Hardie Groove Lining User manual

We value your feedback!

To continue with the development of our products and systems, we value your

input. Please send any suggestions, including your name, contact details, and

relevant sketches to:

Ask James Hardie™

literaturefeedback@jameshardie.co.nz

Make sure your information is up to date

When specifying or installing Hardie™fibre cement products, ensure that you have

the current manual. Additional installation information, warranties and warnings

are available at www.jameshardie.co.nz or Ask James Hardie™ on 0800 808 868.

2 Hardie™ Groove Lining Installation Manual | July 2021 New Zealand

Contents

1 Introduction 4

2 Safe Working Practices 7

2.1 Storage and Delivery 9

2.2 Tips for Safe and Easy Handling of

Hardie™Groove Lining 10

3 Framing 10

3.1 General 10

3.2 Timber 10

3.3 Steel 11

3.4 Preparation 11

4 Installation 12

4.1 Sheet Layout 12

4.2 Fasteners 12

4.3 Fixing To Walls 13

4.4 Full Sheet Fixing 15

4.5 Dado Height Fixing 17

4.6 Fixing Over Plasterboard Lining 19

4.7 Fixing To Ceilings and Sots 19

4.8 Fixing To Masonry Substrates 20

5 Jointing and Corners 21

5.1 Butt Joints 21

5.2 Corners 23

6 Product Information 26

6.1 General 26

6.2 Product Mass 26

6.3 Durability 26

6.4 Fire Properties 26

6.5 Finishes 26

6.6 Maintenance 26

Product Warranty 27

Hardie™ Groove Lining Installation Manual | July 2021 New Zealand 3

1 Introduction

Hardie™Groove Lining combines the appearance of traditional timber tongue and groove wall panelling with the

benefits of modern fibre cement.

Because the baseboard is Hardie™fibre cement, it’s resistant to fire, rot resistant and resistant to moisture damage

when installed and maintained as directed.

Hardie™Groove Lining has decorative v-shaped grooves carved into the front face of the 7.5mm sheet, and is

sanded, ready to be painted in any colour.

Hardie™ Groove Lining can be fixed to the full height of the wall or at dado height to create a decorative, hard-

wearing, impact resistant lining in hallways and to withstand the toughest treatment in family rooms, rumpus

rooms, laundries and bathrooms (not suitable for shower areas).

Hardie™Groove Lining is also ideal for use in ceilings, either to add interest to a modern design, or to create

historical detail on a renovation project.

The main features of Hardie™Groove Lining are:

• Durable internal lining, sot and ceiling sheet.

• Creates suitable surface for paint finish.

• Sheet edges have a ‘half groove’ to achieve concealed sheet joints.

• Reliable impact resistant decorative lining. Ideal for wall lining where walls are prone to damage.

• Resistance to damage from moisture making it ideal for bathrooms, laundries and kitchens.

• Joints won’t pull or shift apart.

• Authentic v-shaped grooves replicate traditional tongue and groove look and style.

• Ideal as feature wall to dado height.

The specifier or other responsible party for the project must ensure the information and details in this guide are

appropriate for the intended application and specific design and detailing is undertaken for areas which fall

outside the scope of this documentation.

Make sure your information is up to date

When specifying or installing Hardie™fibre cement products, ensure you have the current manual. If you’re

not sure you do, or if you need more information, visit www.jameshardie.co.nz or Ask James Hardie™on

0800 808 868.

Hardie™Groove Lining is only for use in internal applications.

For use externally on eaves and sots refer to the Eaves and Sots Installation Manual by James Hardie.

James Hardie conducts stringent quality checks to ensure that any product manufactured falls within our quality

spectrum. It is the responsibility of the builder to ensure that the product meets their aesthetic expectations before

installation. James Hardie will not be responsible for rectifying obvious aesthetic surface variations following

installation. James Hardie will only oer a replacement product if Hardie™Groove Lining supplied are found to be

out of its manufacturing specification.

