Harrison L6 MK.III Service manual

1

l

.~

1

j

r

l,

I 5 I 5 F E I G 5

When ordering Spare parts dways quote

Machine

No.

which is stamped on the bed

at

the tailstock end.

Spares can be obtained through your usual machinery dealer,

or

direct from the

manufacrurers:-

T.

S.

150

P.O.

BOX

20,

HECKMONDWIKE,

YORKSHIRE, ENGLAND

&

SO

S

ITE

ES

Telephone: Heckmondwike

3751

Telegrams: Harrison, Heckmondwike Telex: 55217

3

4

'-~----~~~~'

=,----""'''.~---

SPECIF~

o

AND

LEADING

E

SI

13"

Medel

Admits

between

centres

Bed

length

Swing

over

carriage

(with

cover

removed)

Swing in

gap-diameter

Swing in

gap-in

front

of

faceplate".

Max,

length

of

copy

turning-between

centres

...

Max.

length

of

copy

turning-with

chuck

...

Max. cross slide feed ,..

Max.

compound

slide feed

Swing

over

cross slide

(normal

turning)

Swing

over

cross slide

(copy

turning)

Max.

depth

of

profiling

Min.

front

angle

Max. back angle

Horsepower

of

hydraulic

pump

motor

Max.

movement

of

Tailstock

spindle

Set

over

of

tailstock

spindle

Centre

to

tool

base

(front)

Centre

to

tool

base

(rear)

...

Max.

too!

section

Spindle

speeds-number

Range

with

3 h.p.

motor

Range

with

2-speed

3/1-&

h.p.

motor

Spindle

bored

to

pass

Size

of

morse

taper

centres

...

Leadscrew

Range

of

threads

(TPI)

Norton

Gearbox,

4 TPI Leadscrew

Range

of

feeds

(longitudinal)

Norton

Gearbox,

4

TP!

Leadscrew

Range

of

feeds (cross)

Norton

Gearbox.

4 TPI Leadscrew

Range of

Metric

Pitches.

Metric

Gearbox,

6

mm.

P.

Leadscrew ...

Range

offeeds

(longitudinal),

Metric

Gearbox,

6 mm.

P.

Leadscrew

Range

offeeds

(cross),

Metric

Gearbox,

6 mm.

P.

Leadscrew ...

STANDARD

MODEL

610

or

1016

mm.

1424

or

1830

mm.

238

mm.

505

mm.

114mm.

203

mm.

73

mm.

'102

mm.

9·5

mm.

27

mm.

28·6 x

16

mm,

38

mm.

28·6 x 6

mm.

P

·2-7

mm.

P

·025

-1·00

mm.

·012-

·47 mm.

24"

or

40"

56n'

or

nn"

9i"

20in

4t'

8"

:W

"n

i"

inn

'11-'

x

i"

S

or

16

56-1,250

r.p.m.

34-1.500

or

45-2.000

1-&n

dia.

No.

:3

~-kn

dia. x 4

TPI

4-60

TPI

·0020" -·033"

·OOn"

-·019'

s

WITH

PROFILING

JEQUIPMENT

610

or

1016

mm.

1424

or

1830

mm.

464

or

870

mm.

419

or

825

mm.

203 mm.

73 mm.

159

mm.

140 mm.

51

mm.

102

mm.

9·5

mm.

27

mm.

22·2 mm.

28·6 x

16

mm.

38 mm.

28·6

x 6 mm. P

·2-7

mm. P

·025

-1·00

mm.

·012 -·47

mm.

24"

or

40n

56n"

or

nn"

iSi"

or

34t"

"l6!'

or

n·v

8n

2i"

6t

n

sr

2"

90·

30·

!

'I"

i"

'inn

*"

1u

n x i"

16

45-2,000

i!"

dia.

No.3

'in aia. x 4 TPI

4-60

TP!

·0020" -·033"

·0012" -·019"

"1

I

)

E

E

$1

I--

_________

~~-~

·s

...........

--.-.-

~

~,

~i

1~~

r-~'~~~l---

~

'F"

_~

5/":":'"

l

" \

~

tr

r··

>.:J.

-+------M,

=

~-1=·-·

=-~

6

~

HOlE

IS

AT

THE

REAR

OIL

LEVEL

INDICATOR

HEADSTOCK

FILLER CAP

MAGNETIC

FILTER FILLER CAF FOR

ONE

SHOT

LVBRlCATlON.

WHEN

LUBRICATING

THE

TAILSTOCK

OF

rME

HEADSTOCK.

LEVEL

MUST

BE

MAINT

..

NED.

~~'/~'~

!T

15

ESSENTIAL

TO

LUBRICATE

80TH

SPlNDLE AND

SCREW

BY

THE

FOLLOWING

PROCEDURE

DRAIN.

FUJSH

AND RENEW

HEADSTOCK

OIL

AFTER

FIRST

"THREE

WEEKS

AND THERE

AFTER

EVERY" MONTHS.

c:urrcH

LINKAGE SEHND

REAR.

BED

FAIRNG

(2

POiNTS) OIL

REGULAR¥.

\

\

!.

WIND

THE

SPiNDLE

TO

ITS

EXTREME

BACKWARD POSITION AND LUSRICATE.

THROUGH THE FRONT NIPPLE.

2.

WIND

THE

SPlNDLE FORWARD

APPROXIMATELY

3D

AND

LUBRICATE

THE SCREW THROUGH THE

SAME

NIPPLE.

DAILY

GEAI'UlO)( FILLER CAR

__

_

OIL

DA!LY.---~==--=

OIL

DAiLY.

ITER

MEDIATE

STUD IN

SWING

FRAME

AND

BOTTOM

SHAFT

OF

GEARBOX.

OIL

LEVEL INDICATOR

LEVEL

MVST BE MAINTAINED.

MOTOR

BEARINGS

SHOULD

RECEIVE

REGULAR ATTENTION BUT

DO

NOT

OVER

GREASE.

EXCESSr"vE

GKEASE IN

BEARlNGS

IS

LIABLE

TO CAUSE OVER.

HEATING WHICH MAY

BE

INDICATED

BY

GREASE

RUNNING

FROVI THE BEARINGS.

THE

GREASE

SHOULD

BE

COoViPLETEL'f

RENEWED

EVERY

12

MONTHS.

~I~ir

kJ.~!5§::L'~.~~~

J

[£]

[lQJ¢1

0 i

jI I . I

J I

1-

-I

e

11

u

I

j

~>--I

_--=====~==

RECOMMENDED

.-----

----------

-~

I

-~-

0

II

---~

I HOT

LUBRICATION

IO~;

~lDES

DAILY.

I

i

--------------------~~

lUBRICANTS

I

MOB!l

I

SHEll

I

ESSO

I

1B.f'.

i

REGENT

I

AMOCO

I

CASTROl

I

GULF

I'

SUN

I I PIOWIER I

TEXACIO

I

lOil

CO.

Headstock,

Apron,

Slide- \

D.I.E.

I ELLUS

'I

NUTO

'I

ENERGOL

I

RANDO

I

INDOiL

HYSPIN

II

SERVICE I SUNVIS

ways and Nipples ... ... HEAVY

33

H.44 H P20 i H

DC

31

AWS

68

61

I

831

MEDIUM I I I

II

I I I

Feed

Gearbox ... ...

II

VACTRA

I VITREA I

ESSTIC

I

B.P.

REGAL

INDUSTRIAL

ALPHA

SECURITY

I----;S:-:-U'-;:-N7:"V"-;:IS::--

OIL

EXTRA

OIL

I

65

ENERGOL

II

OIL

G

lOlL

617

85

851

HEAVY

72 I

HP60

R.&O.

I

95

Motor

grease

cups

... I MOBILPLEX I

ALVANIA

I BEACON ENERGREASE

I'

