Hardy Process Solutions HI 6600 Series User manual

HI6600seriesQuickStartGuide

HI6600seriesisamodularsystemofweightprocessorsthatcandeliver

upto30channelsoffast,stable,high‐resolutionweightvaluestoPLCs,

PACsandDSCsoverasinglefieldbusnetwork.

ThisQuickStartGuideisintendedforusersthatarealreadyfamiliar

withsettingupHardyProcessSolutionsweighinginstruments.

AcompleteUser’sGuidecanbefoundunderDocumentsandPrograms

online:www.hardysolutions.com

NavigatetotheProductmenu>WeighingInstruments>Weight

Processors>HI6600>Docs&Programs

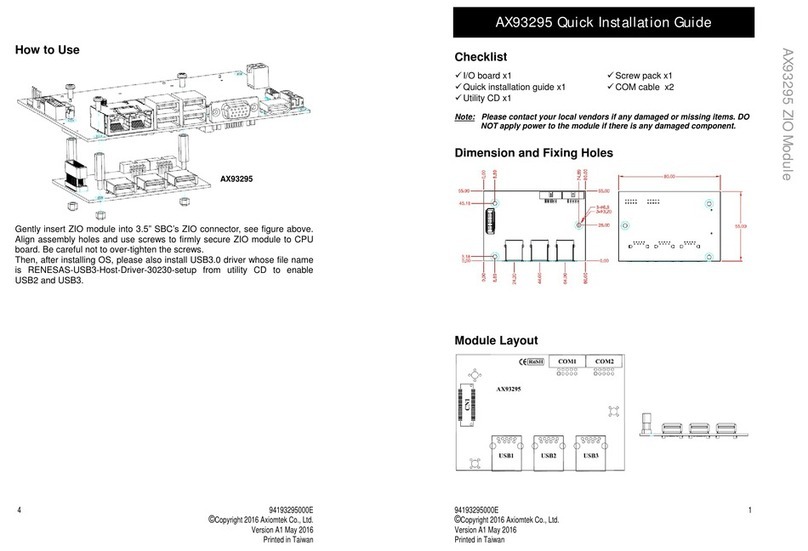

DINRailInstallation:

1. PlacethetopslotoftheinstrumentontotheDINrailfirst.

2. Rotatetheinstrumentdownuntilthebottomtaboftheinstrument

engugeswiththeDINrail,thenpressfirmlyonthebottomonthe

instrumentuntilitsnapsinplace.

Note:HeavyGageDINrailrecommended.

3. CheckforproperDINrailengagementby gently lifting upon the

bottomandmakingsuretheinstrumentissecurlyinplace.

4. Repeatwithadditionalunitsasrequiredforyoursystem.

5. ToremoveaninstrumentfromaDINrail,disconnectwiringthenlift

uponthebottom‐frontcornerofthemoduleuntilitsnapsoff.

Note:Themaximumdistancebetweenthefirstandthelast

moduleinthesystemis500feet(150meters).

TheGatewayshouldplacedattheendofasystem

Wiring:

1. AfterunitsaresecurelymountedonDINrail,removeterminal

connectorsmakingnoteofthewiringmarkingsfoundonthe

connectorlabelslocatedontheinstruments.