4 Hardie™ Groove Lining Installation Manual | July 2021 New Zealand

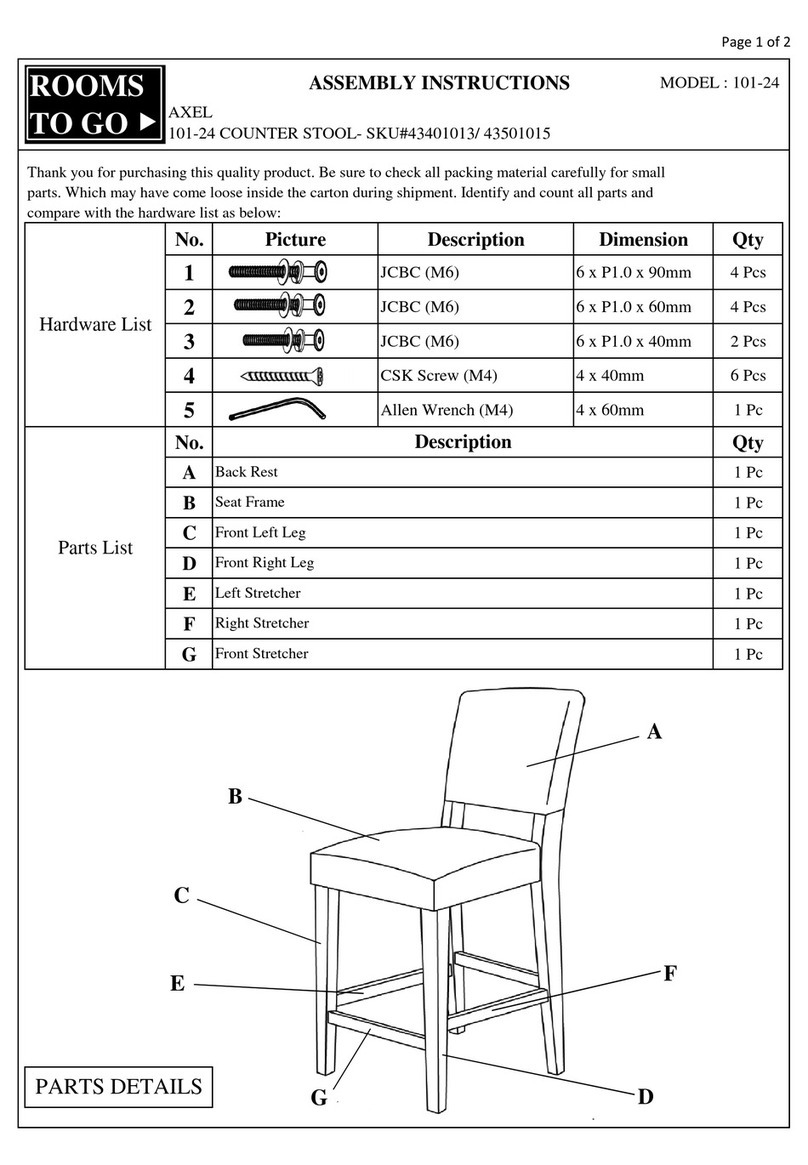

Table 1

Product Description Description

5mm

100mm

Half groove edge

2.5

mm

Hardie™Groove Lining is a

v-grooved internal lining board

with the look of timber and the

durability of fibre cement.

Individual batten widths are

100mm

Sheet sizes:

2400mm x 1200mm x 7.5mm

Product code 400246

2700mm x 1200mm x 7.5mm

Product code 400245

Note: All dimensions and masses provided are approximate only and are subject to manufacturing tolerances.

Table 2

Product/Accessories/Tools supplied by James Hardie

Product Description Code Product Description Code

Hardie™Blade Saw

Blade 184mm diameter,

poly diamond blade,

for fast, clean cutting of

Hardie™fibre cement.

300660 FibreTEKS®Screw

For fastening to 0.75mm

to 1.0mm BMT steel

frames.

Class 3 finish. Length:

30mm x 9g

® denotes a registered

mark of Buildex®

1000/box

303840

Hardie™Base Coat

For finishing fastener

heads.

Volume: 4kg Pail

15kg Bag

304490

304491

Hardie™Drive Screw

s/s 316

30mm x 7g

100/jar

300928

Sot Scotia Mould 2

pcs.

(base and cap)

2400mm

300916 Villadrive™Wood Screw

Envirodrab coating.

Length: 30mm x 6g

100/jar

300992

5kg/box

300993

1000

collated

300994

Hardie™Knife

Scoring tool for easy

cutting.

305926

Hardie™ Groove Lining Installation Manual | July 2021 New Zealand 5

Table 3

Product/Accessories/Tools not supplied by James Hardie

James Hardie recommends the following products for use in conjunction with its Hardie™Groove Lining. James

Hardie does not supply these products and does not provide a warranty for their use. Please contact the

component manufacturer for information on their warranties and further information on their products.

Hardie™Flex nails

40 x 2.8mm galvanised or stainless

steel 316 fibre cement nails for

fastening to timber.

Fibreshear

Electric cutting tool.

Adhesive Sealant

Sika®Sikaflex®11FC, Bostik®Seal N

Flex-1, Fuller™Max Bond™, Selleys®

Liquid Nails

Brad Nail

ND 50

To be used in conjuction with 6mm

bead of adhesive on a stud/nogs.

Only suitable for internal walls.

6 Hardie™ Groove Lining Installation Manual | July 2021 New Zealand

2 Safe Working Practices

WARNING - DO NOT BREATHE DUST AND CUT ONLY IN WELL VENTILATED AREA

Hardie™fibre cement products contain sand, a source of respirable crystalline silica. May cause cancer if

dust from product is inhaled. Causes damage to lungs and respiratory system through prolonged or repeated

inhalation of dust from product.

Intact fibre cement products are not expected to result in any adverse toxic eects. The hazard associated with

fibre cement arises from the respirable crystalline silica present in dust generated by activities such as cutting,

rebating, drilling, routing, sawing, crushing, or otherwise abrading fibre cement, and when cleaning up, disposing

of or moving dust.

When doing any of these activities in a manner that generates dust, follow James Hardie’s instructions and best

practices to reduce or limit the release of dust.

If using a dust mask or respirator, use an AS/NZS 1716 P1 filter and refer to Australian/New Zealand Standard

1715:2009 Selection, Use and Maintenance of Respiratory Protective Equipment for more extensive guidance and

more options for selecting respirators for workplaces. For further information, refer to our installation instructions

and Safety Data Sheets available at www.jameshardie.co.nz.

FAILURE TO ADHERE TO OUR WARNINGS, SAFETY DATA SHEETS, AND INSTALLATION INSTRUCTIONS MAY LEAD

TO SERIOUS PERSONAL INJURY OR DEATH.

Crystalline Silica is

• Commonly known as sand or quartz

• Found in many building products e.g. concrete, bricks, grout, wallboard, ceramic tiles, and all fibre cement

materials

Why is Crystalline Silica a health hazard?

• Silica can be breathed deep into the lungs when present in the air as a very fine (respirable) dust

• Exposure to silica dust without taking the appropriate safety measures to minimise the amount being breathed

in, can lead to a potentially fatal lung disease – silicosis – and has also been linked with other diseases including

cancer. Some studies suggest that smoking may increase these risks

• The most hazardous dust is the dust you cannot see!

When is Crystalline Silica a health hazard?

• It’s dangerous to health if safety protocols to control dust are not followed when cutting, drilling or rebating a

product containing crystalline silica

• Products containing silica are harmless if intact (e.g. an un-cut sheet of wall board)

Hardie™ Groove Lining Installation Manual | July 2021 New Zealand 7

Avoid breathing in crystalline silica dust

Safe working practices

NEVER use a power saw indoors or in a poorly ventilated area

NEVER dry sweep

ALWAYS use M Class or higher vacuum or damp down dust before sweeping up

NEVER use grinders

ALWAYS use a dust reducing circular saw equipped with a sawblade specifically designed to minimise dust

creation when cutting fibre cement – preferably a sawblade that carries the Hardie™Blade name or one with

at least equivalent performance – connected to an M Class or higher vacuum

Before cutting warn others in the area to avoid dust

ALWAYS follow tool manufacturers’ safety recommendations

ALWAYS expose only the minimum required depth of blade for the thickness of fibre cement to be cut

ALWAYS wear a properly-fitted, approved dust mask or respirator P1 or higher in accordance with applicable

government regulations and manufacturer instructions

Consider rotating personnel across cutting tasks to further limit respirable silica exposures.

