5

EN RU

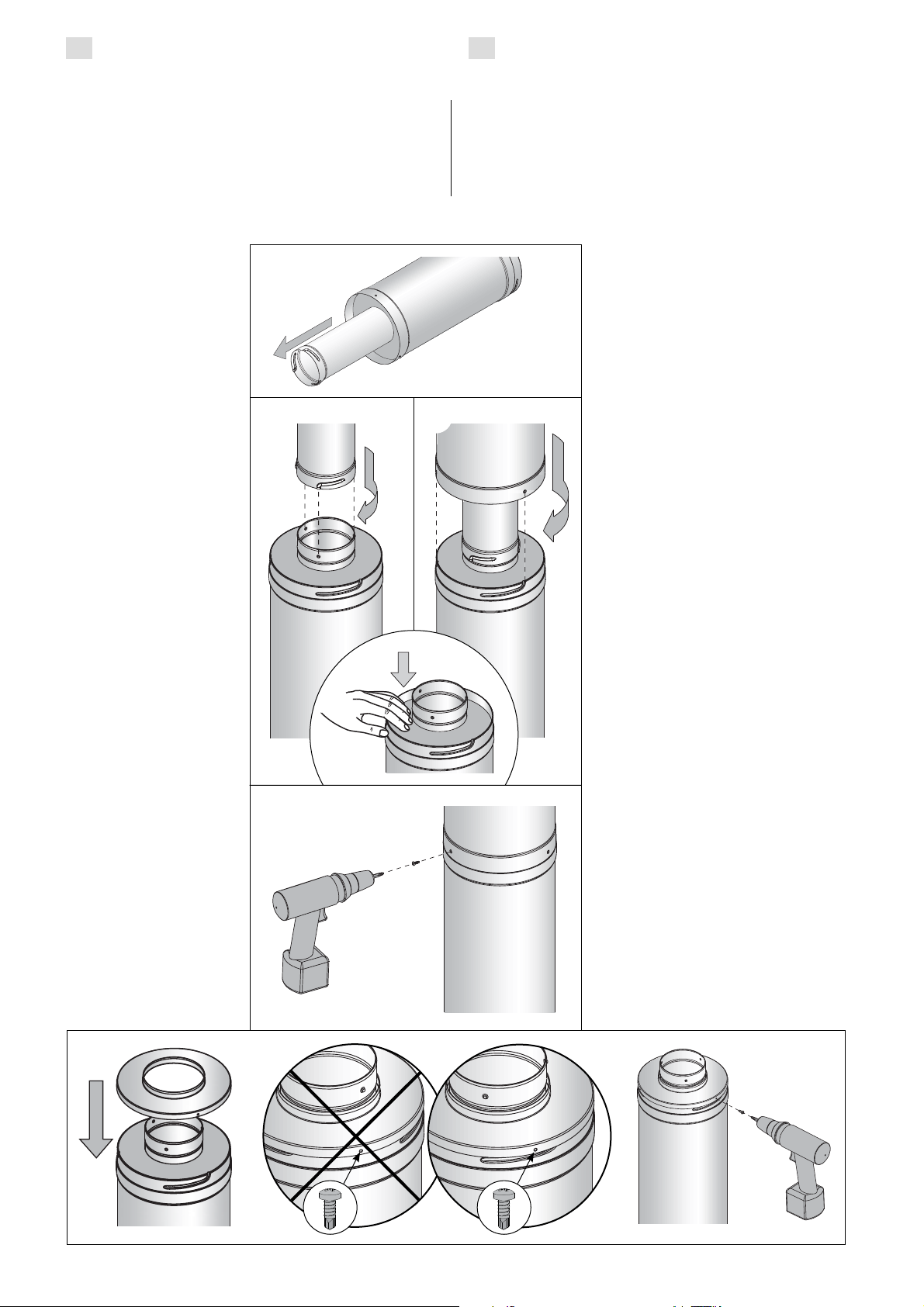