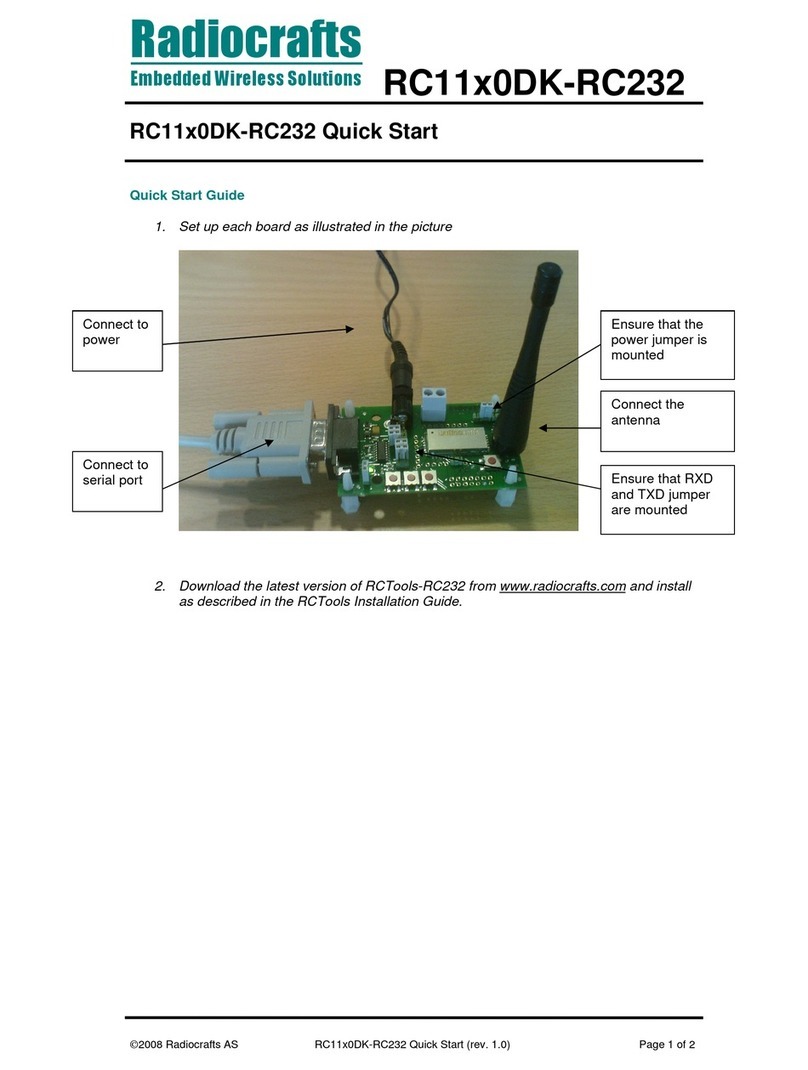

HardyGatewayModule WeightProcessingModule

2. CableHardyNetPortslocatedonthebottomoftheunitsinseries

usingCat5ecablewithRJ‐45connectors.

3. CabletheDCpowerlocatedonthebottomoftheunitsusingthe

ModuleI‐IDiagramandbyfollowingthenotesforPowerInput

terminations.

PowerInputTerminationNotes:

a) ItisNOTnecessarytoprovidepowertoeverymodule.Poweris

distributedfromtheGatewayModuletoothermodulesonthe

systemviatheHardyNetPortandtheCat5ecabling.

b) Youmustuseapower‐limited12‐24VDCpowersupply(Class2)

ontheDCinputwiring.DCpowershouldbesuppliedbyaclean

primaryline,directlyfromtheDCpowersource.

c) MakesuretheVDCsourceisoffbeforeconnectinganywiresto

themoduleandbeforepluggingintheterminalconnectors.

d) Connectthe24VDCvoltagewire,groundwireandshieldwire

totheconnectorthatplugsintotheDCvoltagesocketlocated

onthebottomoftheGatewaymodule.Thefactoryinstalled

jumperconnectstheEarthgroundandtheinternalground

makingthemcommon,andshouldremaininplace.

4. Cabletheloadcellsor

othertypeofstrain‐

gaugebasedsensors

totheWeight

ProcessingModulesusingtheI‐Idiagramandbyfollowingthenotes

forWeightScaleInputTermination:

5. CablethecommunicationportsonlocatedontheGatewayterminal

accordingtotheprotocolusedandbyfollowingtheI‐Idiagramfor

HardyGatewayModuleavailableontheHardywebsite.

6. Connecttheoptionaldisplaytothedisplayportlocatedonthe

HardyGatewaymodule.

7. Powerupsystem.

InitialSet‐Up:

SetUpmaybeperformedthroughanoptionalfrontpaneldisplayor

throughtheintegratedWebserver.IfsettingupusingtheWebserver,

connectanEthernetcablebetweentheHardyGatewayModuleand

followtheCommunications>EthernetTCP/IPinstructionsshown

belowbeforeproceeding.

DiscoveringWeightProcessingModulespresentonthesystem:

ThesystemrequiresaprocessofdiscoverythatallowstheGateway

ModuletoidentifyandtestcommunicationswithallWeightProcessor

ModulesconnectedontheHardyNet.Thediscoveryprocessis

automaticallyinitateduponpowerupofthesystem;verifyallmodules

onthesystemhaveberegisteredbytheGatewaybycheckingthe

channelnumbercountlocatedintheHardyNetsub‐menuofthe

Gatewaymodulemenustructure.

TheChannelIdentificationandchannelordernumbermayalsobe

modifedintheHardyNetsub‐menusectionduringsystemsetup.

Oncethediscoveryprocessiscompleted,proceedtosettingupeach

individualchannelbyfollowingthebasicSETUPinstructionsforeach

channeloutlinedbelow.

Suggestedstepswhensettinguptheinstrumentforthefirsttime:

ChooseaspecificWeightProcessorModuletosetupbyselectinga

channeleitherfromthefrontpaneldisplayoronthewebserver.

SETUP(minimum)

1) SelectUnitofMeasure

2) InputTotalScaleCapacity

3) SelectGraduationSize

4) SelectDecimalPointPosition

5) InputMotionTolerance

Filter

1) NumAverages

2) Waversaver

Calibration

1) CalDate

2) CalMethod

a. C2eCal

b. HardCal

3) CompleteCalProcedure

Channel

1) Choosechanneltoset‐up

Calibration: Sectionusedtocalibratetheinstrumenttothe

sensor(s)used.

C2eCAL–ElectronicCalibration

1) Removeallweightfromthescale.

2) Setgravitycorrectionforlocationofweighingsystem

3) PressDoC2Cal.

4) Placeaverificationweightonthescaletoensurecalibrationis

successful.

