VENTING

Only For Qualied Installers 16

908 6”PipeLength,Galvanized

908B 6”PipeLength,Black

907 9”PipeLength,Galvanized

907B 9”PipeLength,Black

906 12”PipeLength,Galvanized

906B 12”PipeLength,Black

n/a

n/a

904 24”PipeLength,Galvanized

904B 24”PipeLength,Black

903 36”PipeLength,Galvanized

903B 36”PipeLength,Black

902 48”PipeLength,Galvanized

902B 48”PipeLength,Black

911 AdjustableLength,11”-14”,Galv.

911B AdjustableLength,11”-14”,Black

945 45oElbow,Galvanized

945B 45oElbow,Black

990 90oElbow,Galvanized

90B 90oElbow,Black

n/a

929 RestrictorDisc

949 RoundCeilingSpt/WallThimbleCvr

941 CathedralCeilingSupportBox

988 WallStrap

989 ElbowStrap

942 WallThimble

963 CeilingFirestop

n/a

970 BasicHorizontalTerm.Kit

971 HorizontalTerminationKitA

978 VerticalTerminationKit

991 HighWindTerminationCap

985 HorizontalSquareHighWindTermination

953 StormCollar

943 AdjustableFlashing,0/12-6/12

943S AdjustableFlashing6/12-12/12

950 VinylSidingStandoff

n/a

982 SnorkelTerminationCap14”

981 SnorkelTerminationCap36”

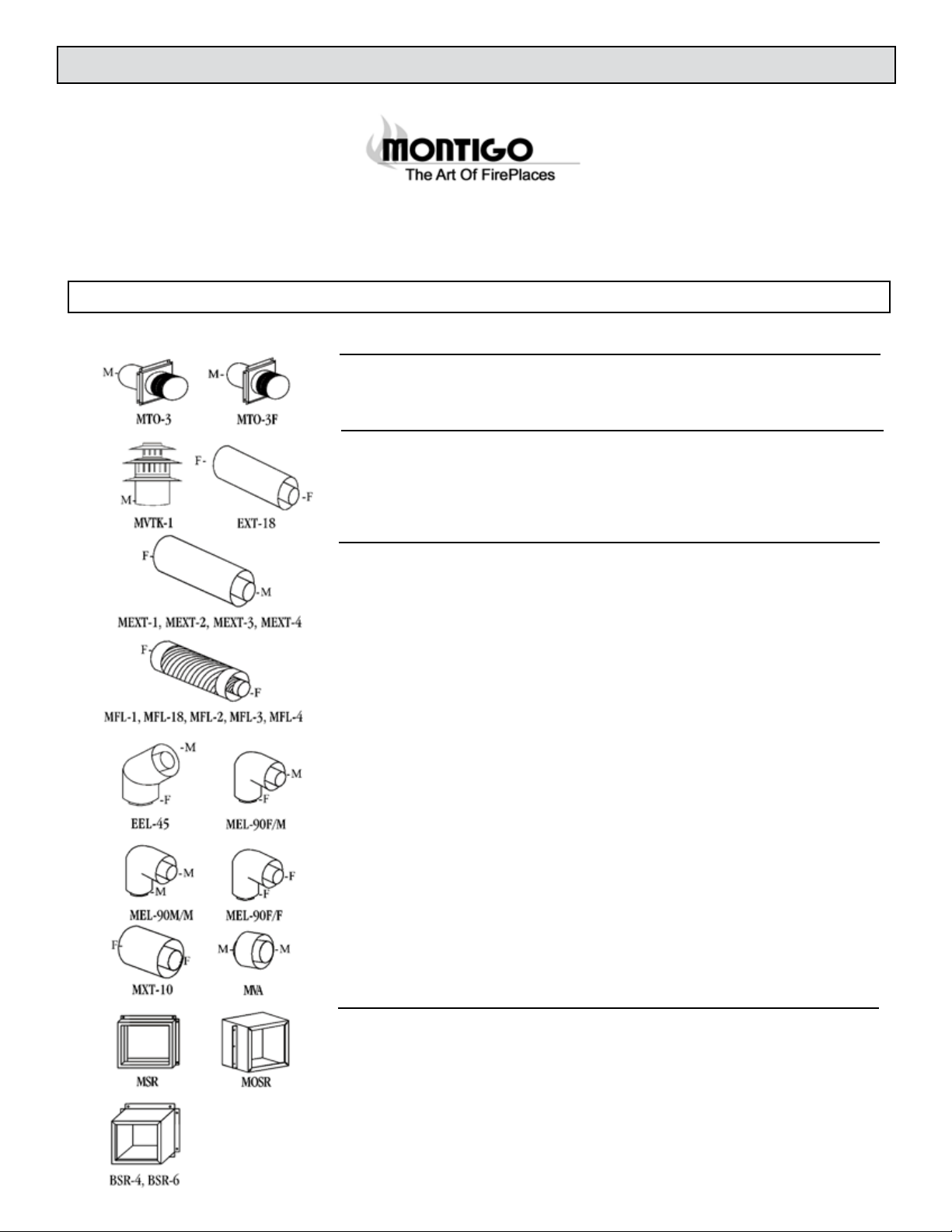

4DT-6 6”PipeLength,Galvanized

4DT-6B 6”PipeLength,Black

4DT-9 9”PipeLength,Galvanized

4DT-9B 9”PipeLength,Black

4DT-12 12”PipeLength,Galvanized

4DT-12B 12”PipeLength,Black

4DT-18 18”PipeLength,Galvanized

4DT-18B 18”PipeLength,Black

4DT-24 24”PipeLength,Galvanized

4DT-24B 24”PipeLength,Black

4DT-36 36”PipeLength,Galvanized

4DT-36B 36”PipeLength,Black

4DT-48 48”PipeLength,Galvanized

4DT-48B 48”PipeLength,Black

4DT-AJ AdjustableLength,11”-14”,Galv.

4DT-AJB AdjustableLength,11”-14”,Black

4DT-EL45 45oElbow,Galvanized

4DT-EL45B 45oElbow,Black

4DT-EL90 90oElbow,Galvanized

4DT-EL90B 90oElbow,Black

4DT-AA ApplianceAdaptor,Black

4DT-RD RestrictionDisc

4DT-CS CeilingSupport

4DT-CSS CathedralSupportBox

4DT-WS/B WallSupportBand

4DT-OS OffsetSupport

4DT-WT RoundWallThimble,Black

4DT-FS FirestopSpacer

4DT-TP TrimPlate,Black

4DT-HKA HorizontalTerm.KitA

4DT-HKB HorizontalTerm.KitB

4DT-VKC VerticalTerminationKit

4DT-HVC HighWindVerticalCap

4DT-HHC HighWindHorizontalCap

4DT-SC StormCollar

4DT-AF6 AdjustableFlashing,0/12-6/12

4DT-AF12 AdjustableFlashing6/12-12/12

4DT-VS VinylSidingStandoff

4DT-VSP VinylSidingShieldPlate

4DT-ST14 SnorkelTermination14”

4DT-ST36 SnorkelTermination36”