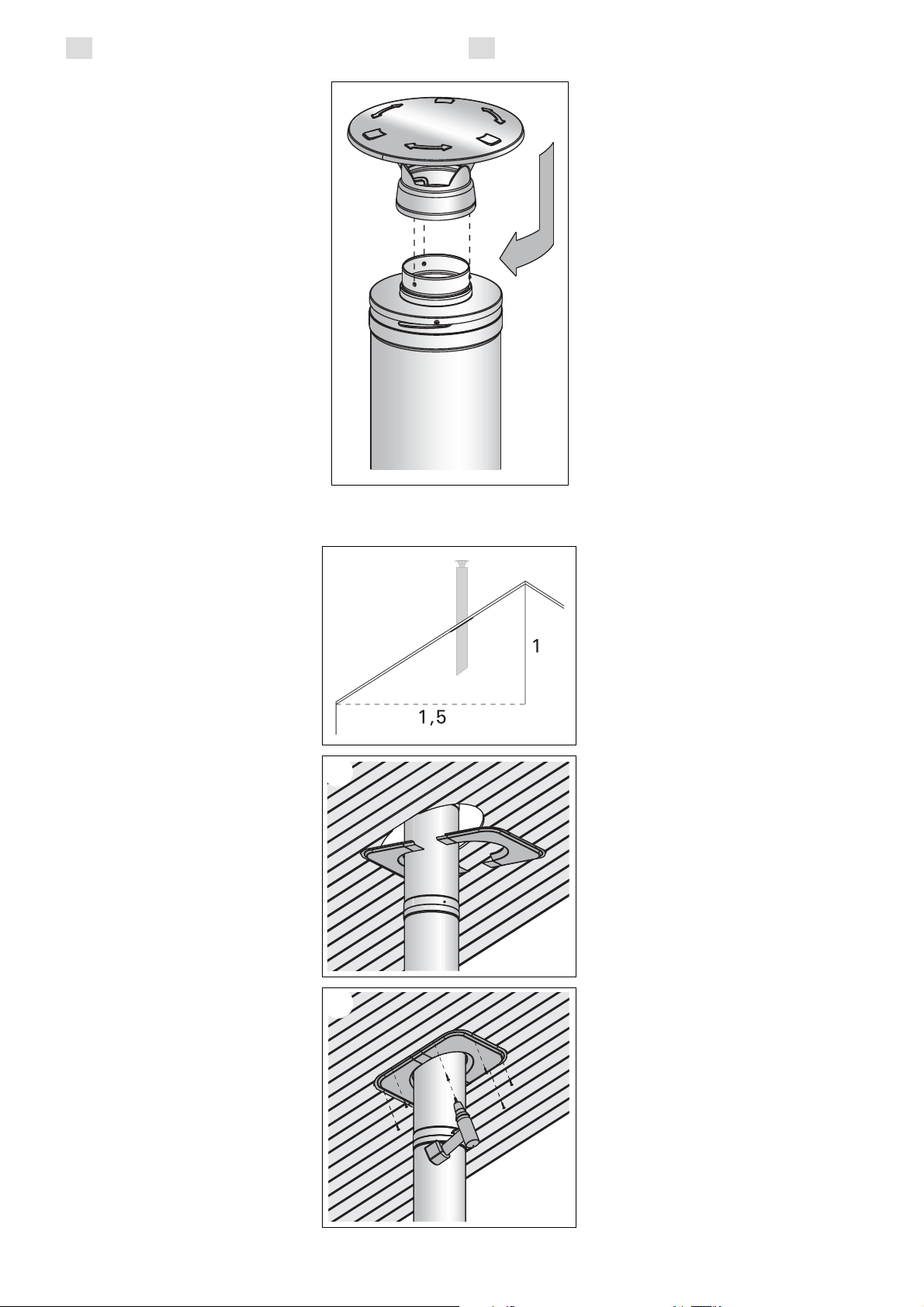

Figure 4.

Ðèñóíîê 4.