REGAL

II

AMOUTH

I·

SPHEEROL

GULFCROWN

I

SUN

I

48

II

GREASE GREASE

LS

3 STARFAK GREASE A P3 GREASE I PRESTIGE

3 i 3 I I PREMIUM 3 I 3 3

43

-------------'-----

-

--

--_.-

- -

-----

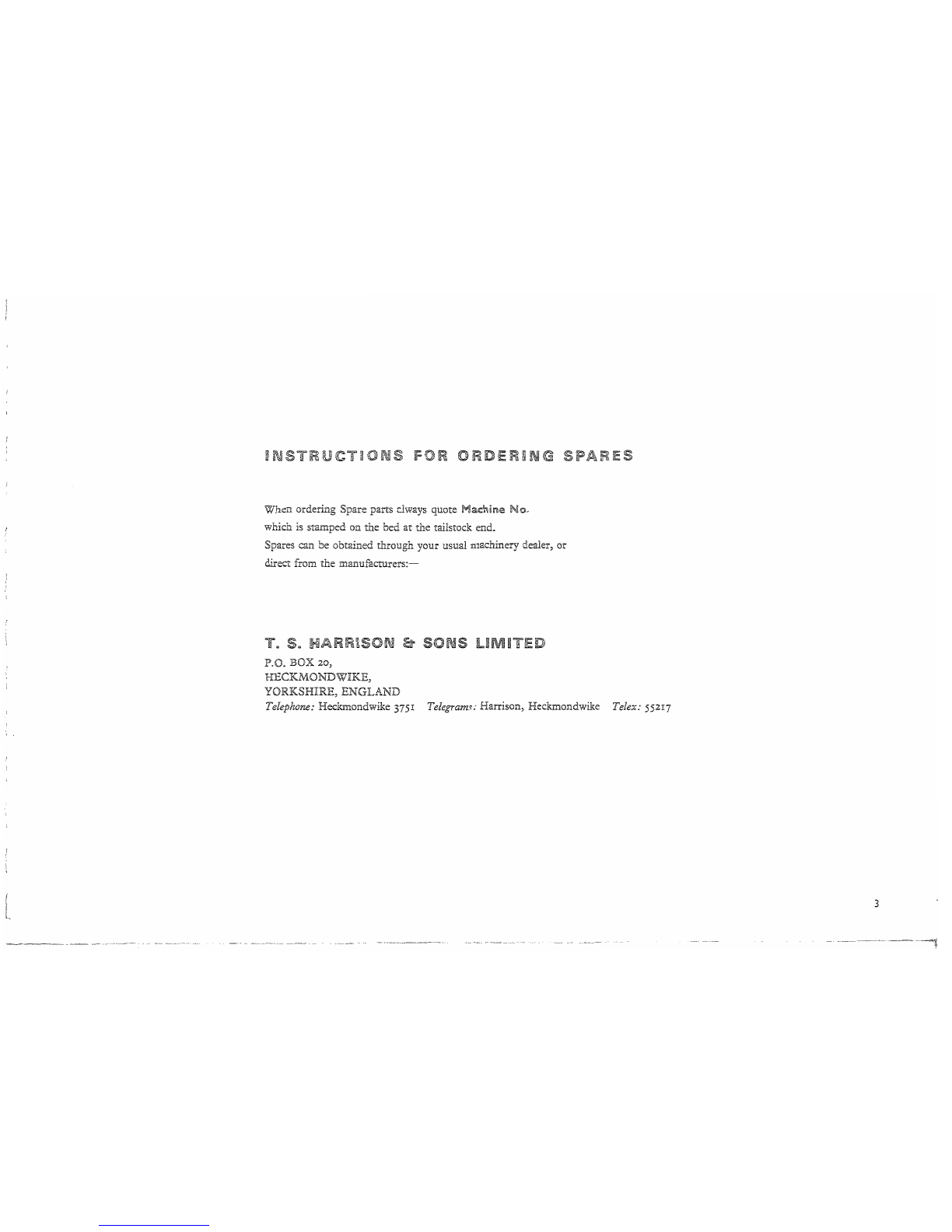

LUBRICATiON

Complete

lubrication

is

essential

before

running

a

new

lathe

and

light

ruIllling

for

a

short

period

is reco:::n.mended.

Daily

lubrication

will

reduce

wear

and

ensure

trouble

free ru.ll.ning.

All

nipples

are

easily

visible

and

an

oil

gun

is

provided.

Wnen

iubricatL.'g

D.'1e

tailstock

it

is

essential

to

lubricate

both

spindle

and

screw

by

the

following

procedure:-

I.

Wind

the

spindle

to

its

extreme

backward

position

and

lubricate

through

the

front

nipple

on

the

top

of

the

taiistock.

2.

WL.,d

the

spindle

forward

approx.

3"

and

lubricate

the

screw

through

the

same

nipple.

The

headstock

oil level

should

be

maintained

at

the

height

shown

on

the

sight

glass.

)\

. \

}

l.

I

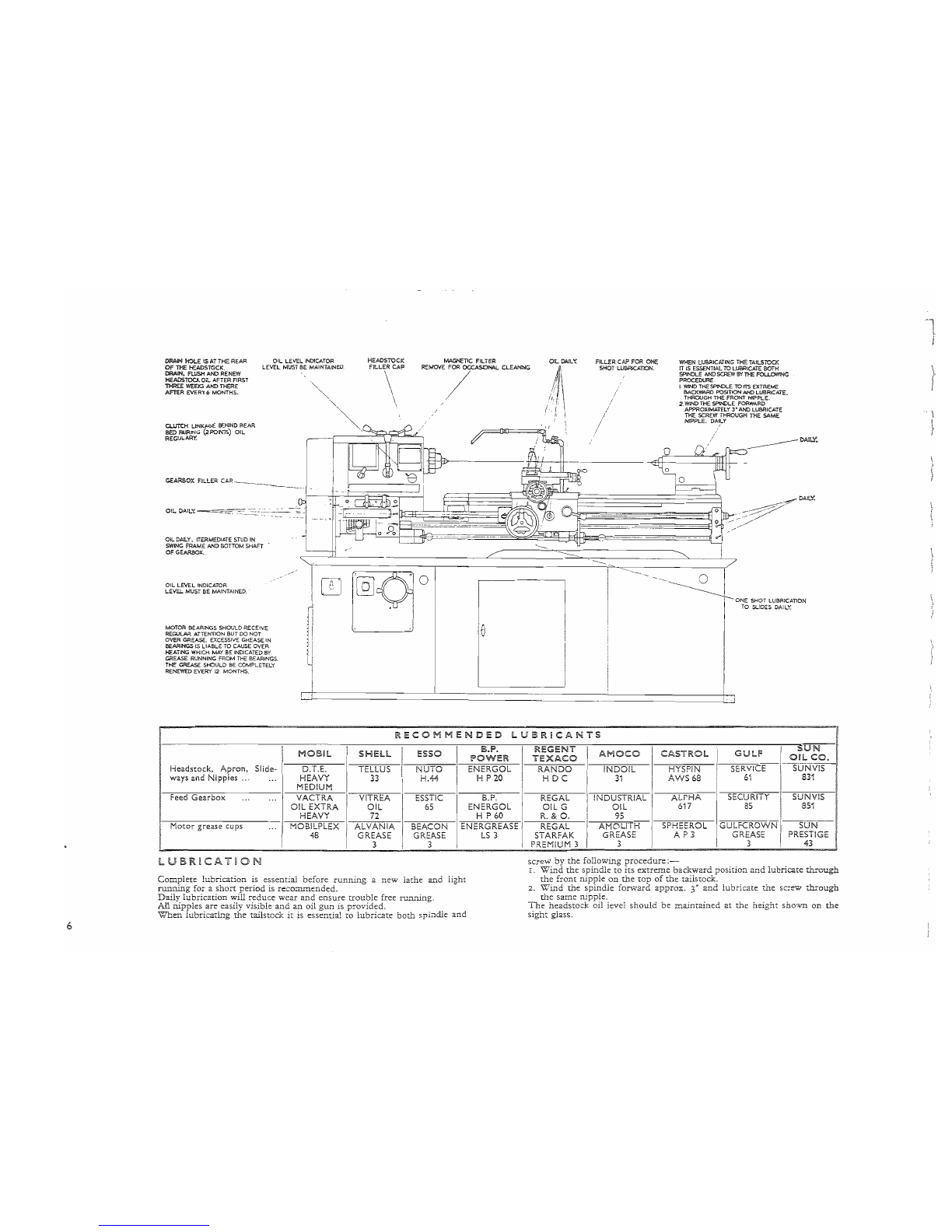

The

!Tillin

purpose

of

this

booklet

is

to

provide

users

wit..~

a

full

list

of

par::s,

should

replacements

become

necessary.

When

ordering

spares

please

quote

the

paz-t

number~

description

and

the

LATHE

NUJ\i.BER, wt-.ich

will

be

found

stamped

at

the

tailstock

end

of

the

bed.

Attention

has

been

drawn

to

a

few

points

?lhich

may

be

of

use

to

~he

JtJ

ST

.,~

L L

f~

TEO

t~

Siing;ng:

Holes

are

provided

in

the

base

under

the

~eadstock

and

tailstock

ttuougb.

'.vhich a

oar

IT".1.ay

be

passed.

for

slinging

p1l:poses.

Care

should

be

taken

to

avoid

the

lifting

ropes

bearing

on

the

lead-screw

or

feed

,od.

C~eaning:

.('\11

bright

surfaces

are

covered

'with

an

anti-corrosi~'le

compound

before

despatch

from

the

works.

This

should

be

removed

with

petrol

or

para..f1in

before

putting

the

machine

into

operation.

Leven~i1g:

Because

of

the

rigid

integrated

construction

of

the

bed

and.

canine:

D2se

the

machine

is

inherently

accurate

and

caDable

of

oerfonnance

within

the

specification,

when

it

leaves

the

works.

~

A

The

Iathe

shouid

not

be

boited

down

but

should

be

IO'Y\;'ered

on

to

locating

pins

secured

to

a

rigid

floor

and

the

jacking

screws

adjusted

to

eli-rninate

rock.

By

bolting

JOi;v-n,

distortion

could

occur,

introducing

twist

in

the

bed

and

the

resultant

damage

may

not

be

corrected

by

releasing

the

nuts

on

the

bolts.

It

is

advisable

to

support

the

jacking

screws

on

steel

plates.

The

screws

should

be

ad1usted

::0

enable

the

he3dstock

end

of

the

lathe

being

slightly

higher

than

the

tailstock

end

so

that

the

front

of

the

machine

is

raised

relative

to

the

rear.

This

facilitates

return

of

the

coolant

to

the

Slli"TIp.

Before

despatch

the

machine

has

been

carefully

tested

for

smooth

rUlli-llng

and

accuracy.

(See

test

chart.)

Any

checks

for

accuracy

MUST

be

made

with

I

purchase:

of

a

HHARRISO~"

lathe,

!:J.1.e

observance

of

'yvhicn

will

ensure

satisfactory

se:-'"·lice.

New

developments

and. modil-l.cations

resultL."1g

in

improved

perio:rma...""1c':

ill2y

be

incorporated

from

time

to

tL,Tle

on

them

and

the

right

is reser;red

to

modify

the

specification

as

may

be

:-equired.

the

macr-jne

on

a

rigid

floor.

Ensure

th2t

me

test

mandrels

are

true,

clea..'1.

and

free

from

burrs

on

the

taper

seating.

