

PERIODIC MAINTENANCE

2

CONTENTS

PERIODIC MAINTENANCE

MAINTENANCE PROCEDURES

BATTERY

VALVE CLEARANCE

SPARK PLUG

THROTTLE CABLE PLAY

FUEL HOSE AND SECONDARY AIR HOSE

FUEL FILTER

DRIVE CHAIN

BRAKES

TIRES

STEERING

FRONT/REAR

LIGHTS AND SIGNAL LIGHTS

CHASSIS AND ENGINE MOUNTING BOLTS AND NUTS

COMPRESSION PRESS

AIR CLEANER

ENGINE OIL

OIL STRAINER

CLUTCH

CARBURETOR

ABSORBER

MUFFLER MOUNTING NUTS & BOLTS

CYLINDER HEAD & CYLINDER NUTS &BOLTS

...........................

......................

...........................................

...................

..................................

........................................

......

.........................................

.......................................

.......................................

............................................

........................................

...............................

..........................................

..............................................

............................................

.......................................

...............................

2-3

2-4

2-5

2-5

2-6

2-7

2-8

2-9

2-9

2-9

2-10

2-10

2-10

2-11

2-14

2-15

2-16

2-16

2-17

2-17

2-18

.......................................

2-1

2-3

..........................

...........................

................

............

