Hardt INFERNO 3500 User manual

Hardt Equipment Manufacturing Inc.

1400 - 50

th

Avenue, Lachine

Quebec, Canada, H8T 2V3

Technical Support

Tel: (800) 387-6847

(514) 631-7271

Fax: (514) 631-5443

Sales

Tel: (888) 848-4408

www.hardtequipment.com

HARDT

Responsive, Reliable Solutions

INFERNO 3500

GAS-FIRED, SELF-

CLEANING ROTISSERIE

Operation Manual

This manual is to be left with the customer for future reference.

CUS

-

013

-

0027

-

0

2

Page 2 of 18

CUS-013-0027-02

1.Important Information

The terms Hardt®, Food Systems Resource®, Inferno®, Elemendt®, and the symbol depicting six circles, and other

distinctive terms, are registered and unregistered trademarks of Hardt Equipment Manufacturing, Inc. and associated

companies. Covered by U.S. Patent no. 7,060,942; U.S. Patent 6,127,659; and U.S. Patent 7,241,977. Other patents

pending. © 2011 - 2016 Hardt Equipment Manufacturing, Inc. All rights reserved.

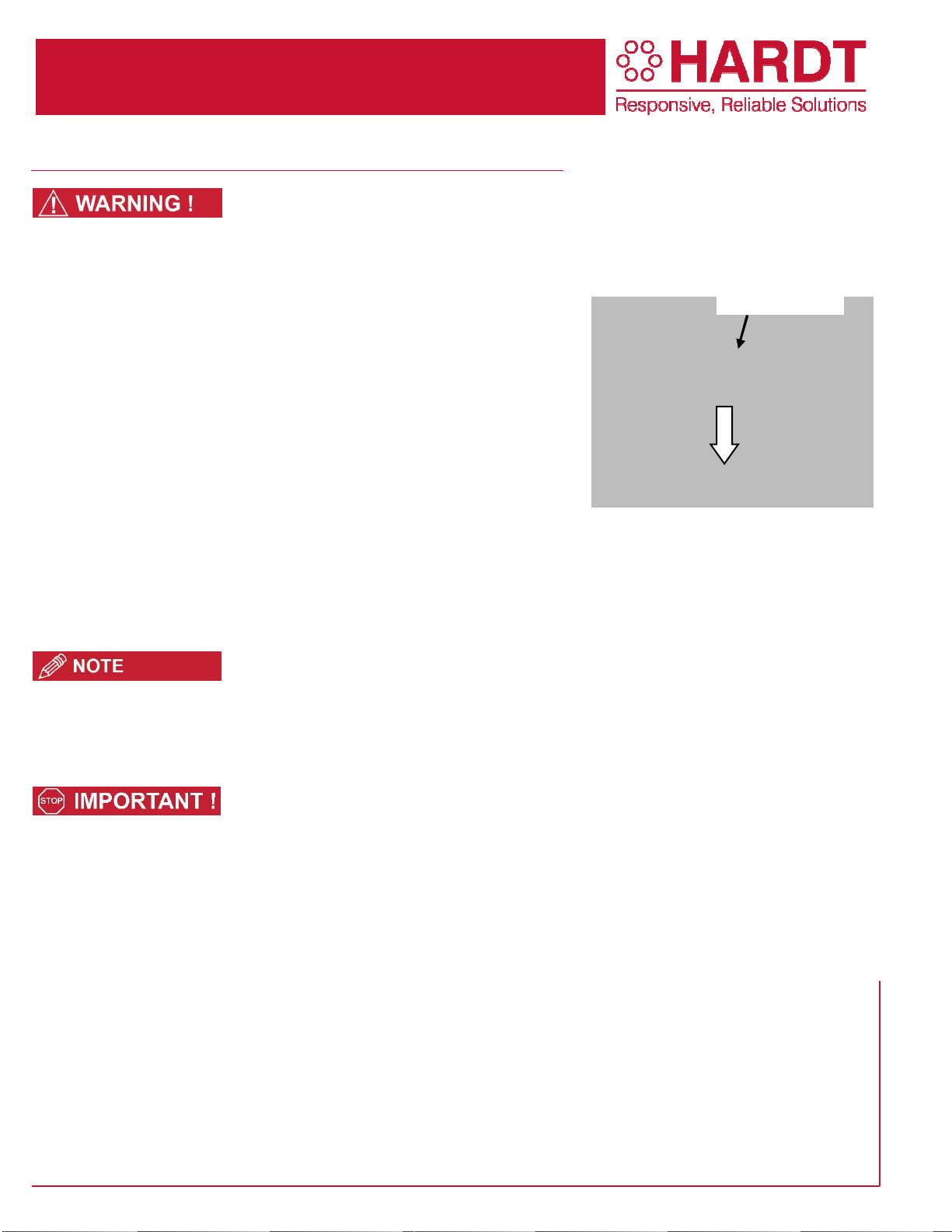

WARNING

Improper installation, adjustment,

alteration, service or maintenance can

cause property damage, injury or death.

Read the installation, operating and

maintenance instructions thoroughly before

installing or servicing this equipment.

WARNING

Do not store or use gasoline or other

flammable vapors or liquids in the vicinity

of this or any other appliance.

Keep the area surrounding the rotisserie

free of any combustible material.

IMPORTANT

You must post in a prominent location,

instructions to be followed in the event the

user smells gas. Specific instructions can

be obtained from your local gas supplier.

Page 3 of 18

CUS-013-0027-0

2

2.Table of Contents

1. Important Information..................................................................................................................... 2

2. Table of Contents............................................................................................................................ 3

3. Safety............................................................................................................................................... 4

3.1 About this Manual...................................................................................................................................................4

3.2 Equipment Safety...................................................................................................................................................4

3.3 What to do if a Service Issue Occurs......................................................................................................................4

3.4 Food Safety............................................................................................................................................................5

4. Equipment Diagrams...................................................................................................................... 6

4.1 Single Standard Rotisserie.....................................................................................................................................6

4.2 Single Top Vent Rotisserie.....................................................................................................................................7

4.3 Double Deck Rotisserie..........................................................................................................................................8

4.4 Control Panel Layout..............................................................................................................................................9

5. Operation....................................................................................................................................... 10

5.1 Morning Startup....................................................................................................................................................10

5.1.1 Starting the Rotisserie..............................................................................................................................10

5.2 Cooking Procedure...............................................................................................................................................11

5.3 Loading & Unloading the Rotisserie......................................................................................................................12

5.3.1 Loading the Skewers ...............................................................................................................................12

5.3.2 Unloading the Skewers............................................................................................................................12

5.4 Controller Functions.............................................................................................................................................13

5.4.1 Buzzers and Alarms.................................................................................................................................13

5.4.2 Programming...........................................................................................................................................13

5.4.3 Programming Favorites............................................................................................................................13

6. Maintenance.................................................................................................................................. 14

6.1 Daily Cleaning......................................................................................................................................................14

6.1.1 During the Day.........................................................................................................................................14

6.1.2 At the End of the Day...............................................................................................................................14

6.1.3 Description of Operation..........................................................................................................................14

6.1.4 AutoClean Operation...............................................................................................................................14

6.1.5 AutoClean effectiveness evaluation..........................................................................................................15

6.2 Weekly Inspection................................................................................................................................................15

7. Troubleshooting............................................................................................................................ 16

7.1 Rotisserie does not Operate.................................................................................................................................16

7.2 Safety Lockout.....................................................................................................................................................16

7.3 Replacing the Halogen Lamp................................................................................................................................17

8. Available Accessories.................................................................................................................. 18

Page 4 of 18

CUS-013-0027-02

3.Safety

3.1 About this Manual

This manual contains information necessary for the operation of the HARDT Inferno 3500 rotisserie. Retain this manual

for future reference. To help the reader in the utilization of this manual certain information has been highlighted using the

following conventions:

INFORMATION

THAT

REFERS TO ACTIONS WH

ICH MAY HAVE CONSEQU

ENCES

POTENTIALLY DANGEROUS TO OPERATOR AND/OR THE ROTISSERIE

Information for proper installation and functioning.