Clean,

and

inspecr

the

internal

taper

of

the

spindle

before

inserting

the

mandrel.

I

DETAILS

OF

ANI

DISCREPANCY

BETWEEN

THE

TEST

G-1P..RT

AND

YOUR

O~

TESTS

SHOULD

BE

REPORTED

TO

THE

MANUFACTURERS

BEFORE

ANY

ADJUSTMENT

IS

MADE.

EtectdcaJ

connection:

The

supply

wires

should

De

cOffilected

to

L.~e

isolator

switch

at

the

end

of

the

cabinet

in

b.'1e

usual

IT'.:.ar'u·.ler.

~nitiaj

opera.tion:

It

is

important

to

ma...'r.ce

sure

that

t...~e

feed

or sc:rewC"utt:ng

levers

are

in

the

disengaged

position

Defore

operating

the

Lathe

other;:;ise

damage

can

be

caused

by

the

saddle

or

tools

running

into

the

headstock

or

tailstock.

f...!.s

the

headstock

is

the

most

important

unit

of

the

Lathe

only

the

best

IT"A2teriais

and

workmanship

are

incorporated

in

this

assembly.

All

the

gear

teeth

are

induction

hardened

to

45°:500

Brindl

and

honed

to

a

smooth

and

accurate

form.

The

hardening

may

result

in

a

SOline.

of

higher

pitch

than

is

evident

on

a

Lathe

which

does

not

have

hardened

gears.

To

ensure

satisfactory

operation

of

the

bearings

it

is

essential

to

run

in

the

macl1ine

at

lower

speeds

only

duriIlg

the

first

40/50

hours

of

operation.

After

Lhis

initial

run

in

period

we

also

recommend

that

a

further

gradual

build-up

to

the

top

speed

operation

is followed.

7

~f

..

8

FRONT

CiE.AA

saEC1'OR

LEVER.

INTERLOCKED

GEAR

SELES:TORS.

I..OCKli'IG

NUT

FOR

Sffl>IU.

SLIDE.

~ERDIALS.

TAiLSTOCK

ouu.

I..OCKli'IG

LEVER

TAlLSTOCIC

I..OCKli'IG

LEV-at.

FEED

REVERSE

LEVEl'l

GEAR

SELECTOR

LEVE'

\\

LEADSCREW

TORQUE

LlMlTER

~I

'II

,.

'---'i..L--IUl'

I I I

~.

1--

r:.

OR

DOG

CLUTCH.

" : 4

-*

s:;;

...

I

II

(rnWVl'!

'£Jd

'1

I

"'~!

n

FEED

CHANGE

LEVE

}

r~

i (') I

SLIPPiNG

CLUTCH/

/ • i

ISOLATOR.

it

11

1

ELECTRiCAL CONTROL

PANEL./'

i

/

--------------c)!,~

10

V

\,J

I 0 0 [f'j1

!

~'I

i / I

' I

I / I

I

,/

I

oj

I."

/'

J

!

/

/

/

!

I~:~!~i--------------f-------

I

!

I

! I

,

II

r'

.

f'l

V

1

Ii

I I

, !

(~

CLlITO-l

OPERAT!NG

LEVER.

SCREwc.:rTING

iNCXCATOR

[)tAL.

N

\

\

\ I

, I

\1

1

r \

!

",i

~

~

i~

APRON KANUWHEEL.

El

Ii:

I .

i

I

!

o

~-.J

FEEDSHAfT ENGAGING LEVER.

.

MiCROMETER

DtAL.

ThILSTOCK

OPEAATI'IG

HANDI'Il-EEL

TOPSUDE OPERATING

EtALL

KAND'..E.

LEAD5CREW

FEEDSHAFT.

:rHlRD5HAFT

CLlJTCH

OPERATING.

CROSS SLOE OPERATNG

~r-EEL

EADSCREW

ENGAGNG

LEv-:R.

CWTCH

OPERATiNG

LEVER.

SURFACING

I>ND

SLDlNG

FEED

CHANGE KNOB.

'\

I

1

{

L

f

)

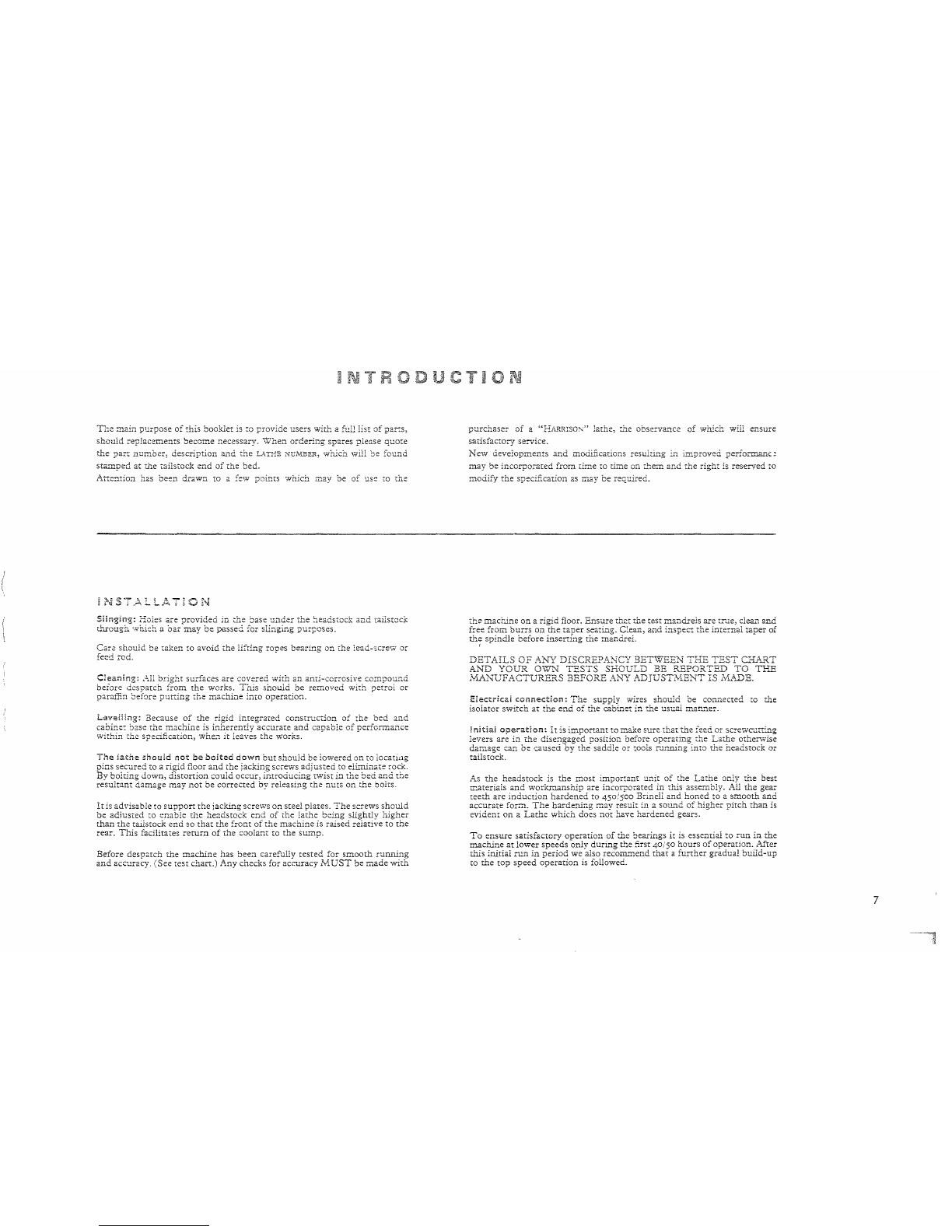

All control levers are shown on

the

illustration on the opposite page.

Eiecukai

Controls.

A single panel,

on

the

front

of

the lathe,

contains all

the

electrical controls within easy reach

of

the

operator.

A Dush-button oneratedstarterwithoverload

and

no-voltprotection

is

~tandard

equip'ment

on

all machines;

other

controlsavailable being

two speed, reversing

and

coolant

pump

rotary type switches.

(b)

HeadstocK.

Speed changes should only

be

made when

the

spindle

is

stopped.

The

standard machine incorporates a start/stop

mechanical clutch and brake operated via a

third

shaft by control

levers adjacent to gearbox and apron.

An

alternative electrical

control by similar levers and

third

shaft provides direct reverse to

the

spindle

in

addition

to

forward

and

stop.

A tV\'o-position front gear lever selects

the

high speed range when

in

the

right-hand

position and

the

low speed range

in

the left-hand

position and this, used in conjunction with

the

two position twin

selectors at

the

top

of

the headstock, gives a total

of

eight spindle

speeds" Freely siiding gears combined

"Nith

a direct reading speed

chart ensures effortless and instantaneous speed change.

Forward

or reverse rotation

of

the

feed gear train

is

obtained

by

a selector lever at the front

of

the headstock.

(c)

Norton

Feed

Gear

box.

Thirty-six

changes

of

threads

and

feeds are obtained

by

manipulation

of

the

tumbler

lever

in

conjunc-

tionwith the nvo adjacent compoundgear levers.

The

lever positions

are determined by reference to the direct reading screwcutting

and

feed chart.

For

changewheei combinations see charts on page

12.

An

additional

unit

can be supplied giving lever operated selection

of

English or

Metric

threads. A range

of

I5

Metric

thread pitches

from

0"5

to 7 mm. together with the standard range

of

4 to

60

TPI

is

directly available.

With

the

metric gearbox, 30 metric pitches are available having a

range from

0"2

to

7 mm. pitch. Extra change wheels can be

supplied for Metric/English conversion giving a

thread

range

of

4 to 60

TPI.