https://www.motomanuals.net/

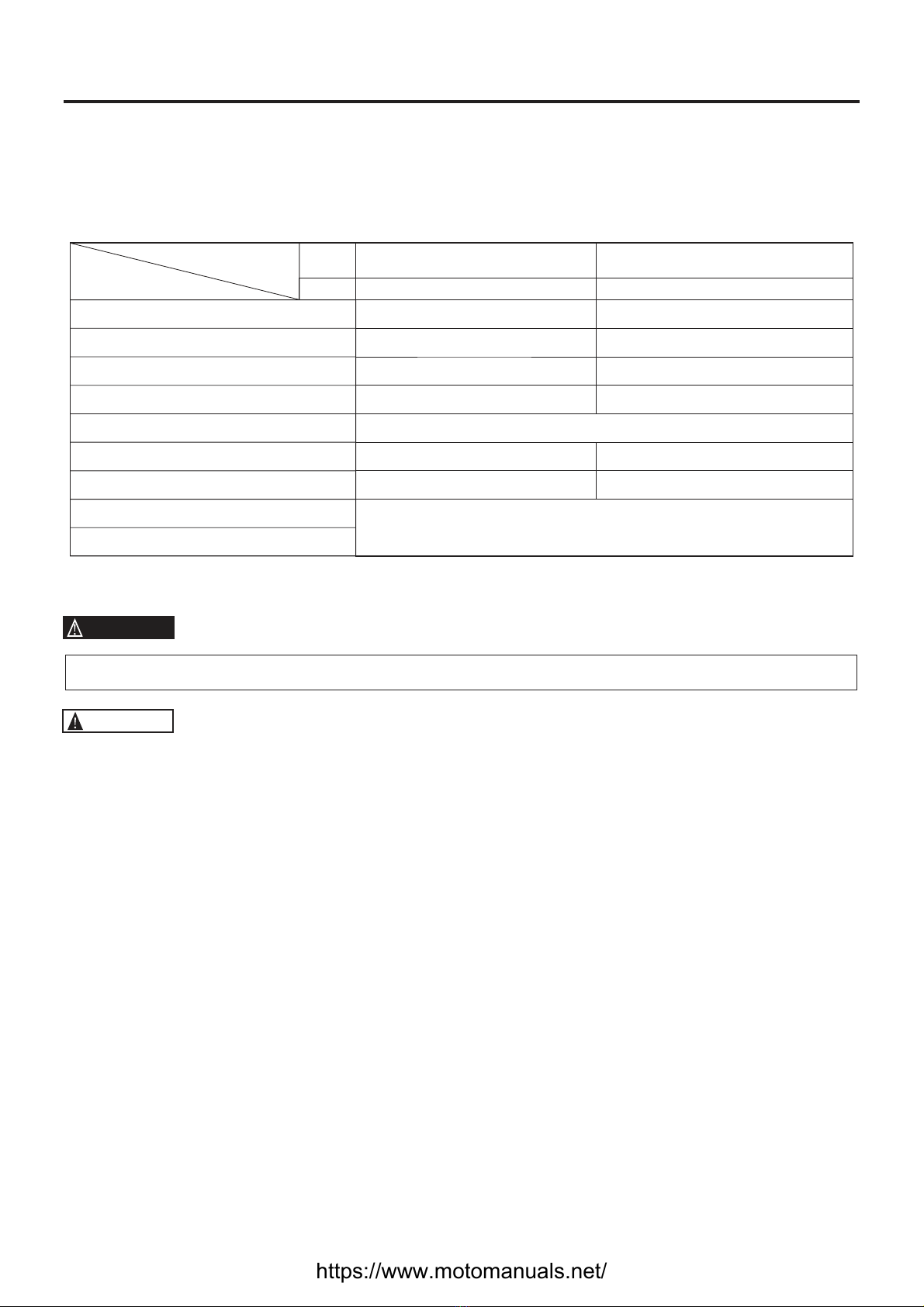

PERIODIC MAINTENANCE

The chart below lists recommended intervals for all the required periodic service work necessary to keep

the motorcycle operating at performance and economy. Mileage are expressed in terms of kilometer and

times for your convenience.

NOTE:

More frequent servicing should be considered if the motorcycle is operated under the rough conditions.

PERIODIC MAINTENANCE CHART

INTERVAL

ITEM km

month

Clutch

Carburetor (Idle speed)

Oil strainer

Engine oil

Spark plug

Valve clearance

Air cleaner

Battery

PERIODIC MAINTENANCE

2-1

_

_

_

_

_

6,000

12

_

6

1,000

3

2-3

2-5

2-4

2-6

2-7

2-8

2-9

2-9

2-9

PAGE

Inspect

Inspect

Inspect

Inspect

Inspect

Tighten

Clean

3,000

Inspect

Inspect

Inspect

Inspect

Inspect

Tighten

Clean

The first change at Initial 500 km, the second

change at 1,000km total mileage, while

further change Every 3,000 km.

Clean Every 12,000 km

Replace Every 12,000 km

Throttle cable play _

2-10

Inspect Inspect

Front and rear absorber

Chassis and engine mounting bolts

and nuts

Steering

Tires

Brakes

Drive chain

Fuel filter

Fuel hose and secondary air hose

Lights and signal lights

Inspect

Inspect

Inspect

Inspect

Inspect

Inspect

Inspect

_

Inspect, clean & lubricate Every 1,000 km

Replace Every 4 years

Inspect

Inspect

Inspect

Inspect

Inspect

Inspect

Inspect

Inspect

_

_

_

_

_

_

_

2-10

2-10

2-11

2-14

2-15

2-16

2-16

2-17

2-17

NOTE:

The inspection items above may require, if necessary, further cleaning, tighten, adjustment or replacement

"- stands for not required."

Replace

Muffler mounting nuts &bolts _2-5

Tighten Tighten

Cylinder head&cylinder nuts &bolts

https://www.motomanuals.net/

_

_

_

_

_

_

12

LUBRICATION CHART

The following is a basic lubrication requirement for a motorcycle operated in an economical manner and

based on the mileage displayed by the odometer.

INTERVAL

ITEM km

month

Initial and Every 6,000 km Every 12,000 km

6

Engine oil

Grease

Engine oil Every 1,000 km

Grease or engine oil

Grease Every 2 years or 24,000 km

Grease

Grease

Grease

Throttle cable

Throttle grip

Odometer cable

Speedometer gear box

Drive chain

Brake pedal axle

Brake cam

Steering bearing

Rear rocker arm bearing bush

PERIODIC MAINTENANCE

2-2

NOTE:

“-"stands for not required

Do not apply too much lubrication grease on the brake cam to prevent the brake from slipping.

