Hart Scientific 1502A User manual

a

WARNING

To ensure the safety of operating personnel, and to avoid damage to this equipment:

DO NOT operate this unit without a properly grounded, properly polarized power cord.

DO NOT connect this unit to a non-grounded, non-polarized outlet.

DO USE a ground fault interrupt device.

WARNING

To ensure the safety of personnel, and to avoid damage to this equipment:

DO NOT use this unit in environments other than those listed in the user’s manual.

Follow all safety guidelines listed in the user’s manual.

WARNING

CALIBRATION EQUIPMENT SHOULD ONLY BE USED BY TRAINED PERSONNEL.

Table of Contents

1 Introduction. . . . . . . . . . . . . . . . . . . . . . 1

2 Specifications and Environmental Conditions . . . 3

2.1 Specifications . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Environmental Conditions . . . . . . . . . . . . . . . . 4

2.3 Warranty . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Safety Guidelines . . . . . . . . . . . . . . . . . . 7

4 Quick Start . . . . . . . . . . . . . . . . . . . . . . 9

4.1 Unpacking . . . . . . . . . . . . . . . . . . . . . . . . 9

4.2 Power . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.3 Connecting the Probe. . . . . . . . . . . . . . . . . . . 9

4.4 DC Power Option . . . . . . . . . . . . . . . . . . . . 10

5 Parts and Controls . . . . . . . . . . . . . . . . . 13

5.1 Front Panel Buttons . . . . . . . . . . . . . . . . . . . 13

5.2 Rear Panel . . . . . . . . . . . . . . . . . . . . . . . 14

6 General Operation . . . . . . . . . . . . . . . . . 15

6.1 Selecting Units . . . . . . . . . . . . . . . . . . . . . 15

6.2 Parameter Menus . . . . . . . . . . . . . . . . . . . . 15

6.3 Menu Lockout . . . . . . . . . . . . . . . . . . . . . . 15

6.4 Selecting the Probe Characterization . . . . . . . . . . 17

6.4.1 Setting the Probe Characterization Type . . . . . . . . . . . . 17

6.4.2 Setting the Characterization Coefficients . . . . . . . . . . . . 17

6.4.3 ITS-90 PRT and Coefficients . . . . . . . . . . . . . . . . . . 18

6.4.4 Callendar-Van Dusen (RTD) Conversion . . . . . . . . . . . . 20

6.4.5 IPTS-68 Conversion . . . . . . . . . . . . . . . . . . . . . . 20

6.4.5.1 Setting the Characterization Coefficients . . . . . . 21

6.4.5.2 Testing the Coefficients . . . . . . . . . . . . . . . 21

6.5 Filtering . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.6 Setting the Current . . . . . . . . . . . . . . . . . . . 22