3.2 Equipment Safety

THERE ARE SOME SAFET

Y CONSIDERATIONS TO

TAKE INTO ACCOUNT WH

EN

OPERATING THIS EQUIPMENT. IT IS IMPORTANT THAT YOU UNDERSTAND

THIS DOCUMENT AND THE SAFETY PRECAUTIONS WRITTEN HERE.

•

Read all documentation; only people who have

read and understand the documentation should

use the equipment.

•Do not use this equipment for anything other than

its intended use.

•Do not operate this equipment if it is damaged in

any way.

•Do not use unauthorized accessories.

•Do not operate this equipment near flammable

materials.

•Always check for gas leaks; vacate the area and

call the gas supply company if any are detected.

•Clean the equipment every day; build-up of waste

in the rotisserie can cause fires.

•When the unit is plugged in, there are potentially

dangerous voltages present in the control circuits;

do not open the electrical compartment as there

are potentially lethal voltages present.

•

Do not cover any vents.

•Always check for water leaks; do not operate if

leaks are visible.

•Do not immerse the cord or plug in water.

•Use only approved detergents.

•Keep hair and loose clothing away from any

moving parts.

•Do not work with any hot surfaces without wearing

protective gloves and an apron.

•Keep the area around the rotisserie clear of

combustibles.

•Any equipment that burns gas carries a risk of

producing carbon monoxide; if headaches,

dizziness, shortness of breath, nausea, vomiting or

confusion are encountered, shut down all

equipment and vacate the area. Have the

equipment inspected immediately.

Contact

Hardt

or an approved service provider immediately if any problems are

encountered with your equipment.

FAILURE TO FOLLOW THESE SAFETY PRECAUTIONS CAN RESULT IN INJURY,

DEATH AND/OR PROPERTY DAMAGE.

This appliance is equipped with a restr

aint cable. In the event the cable is

disconnected for inspection or cleaning, ensure that it is reconnected before you

operate the rotisserie.

3.3 What to do if a Service Issue Occurs

•Follow the steps detailed in the Troubleshooting section of this manual

•Contact your local authorized service partner. A list of service providers is available at www.hardt.ca

•Please review your warranty document to be sure of what is covered.

Additional Important Information

Page 5 of 18

CUS-013-0027-0

2

3.4 Food Safety

THERE ARE PRECAUTION

S THAT NEED TO BE TA

KEN WHEN WORKING WIT

H

RAW MEATS, FAILURE TO FOLLOW PROPER FOOD PREPARATION

PROCEDURES CAN RESULT IN ILLNESS AND DEATH. SOME PRECAUTIONS

ARE LISTED IN THIS DOCUMENT BUT YOU SHOULD NOT RELY SOLELY ON THIS

DOCUMENT FOR FOOD SAFE PROCEDURES. IT IS RECOMMENDED THAT ONLY

PERSONS WHO ARE FULLY TRAINED IN FOOD SAFETY SHOULD PREPARE

FOOD ITEMS.

•Wash all surfaces and equipment that comes into contact with raw meat or its juices.

•Always thoroughly wash your hands after working with raw meat.

•Do not allow raw meat or its juices to contact cooked meat.

•Use separate utensils for working with raw and cooked meat.

•Use separate containers/trays for holding raw and cooked meat.

•Always use a clean food thermometer to ensure meat is at a safe temperature before removing from the

rotisserie.

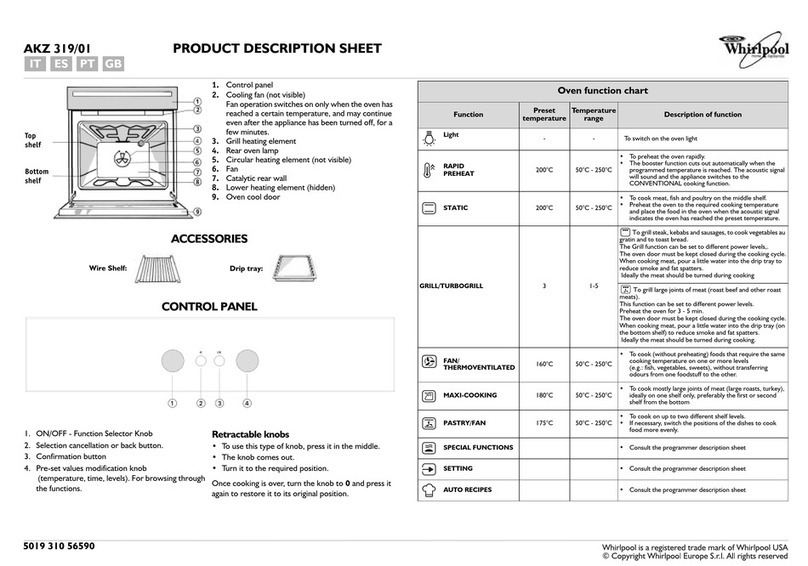

The table below describes how long each type of meat must be at a specific temperature to ensure that all bacteria are

killed. Always use a calibrated food thermometer to ensure that your product reaches these temperatures for the

specified time period before considering it safe for consumption.

Safe Cooking Times and Temperatures

*

Product

Temperature/Time

Poultry (Whole or ground duck, chicken or turkey) 165˚ F, 74˚ C, for 15 seconds

Stuffing and stuffed meat, fish, poultry and pasta 165˚ F, 74˚ C, for 15 seconds

Ground meat (beef, pork, and other meat) 155˚ F, 68˚ C, for 15 seconds

Injected meat (brined ham and flavour injected roasts) 155˚ F, 68˚ C, for 15 seconds

Pork, beef, veal, lamb, Steaks/Chops 145˚ F, 63˚ C, for 15 seconds

Roast 145˚ F, 63˚ C, for 4 Minutes

Seafood (fish, shellfish, crustaceans) 145˚ F, 63˚ C, for 15 seconds

Commercially processed ready-to-eat food 135˚ F, 57˚ C (Hot held for service)

*

National Restaurant Association,

ServSafe Course book

, Fifth Edition, New Jersey, Prentice H

all, 2008

The values listed in this table are industry standard minimum temperatures to ensure

food is safely cooked, and may not represent the temperatures dictated by your

company.

