The tail stock can be fastened on the lathe bed by tightening the

locking block through one locking handle, there is a sleeve in the tail

stock, the taper of it is MT3, there is another locking handle which can

tight the sleeve at any position, when you rotate the hand wheel of the

tailstock, the sleeve can be moving.

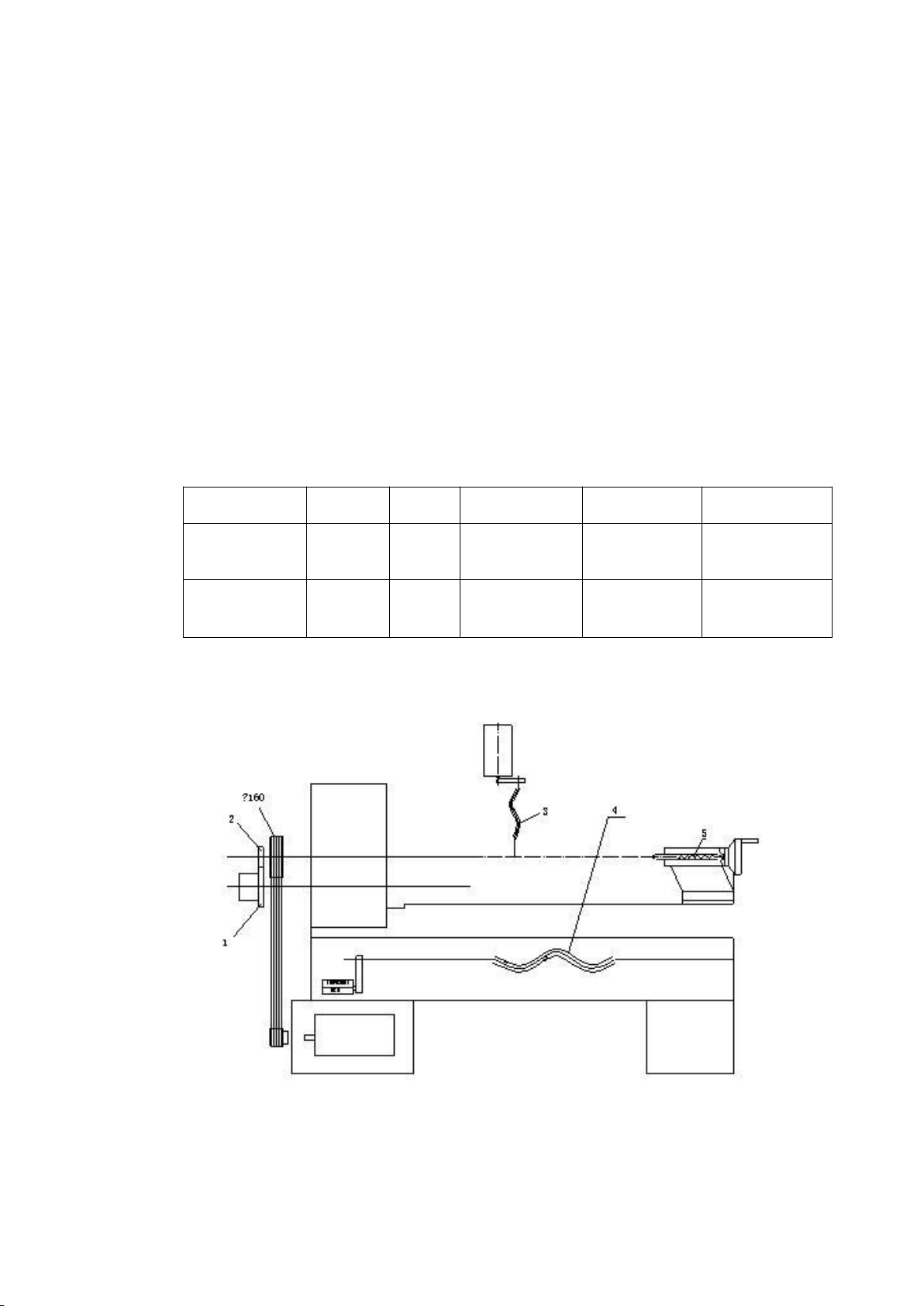

6. THE TRANSMISSION SYSTEM

THE MAIN SPINDLE SPEED ROTATION

The speed of spindle is transmitted by triangular belt, the motor

(YL100-4) will get the different speeds through the frequency

converter, so the main spindle speed will be changed with it.

THE MOVEMENT OF LONGITUDINAL FEEDING

The longitudinal feeding of the cross slide is supported by the step

motor(110byg5500) fixed on the lathe bed, the longitudinal feeding

speed will be changed by controlling the lead screw speed.

THE MOVEMENT OF CROSS FEEDING

The longitudinal feeding of the cross slide is supported by the step

motor(110byg5500 or 90BYG3502) fixed on the cross slide, the

cross feeding speed will also be changed by controlling the lead

screw speed.

To ensure for the spindle to run a circle while the tool post to move a

lead, so we fix a photoelectric encoder on the left side of the

headstock, the speed proportion from the spindle to photoelectric

encoder is 1:1, the photoelectric encoder will coordinate with the

step motor or serve motor to ensure for the spindle to run a circle

while the tool post to move a lead (that is, the thread pitch to be

processed), it saves trouble to change gears and the thread

processing ranges are also widened.