Hara Systems OSTSen-9250 User manual

OSTSen-6500 v1.0 1 of 9 Hara Systems Inc.

OSTSen-6500 User Guide

Ver 1.0

Hara Systems Inc.

OSTSen-6500 v1.0 2 of 9 Hara Systems Inc.

1. OSTSen-6500 Overview

OSTSen-6500 is a high performance motion tracking module, which is based on

InvenSense MPU-6500. The MPU-6500 is the a 6-axis Motion Tracking device that

combines a 3-axis gyroscope, a 3-axis accelerometer, and a Digital Motion

Processor™ (DMP™) all in a small 3x3x0.9mm package. It also features a 4096-byte

FIFO that can lower the traffic on the serial bus interface, and reduce power

consumption by allowing the system processor to burst read sensor data and then go

into a low-power mode. With its dedicated I2C sensor bus, the MPU-6500 directly

accepts inputs form external I2C devices. MPU-6500, with its 6-axis integration, on-

chip DMP, and run-time calibration firmware, enables manufacturers to eliminate the

costly and complex selection, qualification, and system level integration of discrete

devices, guaranteeing optimal motion performance for consumers. MPU-6500 is also

designed to interface with multiple non-inertial digital sensors, such as pressure

sensors, on its auxiliary I2C port.

The Gyroscope has a programmable full-scale range of ±250, ±500, ±1000, and

±2000 degrees/sec and very low rate noise at 0.01dps/√Hz. The accelerometer has a

user-programmable accelerometer full-scale range of ±2g, ±4g, ±8g, and ±16g.

Factory-calibrated initial sensitivity of both sensors reduces production-line calibration

requirements.

Other industry-leading features include on-chip 16-bit ADCs, programmable digital

filters, a precision clock with 1% drift from -40°C to 85°C, an embedded temperature

sensor, and programmable interrupts. The device features I2C and SPI serial

interfaces, a VDD operating range of 1.71 to 3.6V, and a separate digital IO Supply,

VDDIO from 1.7V to 3.6V.

Communication with all registers of the device is performed using either I2C at

400kHz or SPI 1MHz. For applications requiring faster communications, the sensor

and interrupt registers may be read SPI at 20MHz.

By leveraging its patented and volume-proven CMOS-MEMS fabrication platform,

which integrated MEMS wafers with companion CMOS electronics through wafer-

level bonding, InvenSense has driven the package size down to a footprint and

thickness of 3x3x0.90mm (24-pin QFN), to provide a very small yet high performance

low cost package. The device provides high robustness by supporting 10,000g shock

reliability.

2. Applications

· TouchAnywhere™ technology (for “no touch” UI Application Control/Navigation)

· MotionCommand™ technology (for Gesture Short-cuts)

· Motion-enabled game and application framework

· Location based services, points of interest, and dead reckoning

· Handset and portable gaming

· Motion-based game controllers

· 3D remote controls for Internet connected DTVs and set top boxes, 3D mice

· Wearable sensors for health, fitness and sports

3. Features of MPU-6500

3.1 Gyroscope Features

The triple-axis MEMS gyroscope in the MPU-6500 includes a wide range of features:

· Digital-output X-, Y-, and Z-axis angular rate sensors (gyroscopes) with a user-

programmable full-scale range of ±250, ±500, ±1000, and ±2000°/sec and

OSTSen-6500 v1.0 3 of 9 Hara Systems Inc.

integrated 16-bit ADCs

· Digitally-programmable low-pass filter

· Gyroscope operating current: 3.2mA

· Factory calibrated sensitivity scale factor

· Self-test

3.2 Accelerometer Features

The triple-axis MEMS accelerometer in MPU-6500 includes a wide range of features:

· Digital-output X-, Y-, and Z-axis accelerometer with a programmable full scale

range of ±2g, ±4g, ±8g and ±16g and integrated 16-bit ADCs

· Accelerometer normal operating current: 450μA

· Low power accelerometer mode current: 6.37μA at 0.98Hz, 17.75μA at 31.25Hz

· User-programmable interrupts

· Wake-on-motion interrupt for low power operation of application processor

· Self-test

3.3 Additional Features

The MPU-6500 includes the following additional features:

· Auxiliary master I2C bus for reading data from external sensors(e.g. magnetometer)

· 3.4mA operating current when all 6 motion sensing axes active

· VDD supply voltage range of 1.8 ~ 3.3V ±5%

· VDDIO reference voltage of 1.8 ~ 3.3V ±5% auxiliary I2C devices

· Smallest and thinnest QFN package for portable devices: 3x3x0.9mm

· Minimal cross-axis sensitivity between the accelerometer, gyroscope axes

· 4096 byte FIFO buffer enables the applications processor to read the data in bursts

· Digital-output temperature sensor

· User-programmable digital filters for gyroscope, accelerometer, and temp sensor

· 10,000 g shock tolerant

· 400kHz Fast Mode I2C for communicating with all registers

· 1MHz SPI serial interface for communication with all registers

· 20MHz SPI serial interface for reading sensors and interrupt registers

· MEMS structure hermetically sealed and bonded at wafer level

· RoHS and Green compliant

OSTSen-6500 v1.0 4 of 9 Hara Systems Inc.

4. Application Information

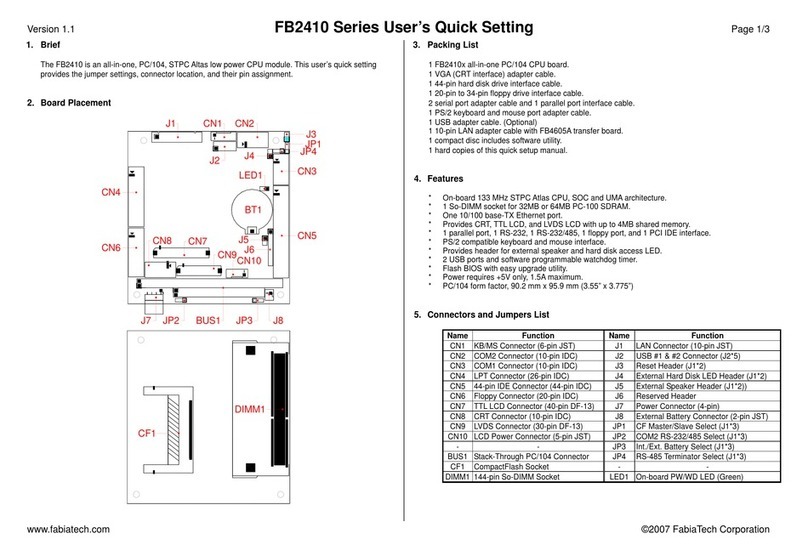

4.1 Module Pin Out and Signal Description

Pin

Number

Pin Name

Pin Description

1

VCC

Power supply voltage

2

GND

Power supply ground

3

SCL

I2C serial clock (SCL); SPI serial clock(SCLK)

4

SDA

I2C serial data (SDA); SPI serial data input(SDI)

5

AD0

I2C Slave Address LSB (AD0); SPI serial data output(SDO)

6

NCS

Chip select (SPI mode only)

7

INT

Interrupt digital output (totem pole or open-drain)

8

ADA

Auxiliary I2C master serial data

9

ACL

Auxiliary I2C master serial clock

10

FSYNC

Frame synchronization digital input.

Connect to GND if unused

< Top View >

VCC

GND

SCL

SDA

NCS

INT

FSYNC

ADA

1

2

4

6

3

10

8

7

AD0

ACL

5

9

Orientation of Axes of Sensitivity

and Polarity of Rotation

+Z

+Z

+Y

+Y

+X

+X

OSTSen-6500 v1.0 5 of 9 Hara Systems Inc.