When driving on wet roads or under rainy conditions, lubricate the parts with engine oil or grease to avoid

rust. Be sure to remove oily contamination or rust.

WARNING

CAUTION

https://www.motomanuals.net/

+

-

MAINTENANCE PROCEDURES

BATTERY

Inspect at Initial 1,000 km and Every 3,000 km

Unlock and open the saddle; remove the wires

on both the positive and negative poles,

Remove the battery.

●

NOTE:

When remove the battery, remove the negative

wire first.

+_

_

Inspect the electrolyte level, which should be

kept within “UPPER LEVEL” (the upper limit)

and “LOWER LEVEL” (the lower limit). If the

level is below the , pour the

distilled water up to the .

“LOWER LEVEL”

“UPPER LEVEL”

●

NOTE:

Only the distilled water should be poured.

UPPER

LOWER

Once the battery is put into use, no more diluted

sulfuric acid should be poured.

Do not bend, clog the exhaust pipe of the

battery or alter its path. Make sure that one end

of the pipe is securely connected with the

battery while the another end is through.

When connecting to the battery, be sure to

connect the positive and negative poles

correctly. The red wire is for the positive pole

while the black wire is for the negative pole.

Wrongly connecting to the battery poles may

result in damage to the electrical circuit and the

battery itself.

Please refer to page 6-12 for information about the

battery charging time and current.