COOKING ANY NEW PRODUCT OR ANY CURRENT PRODUCT PREPARED IN A

DIFFERENT WAY REQUIRES A VALIDATION OF COOKING TIMES AND COOKING

TEMPERATURES BY MEASUREMENT OF INTERNAL PRODUCT TEMPERATURES.

DO NOT ASSUME SAFE COOKING PARAMETERS EXIST WITHOUT PERFORMING

FOOD-SPECIFIC TESTS. ALWAYS MEASURE THE INTERNAL TEMPERATURE OF

A PRODUCT BEFORE ENDING THE COOKING. ACCEPTED INTERNAL

TEMPERATURES SHOULD NOT BE LOWER THAN THOSE PUBLISHED FOR

ESTABLISHED FOOD SAFETY STANDARDS.

Consult Hardt if you need help setting up a food safety program.

Page 6 of 18

CUS-013-0027-02

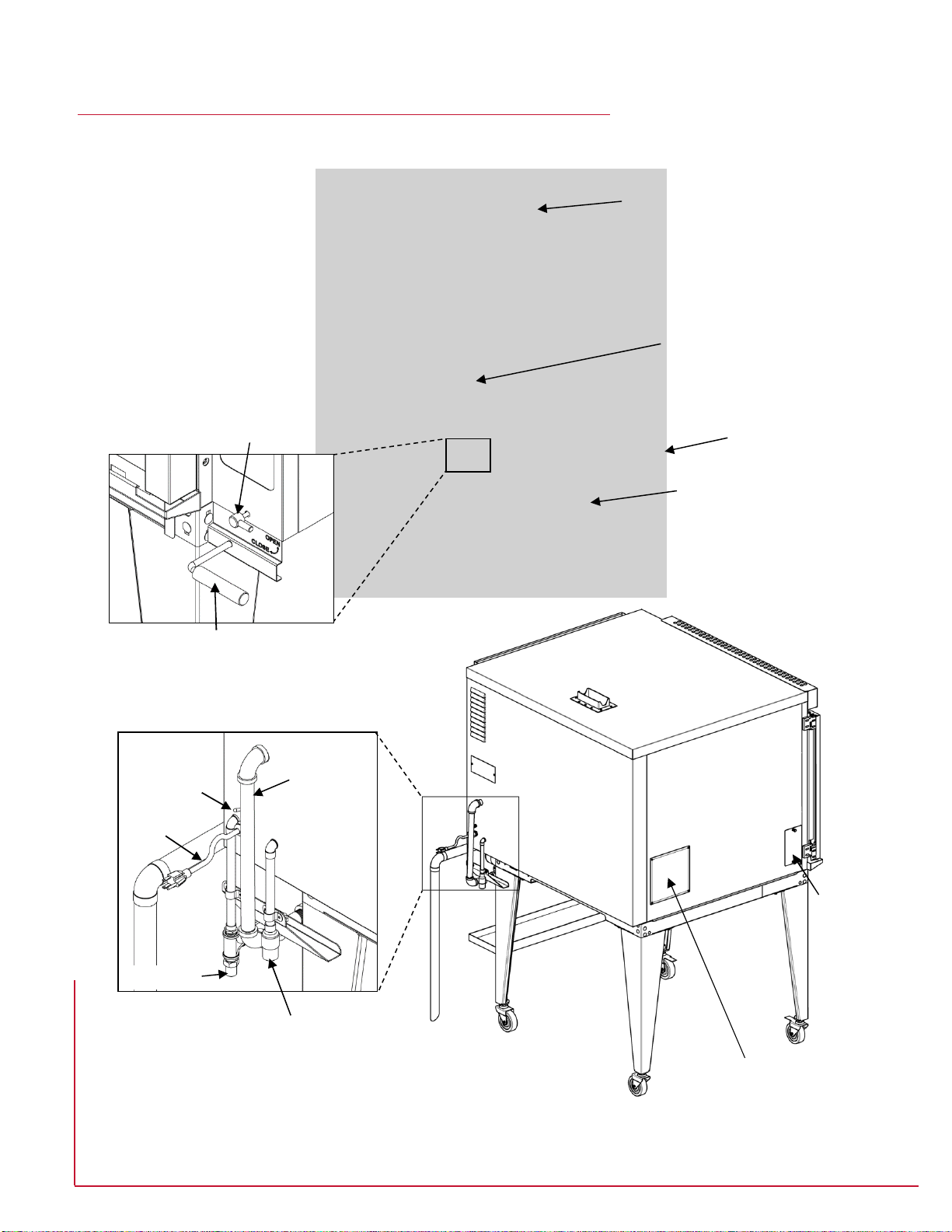

Auto Clean

Drain

Electrical

Cord

Water Inlet

Gas Inlet

Power Switch

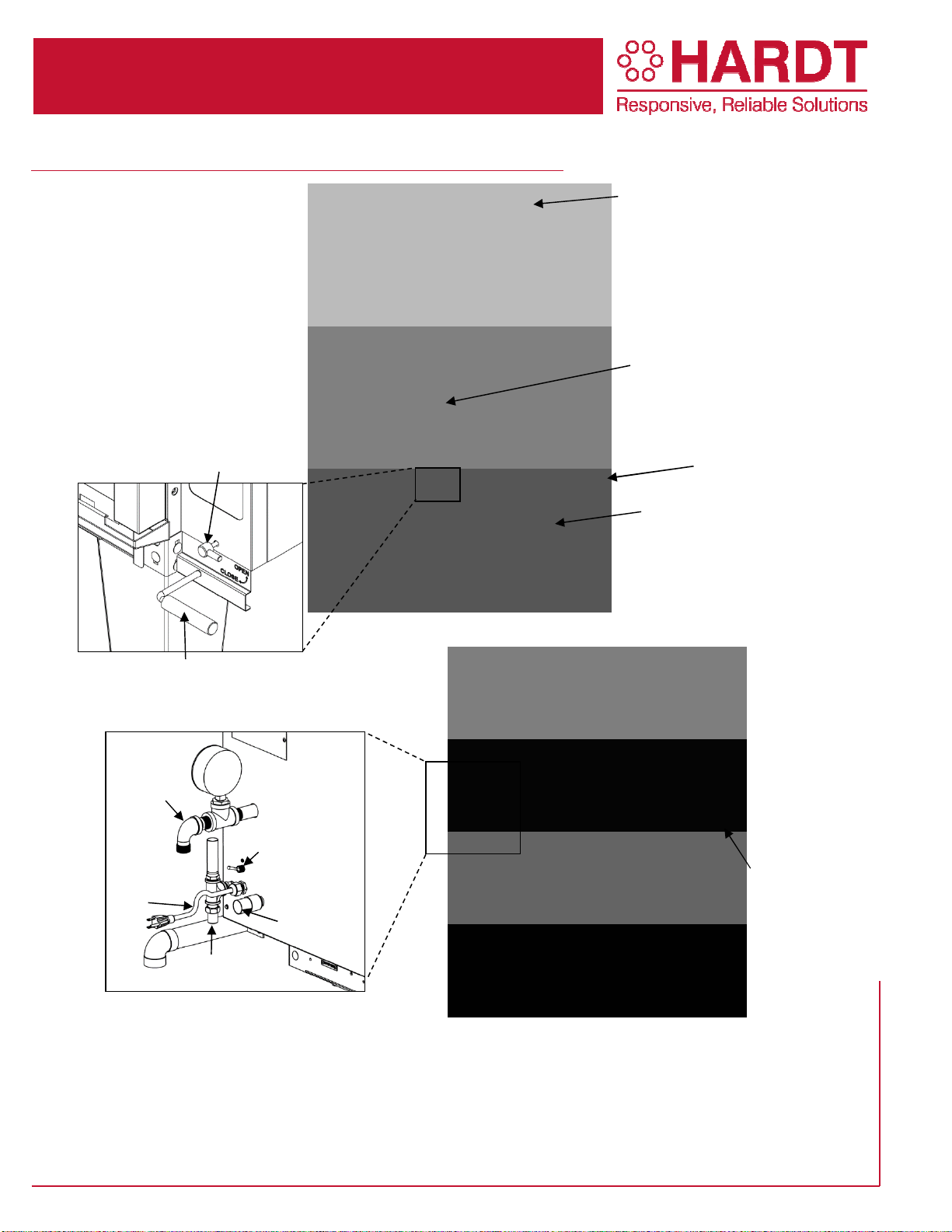

4.Equipment Diagrams

4.1 Single Standard Rotisserie

Figure 4-1: Single Unit

Halogen Lamp

Access Panel

Drain

/ Overflow

(1.5”)

Control Panel

Chimney

Degreaser Shelf

Manual Drain Valve Handle

Water Inlet Valve Handle

Page 7 of 18

CUS-013-0027-0

2

4.2 Single Top Vent Rotisserie

Figure 4-2: Single Unit

Drain

/ Overflow

(1.5”)

Control Panel

Vent

Degreaser Shelf

Manual Drain Valve Handle

Water Inlet Valve Handle

Halogen Lamp

Access Panel

Gas Inlet

Power Switch

Water Inlet

Auto Clean Drain

Electrical