6.7 Power Saver. . . . . . . . . . . . . . . . . . . . . . . 22

7 Digital Communications Interface . . . . . . . . . 23

7.1 Serial Interface . . . . . . . . . . . . . . . . . . . . . 23

7.1.1 Setting the Baud Rate. . . . . . . . . . . . . . . . . . . . . . 24

7.1.2 Automatic Transmission of Measurements . . . . . . . . . . . 24

7.1.3 Time Stamp and System Clock . . . . . . . . . . . . . . . . . 24

7.1.4 Duplex Mode and Linefeed . . . . . . . . . . . . . . . . . . . 25

7.2 GPIB Interface. . . . . . . . . . . . . . . . . . . . . . 25

7.2.1 Setting the Address . . . . . . . . . . . . . . . . . . . . . . . 26

7.2.2 Setting the Termination Character . . . . . . . . . . . . . . . 26

7.2.3 Time Stamp . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

i

7.3 Remote Commands . . . . . . . . . . . . . . . . . . . 26

7.3.1 Measurement Commands . . . . . . . . . . . . . . . . . . . 26

7.3.1.1 Reading Temperature . . . . . . . . . . . . . . . . 28

7.3.1.2 Automatically Transmitting Measurements. . . . . . 29

7.3.1.3 Selecting the Unit of Measurement . . . . . . . . . 29

7.3.1.4 Enabling the Time Stamp . . . . . . . . . . . . . . 29

7.3.1.5 Setting the Clock . . . . . . . . . . . . . . . . . . . 29

7.3.2 Probe Characterization Commands. . . . . . . . . . . . . . . 29

7.3.2.1 Selecting the Characterization . . . . . . . . . . . . 29

7.3.2.2 Testing the Characterization . . . . . . . . . . . . . 30

7.3.3 Sample Commands . . . . . . . . . . . . . . . . . . . . . . . 30

7.3.3.1 Setting the Filter . . . . . . . . . . . . . . . . . . . 30

7.3.3.2 Setting the Probe Current . . . . . . . . . . . . . . 30

7.3.3.3 Setting the Power Saver . . . . . . . . . . . . . . . 31

7.3.4 Communication Commands . . . . . . . . . . . . . . . . . . 31

7.3.4.1 Setting the Duplex Mode . . . . . . . . . . . . . . . 31

7.3.4.2 Setting the Linefeed Option . . . . . . . . . . . . . 31

7.3.5 Calibration Commands . . . . . . . . . . . . . . . . . . . . . 31