PERIODIC MAINTENANCE

2-3

WARNING

CAUTION

https://www.motomanuals.net/

1

2

43

front

cover

screw

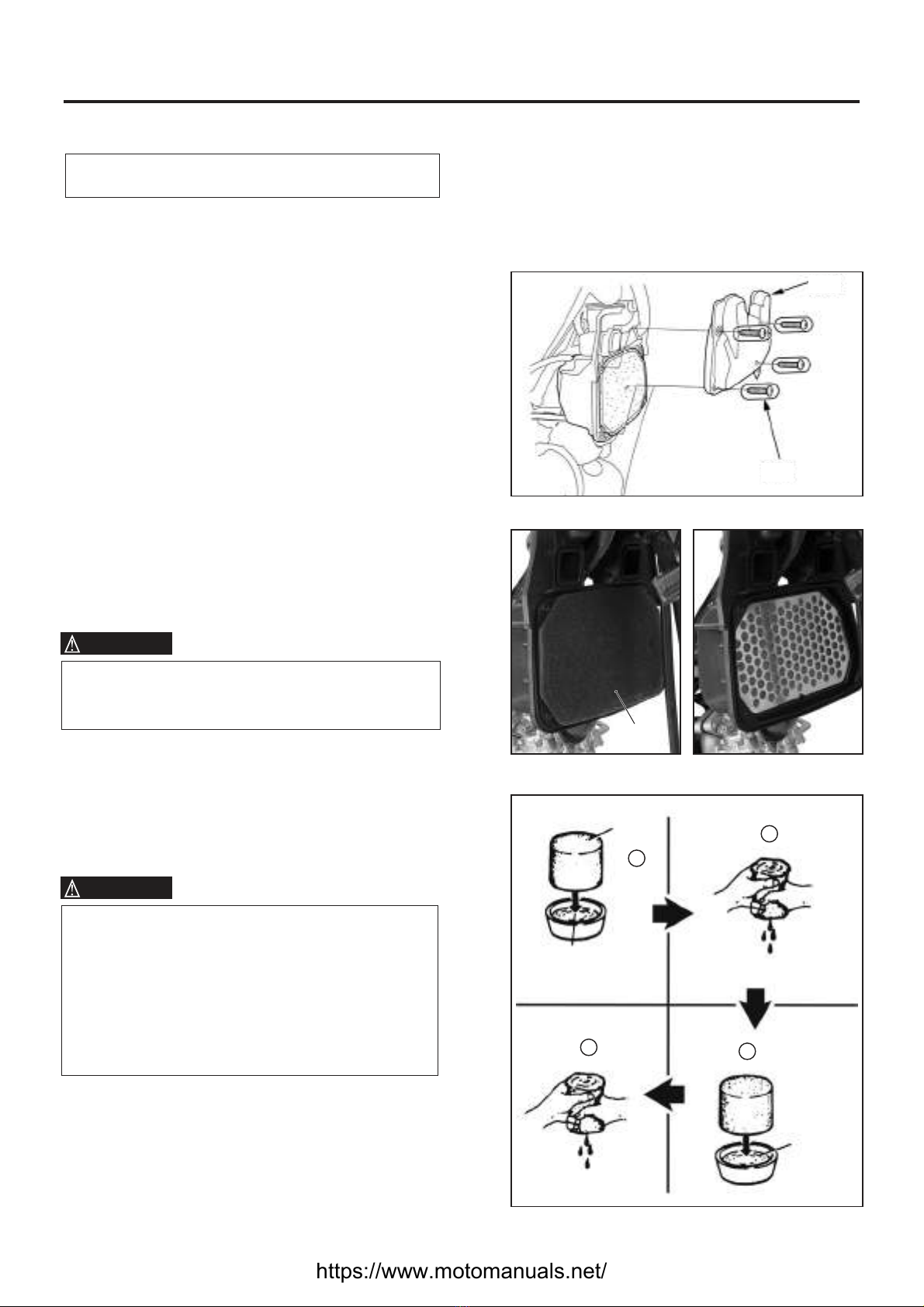

AIR CLEANER

Clean at Initial 1,000 km and Every 3,000km.

If the air cleaner is clogged with dust, intake

resistance will be increased with a resultant

decrease in power output and an increase in fuel

consumption.

Remove the front basket (for HJ110-2) and the

front panel,

Remove s

Loosen the front cover screws of the air cleaner

element, remove the front cover, the element

and the element support.

.the front left / right side cover

Pour non-flammable detergent into a wash pan

of appropriate size, dip the element into the

detergent solution and clean it.

Squeeze the liquid out of the element by

pressing it with both hands. Never twist the

element to avoid breaking it.

Dip the element into the engine oil again,

squeeze out excessive oil to keep the element

slightly wet.

●

●

●

●

●

●

Look carefully for fractures on the element

before and during cleaning. In case fractures

are found, replace the element immediately.

Assemble the element in the reversed order of

disassembly. Make sure the element is

correctly installed at specified position and

properly sealed.

●

When driving in dusty environments, please

carry out filter element inspection, clean and

replacement more frequently. If any

defect such as clog, damage or dust infiltra-

tion occurs, replace it immediately. Do not

wait until the next scheduled maintenance.

Start the engine without installing the

filter element will accelerate engine wear-off.

Engine oil

Non-flammable

detergent

Element

Element

PERIODIC MAINTENANCE

2-4

WARNING

WARNING

https://www.motomanuals.net/

CYLINDER HEAD & CYLINDER

NUTS & BOLTS

Tighten at Initial 1,000 km and Every 3,000 km

CYLINDER HEAD LEFT NUT

Tighten the right nut of the cylinder head to the

s.pecified torque

●

Specified torque: 8-12 N m•

Specified torque: 15-18 N m•

CYLINDER HEAD NUTS

●Tighten the nuts of cylinder head

.to the

specified torque

CYLINDER HEAD SIDE BOLT

Specified torque: 15-18 N m•

Specified torque: 8-12 N m•

CYLINDER MOUNTING BOLT

Tighten the cylinder connecting bolt

.to the

specified torque

●

●Tighten the cylinder mounting bolt

.to the

specified torque

PERIODIC MAINTENANCE

2-5

Cylinder mounting bolt

Cylinder head side bolt

MUFFLER MOUNTING NUTS & BOLTS

Tighten the muffler mounting nuts and bolts.