4.2 MPU-6500 Pin out and Signal Description

Pin Number

Pin Name

Pin Description

7

AUX_CL

I2C master serial clock for connecting to external sensors

8

VDDIO

Digital I/O supply voltage

9

AD0/SDO

I2C Slave Address LSB (AD0); SPI serial data output(SDO)

10

REGOUT

Regulator filter capacitor connection

11

FSYNC

Frame synchronization digital input.

Connect to GND if unused

12

INT

Interrupt digital output (totem pole or open-drain)

Note: The Interrupt line should be connected to a pin the

Application Processor(AP) that can bring the AP out of

suspend mode.

13

VDD

Power supply voltage and Digital I/O supply voltage

18

GND

Power supply ground

19

RESV

Reserved. Do not connect

20

RESV

Reserved. Connect to GND

21

AUX_DA

I2C master serial data, for connecting to external sensors

22

nCS

Chip Select (SPI mode only)

23

SCL/SCLK

I2C serial clock (SCL); SPI serial clock(SCLK)

24

SDA/SDI

I2C serial data(SDA); SPI serial data input(SDI)

1-6, 14-17

NC

No Connection Pin. Do not connect

l MPU-9250 I2C 7bit device address: 0x69 ( In module : AD0 is HIGH )

0x68 ( In module : AD0 is LOW )

MSB

LSB

1

1

0

1

0

0

X

R/W

< MPU-6500 Pinout ( Top View) > < Orientation of Axes of MPU-6500 >

OSTSen-6500 v1.0 6 of 9 Hara Systems Inc.

5. Module Dimension

< OSTSen-6500 module >

12.065mm

10.16mm

2.54mm

1

2

4

6

3

10

8

7

5

9

OSTSen-6500 v1.0 7 of 9 Hara Systems Inc.

6. I2C Communications

OSTSen-6500 v1.0 8 of 9 Hara Systems Inc.

7. Demo System

OSTSen-6500 Data Display on PC

32 bit

Processor

USB

VCC

GND

SCL

SDA

PC

Demo System

USB

OSTSen-6500 v1.0 9 of 9 Hara Systems Inc.

8. Reference

1) https://www.invensense.com/products/motion-tracking/6-axis/mpu-6500/

2) https://www.invensense.com/wp-content/uploads/2015/02/MPU-6500-

Datasheet2.pdf

3) https://www.invensense.com/wp-content/uploads/2015/02/MPU-6500-Register-

Map2.pdf

4) https://www.invensense.com/wp-content/uploads/2015/02/AN-IVS-0001EVB-00-

v1-3.pdf

5) https://github.com/rpicopter/ArduinoMotionSensorExample

6) https://create.arduino.cc/projecthub/Aritro/getting-started-with-imu-6-dof-motion-