HardCal‐TraditionalCalibration

1) InputtheSpanWeight.Thespanweightshouldbeabout80%

ofthescalecapacity.

2) InputCalLowWeight.Withnothingonthescale,theCalLow

Weightis0,with5lbsonthescale,theCalLowWeightwould

be5.

3) PressDoCalLowtosetthelowpointonthecalibrationcurve.

4) PlacetheSpanWeightontothescale.

5) PressDoCalHi.

RefertoUser’sGuideifadjustmentstoothercalibration‐related

parametersarerequired.

Communication:Sectionusedforsettingupcommunicationsto

theinstrument.

EthernetTCP/IP

1) ConnectanEthernetcablebetweentheinstrument’sRJ45

connectorandaPC,thenpoweruptheinstrument.Across‐

overcableisnotrequired,butcanbeused.

2) Theinstrumentwillauto‐negotiatesettingssuitableforavariety

ofoperatingsystemsandnetworkconfigurations.Wait

approximately15secondsandchecktoseeifthegreenlightof

theEthernetportisonandblinking–ifso,skiptostep8–you

areconnected.

3) IfthegreenlightontheEthernetportdoesnotlightup,check

thattheunit’sEnableDHCPisturnedoffandfollowsteps4

through9.

4) Usingtheunit’sFixedIPaddress(thedefaultis

192.168.000.100),thePCmustnowbeassignedauniqueIP

address(forexample,192.168.000.101)

TherearetwosimplerulesfortheIPAddress:

Itmusthavethesamenetworkidentifierasthecomputer.

Itmusthaveadifferentnodeidentifierthanthecomputer.

5) OnaPCrunningwindows,openInternetProperties(TCP/IP).

6) Clickinthe‘UsetheFollowingIPAddress’checkbox;thenenter

thefollowingintotheTCP/IPPropertiesdialog.

IPAddress=192.168.0.101

SubnetMask=255.255.255.000

7) SelectOKontheTCP/IPPropertiesdialogbox.Thecomputeris

nowfullyconfigured.Toreturnthecomputertotheoriginal

networksettings,returntothe‘InternetProperties(TCP/IP)

dialog,select‘ObtainanIPaddressautomatically,’andclickOK.

8) TheHI6500seriesinstrumentisnowconfiguredto

communicatewiththePC.EntertheHI6500seriesinstrument

IPaddressintotheWindowsPCWebbrowsertoaccessthe

embeddedwebbrowser.Forexample:http://192.168.000.100

SeetheHI6600User’sGuideforsettingupEtherNet/IP,Ethernet‐UDP

andModbus‐RTUcommunicationprotocols.

MENUTREE

Diagnostics:Sectionusedfordiagnosticsofsystem.RefertoUser’s

Guideiftroubleshootinganduseofdiagnosticsmenuis

required.

Display:Sectionusedforadjustingvariousaspectsofthedisplay,

includingcontrast,brightness,andsplitscreenfeature.

Filter:Sectionusedtostabilizeweighreadingsinanunstable

environment.

WAVERSAVER:Presstheenterbuttonandusethe

arrowkeystoselecttheappropriatesetting.

WAVERSAVEReliminatesunwantednoiseandis

typicallysetat1.0Hz.

NumAverages:Setthenumberofreadingstoaverage

toprovideastableweight.

Information:Sectionusedforcheckinginstrumentserialnumber,

andfirmwarerevision.

Language:Sectionusedforchanginglanguage.

Operations:SectionusedforsettingupparametersrelatedtoTare,

CountandZeroofscale.

Security:ItishighlyrecommendedtoseetheUser’sGuidefor

settingupsecurityfunctionsontheinstrument.

Impropersetupofthesecuritysettingscouldcausea

usertobelockedoutfromusingthedevice.

Setup:Sectionusedforsettingupoperationparametersofthe

instrument.

Capacity:Setsthenormaloperatingcapacityofscale.

DecimalPoint:Setstodecimalpointfortheweightresolution.

Grads:Setsthegraduationsizeofthedisplayincrements.

InstrumentID:Allowstheinstrumenttobenamed.

MotionTol:Choosethelevelofacceptablescaleinstability.

OperatorID:OptionalareaforenteringanoperatorID.

Unit:Choosetheunitssuchaslbsorkgthatisdesiredto

showonthescale.

Notes

HardyProcessSolutionssincerelyappreciatesyourbusiness.Weencourage

inputabouttheperformanceandoperationofourproductsfromour

customers.Shouldyounotunderstandanyinformationinthisguideor

experienceanyproblemswiththisproduct,pleasecontactourTechnical

SupportDept.at:

Phone:(858)278‐2900

TollFree:1‐800‐821‐5831

FAX:(858)278‐6700

E‐Mail:hardysupport@hardysolutions.com

Orvisitourwebsiteat:

http://www.hardysolutions.com

ProudlymadeintheU.S.A

PN:0596‐0334‐01Rev.A07/15

Other Hardy Process Solutions Computer Hardware manuals