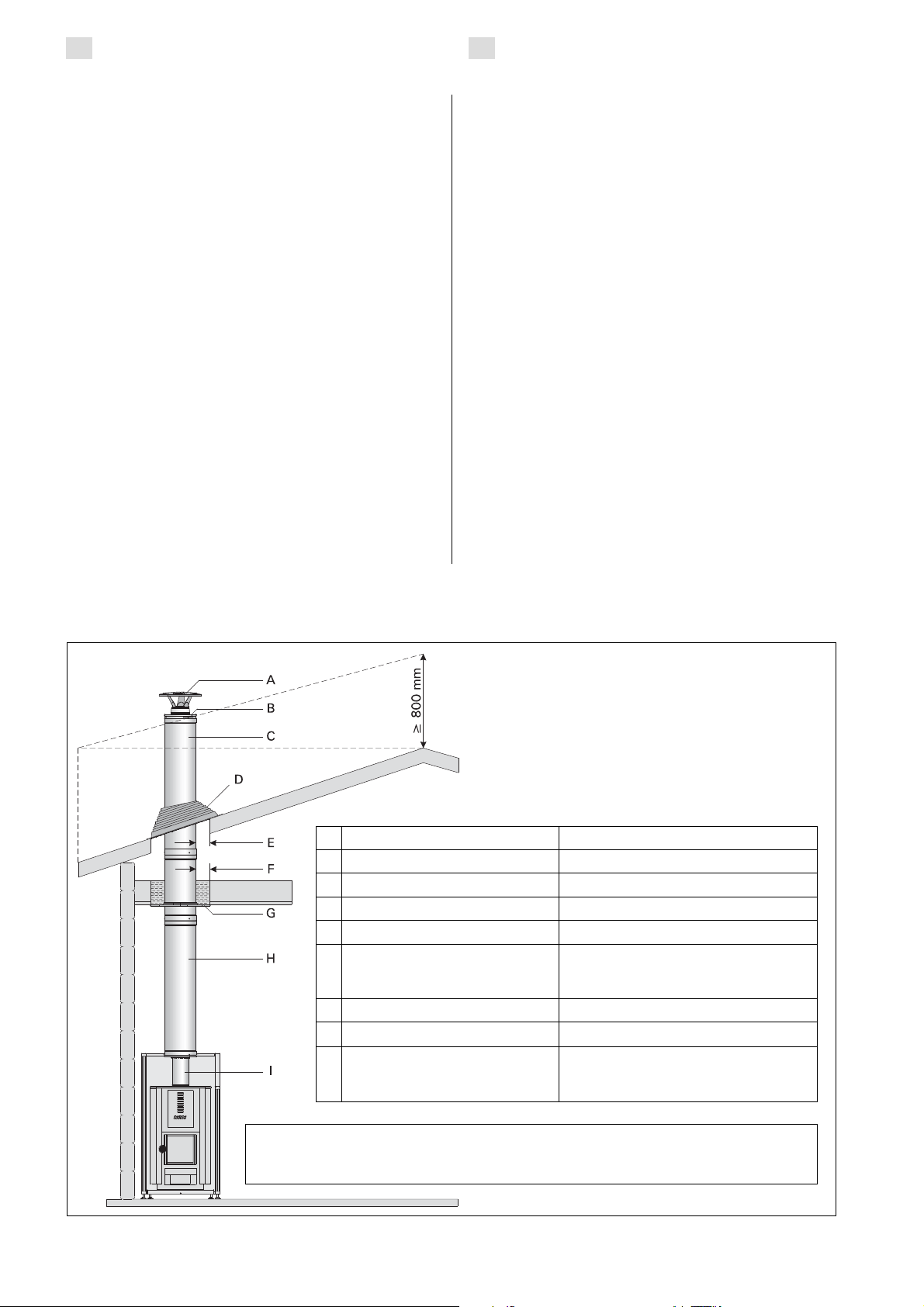

Figure 2. Examples of chimney heights required for fire safety regulations.

Ðèñóíîê 2. Ïðèìåðû òðåáîâàíèé ïîæàðíîé áåçîïàñíîñòè ê âûñîòå äûìîõîäà.

2. Protective distances

The protective distance between the inflammable

structures and the chimney outer casing must be

minimum 100 mm. In lead-through the chimney

and the roof structures have to be filled with fire-

resistance rated mineral wool. If the connecting

pipe in the forward end is of non-isolated

material, the protective distance from this pipe

to inflammable construction materials needs to

be 1000 mm. Furthermore, the isolated chimney

should be visible up to a minimum

of 430 mm (figure 3).