Use one of the following for cutting:

Best

• Hardie™Knife

• Hand guillotine

• Fibreshear

Better

Dust reducing circular saw equipped with Hardie™Blade Saw Blade and connected to a M Class or higher

vacuum.

When cutting outdoors

Make sure you work in a well ventilated area

Position cutting station so wind will blow dust away from yourself and others in the working area

Cut products with either a Hardie™ Knife or fibre cement shears or, when not feasible, a Hardie™ Blade Saw

Blade (or equivalent) and a dust reducing circular saw connected to a M Class or higher vacuum

When sawing, sanding, rebating, drilling or machining fibre cement products, always:

- Wear your P1 or higher mask (correctly fitted in accordance with manufacturers’ instructions), ask others to

do the same.

- Keep persons on site at least 2 metres and as far as practicable away from the cutting station while the saw

is in operation

- If you are not clean shaven, then use a powered air respirator with a loose-fitting head top

- Wear safety glasses

- Wear hearing protection

- When others are close by, ask them to do the same

Make sure you clean up BUT never dry sweep. Always hose down with water/wet wipe or use an M Class or

higher vacuum

8 Hardie™ Groove Lining Installation Manual | July 2021 New Zealand

When cutting indoors

Never cut using a circular saw indoors

Position cutting station in a well ventilated area

Cut ONLY using a Hardie™Knife, hand guillotine or fibreshears

(manual, electric or pneumatic)

Make sure you clean up BUT never dry sweep. Always hose

down with water/wet wipe or use an M Class or higher

vacuum

Working instructions

Hardie™Blade Saw Blade

The Hardie™Blade Saw Blade used with a dust-reducing saw is

ideal for fast, clean cutting of Hardie™fibre cement products. A

dust-reducing saw uses a dust collector connected to a M Class or

higher vacuum. When sawing, clamp a straight edge to the sheet

as a guide and run the saw base plate along the straight edge

when making the cut.

Hole forming

For smooth clean cut circular holes:

• Mark the centre of the hole on the sheet

• Pre-drill a ‘pilot’ hole

• Using the pilot hole as a guide, cut the hole to the appropriate diameter with a hole saw fitted to a heavy duty

electric drill

For irregular holes:

• Small rectangular or circular holes can be cut by drilling a series of small holes around the perimeter of the hole

then tapping out the waste piece from the sheet face

• Tap carefully to avoid damage to sheets, ensuring that the sheet edges are properly supported

2.1 Storage and delivery

Keeping products and people safe

O loading

Hardie™fibre cement products should be o-loaded carefully by hand or by forklift

Hardie™fibre cement products should not be rolled or dumped o a truck during the delivery to the jobsite

Storage

Hardie™fibre cement products should be stored:

In their original packaging

Hardie™ Groove Lining Installation Manual | July 2021 New Zealand 9

Under cover where possible or otherwise protected with a waterproof covering to keep products dry

O the ground – either on a pallet or adequately supported on timber or other spacers

Flat so as to minimise bending

Hardie™fibre cement products must not be stored:

Directly on the ground

In the open air exposed to the elements

James Hardie is not responsible for damage due to improper storage and handling.

2.2 Tips for Safe and Easy Handling of Hardie™Groove Lining

Carry with two people

Hold near each end and on edge

Exercise care when handling sheet products to avoid damaging the edges/corners

3 Framing

3.1 General

Hardie™Groove Lining can be fixed to either timber or light gauge domestic type steel framing. The framing used

must comply with the relevant building regulations and standards and the requirements of this manual.

Note: Hardie™Groove Lining must not be used in shower areas.

3.2 Timber

Timber framing must comply with the durability requirements of Clause ‘B2’ of the NZBC. Timber must be treated

as per the requirements of the NZS 3602.

Timber framing sizes and set out must satisfy the minimum requirements of NZS 3604 and this installation guide.

The minimum stud width of 35mm may be used. However, where butt jointing is used the minimum stud width is

45mm at the joint. See Figure 13.

Reference NZS 3604 ‘Timber-framed Buildings’.

10 Hardie™ Groove Lining Installation Manual | July 2021 New Zealand

3.3 Steel

The minimum size for steel stud framing should be 64mm deep x 0.55mm base metal thickness (BMT). Steel

framing shall comply with NASH 3405 Steel Framed Buildings. Steel sections shall be galvanised or zinc coated of

0.55mm — 1.6mm BMT. Studs must not be less than 38mm wide at butt joints.