Change Wheel combinations are given on page 13.

(d)

Apron.

Instantaneous engagement

and

disengagement to

both

feeds

is

obtained by

the

trip

lever

of

the

drop

Olit

worm box situated

at

the

base

of

the

apron.

The

feed selector knob which

is

directly

below

the

cross slide handwheel should be

pushed

in for sliding

feeds and pulled out for surfacing feeds.

Engagement

of

the

leadscrew for screwcutting is by means

of

the

lever

at

the right

of

the

apron wpich is pulled

up

for engagement

and

pushed down for disengagement. Simultaneous engagement

of

leadscrew and feed

rod

is

prevented

by

interlocking control.

The

carriage may be locked

to

the

bed

by means

of

the hexagon

screw on the

right-hand

side

of

the carriage.

Exact repeat

of

leadscrew engagement

is

obtained with the screw-

cutting

indicator.

On

English models:

To

cut

even threads

per

inch, engage at any graduation.

To

cut

odd

tf-....reads

per

inch, engage

at

any

numbered

graduation.

To

cut

haifrhreads

per

inch, engage

at

graduations I

or

3.

To

cut

quarte:

threads

per

inch, engage

at

graduation

I-

On

Metric

models:

To

cut

·5, ·75,

I,

l"5,

2,

3 and 6 mm. P. engage at any graduation.

To

cut

r·25, 2"5, 5

and

10

mm.

P.

engage at any

numbered

graduation.

To

cut

4 mm. P. engage

at

graduations

60

or

120.

The

indicator dial cannot be used for metric, B.A.

and

other

special threads when a 4

TPI

leadscrew

is

fitted.

It

can be used for metric threads (divisible into

120)

when a 6 mm.

pitch

leadscrew is fitted,

but

not

for special threads, including

English

and

American.

For

all speciai threads

it

is

necessary to

maintain engagement

of

leadscrew and an electrical reversing

switch can be supplied for returning the carriage, enabling repeat

cuts to be taken.

(e) Slideso Cross slide

and

compound slide are fitted with friction

grip micrometer dials graduated to read

"OOI

in.

The

compound

slide assembly

is

arranged

to

rotate

through

360 degrees

on

the

graduated cross slide

and

locking is by means

of

the

two

nuts

on

the

swivel slide.

Micrometer

dials are also available to read

0·02

mm.

(f)

TailstocKo Clamping to

the

bed

is

effected by

the

lever

at

the

rear

and

spindle, quill locking

is

by means

of

the

pad

bolton top

of

the

tailstock.

9

~'--

10

FI

I

SE

F E

operations other than turning are possible

on

a lathe fitted with a few attachments and these

enable further operations ttl be carried out without

The

following attachments are avaiiable for recourse to special machines.

Lathes.

Collet

Attachments.

This

type

of

chuckprovidesa

most

accurate

means

of

gripping

work,

the

accuracy being

0'0005

in.

at

the

collet

nose,

and

0'003

in.

at

a distance 3 in. out.

Use

of

attachments

is

not

restricted to cylindrical work

and

collets

for

square

or

hexagonal

bar

can

be

prov"ided.

(i)

Draw

Tube

Type

CoHet

Attachment

To

fit

the

attachment,

remove chuck or faceplate,

centre

and

sleeve

from

spindle nose. Pass

the

draw

tube

through

the

spindle

from

nose,

then

assemble

hand

wheel

and

clamping

nut

onto

tube.

Mount

the

spindle nose cover

onto

taper

and

secure

with

draw-nut

which is integral with spindle. Assemble

the

closer

bush

into

mouth

of

spindle,

insert

required

size

of

collet

and

screw onto

draw

tube.

The

standard

range

of

collets is

from

16"

to

If'

maximum

in

increments

of

-(5-'7-

but

any

size

within

this

range

(including metric) can

be

provided.

eli)

Mu!tisize

Collet

Attachment.

The

complete assembly

is

mounted

on

the

spindle nose. Collets are

inserted

after

removing

the

closer "bush \vith

the

-v;'Tench

provic.ed.

The

capacity

of

the

attachment

is

1"

to I

~"

and

is coyered

bv

II'

coll~ts.

-

~

Tap~r

Turnir;.g

t;.tta~hme!1t.

~'h.ilst.it

is,

preferr,e?

that

this

att2.cnr;ren~

be

ntt.ea

at

t~e~~jorks,

l1ttl,e

Gl~CU1~y

..

s00Uld

b~

e:p~rl

ence~

Dy

tne

en

4g:neer .WlS?lng to

m~K;

tIns

a.ciOltlc·n

t~t

t?e.latne.

Bolt holes are

drilled

In

tne

rear

01

tne

carr12ge

on

all

lathes

to

acc~pt

the

support

bracket

of

the

attachment

and an

assembly

instruction

draviing

is

supplied

,-vith

each unit.

Taper

TUi"ning

of

lengths

up

to I I in. (297 mm.:; w'ith

included

angles

up

to

20

d~grees

can

be

carried

out,

graduater. scales being f'rovide·2.) :-eading degrees

~t

the

ta~lstock

end

~nd

inche~

taper

per

foot

~:

the

head~t~cK

end.

instrUCtIons for sett1ng

up

p:n

..

OT

to

tap~:-

turning

are

as

10110\\'s

-

Re

'loase

tho

t\"O

~U~C

,~'lam";~~

·i-e

,'-,;,,01

'b~r

on.

~O

t\"o

.................

~

"~-

1.J.

1...:)

....

'1.

~'.I..:lb

l::.~l

.....

_:~

1

......

;.

G,,,

~

::;"_<',

I.

".L.l..1..-

reqUlred

angle

D=\~

means or

the

8.Q}ust.:ng

scre'l,;;:

a1

tne

rear

and

reclaffip. Release

the

t\VO

socket

head

cap screv.rs

at

the

left-band

side

of

the

att2ct:ment

-these

mus:

Temaa).

released

during

taper

turning.

Taper

turning

at

any

point

along

the

bed

can

be

achieved

by

setting

the

support

bracket

at

the

rear

end

of

the

bed

to

the

desired

position.

/w~~

~"

"

rT

{--I

/

~

~~.

/"

,--+j'"

~,

~~

t--4~

~

~

~ ~

;j-<

I

~'-.

---'.-{

,-

s~~

__

_

1'-1

!-.,:

------'3J.+----

-------

.Y.""~

••

~~--~

--~

~

--~_.~:=:--:"-

7:

~~---~

L..:

---:--------::::::::::=.-.

--~

A-

--....,:;;

~

~

~--'

--5

Cb"TRA,.:S!NG

MA>:j:<~

F,S

Y

~i

i:

~

~

;:'9 Z

~

'-""""c

For

set

up

shov:r:

in

Fig~

"y

\vith saddle traversing

In

ciirecti~n

'A'

2~d

set uf_.shoWD

in.

~ig:.

Z

\vit~,

s~ddle

traverSIng

In

GlrectlOn

1)'

1t

IS

adVIsable

to

ellTII1Ilate

~acklas?

b.e~\v~en

cro:s

s~ide

sc;~"v;~.

and~

~U!