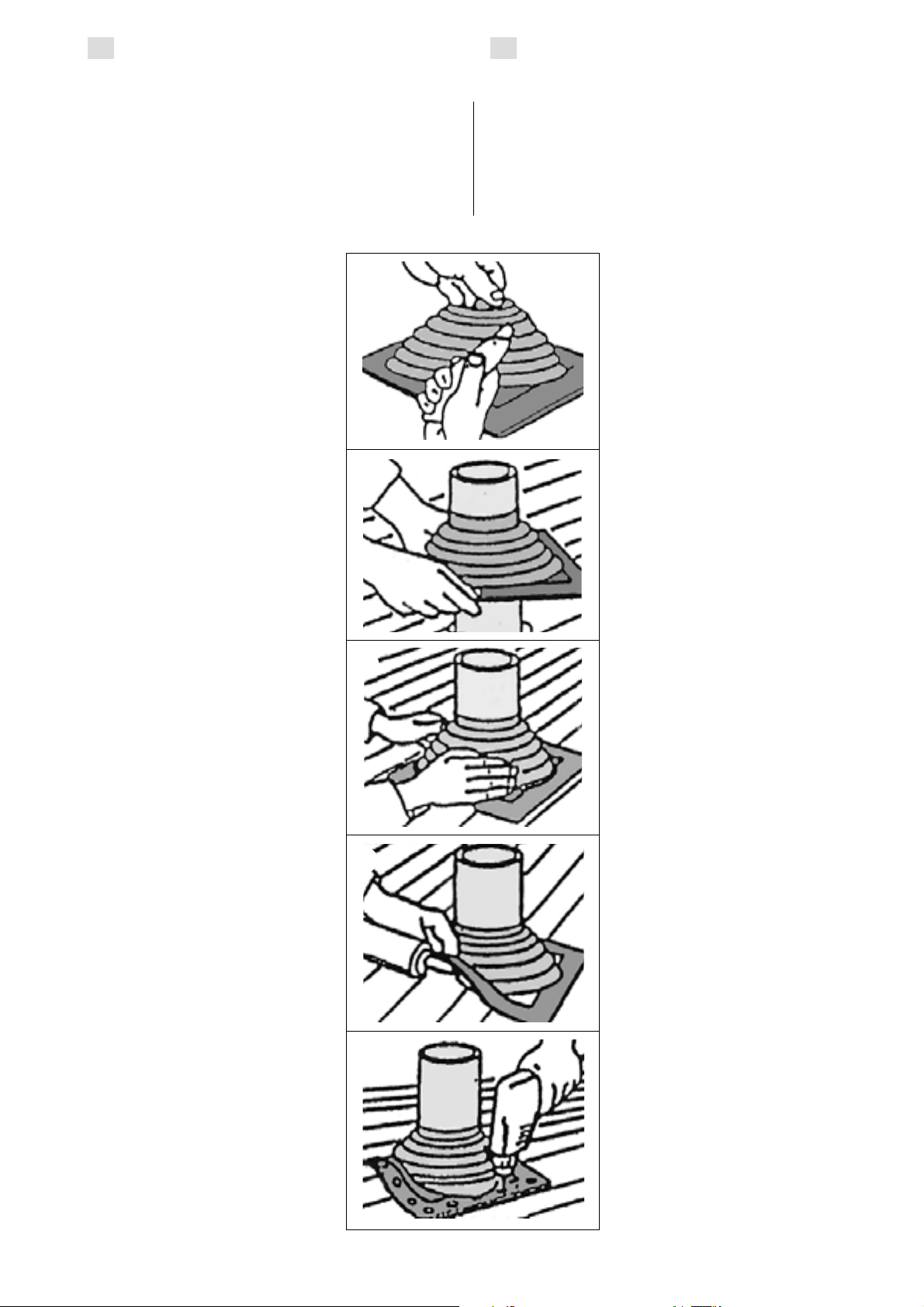

If the chimney is connected to a

sauna stove equipped with a pipe-

model water tank, the bare part of

the smoke pipe must be equipped

with a radiation cover (figure 4).

The water tank installation should

follow the protective distances

from the mounting instructions.

In case the protective distance

requirements for the furnace

are higher than for the chimney

the distance can be reduced

by installing non-flammable

protective plates. The protective

distance requirements are

specified in the installation

manual. A single flange halves the

protective distance and a double

flange to a quarter. Either a 7.0

mm non-flammable wallboard or a

minimum 1.0 mm metal sheet can

be used for such light protection.

The board or sheet gap from the

protected, inflammable material

must be minimum 30 mm and

the air circulation secured in

the gap through the lower and

upper end of the protecting

construction. If a double flange

protective plate is used, a 30 mm

gap should be constructed using

bushing manufactured out of non-

flammable materials allowing free

air circulation through the upper

and lower end of the plates.