7.3.5.1 Entering the Password . . . . . . . . . . . . . . . . 31

7.3.5.2 Setting the Menu Lockout . . . . . . . . . . . . . . 31

7.3.5.3 Setting the Calibration Coefficients . . . . . . . . . 32

7.3.5.4 Setting the Serial Number . . . . . . . . . . . . . . 32

7.3.6 Other Commands . . . . . . . . . . . . . . . . . . . . . . . . 32

7.3.6.1 Instrument Identification . . . . . . . . . . . . . . . 32

7.3.6.2 Reading a List of Commands . . . . . . . . . . . . 32

8 Calibration Procedure . . . . . . . . . . . . . . . 33

8.1 Accessing the Calibration Parameters . . . . . . . . . 33

8.2 Calibration Procedure . . . . . . . . . . . . . . . . . . 34

9 Maintenance . . . . . . . . . . . . . . . . . . . . 35

10 Troubleshooting . . . . . . . . . . . . . . . . . . 37

ii

iii

Figures and Tables

Figure 1 Connecting a four-wire probe . . . . . . . . . . . . . . . . 10

Figure 2 12 V DC power source polarity . . . . . . . . . . . . . . . 11

Figure 3 1502A Front Panel . . . . . . . . . . . . . . . . . . . . . 13

Figure 4 1502A Back Panel . . . . . . . . . . . . . . . . . . . . . 14

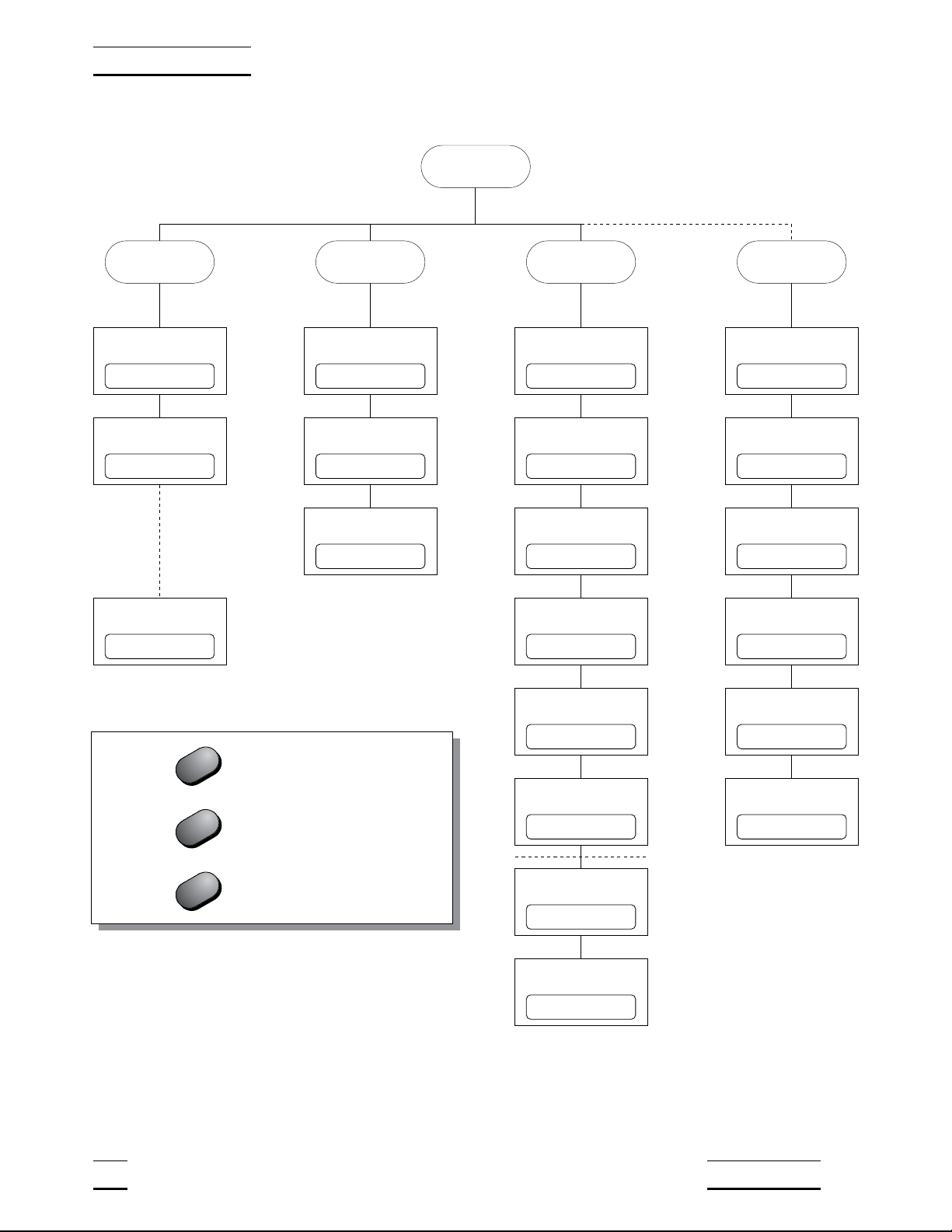

Figure 5 Parameter Menu Structure . . . . . . . . . . . . . . . . . 16

Table 1 Matching Certificate Values to 1502A ITS-90 Coefficients . 18

Table 2 Setting Coefficients Rtpw, a5, and b5. . . . . . . . . . . . 19

Table 3 Setting Coefficients Rtpw, a8, b8, a4, and b4. . . . . . . . 19

Table 4 Setting Coefficients R(273.16), a6, b6, c6, and d . . . . . . 20

Figure 6 Serial Cable Wiring . . . . . . . . . . . . . . . . . . . . . 23

Table 5 Command List. . . . . . . . . . . . . . . . . . . . . . . . 27

Table 5 Command List Continued . . . . . . . . . . . . . . . . . . 28

1 Introduction

The Hart Model 1502A is a low-cost high-accuracy digital thermometer readout

designed to be used with 25Ωand 100ΩRTDs and SPRTs. Its unique combi-

nation of features makes it suitable for a wide variety of applications from labo-

ratory measurement to industrial processes. Features of the 1502A include:

•Measures 25Ωand 100ΩRTDs and SPRTs

•Four-wire connection eliminates lead resistance effects

•Accuracy: 0.006°C at 0°C

•Resolution: 0.001°C

•Fast one-second measurement cycle

•Adjustable digital filter

•Accepts ITS-90 characterization coefficients

•Also accepts Callendar-Van Dusen and IPTS-68 coefficients

•Adjustable excitation current

•Displays temperature in Celsius, Fahrenheit, or Kelvin or displays resis-

tance in ohms

•Password protection of critical parameters

•Large, bright eight-digit LED display

•Serial RS-232 interface standard; IEEE-488 GPIB interface optional

•Detachable power cord

•Optional 12 V DC power

•Light weight, small and portable

•Sturdy, reliable construction

1502A Manual Rev. 952801 1

1 Introduction

2 Specifications and Environmental

Conditions

2.1 Specifications

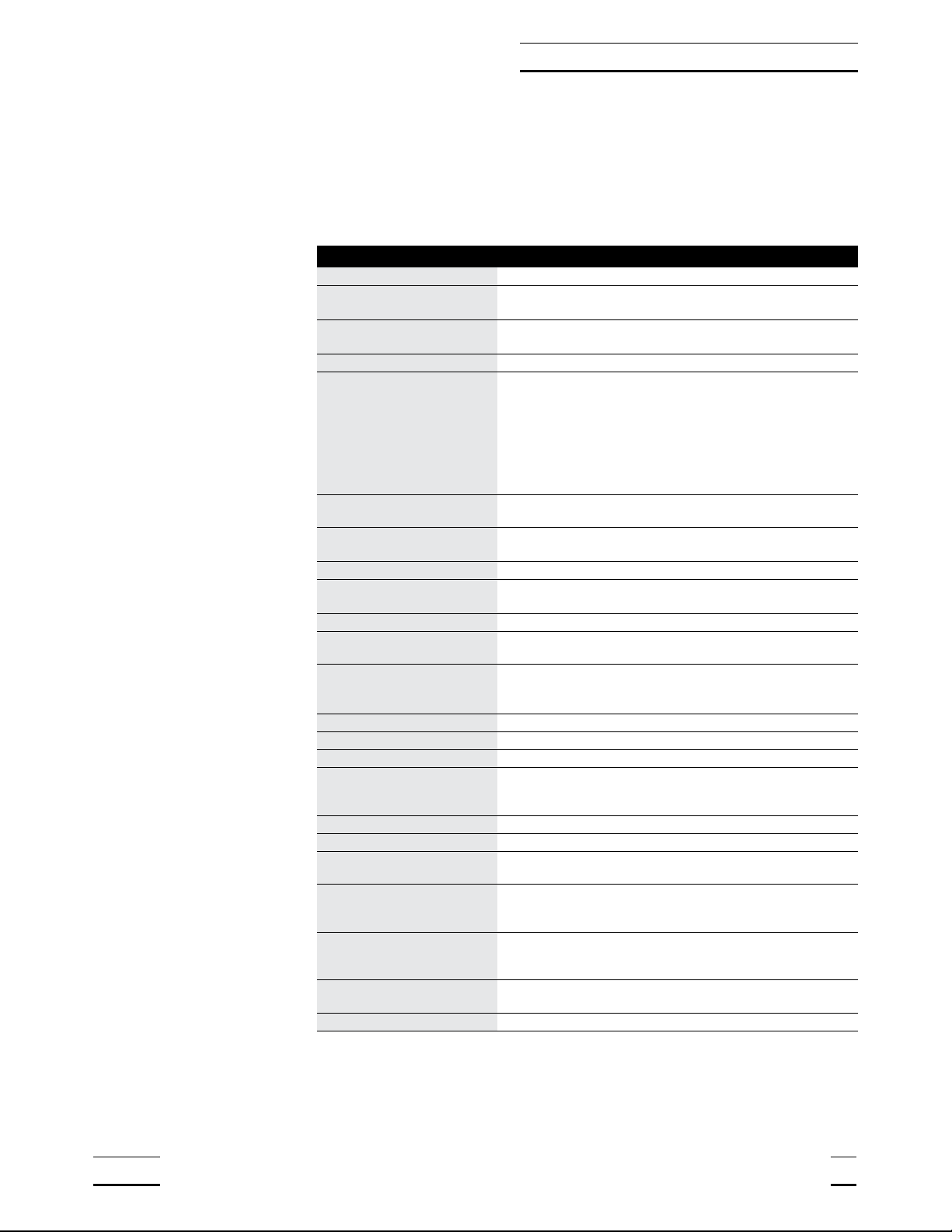

Specifications

Resistance Range 0Ωto 400Ω, auto-ranging

Resistance Accuracy, one

year1

0Ωto 20Ω: 0.0005Ω

20Ωto 400Ω: 0.0025% (25 ppm) of reading

Resistance Accuracy, short

term1, 2

0Ωto 30Ω: 0.0005Ω

30Ωto 400Ω: 0.0015% (15 ppm) of reading

Temperature Range3–200°C to 962°C (–328°F to 1764°F)

Temperature Accuracy1, 3, 4 –100°C: 0.004°C

0°C: 0.006°C

100°C: 0.009°C

200°C: 0.012°C

300°C: 0.015°C

400°C: 0.018°C

500°C: 0.021°C

600°C: 0.024°C

Temperature Coefficient of

Resistance1

1 ppm/°C

Resistance Resolution 0Ωto 20Ω: 0.0001Ω

20Ωto 400Ω: 0.001Ω

Temperature Resolution 0.001°C

Probe Nominal R(0.01°C): 25Ωto 100Ω

RTD, PRT, or SPRT

Probe Connection 4-wire with shield, 5-pin DIN connector

Maximum acceptable lead re-

sistance

100Ω

Probe Characterizations ITS-90 sub-ranges 4, 6, 7, 8, 9, 10, and 11

IPTS-68: R0,α,δ, a4, and c4

Callendar-Van Dusen: R0,α, δ, and β

Probe Excitation Current 0.5 and 1 mA , reverses every 0.25 seconds

Measurement Period 1 second

Digital Filter Exponential, 0 to 60 seconds time constant (user-selectable)

Communications RS-232 serial standard

IEEE-488 (GPIB) optional, conforms to IEEE-488.1, capability

AH1, SH1, T6, L4, DC1

Display 8-digit, 7-segment, yellow-green LED; 0.5 inch high characters

Clock accuracy, typical 0.01%

Operating Temperature

Range

Full accuracy: 16°C to 30°C

Absolute: 0°C to 55°C

AC power 115 VAC ±10%, 50/60 Hz, 10 VA, nominal

230 VAC ±10%, 50/60 Hz, 10 VA (optional)

Detachable power cord

DC power (optional) 10 to 14 VDC, 1 A maximum

(220 mA typical, normal mode; 120 mA typical, power saver

mode)

Size 5.6 inches (14.3 cm) wide x 7.1 inches (18.1 cm) deep x 2.4

inches (6.1 cm) high

Weight 2.2 lb. (1.0 kg)

1502A Manual Rev. 952801 3

2 Specifications and Environmental Conditions

1Accuracy specifications apply within the recommended operating temperature range. Accuracy

limits are increased by a factor of the temperature coefficient outside this range.

2Short-term accuracy includes nonlinearity and noise uncertainties. It does not include drift or cal-

ibration uncertainties.

3The temperature range may be limited by the sensor.

4Temperature accuracy is for the 1502A only. It does not include probe uncertainty or probe char-

acterization errors.

2.2 Environmental Conditions

Although the instrument has been designed for optimum durability and trou-

ble-free operation, it must be handled with care. The instrument should not be

operated in an excessively dusty or dirty environment. Maintenance and clean-

ing recommendations can be found in the Maintenance Section of this manual.