Cord

Flame Sensor

Access Panel

Page 8 of 18

CUS-013-0027-02

4.3 Double Deck Rotisserie

Figure 4-3: Double Deck Unit

Drain / Overflow (1.5”)

Control Panels

Degreaser Shelf

Chimneys

Chimney Bracket

Manual Drain Valve Handle

Water Inlet Valve Handle

Halogen Lamp

Access Panel

Machine Room

Ventilation Elbow

Flame Detector

Access Panel

Auto Clean

Drain

Electrical

Cord

Water Inlet

Gas Inlet

Power Switch

Page 9 of 18

CUS-013-0027-0

2

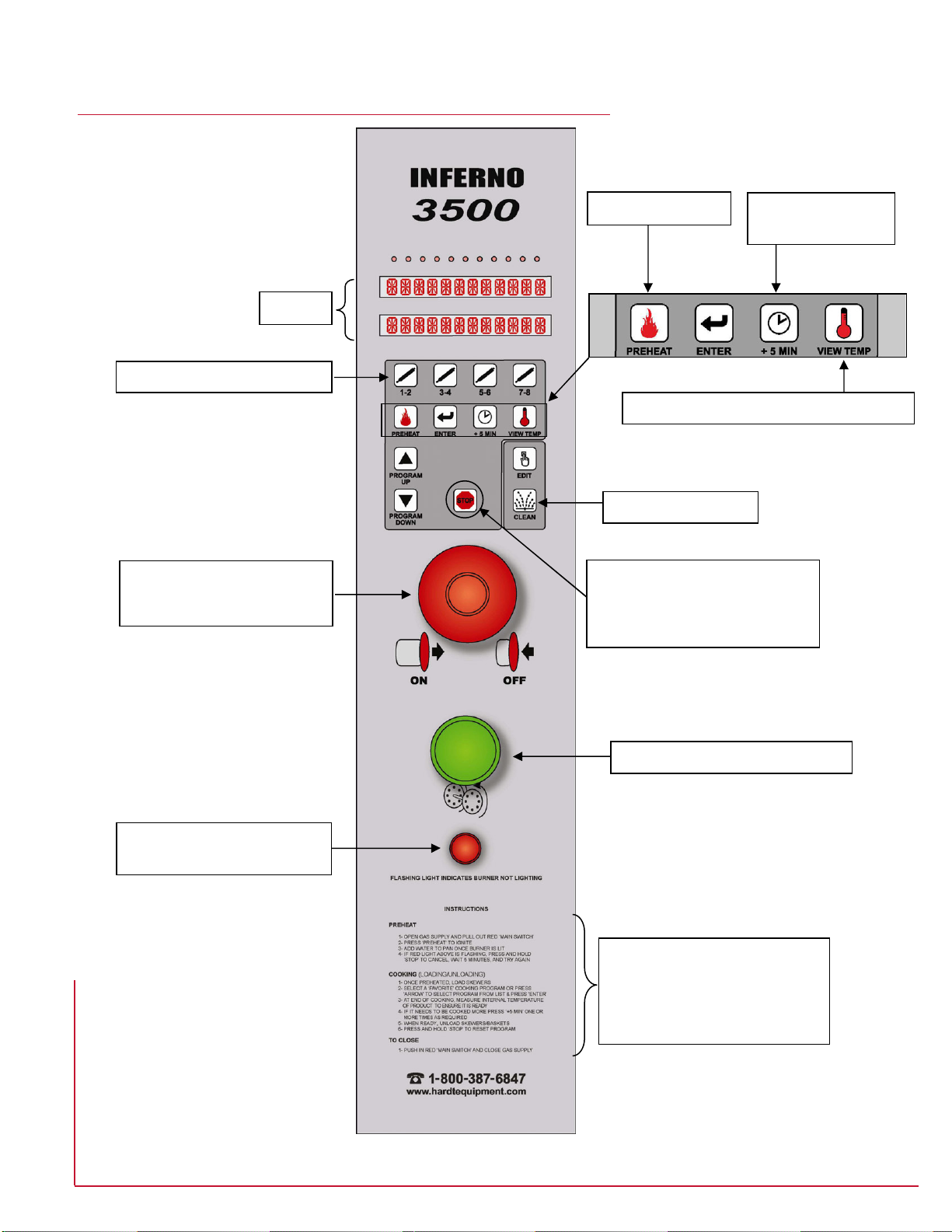

4.4 Control Panel Layout

Figure 4-4: Control Console

Display

Favorite Program Selection

Main On/Off Switch (Red)

IN CASE OF EMERGENCY

PUSH TO STOP

Alarm Lamp

(Indicates burner not lighting)

Preheat Function Incremental Cook

Time Addition

Manual Advance Switch (Green)

Basic Operation Instructions

and Hardt Contact Information

Read this manual for detailed

operation instructions.

Press once stops the buzzer

Press and hold 3 seconds

stops all actions except clean

AutoClean Function

Show current temperature of rotisserie.

Page 10 of 18

CUS-013-0027-02

5.Operation

5.1 Morning Startup

ALWAYS TURN VENTILAT

ION SYSTEM ON BEF

ORE STARTING ROTISSE

RIE. IT

IS REQUIRED TO REMOVE COMBUSTION BY-PRODUCTS AND GREASE-LADEN

AIR.