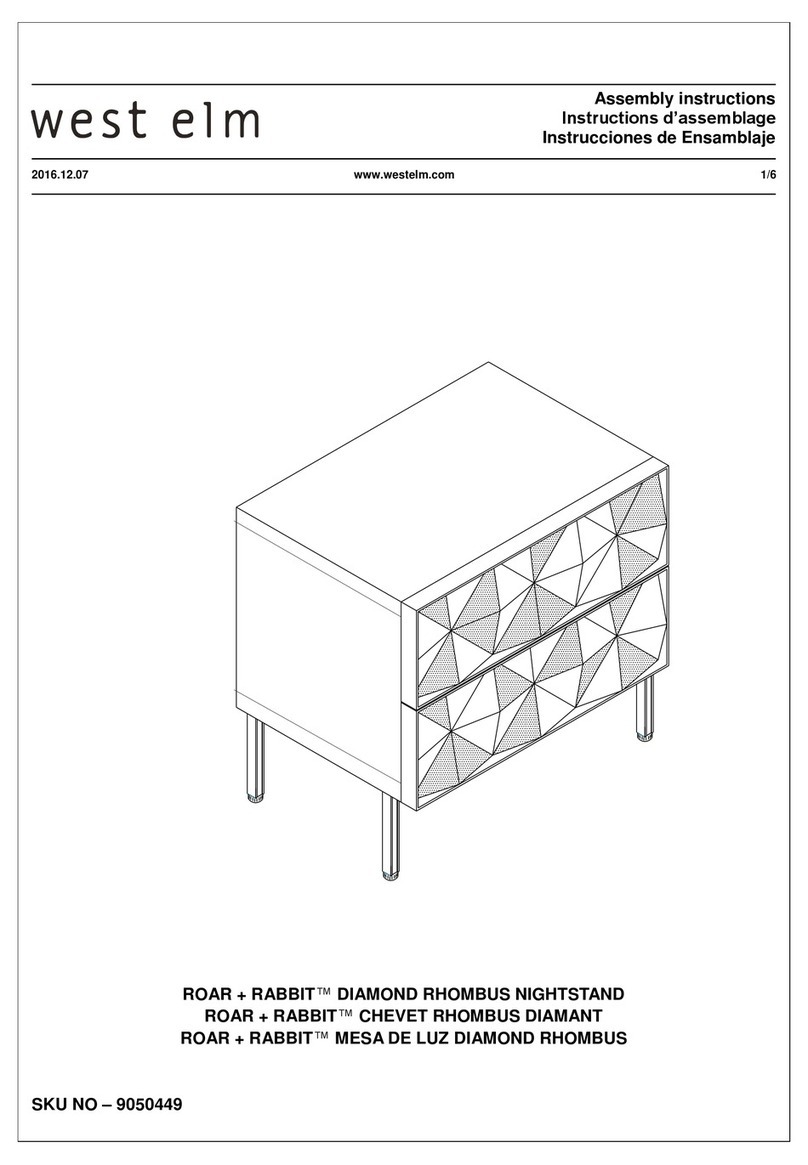

Figure 1: Frame straightness

3.4 Preparation

Ensure frame is square and work from a central datum line. Frames must be straight and true to provide a flush

face to receive the sheeting.

A suggested maximum tolerance of between 3mm and 4mm in any 3000mm length of frame will give best

results. Hardie™Groove Lining will not straighten excessively warped or distorted frames and any warping may

still be visible after the internal lining is installed.

Hardie™ Groove Lining Installation Manual | July 2021 New Zealand 11

4 Installation

4.1 Sheet Layout

Hardie™Groove Lining is usually fixed vertically. Sheet joints must coincide with the centre line of the framing

member.

The long edges of the sheet have a unique half groove, which achieves a concealed joint.

Where fixing half height sheets as a dado wall, provide a row of noggings to allow for fastening of the sheet edge.

When fixing around window openings, best practice would be to align the sheet joints with the window jamb.

4.2 Fasteners

Fasteners must have the appropriate level of durability required for the intended project.

Fasteners must be fully compatible with all other material that they are in contact with to ensure the durability and

integrity of the assembly.

• On timber frame use Villadrive™screws 30mm x 6g or Hardie™Drive stainless steel screws for quick installation

of Hardie™Groove Lining.

• Alternatively the Hardie™Groove Lining can be fixed with 40 x 2.8mm Hardie™Flex nails or ND 50 brad nails.

• For fixing Hardie™Groove Lining to 0.55 – 1.0mm BMT steel framing, use 30mm Buildex®FibreTEKS collated

screws.

Nails must be finished flush (Figure 2). Screws can be driven 0.5mm below the sheet surface to achieve the

required finish level (Figure 2). In steel framing the fasteners should be driven as close as possible to the stud

corners to avoid deflection of the stud flange, see Figure 3.

Drive screw 0.5mm

below sheet surface

Flush nailing

HardieFlex nail

and Brad nail

Unacceptable:

under driven

Unacceptable:

over driven

Figure 2: Fastener depth

12 Hardie™ Groove Lining Installation Manual | July 2021 New Zealand

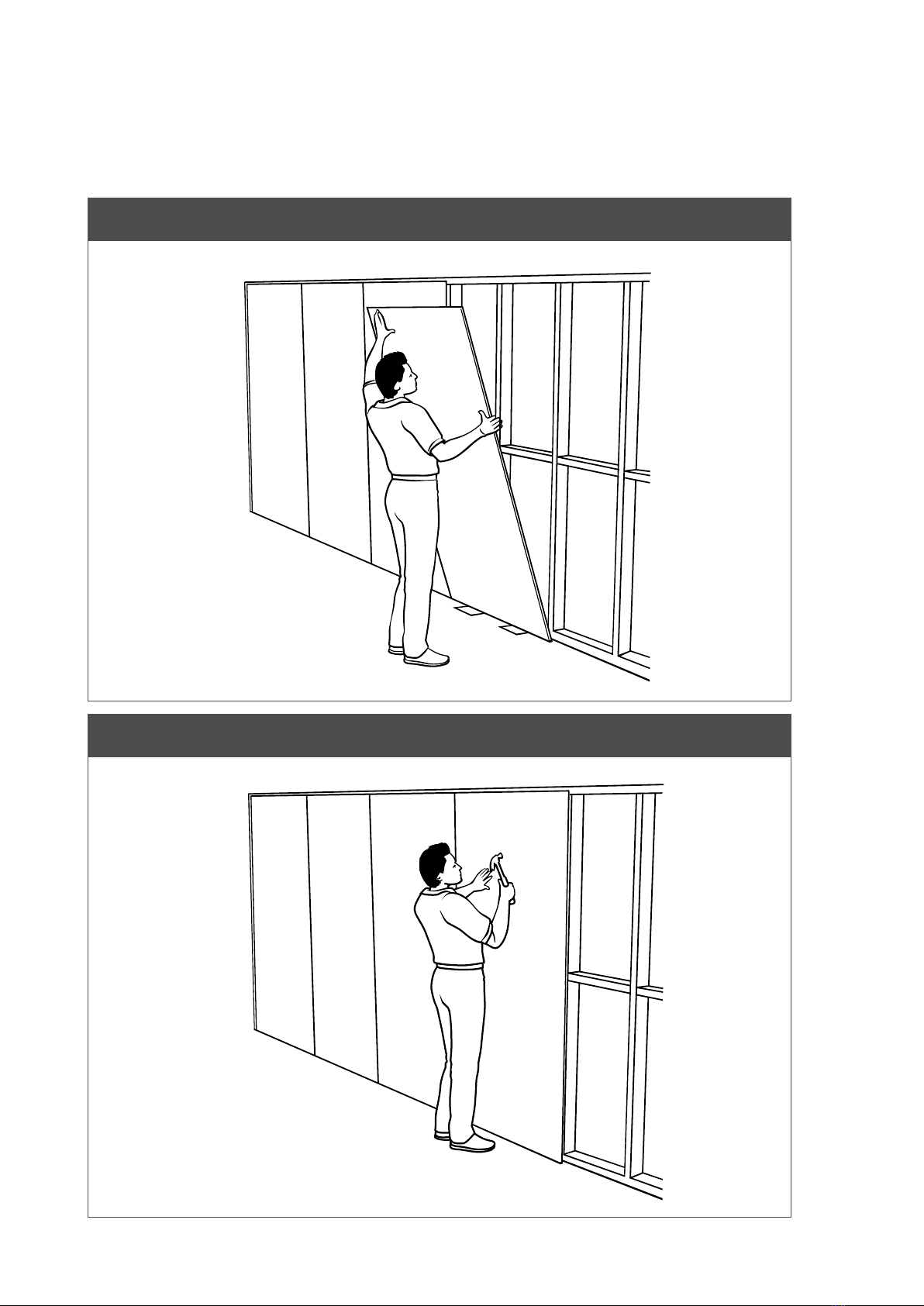

STEP 1

Fix sheet to the

open side of flange

STEP 2

Fix the next sheet to

the web side of the stud

NOTE:

By installing

the sheets in this

sequence a flush

outside surface is

maintained.

Figure 3: Screw fastening

Note: Do not place nails or screws within 100mm of the adhesive daubs.

4.3 Fixing to Walls

Step 1

Place 6.0mm o-cut packers along floor as temporary support for sheets.

This allows provision for frame movement. Put sheet in place as shown.

Step 2

Fix sheet starting from the centre of sheet and working outwards to avoid any druminess. For fastener spacings

refer to Figures 6 and 8 for full height and dado height walls respectively.

Final step

Fix remaining sheets in similar sequence.

Hardie™ Groove Lining Installation Manual | July 2021 New Zealand 13

Figure 4: Sheet installation

Figure 5: Sheet fixing

14 Hardie™ Groove Lining Installation Manual | July 2021 New Zealand

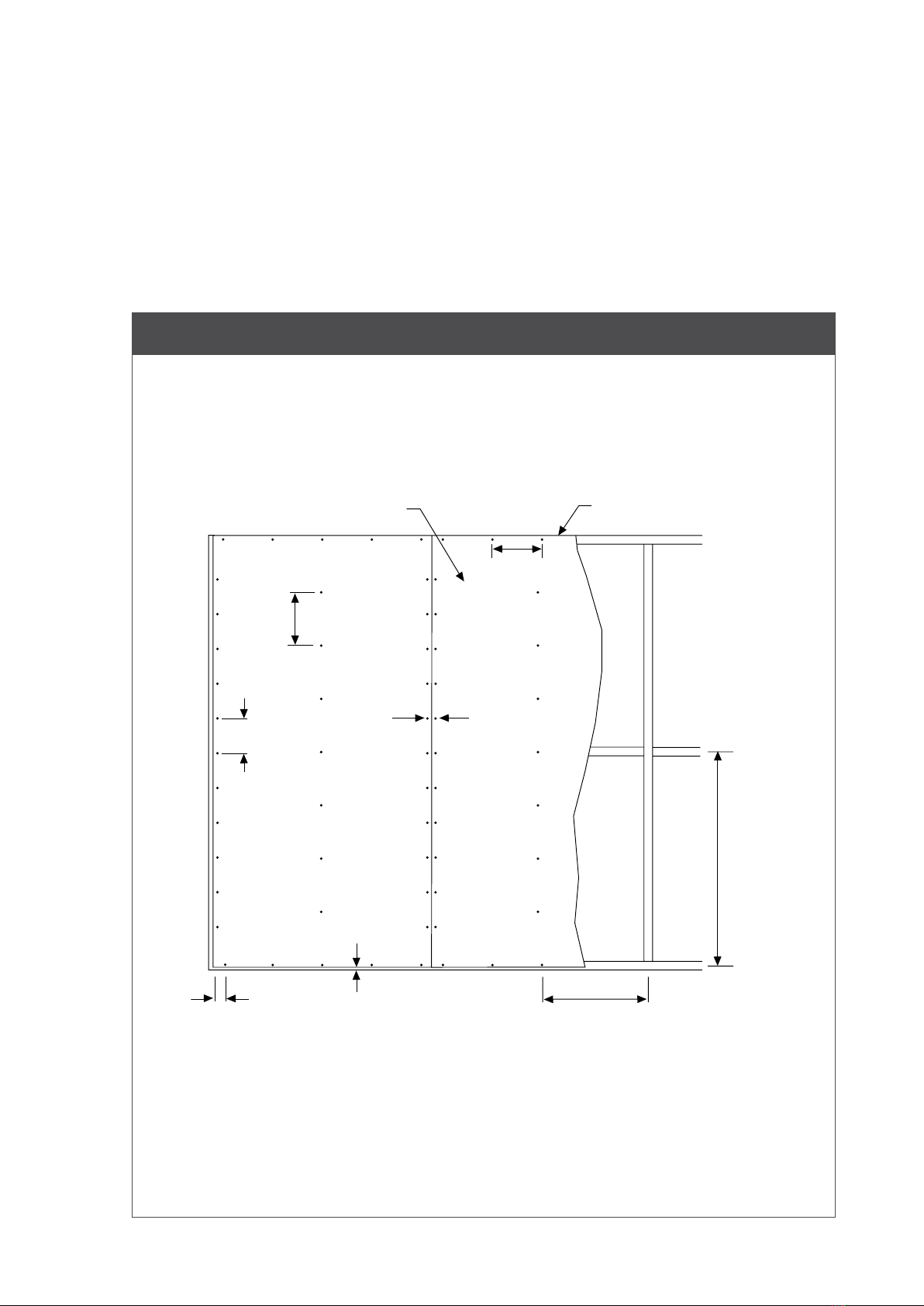

4.4 Full Sheet Fixing

When fixing full sheets of Hardie™Groove Lining to framed walls, fasten sheets as shown in Figure 6. Sheet butt

joints must coincide with the centre line of framing members.

50mm min.

at corners

gap

6mm

6mm gap

200mm

max.

600mm

max.

12mm min.

from edge

200mm

max.

HardieGroove Lining

300mm

max.

1200mm

min.