The instrument operates safely under the following conditions:

•temperature range: Absolute 0–55°C (32–131°F); Recommended

16–30°C (61–86°F)

•ambient relative humidity: 15–50%

•pressure: 75kPa–106kPa

•mains voltage within ±10% of nominal

•vibrations in the calibration environment should be minimized

•altitude does not effect the performance or safety of the unit

4 Manual Rev. 952801 Hart Scientific

2 Specifications and Environmental Conditions

1502A Manual Rev. 952801 5

2 Specifications and Environmental Conditions

3 Safety Guidelines

•Operate the instrument in room temperatures between 16–30°C

(61–86°F) (recommended). Allow sufficient air circulation by leaving at

least 3 inches of space between the thermometer and nearby objects.

Note: Accuracy specifications apply within the recommended operating

temperature range. Accuracy limits are increased by a factor of the tem-

perature coefficient outside this range.

•The thermometer is a precision instrument. Although it has been designed

for optimum durability and trouble free operation, it must be handled with

care. The instrument should not be operated in wet, oily, dusty, or dirty en-

vironments.

•The instrument can measure extreme temperatures. Precautions must be

taken to prevent personal injury or damage to objects. Probes may be ex-

tremely hot or cold while connected to the thermometer and when re-

moved from the heat source. Cautiously handle probes to prevent

personal injury. Carefully place probes on a heat/cold resistant surface or

rack until they are at room temperature.

•Use only a grounded AC mains supply of the appropriate voltage to power

the instrument. The thermometer requires less than 1 amp at 115 VAC

(±10%), 50/60 Hz and 230 VAC (±10%), 50/60 Hz.

•Optional DC power of 10 to 14 V DC with 1 amp maximum.

•If a mains supply power fluctuation occurs, immediately turn off the instru-

ment. Power bumps from brown-outs and black-outs can possibly dam-

age the thermometer. Wait until the power has stabilized before

re-energizing the instrument.

1502A Manual Rev. 952801 7

3 Safety Guidelines

4 Quick Start

4.1 Unpacking

Unpack the thermometer carefully and inspect it for any damage that may

have occurred during shipment. If there is shipping damage, notify the carrier

immediately.

Verify that the following components are present:

•1502A Thermometer

•Extra Probe Connector

•Power Cord

•Manual

•Probe (optional—must be purchased separately)

•Battery Pack (optional—must be purchased separately)

4.2 Power

Your 1502A is configured for either 115 VAC (±10%) operation or 230 VAC

(±10%) operation. Be careful to only connect the 1502A to a mains supply of

the correct voltage. Otherwise, the instrument may be damaged. The required

voltage is indicated on the back of the 1502A. The 1502A may draw up to 10

VA. The IEC type power cord connects to the back of the 1502A. The cord

must be plugged in to a grounded outlet. The power switch is located at the

back of the 1502A.

When the 1502A is powered on, wait briefly while it initializes. It will then begin

measuring and displaying temperature.

Because of the quality of the components used in the 1502A, it exhibits nearly

negligible drift as it warms up. The warm-up drift is typically less than 5 ppm.

Nevertheless, to ensure the best accuracy and stability, you may want to allow

the 1502A to warm up for ten minutes before use.

Accurate measurement requires that the probe be connected properly to the

input and the correct probe characterization set.