5.1.1 Starting the Rotisserie

1. With power connected to the rotisserie, turn on the Inferno 3500 by

pulling out the red main on/off switch shown in Figure 4-4.

2. Make sure the drain valve is closed as shown in Figure 5-1.

3. Make sure the gas valve to the rotisserie is opened.

4. Follow the instructions scrolling on the display.

5. Clean the strainers and turn on the ventilation hoods.

6. Once these conditions have been filled, press “ENTER”.

7. Select “PREHEAT” to ignite.

8. Fill the water pan with water using the Water Inlet Valve shown.

Figure 5-1: Drain Valve

References will be made to an “IDLE MODE” in the next few sections that relate to

rotisserie operation. When in IDLE MODE, the controller displays “PREHEAT OR

CLEAN”.

If the red lamp is flashing, indicating the burner did not light, press and hold "STOP" to

cancel. Wait 5 minutes and try again. See the safety lockout section of the

troubleshooting chapter on page 16.

The rotisserie cannot be operated during a power failure. In the event of a

prolonged power failure, do not attempt to operate the rotisserie. Turn off the red

main on/off switch and close the gas valve. When power has been restored, open

the gas valve, pull out the red main on/off switch and resume normal operation.

Water Inlet Valve

Page 11 of 18

CUS-013-0027-0

2

5.2 Cooking Procedure

THE ROTISSERIE IS HOT. ENSURE YOU ARE WEARING OVEN MITTS AT ALL

TIMES WHEN WORKING WITH THE HOT ROTISSERIE.

NEVER LOAD PRODUCT INTO A ROTISSERIE WHICH IS NOT PREHEATED.

CROSS CONTAMINATION OF RAW ONTO COOKED PRODUCT IS VERY

DANGEROUS.

DO NOT LOAD FRESH PRODUCT INTO ROTISSERIE UNTIL COOKING CYCLE IS

COMPLETE AND ALL COOKED PRODUCT IS REMOVED FROM ROTISSERIE.

Refer to the table on page 5 for a list of safe cooking temperatures and times.

The procedures described here are basic. Hardt provides extensive cooking and

food program support and training. Your organization may have specific

instructions that should be followed instead of the ones listed here.

1. Following a preheat cycle (see section 5.1.1); the display will indicate “OVEN READY” when the correct

temperature for loading the rotisserie has been reached.

2. Open the door and load the product as per the procedure described in section 5.3.1.

3. Close the door.

4. Select a “FAVORITE” preset recipe (indicated as 1-2, 3-4, 5-6 and 7-8 on the keypad in Figure 4-4: Control

Console on page 9) or press an arrow (“UP” or “DOWN”) to select another program from the saved list. To select

a program, press “ENTER” on the keypad.

The numbers on the favorite buttons dictate how many skewers are to be used. Select

‘1-2’ if using one or two skewers, select ‘3-4’ if using three or four skewers, etc.

5. At the end of the cook, measure product internal temperature. Refer to section 3.4 of this manual for special notes

on product internal temperatures.

6. If the measured internal temperature is insufficient, press “+ 5 MIN” to add five minutes to the cook cycle. The

“+5 MIN” button can be pressed up to three times to add a total of 15 minutes to the cook time. Repeat this step

until correct internal temperature is reached.

7. Press “STOP” and hold for 3 seconds to end and reset the program.

8. Unload skewers from rotisserie following the procedure described in section 5.3.2.

9. Open the water inlet valve to raise the water level. Skim grease down the overflow drain (make sure the liquids

flow freely out of the overflow drain).

10. Close the water inlet valve.

Page 12 of 18

CUS-013-0027-02

5.3 Loading & Unloading the Rotisserie

CROSS CONTAMINATION

OF RAW ONTO COOKED P

RODUCT IS VERY

DANGEROUS.

DO NOT LOAD UNCOOKED PRODUCT INTO ROTISSERIE UNTIL COOKING

CYCLE IS COMPLETE AND ALL COOKED PRODUCT IS REMOVED FROM

ROTISSERIE.

5.3.1 Loading the Skewers

When the rotisserie reaches operating temperature skewers can be loaded.

Open the door to shut off burner and to stop the drive rotation. Use the green Manual Advance Switch (as indicated in

Figure 4-4 on page 9) to position sockets as required.

The orientation of the skewer in the socket will vary depending on the model of

your equipment.

Follow these steps to properly load skewers into the rotisserie.

1. As indicated in diagram ‘A’ below, insert pointed end of the skewer into a hole in the plate on left side of

rotisserie.

2. Align the other end of the skewer with the corresponding socket and push into place (see diagram ‘B’).

3. Slide the skewer back to the left until the shoulder of the tip at the left end of the skewer rests against the left

end plate.

4. Check that the skewer is secured in position (holds in place).

5. Advance the drive to another position using the green manual advance switch. Repeat steps 1-5 as required.

6. Close the door, select the proper cooking program, and the rotisserie will begin to cook.

USE PROTECTIVE CLOTHING WHEN LOADING AND UNLOADING THE

ROTISSERIE.

5.3.2 Unloading the Skewers

1. Open the door to shut off burner and to stop the drive from rotating.

2. Remove each skewer by lifting left end, sliding the skewer to the left and then gently pivot the skewer out of

the rotisserie. Place each skewer on a skewer cart or a cooked food table.

3. Use the green manual advance switch to position skewers (or baskets) as required for removal.

4. Close the door of the rotisserie to resume operation or cooking (burner will reignite).

5. If no further cooking is required, press and hold the “STOP” button for three seconds to end the program.

Figure 5-2: Loading Skewers

A) B)

Slide skewer into the

support plate

Push skewer into socket in

the drive plate.

Align skewer

with s

ocket

Shoulder

Page 13 of 18

CUS-013-0027-0

2

5.4 Controller Functions

This section contains information for basic operation and programming of the Inferno 3500 system. For more detailed

instructions, please refer to the Controls Instruction Manual.

5.4.1 Buzzers and Alarms

(Press STOP once to end a buzzer. Press and hold ‘STOP’ for 3 seconds to stop any action except an AUTOCLEAN

cycle.)

•At the end of a preheat cycle when the correct temperature is reached, a buzzer will sound for 5 seconds.

•If the rotisserie temperature then drops below 150˚F (65.6˚ Celsius), the red alarm lamp will flash and a

message on the controller display will prompt to repeat the preheat cycle.

•At the end of a cooking cycle and of subsequent cook time additions, a buzzer sounds for 10 seconds.

•In case of a Safety Lock Out (gas burner does not light), the red alarm lamp will flash continuously.

5.4.2 Programming

The controls allow many of the rotisserie’s parameters to be accessed and modified. Only the basic programming of

“Favorites” is described in this manual. Additional modification of the parameters must be performed by an authorized

service technician. Please call Hardt Customer Service for further information.

Use UP/DOWN to scroll through menus and to change settings, ENTER to select (and then again to validate selection)

and STOP to exit.

5.4.3 Programming Favorites

A favorite is a shortcut to a cooking program.