b~e~ore

~ngag~ng

~~~

~~~~

~~~:~~~e

c:~L~~t~~~~~n~\~na~~::~:n~\~~Vt~~~l~~

the

correct

:utt':ng

DO~lLj\Jn.

\\:'ith saddle

tra~t"~si:1?

Hi

opposite directions to

tnose

snov\·n. in

Figure~

~-

c~;

Z~

backlash

het"\\Teen

cross

slide

scre\71,~

and

nut

is

removed

no:-m2.1

ad~lancemenI

of

the tooL

Change

0~·Jer

to

normal

turnlIlG

as

fo11oV1S:-

Sct

s\",:ivel

ba:-

to

ze!"0 graduaticn:.

:t~-it~d~a,-;;

5ErpO~::

!J~S.Ck~l

to lailstock

end

0:

bed.

;"

..

Qci~

tne

t\.~·c

soc::et

h:::aC

car

scret;,:s.

M [Hi

ng

.tCa~'!:ach

ment.

"[Iii,.

a.::d~~ncD::

i:.;

mounted

on

to

tbe

COrD.-

pound

s~id~,

replacing

the

lOO~

pr~:<

-rh::

ttt~

<~Jr~cd,

vee

g:-oo\>ed Slide

has

v::.":;:ti:3.:

,,:::::!~'V;

ad!ust:T.

....

'~T

2.I1~~

i'~

3.7"rar~;:...·d

tc;

sv,?ivel

againST

2.

scale

\

,\

}

!,

~.-.--

----

12

sc

E I G

(WITH

ENGUSH

GEARBOX

&-

4 T.p.m.

lEADSCREW)

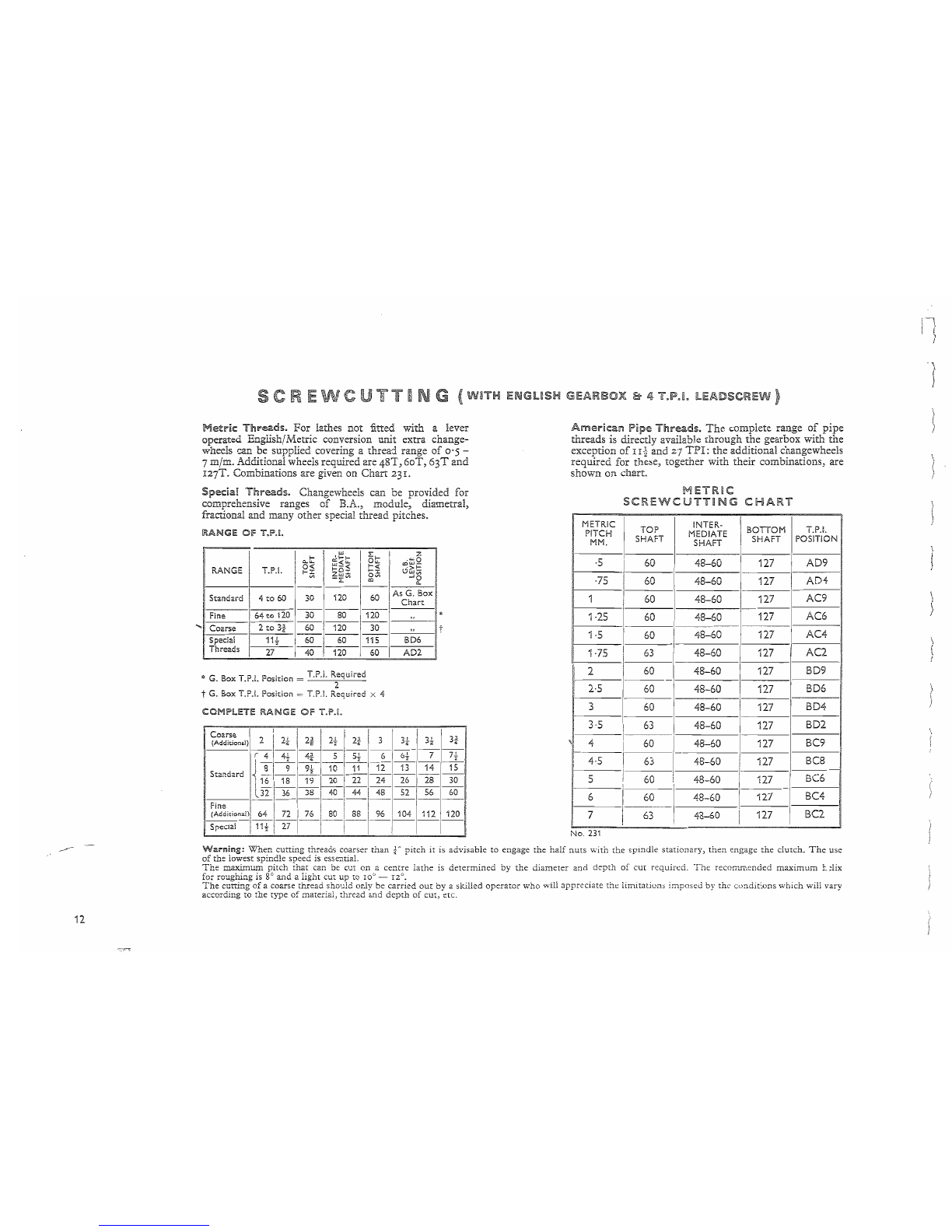

Metric

Threads.

For

lathes not fitted with a lever

operated English/Metric conversion unit extra change-

wheels can be supplied covering a thread range

of

0'5

-

7 m/m. Additional wheels required are

48T,

60T,

63T

and

I27T. Combinations are given on Chart 231.

Special

Threads.

Changewheels can be provided for

comprehensive ranges

of

B.A., module, diametral,

fractional and many other special thread pitches.

RANGE

Of

T.I".!.

Ii

0...1:;:

'I

"'~I:;:

16

1:;:

I

."'6

0<

"'-<

f-<

cow-

RANGE T.P.L

f-l:

~8l:

til:

0G:;~

'Ion,

-:LV>

",V>

-'2

1---

-----1

Standard 4

to

60

30 120 I 60

As,...G

h· Box

i----'

________

1

'-

art

Fine I64

to

120 30 80 I120 "

Coarse I 2

to

3i

60 I 120 I 30

Spedal I

11t

60 1

60

115 BD6

Threads

27

1"4O'1~,

60 AD2

*

" t

* G B T

Pie

't'

_ T.P.1. Required

.

ox

. .

.•

OSI

Ion

- 2

t G. Box T.P.I. Position = T.P.I. Required X 4

COMPLETE

RANGE

OIF

T.P'!.

Coarse I

II

1

II

3

"I

3'

1 I 1 3

(Additional)

2 2"

2.

~

2"

_3_

~ ~

~

r

l 4 I.<LL 44 5 I

52-

6

6'

7 7.l

Standard

1'<

13

1-'~-1-9-;-

-1-0-1::::1::::~::::

-1-2-

-1-~-

-1-4-

-1-~-

!~I~I~I~i~~~I~~

1----'

l32

,~i~'~!~I~~I~I~

Fine I i I

'1

! I

(Additional)1

64 i

7:

.~i

..

80

!~II'~I.~~~

S

pedal

i

11

i I

21

i I

!.

I

American

Pipe

Threads.

The

complete range

of

pipe

threads is directly available through

the

gearbox with

the

exception

of

I I

-~

and

27

TPI:

the

additional changewheels

required for these, together with their combinations, are

shown

on

chart.

METRiC

SCREWCUTTING

CHART

, MEIR.lc I

TOP

I INTER· \ BOTTOM

P~~~

SHAFT MEDIATE SHAFT

SHAFT

I I

·5

60

48-60 I

127

I

I

·75

60

48-60

127

I I

1 I

60

48-60

127

I I I

,

I I

1·25

60

48-60 I

127

I

1·5 I

60

I 48-60 I

127

1·75 1

63

I 48-60

127

I

2 I

60

48-60 I

127

2·5

60

48-60

127

I

1

3 I

60

I 48-60 1

127

I

3·5

I

63

48-60 I

127

4 I

60

I 48-60 I

127

4·5

I

63

I I

I 48-60 I

127

I

5 I

60

1 48-60 I

127

I 1 I

I

i , i I

6 I

60

I 48-60 !

127

I~-

1 I 1

I

63

48-60 i

127

I

I

No.

231

T.P.L

POSiTION

AD9

AD4

AC9

AC6

AC4

AC2

BD9

BD6

BD4

BD2

BC9

BC8

BC6

BC4

BC2

Warning:

When

cutting

threads

coarser

than

f'

pitch

it

is

advisable

to

engage

the

half

nuts

with

the

spindle

stationary,

then

engage

the

clutch.

The

use

of

the

lowest

spindle

speed

is essentiaL

The

maximum

pitch

that

can be

cut

on

a

centre

lathe

is

determined

by

the

diameter

and

depth

of

cut

required.

The

recolTilllended

maximum

r.~!ix

for roughing is

go

and a light cut up to

I00

-

12°.

The

cutting

of

a coarse

thread

should

only

be

carried

out

by

a

skilled

operator

who

will

appreciate

the

limitations

imposed

by

the

conditions

which

will

vary

according

to

the

type

of

material,

thread

and

depth

of

cut,

etc.

"\

j

J

sc

E I

The

machine can be fitted with a lever operated English/Metric

conversion unit which makes available a metric range

of

0'5 to

7 mm. pitches

in

addition to the standard English range

of

4 to

60

TPI.

The

full range

of

metric pitches is listed below.

0·5 I 0·75 1 I 1·25 I 1·5 I 1·75 2

, I I

2·25 2·5 3 I 3·5 4 4·5 5

I I

6 7 I

sc

E I

Metric:

Threads.

(With metric gearbox and 6 mm. Leadscrew)

The

range

of

metric threads

is

0'5 to 7 mm. pitch (coarse) and

0'2

to

0'9

mm. pitch (fine). Change wheels required are

I-30T,

I-41ST,

I-SoT,

and

I-DOT.

A range

of

4 to 60

TPI

can be cut with

the

addition

of

1-6oT

and

r-I27T

change wheels.

fULL

RANG!:

Of

THREADS

PER

INCH

4

~"1~5!1'

6!-

I 7 I

7!,

8 9 9t1 10

-1-1

-1---:j2

--1--'1-

13 I 14 I

15,'

16

1.

I

19

120l

22 24

26~~

32 36 I 38

~

44 48 52 56 60

lEVER

OPERATED

METRIC

CONVERS~ON

If

a customer requires to convert a machine with a standard

English gearbox by fitting a conversion umt, he can fit the unit

at

a

later date.

This

would enable him to obtain a range

of

metric

threads from 0'5 to 6 mm. pitch.

The

full range is listed below.

0·5

075

'±H

15

I

2

251'

4~

6 I I

METRIC

GEARBOX

.&

6mm.

PITCH

lEADSCREW)

I I !NTER-

RANGE PITCH

TOP

MEDIATE BOTTOM I

LEVER

I

OR

T.P.I. SHAFT SHAFT SHAFT POSITION

Metric

I 0·5

to

30

no

48

As

gearbox

(Coarse)

7 mm.

chart

Metric

0·2

to

30

80

120 iAs

gearbox

(Fine) 0·9

mm.

chart

T.P.1. 4

to

60 30 120-127 I 60 As

gearbox

chart

fUll

RANG!:

Of

Hi:; lIftiC

PITCHES

0·2

0-25 0·3

~I

()-4

I0·45 0·5 0·5625 \ 0·6

0·625

(J.7

0-75 I 0·8 I0·875 I 0·9 1 1·1251 1·25

I I

1·5

1·75 2

12-25

2·5 3 3·5 4 4·5

5 6

71

I

13

$.

.......

_ ...

14

I

Periodic

inspection

with

adjustment

where

necessal")'.

as

given

below,

will

ensure

that

this

lathe

retains

its

original

high

standard

of

accuracy

and

periormance.

Drive

Belts.

The

drive motor is mounted on a platform inside

the

cabinet base. Adjustment to

the

vee belt tension is

by

a screw at

the

rear

of

the machine.

Procedure for replacing vee belts is as

follows;-

Remove the drive guard

and

inspection cover from end

of

cabinet base.

Release tension

in

belts by adjusting screw at rear.

Replace belts

and

carefuIIy re-tension.

It

is important to ensure

that

the belts do not slip

as

this would

only increase both pulley and belt wear.

Clutch.

If

slip occurs then adjustment

is

as

foHows;-

Open the drive guard.

Increase the spring load by slightly rotating the

nut

(anti-

clockwise, i.e. left-hand thread) on the end

of

the

dutch

shaft.

Constant operation

of

the

dutch

results eventually in wear

on the driving faces (usually signified by the

dutch

refusing

to drive) and the following adjustment will be necessary.

Stop the motor, leaving the

dutch

in

the

ON

position.

Remove the fairing (at the rear

of

the bed, beneath the

headstock).

Release the outer

nut

on the operating linkage one

complete turn and

re-damp

with inner nut.

The

dutch

should be dismantled at six-monthly intervals

and any lubricant on the driving faces removed by washing

in paraffin.

Headstock

Spindle

Bearings.

Adjustment for wear on the

Timken taper roBer bearings on the main spindle

is

as

follows:-

Remove headstock cover.

TE

E

Release locknut (by turning anti-clockwise, i.e. R.H. thread)

and rotate adjusting

nut

sufficiently to obviate play,

then

re-

tighten locknut.

It

must

be

emphasized

that

this operation

requires

the

utmost care

as

over-tightening can seriously

impair

the

life

of

the bearings.