●

Inspect at Initial 1,000 km and Every 3,000 km

https://www.motomanuals.net/

1

3

2

VALVE CLEARANCE

Inspect at Initial 1,000 km and Every 3,000 km

Remove spark plug, valve inspecting caps

and valve timing inspecting plug . ①,

③

Remove the generator cover cap and rotate

the generator rotor with a 14-mm socket

wrench to set the piston at T.D.C of the

compression stroke.

(Rotate the generator rotor until the “T”line on

the rotor is aligned with the center of hole on

the left crankcase cover.)

②

The crankshaft must be rotated counter-

clockwise. If the crankshaft is already rotated

clockwise due to negligence, it must then be

rotated counterclockwise by two or more turns.

The adjusted valve can only be ensured to be

correct when the “T” mark on the rotor is

aligned with the mark line on the crankcase.

Since when crankshaft rotates clockwise, the

pressure-reducing cam takes action to result in

incorrect valve clearance.

Insert the thickness gauge between the tappet

adjusting screw and valve stem to measure the

clearance of the intake/exhaust valve.

0.03-0.07 mm

09900-20803 Thickness gauge:

TOOL

●

●

●

Valve clearance

Thickness guage

NOTE:

The valve clearance must be checked and

adjusted under cooled engine states.

PERIODIC MAINTENANCE

2-6

CAUTION

https://www.motomanuals.net/

ADJUSTMENT

Loosen the lock nut, turn the tappet adjusting

screw until the gauge feels a slight resistance.

Fix the tappet adjusting screw and tighten the

lock nut to the specified torque.

●

●

09917-14910: Tappet adjusting driver

TOOL

Check the valve clearance again.

Check if the O-ring of the valve inspecting caps

is damaged, replace it if necessary.

Apply engine oil on the O-ring, and mount it

onto the valve inspection caps.

Apply engine oil on the thread of the valve

inspecting caps, and tighten to the specified

torque.

●

●

●

●

Specified torque: 10-14 N m•

Check if the O-rings f

and is damaged,

replace if necessary.

Apply engine oil on the thread parts of both

, and install them.

o valve timing inspection

plug the generator cover cap

valve timing inspection plug and the generator

cover cap

●

●

SPARK PLUG

Inspect at I Every 3,000 km.nitial 1,000 km and Replace Every 12,000 km.

TORCH NHSP LDA6RC or A6RTC

TYPE

KIND

O ring

PERIODIC MAINTENANCE

2-7

Remove the spark plug with a socket wrench.

●

TORCH NHSP LDA7RC or A7RTC

TORCH NHSP LDA8RC or A8RTC

STANDARD

COLDTYPE

HOTTYPE

Pay attention to the color of the ceramic and the electrode of the spark plug. The status of the spark plug

can be determined by observing its color. If the standard spark plug looks wet and black, use a hot plug

instead. If the spark plug looks white, it means that the spark plug has overheated and should be replaced

with a cold one.

ELECTRODE’S CONDITION

Check for the worn or burnt condition of the electrodes. If it is extremely worn or burnt, replace the spark

plug.And also replace the spark plug if it has a broken insulator, damaged thread, etc.