Hold EDIT and a Favorite key simultaneously for three

seconds:

To modify a Favorite recipe:

• Display shows the last selected program

• Use the UP/DOWN buttons to locate any program in memory from 1 to 16

• Press ENTER to save program selection to that Favorite button.

Figure 5-3: Favorite Buttons

Page 14 of 18

CUS-013-0027-02

6.Maintenance

6.1 Daily Cleaning

6.1.1 During the Day

ALWAYS ALLOW THE ROTISSERIE TO SUFFICIENTLY COOL BEFORE

ATTEMPTING TO CLEAN IT.

It is recommended to clean the inner glass with a soft, damp cloth after every cooking cycle. This will lead to optimal

cleaning results without scratching the glass. Avoid using scouring pads or cleaners with grit on glass.

It may also be necessary to replenish or change the water in the oven throughout the day, depending on the quantity

of product cooked.

6.1.2 At the End of the Day

It is recommended to run the AutoClean cycle at the end of the business day, after all cooking has been completed.

6.1.3 Description of Operation

The AutoClean cycle consists of a succession of activities that are completely and automatically controlled by the

rotisserie. The sequence is as follows:

•OVEN COOLDOWN: A period of time required for the rotisserie to reach a safe temperature for cleaning.

•PREWASH: A repetition of soaking in water and draining sequences

•SOAP WASH: Involves the repeated application of a cleaning agent followed by soaking and draining

•FIRST RINSE: A rinsing cycle.

•POWER RINSE: Another, different type of rinsing cycle.

•FINAL RINSE: A series of rinsing cycles involving water collection followed by draining.

6.1.4 AutoClean Operation

ENSURE YOU ARE WEARING INSULATED GLOVES AND APRON AT ALL TIMES

WHEN WORKING WITH THE HOT ROTISSERIE.

1. Verify that there is sufficient degreaser in the bottle.

2. Open the door, and open the drain valve as shown in Figure 6-1: Drain

Valve.

3. Remove any large pieces that are left on the bottom of the water pan.

4. Close the drain valve.

5. Open the Water Inlet Valve to add water to the water pan. Make sure the

water is draining freely and not rising or overflowing out the oven door.

6. Close the Water Inlet Valve. Open the Drain Valve and drain the water

pan completely. DO NOT PUSH THE DEBRIS INTO THE DRAINS.

7. Open the Water Inlet Valve to add a small amount of water to the water

pan. Using a towel wipe the water pan clean removing all particles.

8. Close the Water Inlet Valve.

9. Drain the water pan completely.

10. Close the Drain Valve. The Drain Valve must be closed for the Auto clean to operate.

11. Close the oven door and press the ‘CLEAN’ button and then the ‘ENTER’ button. Read the display. If the Auto

clean has begun it will read either, “CHECKING OVEN TEMPERATURE”, “CLEAN COOLDOWN” or

“PREWASH”.

If the display reads, “CLEAN COOLDOWN” the

AutoClean

will not start

immediately as the cooking cavity is too hot. DO NOT open the door to cool the

rotisserie! It must cool on its own with the door closed so the degreaser works

properly. The AutoClean will start on its own when the unit has properly cooled

Figure 6-1: Drain Valve

Water Inlet Valve

Drain Valve

Page 15 of 18

CUS-013-0027-0

2

For units equipped with the optional sensors

–

If the degreaser

is low, an alarm

will sound and the display will show: “REFILL DEGREASER BOTTLE // PRESS

CLEAN”. Replace the degreaser bottle and start again.

If the display shows: “CLOSE DRAIN VALVE // PRESS CLEAN”, the Drain Valve is

not fully closed. Close it and start again.

12. Clean the outside of the rotisserie.

6.1.5 AutoClean effectiveness evaluation

It is important to consider the condition of the rotisserie after the

AutoClean cycle is finished to verify that the cleaning operations are

functioning correctly. The following images illustrate three states of

cleanliness and their related interpretation.

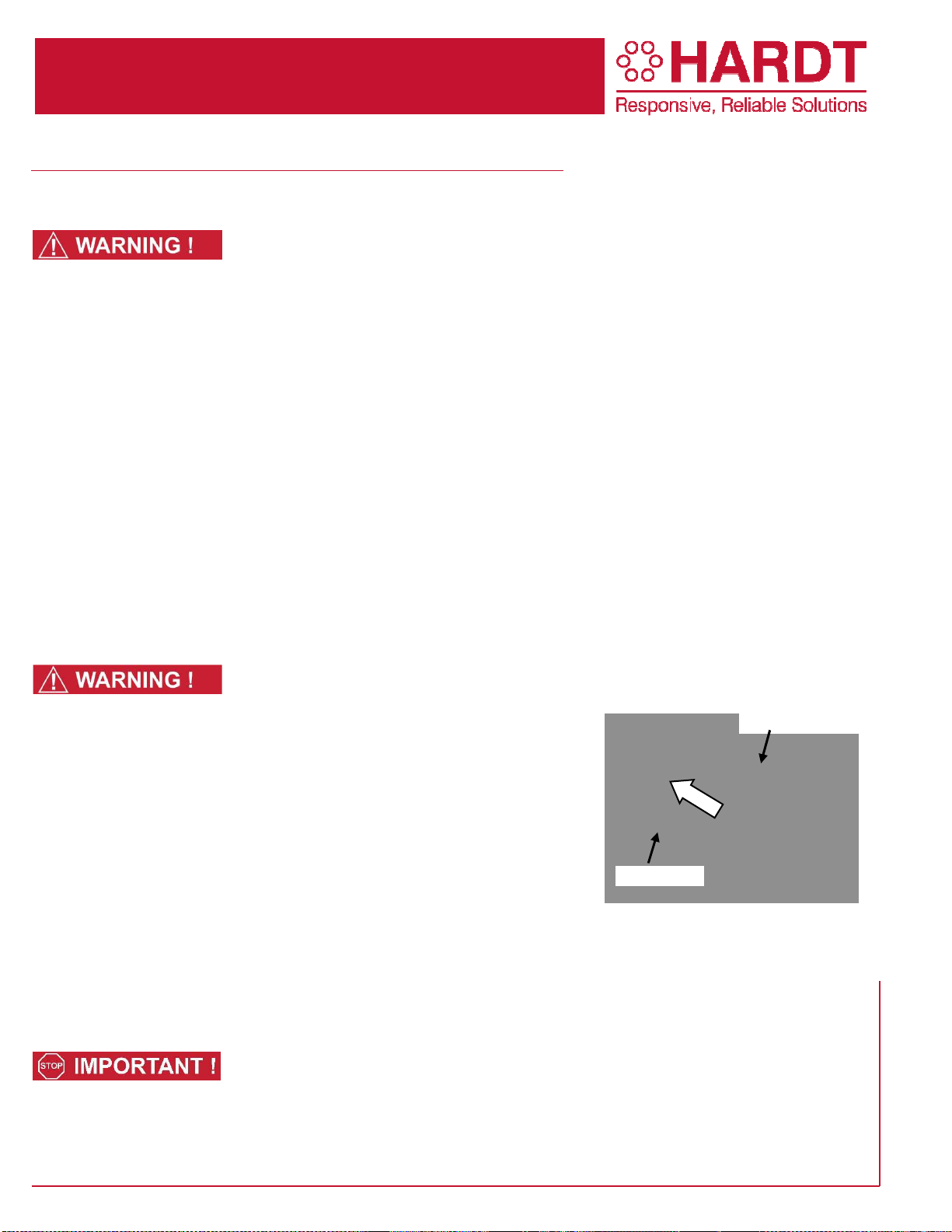

The image in Figure 6-2: Dirty Cavity shows a cavity that has NOT

been cleaned sufficiently to cook in. This may be due to:

•The cleaning procedures not being followed on a consistent

basis.