Sealing compound should be used when refitting the head-

stock cover.

The

magnetic plug (chromed head) which is fitted

in

the

headstock cover

must

be

occasionally removed

and

cleaned

of

any particles

of

steel which may have collected there.

Always replace

the

magnetic plug after cleaning.

Saddle

Adjustment.

To

adjust the rear strip release the four

nuts on the underside

of

the strip, adjust the headless set s.:rews

by turning clockwise

and

re-lock the nuts.

To

adjust the front

strip, release the caphead screw which secures the adjusting screw

and

rotate the latter anti-clockwise,

re-damp

the caphead screw.

Care should be taken to avoid over adjustment.

Cross

Slide

Adjustment.

Take up

of

wear on the taper gib

strip

is

by releasing the locknut, adjusting the screw and

re-locking the nut.

The

gib strip is

of

a length to aliow adjustment over a range

of

wear

but

after a

number

of

adjustments

it

may be necessary to

shorten the screw.

Top

Slide. Adjustment to the strip

is

by releasing the locknuts,

ti[htening the screws

and

re-locking the nuts.

E!ectric

..!

Controis.

All electrical control equipment

is

mounted

on the panel at the front

of

the cabinet and

if

removal is required

it

is I

N.cP

ORT

ANT

to ensure that the isolating switch (line switch)

is

in

the

OFF

position.

The

isolating switch (line switch)

MUST

NOT

be removed until the mains leads have been isolated.

~

(

t

E

Whena

componentis requiredto bemachinedonalathe,

the

following

principal points

must

be settled:

(r)

the

manner

in

which

the

work

should

be

mounted;

(2) the tool set-up to be employed;

and

(3)

the

speeds and feeds

to

be employed.

Turning

between

Centres.

This

method

of

turning necessitates

centre holes being drilled

in

both ends

of

the

work.

The

operation

should

be

performed

by

a special drill givingacountersink

of

60 deg.

angle to suit the lathe centres,

the

centre drill

bei..'1g

held

in

a drill

chuck

mOUJ."1ted

i.11

the

tailstock spindle with

the

workheld

in

achuck.

It

is usual practice

to

carry

out

a facing operation on

the

end

of

the

workpiecebeforecentre-drillingand

itis

essential

that

workoverhang

from chuck jaws, for

both

facing

and

drilling operations, should

be

a

minimum, to ensure concentricity. Centre drills are delicate tools

and easily broken, largely owing to lack

of

sensitivity

in

feeding

the

drill,

and

to work speed being too low.

To

prevent breakage use a

high speed

of

work revolution and a very fine feed.

Wit.1J,

the work mounted between centres,

and

fitted with a driving

dog

and

with

t.1Je

tailstock centre we111ubricated,

it

is

important

that

the

work should befree enough to

turn

by

hand

but

withoutany

end

movement. Owing

to

heat generated

by

the

cutting action,

the

work

expands during machining,

and

if

screwed

up

tightly before cutting

commences,

the

result is

that

the centre

end

maybecomeoverheated

causing damage

~o

both

centre and work.

When using carbide turning tools, the work speed may be so high

that damage to a dead centre may take place however

much

care is

used.

It

is better

then,

to use a revolving centre which rotates with

the

work, and

is

not

therefore affected

by

high work speeds.

Tool

Settings.

Correct tool setting

1S

Important, for accurate

grinding

of

tool angles

is

of

no avail

if

the

tool is improperly set

in

relation

to

the work. While normally

the

tool

point

should

be on

the

centre line

of

the

work, a setting slightly above

centre

is permissible,

L E I E

but

a setting below centre may cause slender work to deflect and

spring

on

the top

of

the tool and out

of

the

centres.

For

all taper

turning

and

screw cutting operations,

it

is essential

that

the cutting

edge

of

the tool be mounted exactly on

the

centre line

of

the work,

oti!erwise discrepancies in taper and thread form

will

result. A

simple way to obtain correct tool height is by setting to one

of

the

lathe centres.

For

parting-off operations, use a tool with a rigid shank and with

the overhang from the toolpost kept to a minimum.

The

cutting

edge

must

be set on the work centre and square to the lathe axis.

Do

not

attempt parting-off unless

the

work is well supported ar.

..

ensure

that

overhang from the chuck is

not

excessive.

Chuck

Work.

When a chuck

is

not

in

use

it

should not be left so

that

cast iron

dust

or other cuttings may enter the bore or parts

of

the

mechanism.

The

bore may be protected by plugging with a

doth,

nevertheless before mounting the chuck on the lathe spindle,

dean

the bore

of

the

chuck and the spindle nose and lubricate with

Molybdenum Disulphide a tube

of

which,

is

supplied with the

machine.

When mounting or removing a chuck, protect the slides

of

the

bed

with a piece

of

wood upon which to rest the chuck before lifting

it

onto

t..'1e

spindle nose. When tightening the chuck jaws, never try

to obtain increased gripping power

by

lengthening

the

arm

of

the

box key.

For

second operation work, or for work which may be'difficult to

hold by standard jaws, the use

of

soft jaws shaped

as

required will

often prove a time saving factor and ensure greater accuracy.

When setting work in an independent four-jaw chuck, make use

15

;l~

1!\iL_

16

R E

COM

MEN

D E D l A

THE

P

RAe

T

~

C

E-(

ell)

i1 t d • }

of

the

setting rings

on

the face

of

the

chuck

to

obtain

an

approxi-

mate location.

It

is

then a simple matter to make

the

final adjust-

ment

for

,~eater

accuracy.

fa.cepla.te

Work.

The

remarks

in

regard to

the

mounti.'1g

of

chucks apply equally to faceplates

and

catch plates. Some castings

or

forgings are so shaped

as

to be difficult to hold

in

a chuck,

but

can

be

damped

on a faceplate by straps

and

bolts utilising the holes

and

slots provided,

but

do not rely entirely

upon

these. Whenever

possible use stops against the work to take

the

pressure

of

the cut.

An angle plate bolted on to the faceplate,

on

to which the work is

mounted,

is

often useful for boring

and

facing operations. Always

ensure that revolving work

is

securely fastened

and

that

a balance

weight is fitted to counteract the out-of-balance effect

of

the

mounting units and work.

Use

of

Steadies.

Long slender work,

if

unsupported between

centres, will tend to whip or

bend

under

pressure

of

the cutting

action.

To

preven~

tl-,is

happening, a travelling steady should be

employed~

When machir:ing black bar, first turn a short length

of

W.~e

bar at the tailstock end to

the:

diameter required, and adjust the

STeady

jRWS

to

touch the

v;~ork,

then lock them in position.

The

javls will then support the

v.;ork

at the point

of

the

cut

all

along the

length. Keep

javls

\vell lubricated during the operation.

A stationary steady can be set up at any point along the

bed

to

support 2 long shaft.

If

the shaft is

or

black barJ a ring

somew<hat

wider than the

of

the res: must be turned

as

a bearing for the

jaVys.

If

the

shaft

is

slender, this

can

be a delicate operation, so that

a sharp pointed. tool with 2 very light cut should

be

employedQ

Another use

of

a stationary steady is when

an

operation requires

to

be

performed

on

the

end

of

a bar.

In

such instances

the

distance

from

the chuck

may

be

too great for machining to take place

without additional