https://www.motomanuals.net/

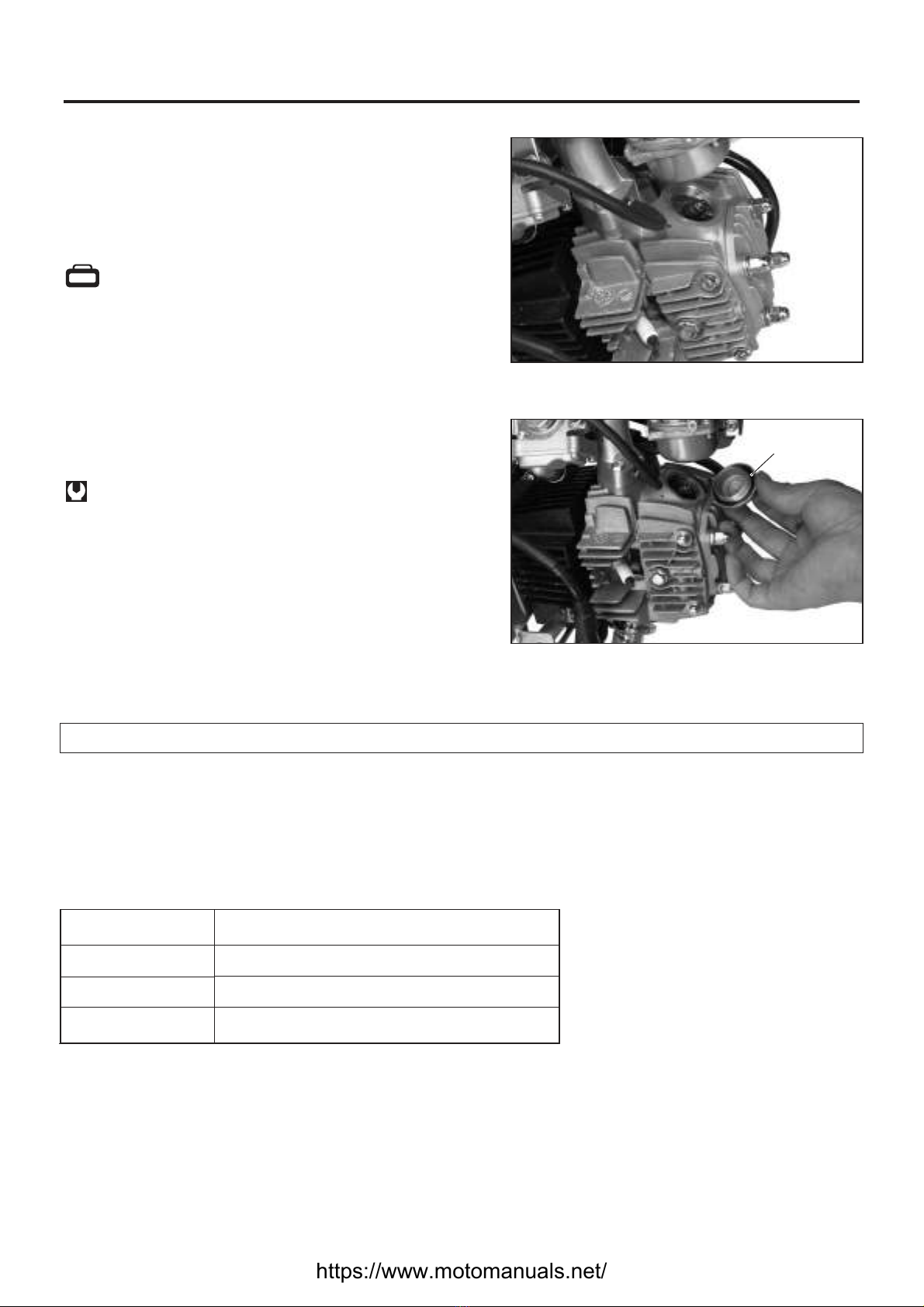

ENGINE OIL

The first change at Initial 500 km, the second

change at 1,000km total mileage, while further

change Every 3,000 km.

Engine oil replacement should be made when the

engine is warm as follows:

Support the motorcycle by the main stand.

Remove the draining bolt on the engine bottom

to drain out the used engine oil after unscrew-

ing the filling hole cover.

Check whether the sealing washer of the

draining bolt is properly mounted; screw the

draining bolt properly to avoid over-tightening.

Fill 800 ml (the first filling of a new motorcycle is

900 ml) engine oil into the filling hole; screw the

filling hole cover properly to avoid over-

tightening.

Start the engine, keep it at idle speed for several

minutes.

Shut down the engine, 1 minute later, check the

oil lever. The oil level should be near the upper

limit mark.