•The AutoClean system having not functioning properly for an

extended period of time.

It will be necessary to clean the rotisserie by hand using regular oven

cleaner (in a spray bottle) and a scrub pad or scraper to remove the

build-up of carbon prior to running the AutoClean cycle.

The AutoClean function will only clean the grease from 1 day's worth

of cooking. It may take a few days of AutoClean and hand scraping to

get the unit back to the point where following the correct procedures

will produce a clean rotisserie in the morning.

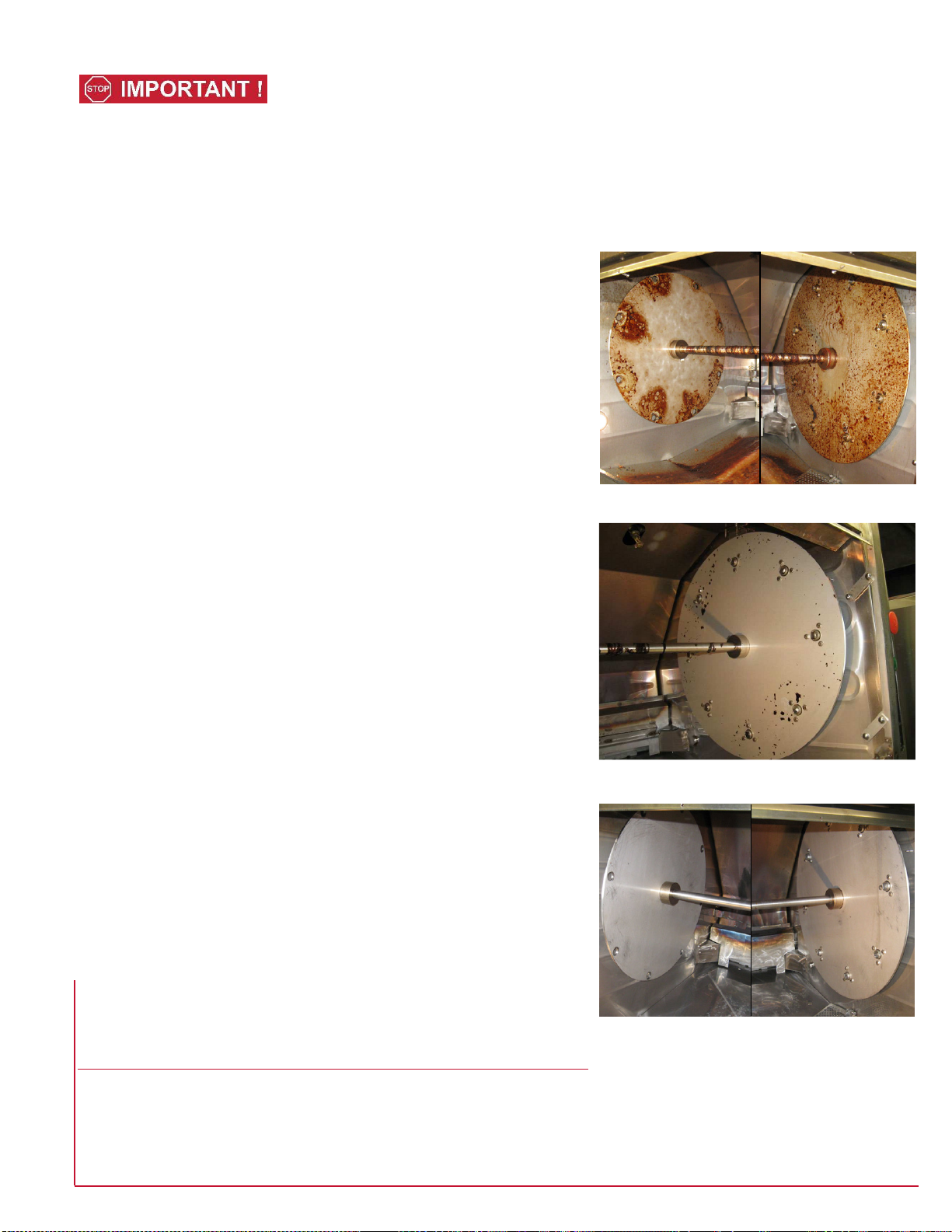

If the rotisserie cavity looks like what is shown in Figure 6-3: Mostly

Clean Cavity, remove the residual flakes with a scrub pad PRIOR to

cooking.