support,

and

if

drilling is required,

the

tailstock

centre is

not

available.

Thus

to

support

L~e

work

by

means

of

a

steady, adjust

the

jaws to

touch

the

work until

it

is

running

true,

and

then

lock

them.

Again, use plenty

of

oil between

the

steady

jaws and

the

revolving work.

DI"i!iing

and

Reaming

from

the

Taiistock.

For

theseoperations

the

work is gripped

in

a chuck or

mounted

on

a faceplate.

It

is

important

L,1.at

the drill

be

started

true

so

that

z..

hole concentric

with the

\~,Tork

diameter is produced, and a common method

em-

ployed to attain this

is

by

centre drilling before commencing normal

drilling.

The

limitation

of

a twist drill

as

a cutting tool is

that

it

follows its

OVln

point which takes

the

line

of

least resistance. Incorrect

grinding

can

cause additional inaccuracies

by

Cr)

cutting edges

being ground to different angles, (2) cutting edges

of

equal angles

but different lengths, (3) ::utting edges

of

unequal angles and

lengths causing the point to be off-centreo It is essential then to see

[hat the radial components

of

the two cutting edges are equal so

that

they constrain

the

drill to follow a direct

path,

but

if

an

accurate bore is required, a drilled. hole should be enlarged

by

a

single point tool and final size obtained

by

reaming~

Straight shank reamers are

held

in

a chuck,

vFhile

taper sha.nks may

be inse:-ted into the tailstock

spindlea

The

reamer should

be

fed

carefully through the hole

by

rotation

of

the tailstock handwheel,

usmg an

ampk

supply

of

lubricant when reaming steel.

1

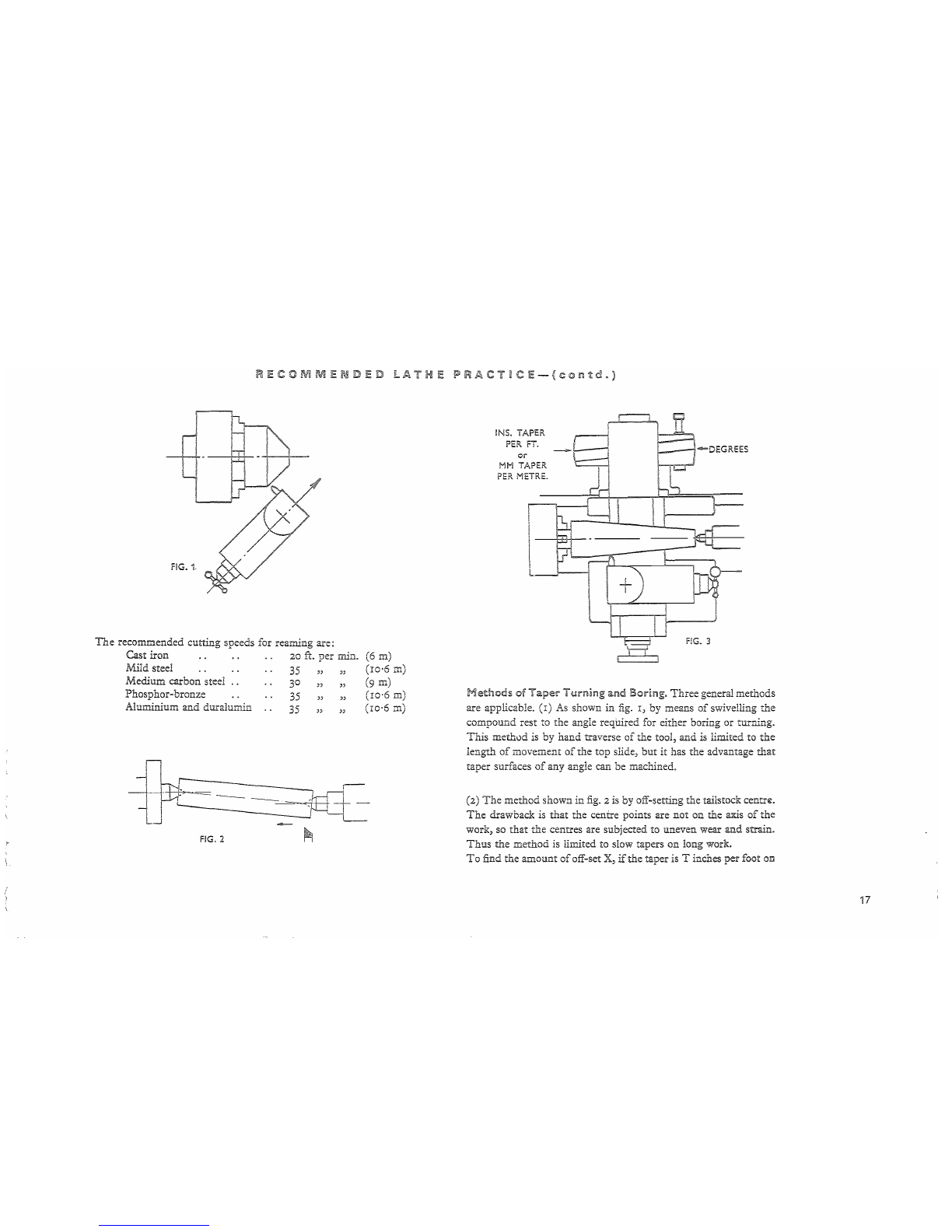

RECOMMENDED

LATHE

PRACT~CE-{c(H'd(L)

F!G.1

The

recommended cutting speeds for reaming are:

Cast iron

20

ft.

per

min.

Mild steel

35

" "

Medium carbon steel

Phosphor-bronze

Aluminium

and

duralurnin

30 " "

35

" "

35

" "

~

r--

--l

--_I

n

I

~

----==~

~:JEtt

FIG.

2

-~

(6

m)

(ro·6

m)

(9

m)

(10'6

m)

(ro·6

m)

r==J

I

INS. TAPER

~

PER

FT.

_ !

or

I

...

MM

TAPER.

PER

METRE.

~

FIG.

3

Methods

of

Taper

Turning

ami

Boring.

Three

general methods

are applicable. (x)

As

shown in

fig.

I,

by means

of

swivelling the

compound rest to the angle required for either boring or turning.

This

method is by hand traverse

of

the tool, and is limited to

the

length

of

movement

of

the top slide,

but

it

has the advantage

that

taper surfaces

of

any angle can

be

machined.

(2)

The

method shown

in

fig.

2

is

by off-setting the tailstock

centr~.

The

drawback is that the centre points are not on the axis

of

the

work, so

that

the

centres are subjected to uneven wear and strain.

Thus

the

method is limited to slow tapers on long work.

To

find the amount

of

off-set X,

if

the taper is T inches per foot

on

17

18

R

Ii:

COM

M

Ii:

N D

Ii:

D

LA

T H

Ii:

P

RAe

T

~.

C

Ii:

- ( © 0

1m

t d . )

..2'

..2

, •

~

t..'

L'

h h X T

xL.

h

..

lameteran

..

lengtn

or

WOb.

1S

'

mc

es, t en =

---me

es

24

or

To

find the amount

of

off-set X,

if

the

taper is T mm.

per

metre

TxL

mm.on diameterand length

of

work is L mm.,

then

X

2,000

lfthe

induded

angle

oftaperis

e,

X = L x

tan~

inches (mm.).

2

(3)

If

the lathe

is

fitted with a taper turning attachment,

fig.

3,

then

more accurate tapers, either external or internal, can be produced

than

by

the two preceding methods.

By

the use

of

this attachment,

the

lathe centres are

not

of

course taken out

of

alignment,

so

that

the bearing surfaces are unaffected.

LATHE

TOOLS

In

mounting turning tools

in

the rest, the tool should only

~xtend

the minimum amount from the rest

to

obtain the maximum support

against the downward pressure

of

the cut.

For

damping

'the tool,

ample pressure

is

provided

wit.'iJ.

the spanner supplied, ane' on no

TOP RAKE ANGLE

--!

,i

\,

\!

,.

rI

~\

~,

J

j

FRONT

CLE..A,RANCE

ANGLE

TABI..IE 1

Cutting

Angies

foe"

1-1.5.5.

and

Cemented

Cae"bkie

Tool$

Materials H.S.S.

Cemented

Carbide

Top

Rake

Clearance

Top

Rake

Clearance

Mild

steel

20°

6°

go

4°-f>°

High

carbon

steei

10° 4°

3°-4

0

4°-6

Q

Soft cast

iron

10°

go

"c-S0

4°-f>°

Chilled

iron

..,

ao

4° (;0 2°-4°

Copper

'12°

1Co

13°

4°-6

0

Brass ..,

0°-6

0 i 0°

3°

4°-6

0

Aluminium

30°

10°

i&~

6c-s0

TAla:"'!: 2

Cutt~ng

Speeds

In

feet

per-

m[;r£~~t~

(mffZtlres

pe~

n'~r~~)

Materiai

H.S.S,

Teols

Cemer:ted

Carbide

Roughing

:-in1shing

Roughing

Fini:hing

fl:.

roo

ft. m.

ft.

m.

ft.

rn.

Mild Steel

'130

40 200

61

200

61

300

91

High

carbon

steel

45

14

60 18 200

6-,

400 122

Soft

Ca'it

iron 60

18

75

23

200

6';

350 107

Chilied

iron

...

'10

3

15

4-5 is

4·5

30

9

Copper

200

6~

200

6~

4')0 122 700 213

Brass .. _ 250 76 400 122 400 122 700 213

Aluminium

300

91

.jDa

122 500

~

52 ,000 3051

TABLE

3

;Feeds

in

Enches

per

fre¥otut~on

(mm.

per-

revoh.rdon)

Material N.S.S. and Cemen.ted

Caib~de

Too:s

Roughing

Fi:lishing

lncnes

mm.

inches

mm.

Mild

steel

.(rlO ·254 -007

·178

High carbo?:

St:;t;

010 ·254 ·007

·i78

Soft

cast

!r'on ·013 ·330 008 ·203

Chilied

:ror, -003 ·203 ·005 ·127

COPDer

-020 -508

-OOB

·203

B~~

...

.~.~

·~m

Aluminium

·0'13

·330 -007 ·178

1

~

RECOMMENDED

LATHE

IPRACT~CE-(contd.)

account should extra pressure

be

applied

by

lengthening

the

leverage

by

dubious means

such

as a piece

of

piping.

Such

methods

are unnecessary,

and

cause damage

not

only

to

the

damping

screws,

but

the

entire

compound

rest.

Boring tools may

be

of

one piece solid forged,

or

may comprise

cutter

inserts fixed

in

a

boring

bar. A

point

of

note

in

regard

to

the

grinding

of

boring tools is

that

the

conditions governing

the

top

rake

and

clearance angles are different

from

those

in

turning,

so

that

a secondary

dearance

is

required

for

the

front

of

the

tool to

clear

the

enveloping curve

of

the

bore.

Speeds

and

feeds.

The

cutting

speed

is expressed

in

surface feet

per

minute,

and

is

the

speed

at

which

the

surface

of

the

work passes

the

tip

of

the

tool.

If

D is

the

diameter

of

the

work

in

inches, N

the

workspeed

in

r.

p.m.,

and

S

the

cutting

speed

in

feet

per

minute,

then

3.82 x S 318 x S (Metres/min.)

N

or

N = D

mm

The

feed

rate

is expressed

in

inches

per

revolution

of

the

headstock

spindle.

The

time

to complete one cut,

in

minutes, can

be

calculated from

Length

of

cut

(in.)

or

(mm)

Spindle

speed

(r.p.m.)

x feed (in.

per

rev.)

or

(mm

per

rev.)

FIG. 4

DEPTH

OF

CUT

FIG.

5

DiRECTION

OF

TOP SLlDE TRAVEL

Tables

I,

2 and 3 give suitable tool angles, cuttingspeeds,

and

feeds

for a range

of

the

common engineering materials.

Screwc!.Itting.

For

cutting

vee threads the top

of

the

tool is placed

at

centre height,

having been previously ground to

the

required shape without any

top

rake.

Note

that

if

the

tool is given

top

rake

the

plan angle

ofthe

tool is

not

the

angle

that

will be reproduced

in

the

work.

Fig. 4 shows

the

use

of

a settinggauge for

both

external

and

internal

threading,

but

when cutting vee threads with

the

tool set

in

this

manner,slowspeedsandlightfeeds arenecessarybecause

the

cuttings

cannot be free flowing without

top

rake

on

the

tooL

Thus

a

better

method

for cutting external vee threads is shown