Figure 6: Full sheet fixing

Hardie™ Groove Lining Installation Manual | July 2021 New Zealand 15

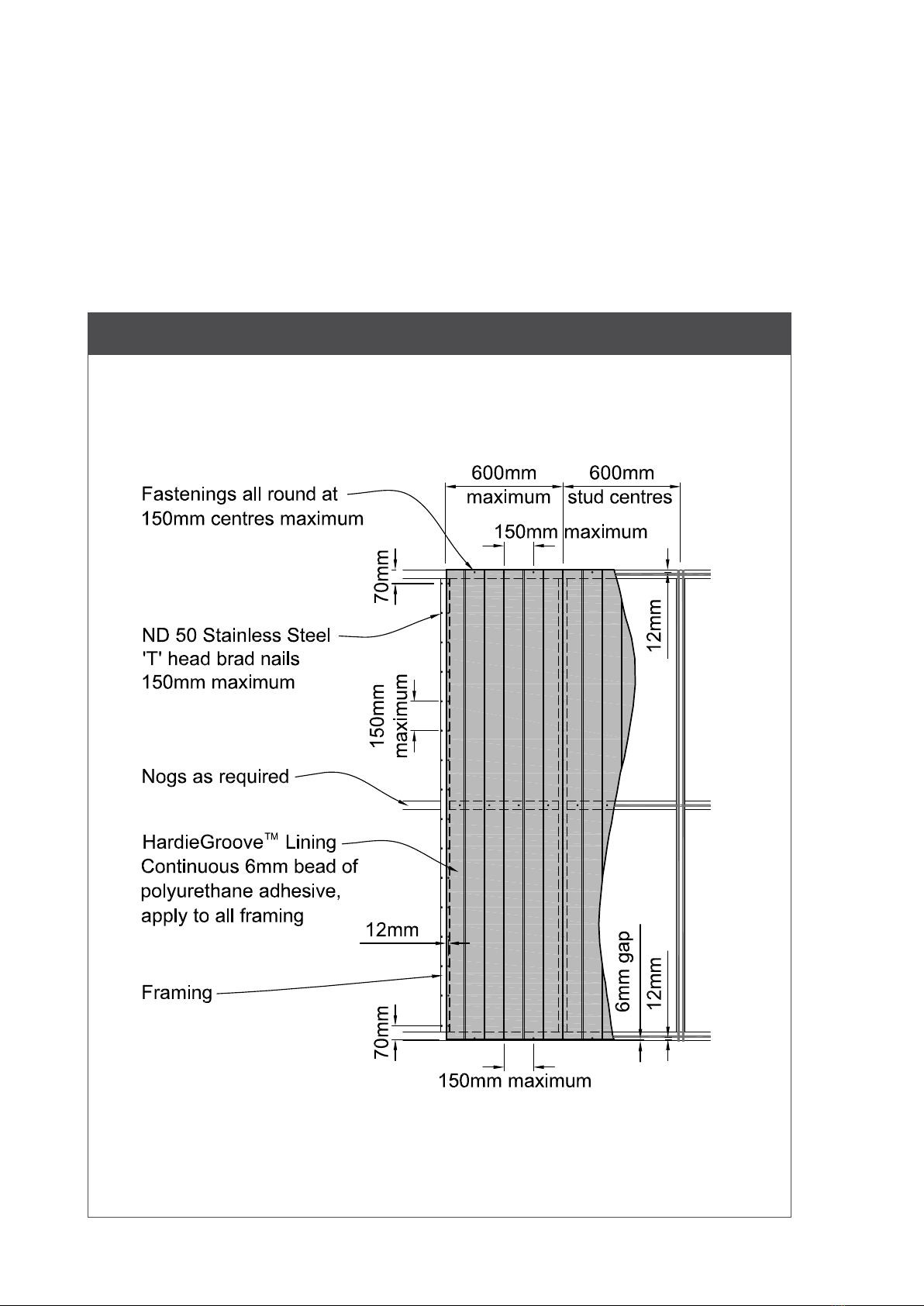

Notes:

1. To reduce the number of visible fixings the centre of the sheet can be fixed with adhesive. See Figure 8 and 9 for details.