●

●

Draining bolt

PERIODIC MAINTENANCE

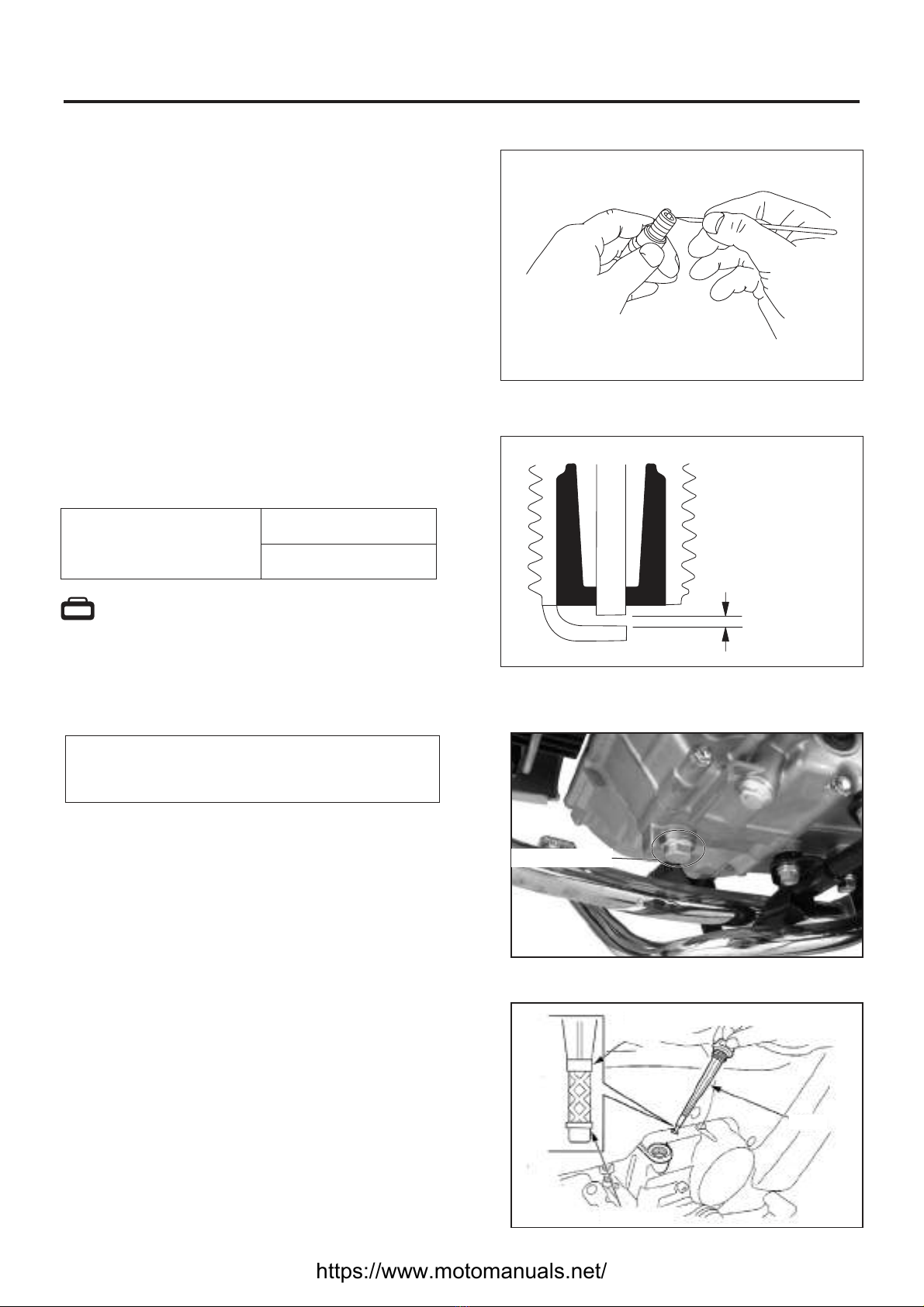

CARBON DEPOSIT

Check for the carbon deposit on the plug.

If the carbon is deposited, remove it with a spark

plug cleaner machine or .a needle carefully

SPARK PLUG GAP

Measure the spark plug gap with a thickness gauge

if it is correct. If not, adjust it to the following gap.