in

fig. 5 where

the

compound

slide

is

swung around so

that

the

tool is fed

in

at

an angle

of

slightlyless

than

half

theincludedangle

of

the

thread

(i.e. approxi-

mately 26 deg. from normal, i.e. 64 deg. on cross slide graduations,

19

L=-._

20

RECOMMENDED

LATHE

IPRACTmCE-{contd.)

when cutting standard

55

deg. threads) so that metal is mostly re-

moved by the left-hand side

of

the

tooL Side rake can be provided

so that heavier cuts can be taken and the chips

flow

easily away.

In

commencing a screwcutting operation, take a light trial cut

and

check the number

of

threads per inch by measuring with a rule

or

screw pitch gauge.

Then

proceed by taking successive cuts until the

full depth

is

reached. Check for depth and accuracy by means

of

the

nut

to fit the screw, or by a thread gauge

of

the ring type.

Tapered threads may be cut by means

of

a taper attachment or by

off-setting the tailstock.

In

either case the tool must be set square to

the work axis, and not to the tapered portion.

Square

Threads.

This section

of

thread

is

often used for multiple

threadedscrews,andtheterms

"pitch"

and

"lead"

shouldbe under-

stood. Pitch

is

the distance from a point on one screw thread to a

correspondingpointon the nextthread,measuredparallelto theaxis.

Lead

is

the distance that a screw thread advances axially in one turn.

Thusona

singlethreadedscrew

the

termsareidentical,

buta

notation

such

as

i in. pitch, ! in. lead, would indicate a two start screw,

and

to produce this,

the

gearbox would require to give a saddle move-

ment

of

! in. for every revolution

of

the

spindle, while

the

tool

would be ground to produce t in. pitch section

of

thread.

The

procedure when cutting a multiple start screw is to set

the

top slide

parallel with lathe axis and cut the first thread

in

the

usual

manner

at

the correct

LEAD.

Cut

subsequent threads

by

advancing

the

top slide each time a distance equal to

the

lead divided

by

the

number

of

starts. This,

of

course, applies to

aU

multiple

threaded

screws regardless

of

thread section.

Acme

and

Worm

Threads.

The

procedure to

be

adopted for

Acme and worm thread cutting is similar to

that

recommended for

vee threads except for the setting angle

of

the

compound slide.

In

this case the thread

induded

angle is 29 deg. so that a slide setting

of

apProx. I3 deg. from normal (i.e. 77 deg. on cross slide

graduations) would be appropriate.

Full depth

of

an Acme thread is 0'5 P +

o'or

in.

and

width at

bottom

is

0'37°7 P - 0'0052 in. where P is

the

thread pitch.

)

)

~

FITTn\lG

AND

USE

OF

ATT

eH

ENTS-(contd.)

graduated

45 degrees each side

of

the

vertical centre line.

An

arbor

for

mounting

between centres

and

driven by

the

lathe driver piate is

available to take I in. bore cutters.

Machining

bythis means is, how-

ever, restricted

to

thin

work

and

so, wherever possible, face

or

end

milling is recommended. Face

and

end

mills togetherwith

Woodruff

key cutters can be provided having morse

taper

shanks for direct

fitting to

the

spindle nose.

Mining

and

Gean::utting

Attachment.

As

in

the previous case,

this

attachment

is

mounted

on

the comDound slide

in

place

of

the

rooIpos!.

On

the vertical slide assembly:

of

similar construction to

the milling

attachment,

is fitted a

support

for

the

work

arbor

together

with indexing mechanism.

Cutter

arbor

add

cutter

are

mounted

be-

tween

the

lathe centres, the drive

being

by driver plate

and

pin.

It

is

important

that,

when setting

up

for gear

cutting,

the

work

arbor

be

exactlyat

right

angles to

the

cutter

arbor

and

the

cutter

directly

under

the centre line

of

the

work arbor. Gears

up

to 7 in. diameter can be

cut

and

cutters covering a wide range

of

gear pitches are available.

Dividing

Attachment:.

Accurate indexing

of

the lathe spindle

is

achieved by use

of

this attachment. Work

mounted

in the chuck,

on

faceplate or between centres can be indexed for operation such

as

graduating, slotting, key seating, etc.

The

attachment

fits on the

top

changewheel shaft after removal

of

the gear,

the

hinged guard

re-

maining open whilst

in

use. A very wide range

of

divisions is possible

withthe

standard

indexplate,

but

special plates canbe provided

when

necessary.

Boring

Table.

This

attachment

fits directly

on

to

the saddle. A

boring

bar

with six cutters for usc between centres can be supplied.

To

fit

the

table, remove the complete cross slide

by

turning

the

handwheel until the slide becomes free

and

can

be

taken from

the

rear

of

the

carriage. Replace by the boring table, feeding on to

the

screw which is

operated

in

the reverse direction. Place the

boring

bar

between

the

lathe centres

and

drive by means

of

the

driver plate.

FQurway

Toolpost:.

It

is

self

indexing

and

positively located.

This

unit

replaces the

standard

type tooIpos!.

American

Toolpost.

Of

the recognised American

pattern

with

swivelling base plate

and

single

clamp

screw.

CQolant

Pump.

The

electric

pump

unit is housed inside the

cabinet base

and

access

is

through the louvre

at

the

R.H.

end

of

the

cabinet.

Feed

StQPs.

(i)

Micrometer

Carriage

Stop.

Clamps to the front vee bed

way

and

used for accurate machining

of

shouldered work.

The

screwed spindle

is

fitted with a micrometer dial

having

O'OOI

in.

or

'02

mm.

graduations.

Four

Position

Carriage

Stop.

Similar to the above, this

unit clamps to the front vee

bed

way

and

is used for

multi-

shouldered work.

The

indexingbody contains four adjustable

screws each

of

which can be used in

turn

to control various

shoulder lengths.

(iii)

Cross

SEde

Stop.

Is located on the cross slide ways

and

is

used

en

facing operations.

Bed

Turret.

This

attachment

is

clamped to the bed ways replacing

the tailstock.

It

comprises a lever operated slide

of

4in. stroke

length

with a six station automatically indexing turret, each station having

an adjustable stop screw. Supplied with the lathe, the

turret

head

is

bored

suitable for I in. diameter tool shanks

but

otherwise is left

solid for boring

in

situ to ensure perfectalignment withtheheadstock

centre.

This

attachment

cannot be used with an extended cross

slide or with hydraulic copying equipment.

Cut-off

Slide.

Used

for parting off and facing operations.

This

quick acting lever operated slide, with front and rear toolposts, is

clamped to the

bed

ways immediately in front

of

the chuck.

Additional

Equipment.

A wide selection

of

equipment available

includes chucks

of

all sizes within the capacity

of

the lathe, t?ilstock

drill chuck,rotating centre,

half

centre, pipe centre,

turning

tools

and

tool holders, etc.

Two

Speed

Equipment:.

Spindle speed ranges can be doubled by

fitting a two speed

motor

and selector switch.

The

standard is 34 to

1500

r.p.m.,

but

other

ranges can be provided.

11

l

ES

R P

The

eq-:Jip:nen! comprises an independently ope:-ated rear tool

sEc.;~

5.:ted

:0

a

h:;.'"G.!."2Ulic:l1y

Dpe:-ated

angle slide, the

'Nhole

being

rr:o~~t~::

:}11

ar:

:::~tcnded

crCJss

slid;:.

(P.~

front compound slide

is

also

:J.tTe:d

rer :1or=al

tu.rTIing.~'

_;etomatic copying control from the

te:np!atc to

F~he

hydraulic slide is

by

iTIeanS

of

a stylus arm,

mounted

a~

:;:p~r

ro11::::

b~ariDgs1

actuating a spool

"type