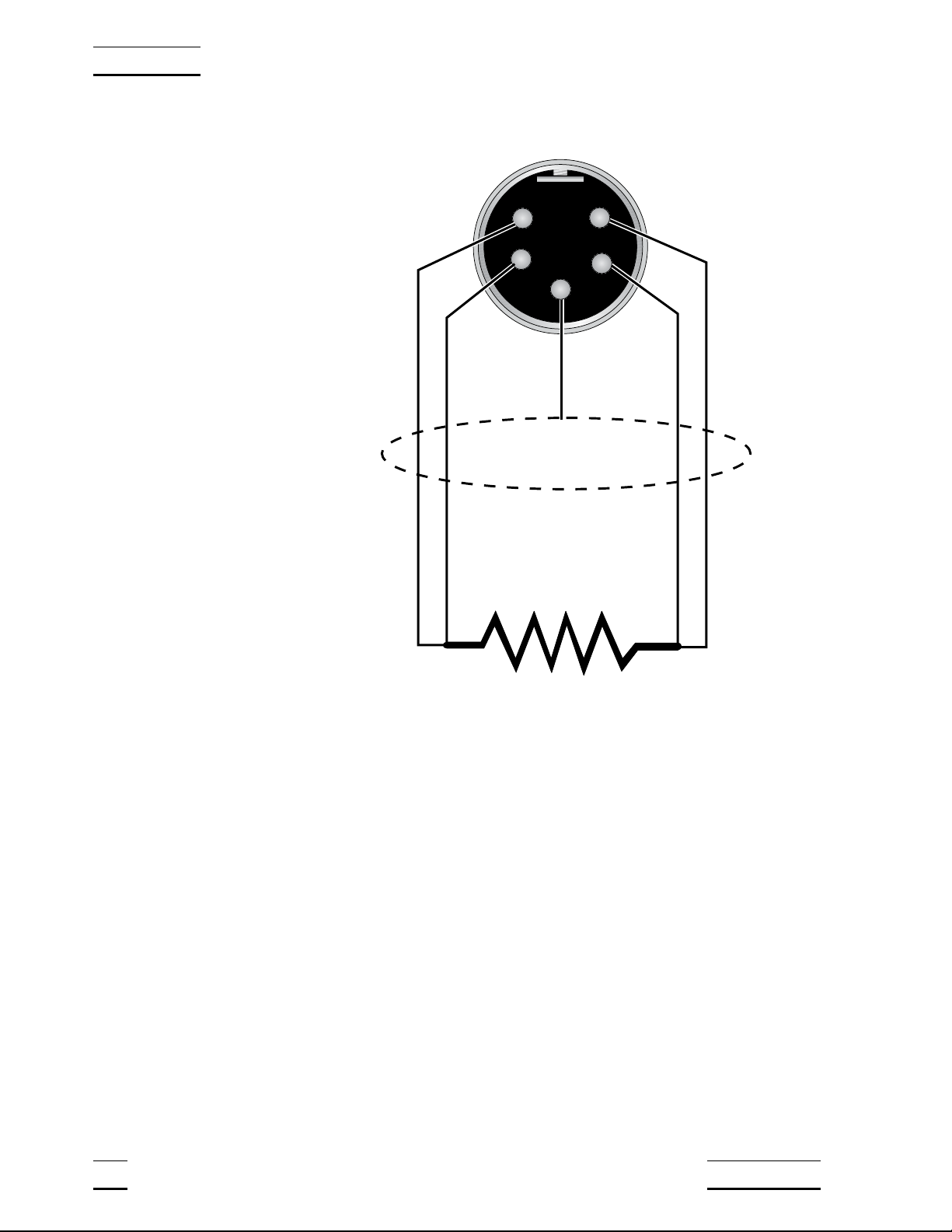

4.3 Connecting the Probe

The RTD or SPRT probe connects to the back of the 1502A using a five-pin

DIN plug. Figure 1 shows how a four-wire probe is wired to the five-pin DIN

connector. One pair of wires attaches to pins 1 and 2 and the other pair atta-

ches to pins 4 and 5. (Pins 1 and 5 source current and pins 2 and 4 sense the

potential.) If a shield wire is present it should be connected to pin 3.

A two-wire probe can also be used with the 1502A. It is connected by attach-

ing one wire to both pins 1 and 2 of the plug and the other wire to both pins 4

and 5. If a shield wire is present it should be connected to pin 3. Accuracy may

be significantly degraded using a two-wire connection because of lead resis-

tance.

1502A Manual Rev. 952801 9

4 Quick Start

4.4 DC Power Option

With the DC power option (Model 2502) installed the 1502A can be powered

from a 12 V battery or other 12 V DC power source. The DC power socket is

located on the rear panel of the 1502A above the AC power jack. The 1502A

accepts a 7/32 inch diameter, two-conductor DC power plug such as

Switchcraft® PN. 760. Observe the correct polarity as shown in Figure 2. The

outside conductor is positive and the inside is negative. The AC power switch

on the rear panel of the 1502A will not switch the DC power.

The optional Model 9313 Battery Pack, available from Hart Scientific, can be

used as a portable power source for the 1502A. It includes a 1.2 amp-hr 12V

sealed lead-acid battery, a DC power cord that plugs into the 1502A’s DC in-

put, a carrying bag, and a battery charger. The battery pack can provide four

to ten hours of operation with each charge depending on whether the power

saver feature is enabled (see Section 6.7).

10 Manual Rev. 952801 Hart Scientific

4 Quick Start

1

24

5

RTD Sensor

Probe Connector

3

Shield

Figure 1 Connecting a four-wire probe

To recharge the battery, disconnect the battery’s plug from the 1502A and plug

it into the mating connector from the battery charger. Attach the charger’s AC

plug into an AC supply of the proper voltage (normally 100 to 125V AC, 50/60

Hz; optionally 200 to 230V AC, 50/60 Hz.). The charger takes about six hours

to fully charge the battery. The charger will stop charging automatically when

the battery is full.

Certain precautions must be observed with the battery and charger. These de-

vices can present safety concerns if misused or damaged. To avoid the risk of

electric shock or fire do not use the charger outdoors or in a dusty, dirty, or wet

environment. If the cord, case, or plug of the charger is damaged in any way

discontinue its use immediately and have it replaced. Never disassemble the

charger. The battery may contain chemicals that are hazardous. To avoid the

risk of exposure to dangerous substances or explosion, immediately discon-

tinue use of the battery if it leaks or becomes damaged. Never allow the bat-

tery to be shorted, heated, punctured, dropped, or squashed. Store the battery

where it will not come into contact with metal or fluids that might short circuit

the battery and where it will be safe from excessive temperatures. When no

longer usable the battery must be recycled. The battery may be returned to the

seller for recycling. Do not dispose the battery in a landfill. Never dispose the

battery in fire as there is danger of explosion which may cause injury or prop-

erty damage.