2. Hardie™Groove Lining can also be fixed using brad nails in conjunction with adhesives to reduce visible fixings.

Figure 7: Brad nail fixing

16 Hardie™ Groove Lining Installation Manual | July 2021 New Zealand

Villaboard™ Lining

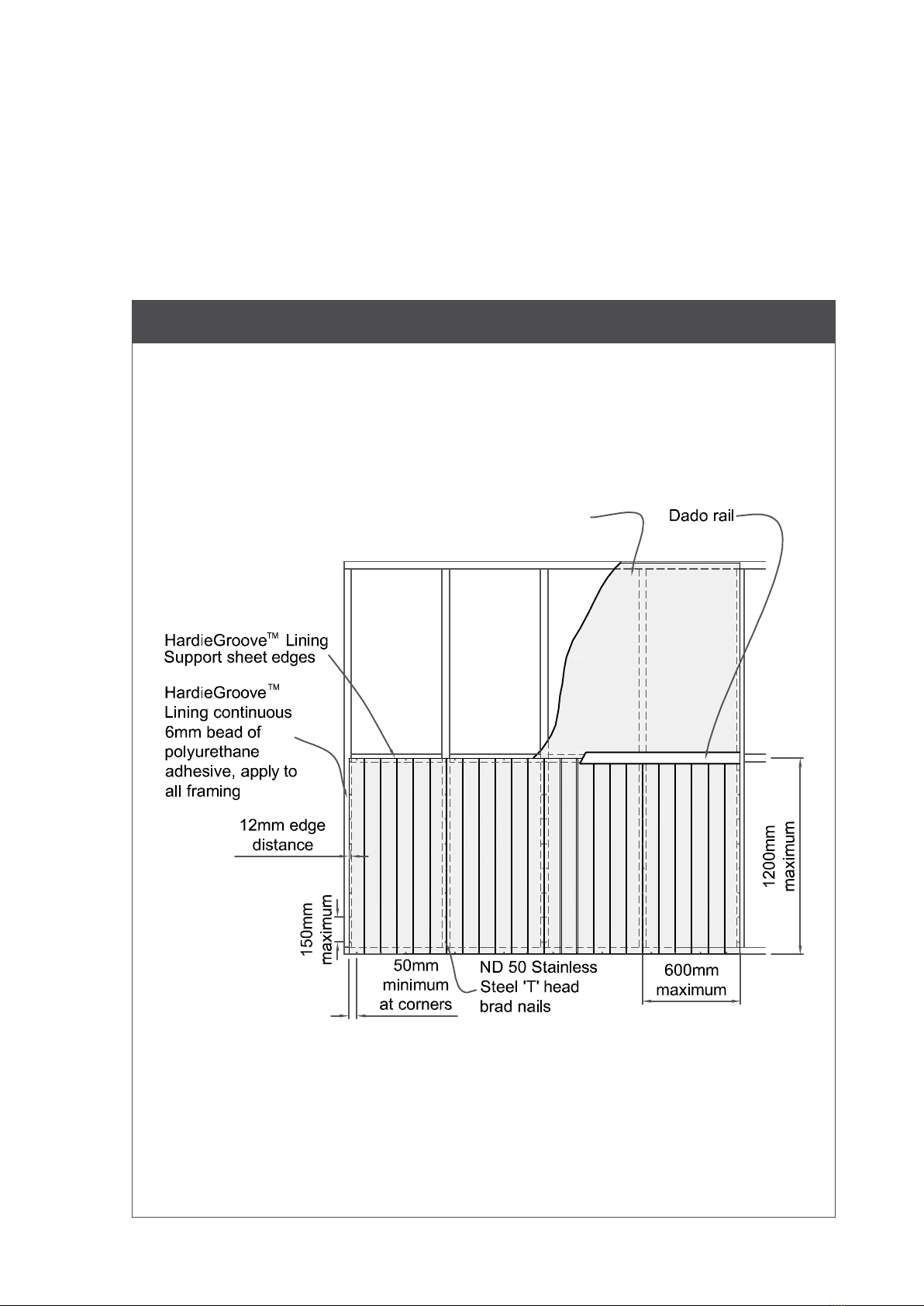

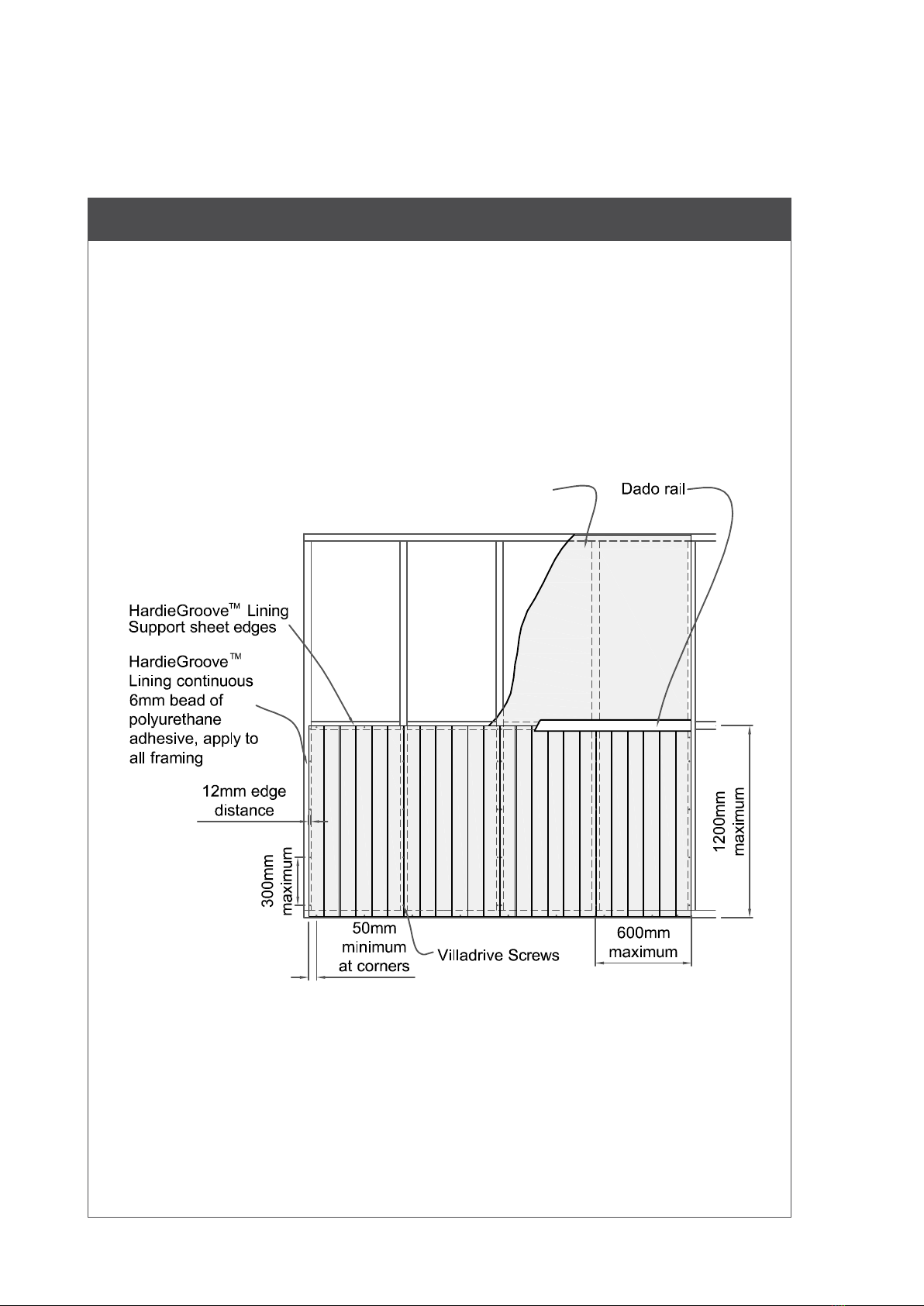

4.5 Dado Height Fixing

Hardie™Groove Lining may be installed to half the wall height to create a dado appearance. Ensure top of sheet

is fixed to an in-line row of noggings as shown in Figure 8 and 9.

Figure 8: Dado height fixing with brads

Hardie™ Groove Lining Installation Manual | July 2021 New Zealand 17

Villaboard™ Lining

Figure 9: Dado height fixing with screws

18 Hardie™ Groove Lining Installation Manual | July 2021 New Zealand

4.6 Fixing Over Plasterboard Lining

Hardie™Groove Lining can be fixed over an existing plasterboard lining. The sheet must be fixed with minimum

50mm nail or a screw 40mm x 8g.