sensor-96e066

l If you need some information or have some questions about OSTSen-6500,

contact ostsen@hanmail.net

Other manuals for OSTSen-9250

1

Other Hara Systems Control Unit manuals

Popular Control Unit manuals by other brands

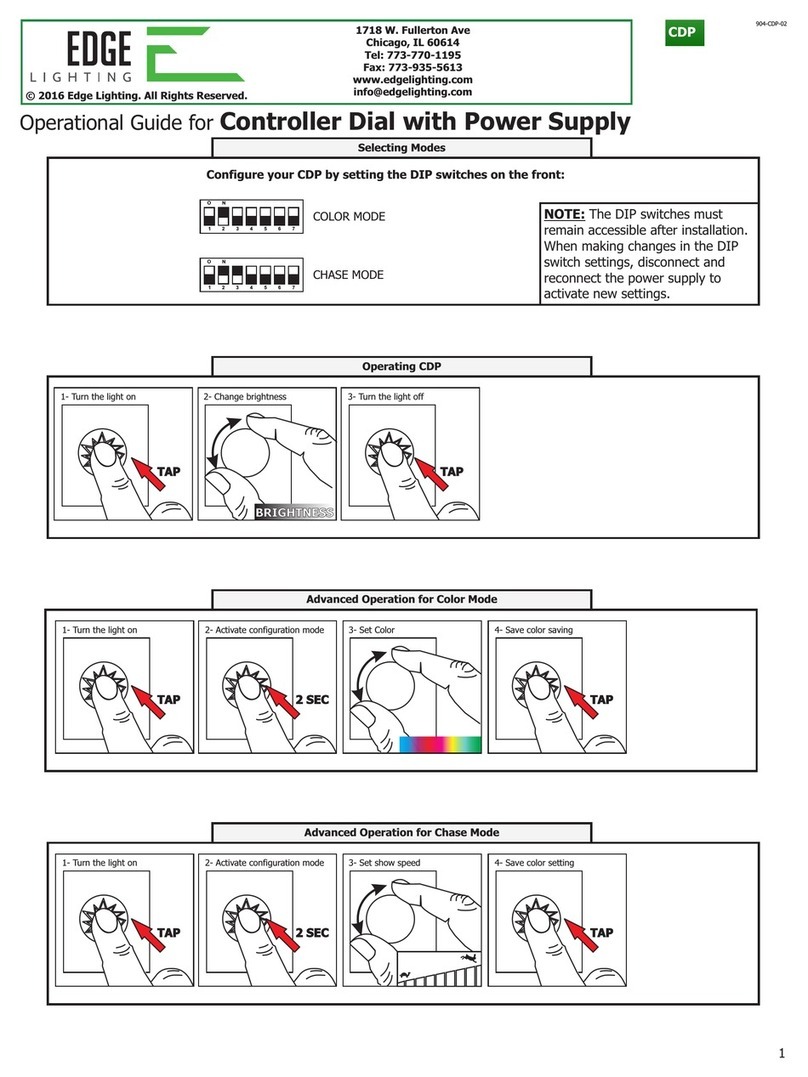

Edge Lighting

Edge Lighting Controller Dial with Power Supply Operational guide

