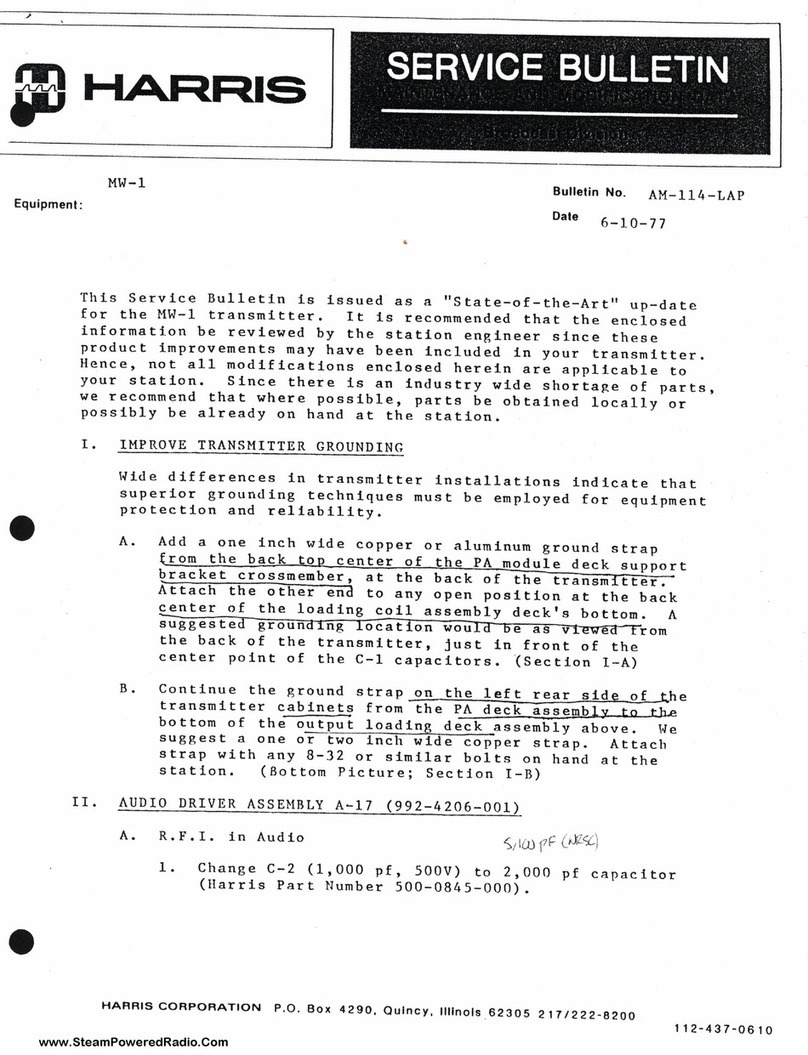

Harris BC-1G User manual

Other Harris Transmitter manuals

Harris

Harris 994 8047 001 User manual

Harris

Harris MW-1 Reference manual

Harris

Harris MW-5 Reference manual

Harris

Harris Ranger Series Quick start guide

Harris

Harris HTlFM User manual

Harris

Harris ZX2500 User manual

Harris

Harris Atlas DVL400 User manual

Harris

Harris DiamondCD Series User manual

Harris

Harris HT 35CD User manual

Harris

Harris SX-1 User manual

Harris

Harris GATES M-6573 User manual

Harris

Harris Gates One 994 9202 002 User manual

Harris

Harris FM-25K Operating and installation instructions

Harris

Harris Z3-48HD+ User manual

Harris

Harris Platinum Series User manual

Harris

Harris Intelligent Transmitter Platinum-i Series User manual

Harris

Harris Platinum HT EL 2000LS User manual

Harris

Harris Micromax User manual

Harris

Harris eCDi User manual

Harris

Harris FM-10H3 User manual

Popular Transmitter manuals by other brands

SMAR

SMAR TP290 Operation and maintenance instruction manual

Extron electronics

Extron electronics FOX3 T 201 user guide

Heat Outdoors

Heat Outdoors QHVCR Quick start guide & instructions

ACME

ACME FCOIII instruction manual

Technalogix

Technalogix TXF-50 operating manual

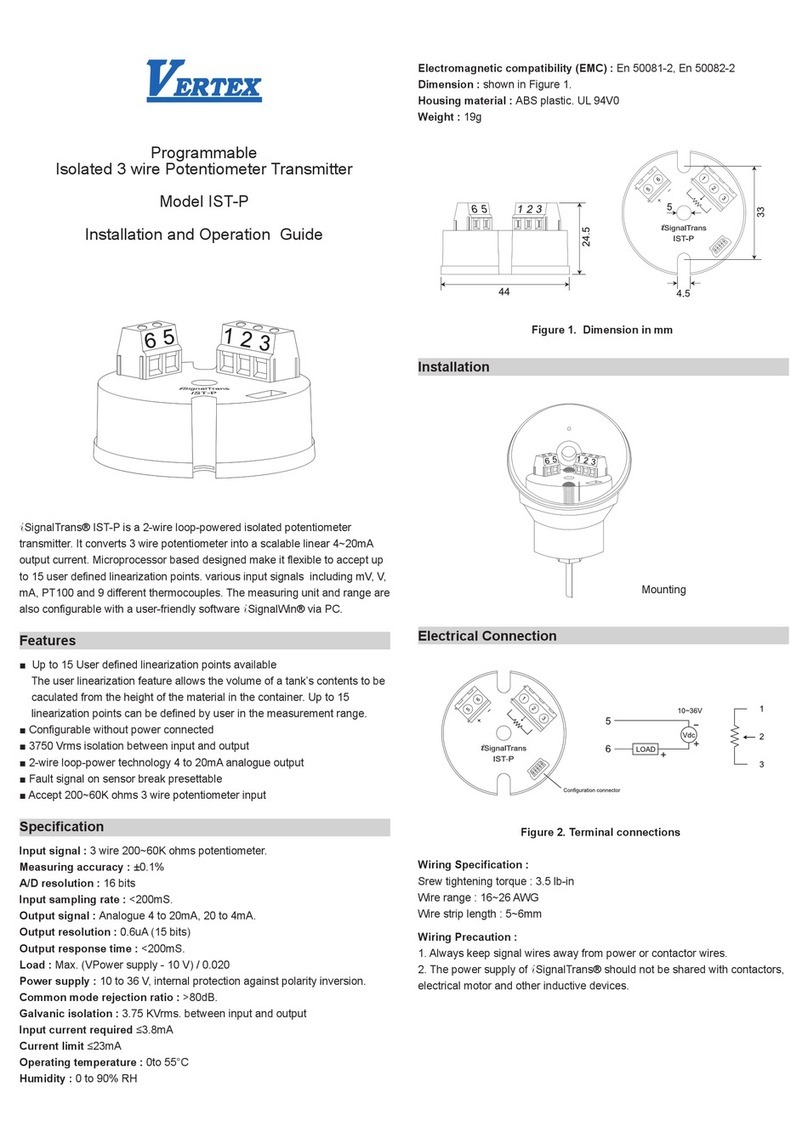

Vertex

Vertex SignalTrans IST-P Installation and operation guide