4.7 Fixing To Ceilings and Sots

For Fixing Hardie™Groove Lining to sot/ceiling, refer to Eaves and Sot Linings Installation Manual for further

detailed information.

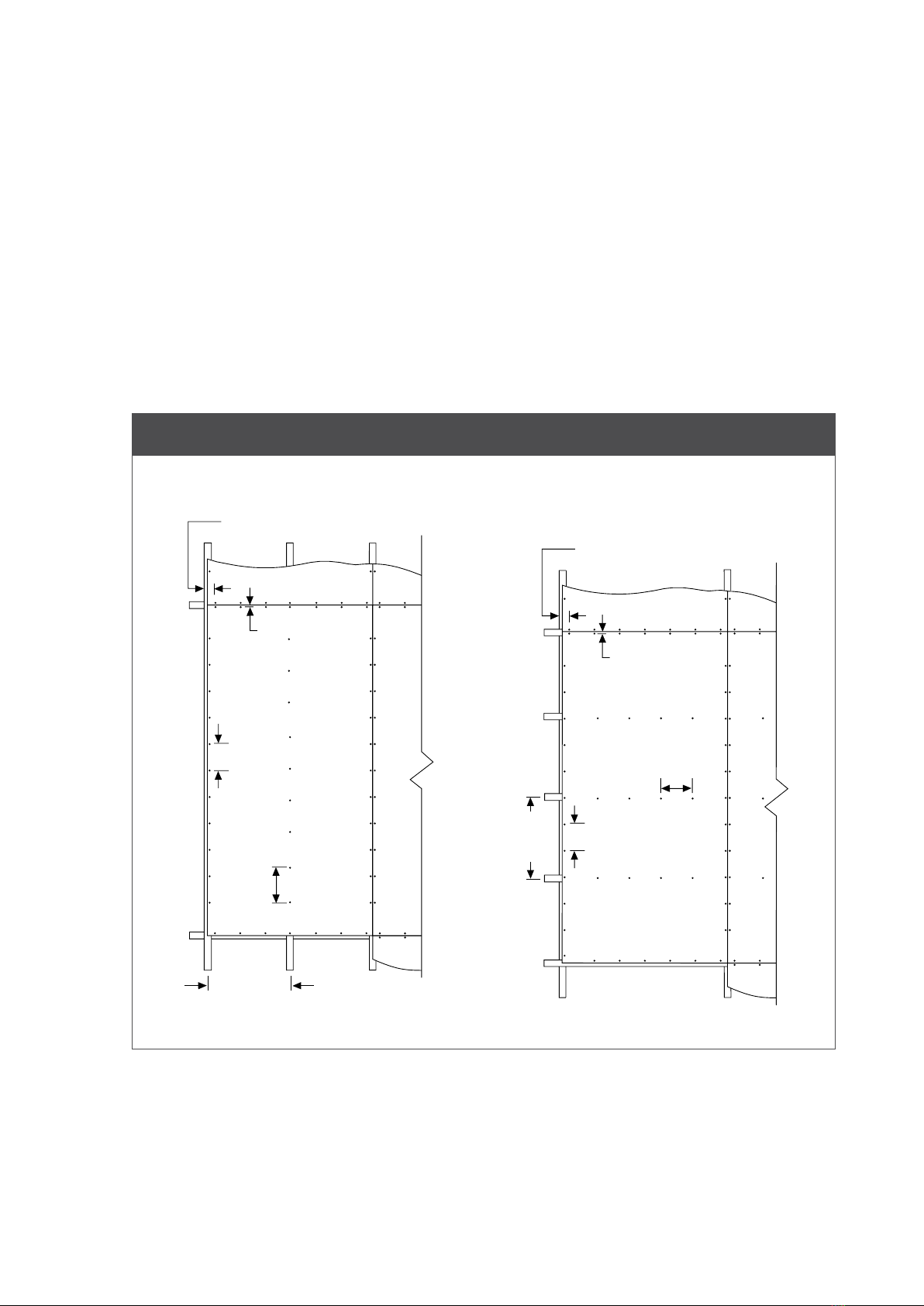

In ceiling applications Hardie™Groove Lining can be fixed either parallel or perpendicular to framing. See Figure

10.

Figure 10: Along joists Across joists

50mm min.

at corners

12mm min.

from edge

200mm

max.

around

edges

250mm

max.

600mm

max centres.

600mm

max centres.

12mm min.

from edge

50mm min.

at corners

200mm

max.

around

edges

250mm

max.

Notes:

1. Fastener fixing method is shown, however, fastener/adhesive fixing method may also be used. See Figure 8 and 9.

2. In ceiling applications do not fix sheets to the bottom chord of roof trusses. Instead, fix to timber battens or metal furring

channels.

3. Do not use brad nails in ceiling/sot applications.

4. When butt jointing short ends of Hardie™Groove Lining in ceiling/sot applications, the short edges must be cut square

and have chamfer formed.

Hardie™ Groove Lining Installation Manual | July 2021 New Zealand 19

4.8 Fixing To Masonry Substrates

Hardie™Groove Lining can be installed over masonry substrates. Refer Figure 11.

Figure 11: Batten/furring channel

HardieGroove

Lining

600mm

max.

6m

6mm gap

m

gap

200mm

max.

50mm min.

from corners

12mm min.

from edge

Fastener

Masonry

200mm

max. centres

200mm

max.

1200mm max.

35mm thick x 45mm wide

timber batten/steel

furring channel fixed to

wall with suitable fasteners

or anchor clips.

20 Hardie™ Groove Lining Installation Manual | July 2021 New Zealand

Table of contents

Popular Indoor Furnishing manuals by other brands

Grizzly

Grizzly T28931 instructions

Unfinished Furniture of Wilmington

Unfinished Furniture of Wilmington T-4818XBT Assembly instructions

Furniture of America

Furniture of America YNJ-15413C5-TV Assembly instructions

DUSK

DUSK Ascot manual

Germania

Germania 1694 Assembly instruction

Möbel AS

Möbel AS KLTS62321 Assembling Instruction