1502A Manual Rev. 952801 11

4 Quick Start

+

–

Figure 2 12 V DC power source polarity

5 Parts and Controls

5.1 Front Panel Buttons

See Figure 3.

The front panel buttons are used to select units of measurement, access oper-

ating parameters, and alter operating parameters. The function of each button

is as follows:

C/Probe—This button selects units of degrees Celsius. In conjunction with the

Menu button, it selects the probe parameter menu.

F/Sample—This button selects units of degrees Fahrenheit. In conjunction

with the Menu button, it selects the sample parameter menu.

K/Comm—This button selects units of Kelvin. In conjunction with the Menu

button, it selects the communication parameter menu.

Ω/Exit (Cal)—This button selects resistance in ohms. While editing a parame-

ter, it cancels the immediate operation and skips to the next parameter. If the

Exit button is pressed for more than one-half second the menu is exited. In

conjunction with the Menu button, it selects the calibration parameter menu.

Menu/Enter—This button allows one of the unit/menu buttons to select a

menu. When editing a parameter, it accepts the new value and skips to the

next operation.

Land R—When editing a numeric parameter, these buttons move be-

tween digits. The selected digit flashes.

Uand D— When editing a parameter, these buttons increase or decrease

the value of the parameter or a selected digit.

1502A Manual Rev. 952801 13

5 Parts and Controls

1502 A

C

Probe

F

Comm

K

Sample

Ω

Exit

Menu

Enter

84.981 C

Figure 3 1502A Front Panel

5.2 Rear Panel

See Figure 4.

Serial Port - The DB-9 connector is for interfacing the thermometer to a com-

puter or terminal with serial RS-232 communications.

Probe Connector - At the rear of the thermometer is the probe connector. The

probe must be connected for operation.

Power Switch - The power switch is located on the rear of the thermometer.

The AC power switch turns the unit on and off. It does not control the DC

power.

Power Cord - At the rear of the calibrator is the removable power cord that

plugs into a standard 115 VAC grounded socket. (230 VAC optional)

DC Power - The DC power, located on the rear of the thermometer, powers

the unit immediately when connected.

IEEE-488 Port (optional) - The GPIB connector is for interfacing the thermom-

eter to a computer or terminal with IEEE-488 communications.

14 Manual Rev. 952801 Hart Scientific

5 Parts and Controls

RS-232

IEEE-488

PROBE

POWER

Made in USA

AMERICAN FORK · UTAH 84003 12V 1.0A

–+

l

0

Figure 4 1502A Back Panel

6 General Operation

This section explains basic operation of the 1502A Thermometer.

6.1 Selecting Units

Temperature can be displayed in degrees Celsius (indicated with “C”), degrees

Fahrenheit (indicated with “F”), or Kelvin (indicated with “A” for absolute). The

resistance of the sensor can also be displayed (indicated with “o” for ohms).

Simply press the appropriate unit button, C, F, K, or Ωto select the units.

6.2 Parameter Menus

Except for unit selection, all functions and operating parameters are accessed

and edited within the parameter menus. There are four menus: the Probe pa-

rameter menu, Sample parameter menu, Comm (communication) parameter

menu, and Cal (calibration) parameter menu. The arrangement of parameters

in the menus is shown in Figure 5 on page 16.

Menus are selected by pressing the Menu/Enter button followed by the appro-

priate menu selection button. The name of the menu will briefly appear on the

display. For example, the Probe menu is selected by pressing the Menu/Enter

button (“SEt?” appears on the display) followed by the C/Probe button

(“ProbE” appears). Selecting the Cal menu requires that you press the

Menu/Enter button then press the Ω/Exit button and hold it down for at least

one second.

The Probe menu contains parameters for selecting the probe characterization

and setting the characterization coefficients. These parameters are explained

in Section 6.4. The Sample menu contains parameters for setting the filter and

excitation current. These are explained in Sections 6.5 and 6.6. The Comm

menu contains communication parameters such as the serial baud rate or

IEEE-488 address. These are explained in Sections 7.1 and 7.2. The Cal

menu contains the calibration parameters. These are explained in Section 8.1.

6.3 Menu Lockout

All menus can be locked out to prevent inadvertently changing parameters. By

default, only the Cal menu is locked out. The lockout option is accessed in the

Cal menu (see Section 8.1 “Accessing the Calibration Parameters”).