Spark plug gap Standard

0.6~0.8 mm

09900-20803: Thickness gauge

TOOL

2-8

●

●

Lower limit

Upper limit

Cover

●

●

0.6-0.8 mm

https://www.motomanuals.net/

OIL STRAINER

Clean Every 12,000 km

The right crankcase cover has to be removed to

check the engine oil strainer. Replace with a new

one if necessary.

PERIODIC MAINTENANCE

2-9

CAUTION

Since the right crankcase cover has to be remov-

ed to check the engine oil strainer, the decision

to replace the strainer should be made by

qualified

Check careful for any oil leak at the

draini g boltn

mechanic.

ly age

.

(HJ110-2) (HJ110-2A)

Inspect at Initial 1,000 km and Every 3,000 km

CLUTCH

Support the motorcycle with the main stand.

Remove the brand plate cover (HJ110-2A).

Loosen the lock nut of clutch adjusting screw

rotate the adjusting screw clockwise by 1 turn

(do not overturn), rotate the adjusting screw

counterclockwise slowly until feeling a slight

resistance.

Rotate the adjusting screw clockwise by 1/18

turn and tighten the lock nut to the specified

torque.

●

●

●

●

NOTE:

When tightening the lock nut, fix the adjusting

screw.

After adjusting, check the operation of the clutch.

Specified torque: 15-18 N m•

(HJ110-2) (HJ110-2A)

Adjusting screw

Lock nut

2

Inspect at Initial 1,000 km and Every 3000 km,

CARBURETOR (IDLE SPEED)

Start the engine, keep it at idle speed till fully

pre-heated.

counter-

clockwise ②

Once the engine has pre-heated, release the

throttle; turn the pilot screw and the air

adjusting screw clockwise or

to keep the idle speed within

1,400~1,600 RPM(refer to page 4-6).

①

●

●

1

NOTE:

The adjustment of the engine idle speed should

be done when the engine has fully pre-heated.

https://www.motomanuals.net/

Inspect at Initial 1,000 km and Every 3,000 km.

6,000 kmReplace Every .

FUEL FILTER

If the fuel filter is dirty with sediment, fuel will not

flow smoothly and may

result.

Clean the filter cup with non-flammable

detergent.

decrease in power output

PERIODIC MAINTENANCE

2-10

THROTTLE CABLE PLAY

Loosen the lock nut .

Turn the adjuster to adjust the cable play to

keep it between 0.5-1.0 mm.

Tighten the lock nut securely after the play

adjustment is completed.

●

●

●

0.5~1.0 mm

Throttle cable play

WARNING

0.5 1.0 mm~

Lock nut

Adjuster

Inspect at Initial 1,000 km and Every 3,000 km

Replace Every four years.

FUEL HOSE AND SECONDARY AIR HOSE

Check for damage, fracture or fuel leakage on the

fuel hose and secondary air hose as well as their

connections. If problem was found, replace the

fuel hose or the secondary air hose immediately.

Fuel hose

Secondary

air hose

Inspect at Initial 1,000 km and Every 3,000 km.

After the adjustment of throttle cable play was

completed, make sure that and

the adjustment has not raised the engine idle

speed.

the throttle grip

position should be able to return freely,

In the meantime, make sure that the engine

idle speed was not caused to change while

turning the handlebar to the left and right.

https://www.motomanuals.net/

This manual suits for next models

1

Table of contents

Other Haojue Motorcycle manuals

Haojue

Haojue EG150 User manual

Haojue

Haojue EG125 User manual

Haojue

Haojue HJ125-7 User manual

Haojue

Haojue EH150 User manual

Haojue

Haojue TZ150S 2015 User manual

Haojue

Haojue NK150 2020 User manual

Haojue

Haojue HJ125-16 User manual

Haojue

Haojue TZ125 User manual

Haojue

Haojue XPRESS User manual

Haojue

Haojue HJ125-8 User manual