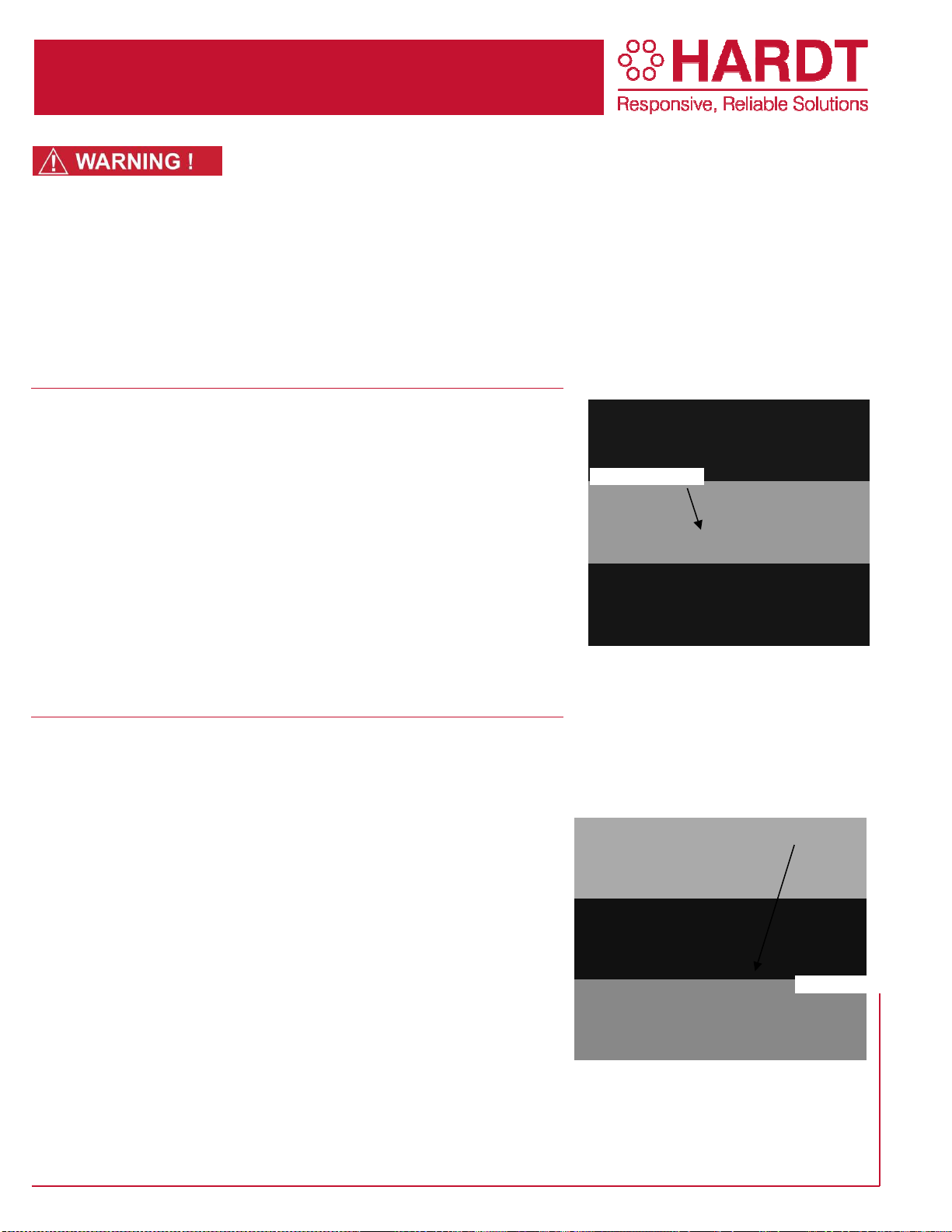

The image shown in Figure 6-4: Clean Cavity – Ready for Cooking

shows a rotisserie cavity that is sufficiently clean and in which cooking

may be performed.

6.2 Weekly Inspection

Thoroughly inspect the venting components supplied with the rotisserie for signs of damage (dents, perforations, etc).

Replace with certified Hardt components if required. Ensure that the electrical cord, water and gas lines are free from

damage and kinks.

Figure 6-2: Dirty Cavity

Figure 6-3: Mostly Clean Cavity

Figure 6-4: Clean Cavity – Ready for Cooking

Page 16 of 18

CUS-013-0027-02

7.Troubleshooting

DISCONNECT POWER TO THE ROTISSERIE BEFORE ANY MAINTENANCE,

SERVICE OR CLEANING IS PERFORMED.

ROTISSERIES EQUIPPED WITH CASTERS ARE SECURED IN PLACE USING A

RESTRAINING CABLE LOCATED ON THE RIGHT REAR UNDERSIDE OF THE

ROTISSERIE. THIS CABLE MUST BE DISCONNECTED PRIOR TO REMOVING THE

ROTISSERIE AND CAUTION MUST BE TAKEN TO ENSURE IT IS CONNECTED

ONCE THE ROTISSERIE HAS BEEN RETURNED TO ITS ORIGINAL POSITION.

THE ROTISSERIE IS HOT WHEN OPERATING. EXERCISE CAUTION WHEN

WORKING NEAR THE HOT ROTISSERIE.

WEAR APPROPRIATE PROTECTIVE CLOTHING.

7.1 Rotisserie does not Operate

The rotisserie does not operate when the red main ON/OFF is pulled out

(i.e. drive does not turn, and no lights in cavity).

SOLUTION:

•Verify that the door is fully closed. The magnetic door switch

disables or enables the ignition system.

•Check rotisserie electrical power: If the rotisserie's lights are off,

check the circuit breaker on the back of the unit as shown in

Figure 7-1. If the circuit breaker is ‘OFF’ (tripped), return to 'ON'.

•If this circuit breaker is ‘ON’, ensure that the power cord is plugged

into the wall and that there is power coming from the socket. If

power is available and the rotisserie still does not operate, contact

your local authorized service partner.

7.2 Safety Lockout

If the red main ON/OFF switch is pulled out, the drive drum will rotate and the igniter will attempt to light the burner. If

there is no flame after six minutes, the rotisserie will go into 'SAFETY LOCKOUT'. Push the red main ON/OFF switch

in to turn the rotisserie OFF.

Possible causes include: the gas supply is shut off, the flame sensor is not sensing flame or there is a component

failure.

SOLUTION:

•If the rotisserie goes into ‘safety lockout’ again. Turn the

rotisserie OFF (push in main ON/OFF switch).

•Verify that the gas supply to the rotisserie and the main gas

valve are both open. Try starting the unit again by pulling the red

main ON/OFF switch out.

•If the rotisserie goes into ‘safety lockout’ again. Turn the

rotisserie OFF.

•If you are certain the rotisserie interior is sufficiently cool to

touch, gently lift the burner cover out of the unit. (Figure 7-2)

(Continued on following page)

Figure 7-1: Circuit Breaker

Figure 7-2: Remove Covers

Circuit Breaker

Burner Cover

Page 17 of 18

CUS-013-0027-0

2

•Using a soft towel, gently wipe the top of the burner and

carefully clean the flame sensor (Figure 7-3). Replace the

covers.

•Try starting the rotisserie again. Pull out the main ON / OFF

switch.

If the rotisserie goes into safety lockout again, there is most likely a

component failure. Turn the rotisserie OFF and contact your local authorized

Hardt service provider.

7.3 Replacing the Halogen Lamp

1. Turn rotisserie OFF (push in main ON/OFF switch) and disconnect

the power cord from the wall receptacle.

2. Allow rotisserie to cool down.

3. Remove the light access panel located on the left side of the

rotisserie by loosening the thumb screws (by hand or using a

screwdriver) (Figure 7-4).

4. Loosen the wing nuts on the light support bracket in order to access

the light (Figure 7-5).

5. While wearing gloves, gently pull the light bulb out of its fixture

(Figure 7-6).

6. Install a new bulb.

7. Position bracket so that the light is oriented towards the center shaft

of the rotisserie. Hand-tighten the two wing nuts.

8. Reinstall access panel.

9. Plug the power cord back into the wall receptacle.

10. Turn the rotisserie ON (pull out main ON/OFF switch).

11. Verify that the replaced bulbs function correctly (it is normal for the

lights to take about 6 seconds to light after the main switch is pulled

to ON). If not, repeat the first four steps of this procedure and make

sure the bulb was correctly inserted in the socket. Reinstall the

access panel, turn the rotisserie ON and recheck. If problems persist,

contact your local authorized service partner.

Figure 7-3: Burner & Flame Sensor

Figure 7-4: Light Access Panel

Figure 7-5: Loosen/Tighten Wing Nuts

Figure 7-6: Replace Bulb

Flame Sensor

Burner

Remove Screws

Do not touch the replacement bulb with

bare fingers or dirty gloves.

Page 18 of 18

CUS-013-0027-02

8.Available Accessories

Please refer to the following table when ordering accessories from Hardt.

Part Name

Description

Illustration

‘V’ Skewers This is the ‘V’ skewer but with a modified end tip so the skewer can

only be loaded one way, ensuring correct positioning of the

product while cooking.

Hanging

Basket Designed for products that should not rotate during cooking. The

basket stays horizontal while the drive turns.

Rib Basket A clamshell basket that is ideal for cooking ribs, chicken parts and

a variety of other products.

Other manuals for INFERNO 3500

4

Table of contents

Other Hardt Oven manuals