If menus are locked out you must enter the correct password (“2051”) to gain

access. After you select the menu (see the previous section) the display will

show “PA= 0000” and allow you to change the number to the correct pass-

word. Use the Land Rbuttons to move between the password digits and

the Uand Dbuttons to increase or decrease the value of a digit. Press En-

ter when all the digits are correct. If the password is entered correctly the first

parameter in the menu will appear.

1502A Manual Rev. 952801 15

6 General Operation

16 Manual Rev. 952801 Hart Scientific

6 General Operation

Menu

Sample Comm (Cal)Probe

Set clockSet filterSet probe type Enter password

Set time stampSet currentSet coefficients Set menu lockout

Set baud rateSet power saver Set CAL0

Set sample periodTest conversion Set CAL 100

Set duplex Set CAL 400

Set linefeed Factory reset

Set GPIB address

Set GPIB EOS

11.23.30FI= 4Pr= t90 PA= 0000

ts= OFFCur= 1.0 LO=CaL

2400 bPS= OFF -0.0006

00.00.01100.0000 +0.0128

duP=FULL -0.0011

LF= ON rESEt?

Add= 22

E= LF

Press after changing a parameter

Press briefly to skip a parameter

Hold to exit the menu

Enter

Exit

Exit

Figure 5 Parameter Menu Structure

6.4 Selecting the Probe Characterization

Before the 1502A can measure temperature accurately it must know how to

calculate temperature from the resistance of the sensor. You must select a

conversion type and enter the proper characterization coefficients. There are

several temperature conversion algorithms available. The one to use depends

on the type of probe you are using and its calibration. The conversion algo-

rithms use coefficients that characterize the sensor. Coefficients are deter-

mined when the probe is calibrated. SPRTs and PRTs often use the ITS-90

algorithms and are provided with ITS-90 characterization coefficients.

6.4.1 Setting the Probe Characterization Type

The probe characterization type and characterization coefficients are set in the

Probe menu. Press the Menu button (“SEt?” appears), then the C/Probe but-

ton. The menu name, “ProbE”, will appear briefly then the characterization

type. The probe characterization types are indicated on the display as follows:

Pr= t90

ITS-90

Pr= rtd

Callendar-Van Dusen

Pr= t68

IPTS-68

Select the desired probe characterization type using the Uand Dbuttons

and pressing the Enter button. After the characterization type is selected the

characterization coefficients follow. The coefficients that appear depend on the

probe type that was selected.

6.4.2 Setting the Characterization Coefficients

Probe characterization coefficients are set within the Probe menu after select-

ing the probe characterization type. Each coefficient appears with the name of

a coefficient shown briefly followed by its value. For example,

A4

+4.336079

For some coefficients, you only need to set the digits in the number. Other co-

efficients also have a sign as shown above (positive sign appears as “+”). Use

the Land Rbuttons to move between the digits (and the sign). The se-

lected digit will flash. Use the Uand Dbuttons to change a digit. Once the

sign and digits are correct, press Enter to accept the number. If you decide to

cancel any changes you have made, you may do so by pressing the Ω/Exit

button. This will immediately skip to the next coefficient.

If the coefficient also requires an exponent, it will appear after setting the num-

ber as follows:

1502A Manual Rev. 952801 17

6 General Operation

E -04

Increase or decrease the exponent using the Uand Dbuttons. Once the ex-

ponent is correct, press Enter to accept it.

6.4.3 ITS-90 PRT and Coefficients

The ITS-90 option is for PRTs calibrated and characterized using the

Interna-

tional Temperature Scale of 1990

equations. The parameters that appear

when ITS-90 is selected are “R0.01", ”A", “b”, “C”, “d”, “A4", and ”b4". These

should be set with the corresponding values that appear on the calibration cer-

tificate for the PRT. The parameter “R0.01" takes the triple point of water resis-

tance, often labeled ”Rtpw" or “R(273.16K)” on the certificate. Parameters “A”,

“b”, “C”, and “d” take the a

n

, b

n

,c

n

, and d coefficients where

n

is a number

from 5 to 11. Parameters “A4" and ”b4" take the a4 and b4 coefficients or the

a5 and b5 coefficients on the certificate.

Any ITS-90 parameter of the 1502A

that does not have a corresponding coefficient on the PRT’s certificate must

be set to 0.

The following table shows which parameter to set for each of the coefficients

that may appear on the certificate. The examples that follow demonstrate how

to set the ITS-90 parameters for certain cases. (Note: If the certificate has two

sets of coefficients, one set for “zero-power” calibration and one set for 1 mA

calibration, use the coefficients for the 1 mA calibration.)

18 Manual Rev. 952801 Hart Scientific

6 General Operation

1502A ITS-90 Coefficient Certificate Value

A a5, a6, a7, a8, a9, a10, or a11

b b5, b6, b7, b8, or b9

C c6 or c7

dd

A4 a4 or a5

b4 b4 or b5

Table 1 Matching Certificate Values to 1502A ITS-90 Coefficients

Table of contents