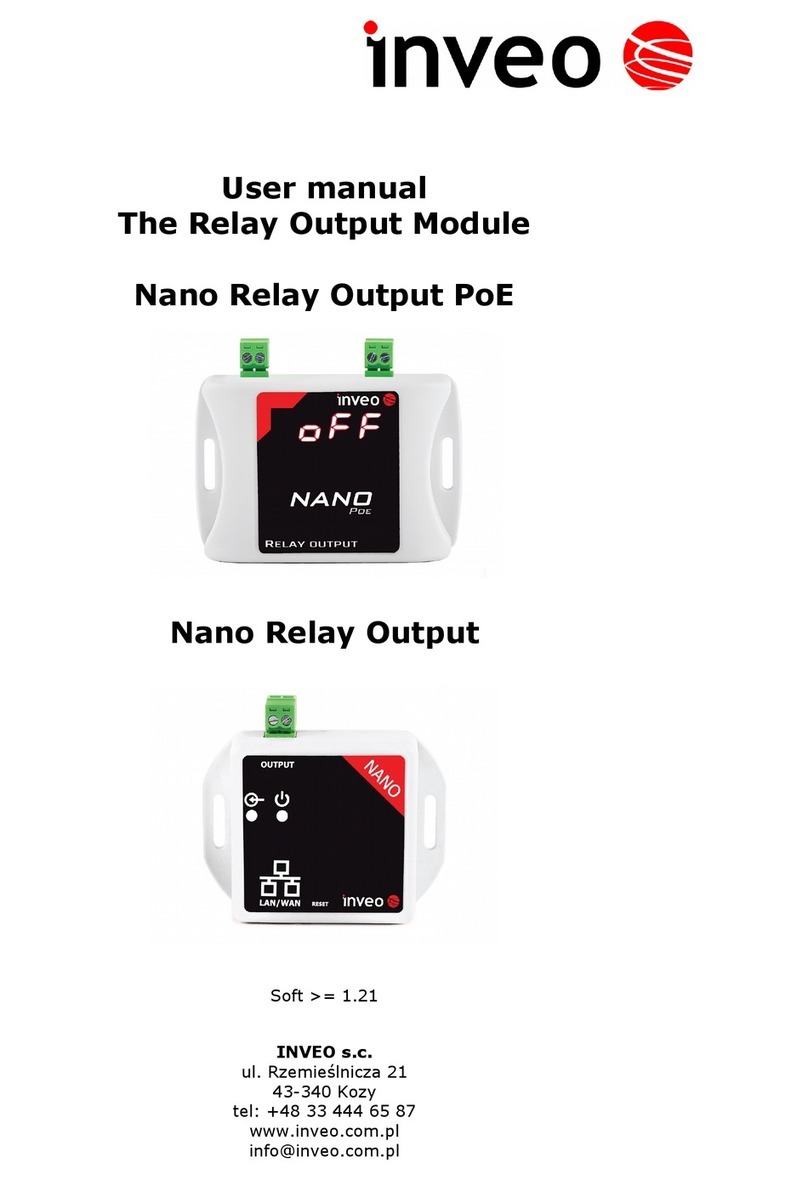

inveo

inveo Nano Relay Output PoE user manual

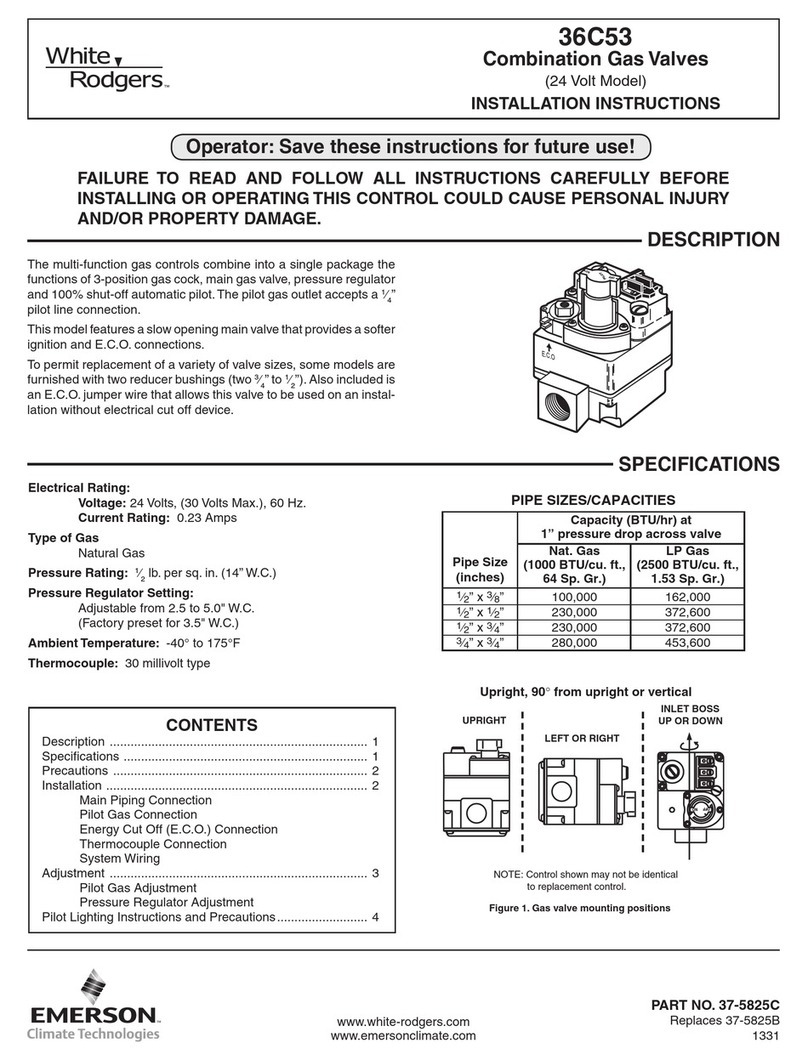

Emerson

Emerson White Rodgers 36C53 Series installation instructions

GEM

GEM 529 eSyLite operating instructions

Primus Wind Power

Primus Wind Power 2-ARAC-103 instruction manual

Burkert

Burkert 0258 operating instructions