More detailed instructions

available from the local fire

authorities.

2. Áåçîïàñíîå ðàññòîÿíèå

Áåçîïàñíîå ðàññòîÿíèå ìåæäó âîñïëàìåíÿþùèìèñÿ

êîíñòðóêöèÿìè è âíåøíåé ñòàëüíîé ðóáàøêîé

äûìîõîäà äîëæíî ñîñòàâëÿòü íå ìåíåå 100 ìì. Ïðè

ïðîâåäåíèè ïðîõîäà ðàññòîÿíèå ìåæäó äûìîõîäîì

è êîíñòðóêöèÿìè êðûøè äîëæíî áûòü çàïîëíåíî

îãíåñòîéêîé ìèíåðàëüíîé âàòîé. Åñëè â íà÷àëüíîé

÷àñòè äûìîõîäà áûëà èñïîëüçîâàíà ïðîìåæóòî÷íàÿ

òðóáà áåç èçîëÿöèè, áåçîïàñíîå ðàññòîÿíèå ìåæäó

äàííûì ó÷àñòêîì äûìîõîäà è âîñïëàìåíÿþùèìèñÿ

êîíñòðóêöèÿìè, ñîãëàñíî òðåáîâàíèÿì

ïîæàðíîé áåçîïàñíîñòè, âîçðàñòàåò äî 1000

ìì. Íåîáõîäèìî ó÷èòûâàòü, ÷òî â ïîìåùåíèè

ó÷àñòîê âèäèìîé èçîëèðîâàííîé òðóáû

äîëæåí ñîñòàâëÿòü íå ìåíåå 430 ìì (ðèñ. 3).

Åñëè äûìîõîä ïîäñîåäèíÿåòñÿ ê êàìåíêå,

îñíàùåííîé âîäîíàãðåâàòåëåì òðóáíîãî

òèïà, òî íåèçîëèðîâàííóþ ÷àñòü âíóòðåííåé

òðóáû íåîáõîäèìî çàùèòèòü ýêðàíîì

òåïëîâîãî èçëó÷åíèÿ (ðèñ. 4). Ïðè ìîíòàæå

ðåçåðâóàðà äëÿ âîäû íåîáõîäèìî ó÷èòûâàòü

òðåáîâàíèÿ ê áåçîïàñíûì ðàññòîÿíèÿì.

Åñëè òðåáîâàíèÿ ê áåçîïàñíîìó ðàññòîÿíèþ

òîïêè âûøå, ÷åì ó äûìîõîäà, òî áåçîïàñíîå

ðàññòîÿíèå ìîæíî óìåíüøèòü ñ ïîìîùüþ

çàùèòíîé ïëàñòèíû, èçãîòîâëåííîé èç

íåãîðþ÷èõ ìàòåðèàëîâ. Òðåáîâàíèÿ ê

áåçîïàñíûì ðàññòîÿíèÿì òîïêè óêàçàíû

â èíñòðóêöèè ïî åå ìîíòàæó. Îäèíàðíàÿ

çàùèòà ñîêðàùàåò áåçîïàñíîå ðàññòîÿíèå

âïîëîâèíó, à äâîéíàÿ çàùèòà – äî îäíîé

÷åòâåðòîé ÷àñòè. Îäèíàðíóþ çàùèòó ìîæíî

èçãîòîâèòü èç íåãîðþ÷åãî ñòðîèòåëüíîãî

ëèñòà, ïîäõîäÿùåãî äëÿ ýòèõ öåëåé,

òîëùèíîé íå ìåíåå 7,0 ìì è ìåòàëëè÷åñêîãî

ëèñòà òîëùèíîé íå ìåíåå 1,0 ìì. Ìåæäó

âîñïëàìåíÿþùèìñÿ ìàòåðèàëîì è çàùèòíûì

ýëåìåíòîì íåîáõîäèìî îñòàâèòü çàçîð íå

ìåíåå 30 ìì, îáåñïå÷èâàþùèé ñâîáîäíóþ

öèðêóëÿöèþ âîçäóõà ìåæäó âåðõíèìè è

íèæíèìè ïëàñòèíàìè çàùèòíîãî ýëåìåíòà.

Ïðè èñïîëüçîâàíèè äâóõñëîéíîé çàùèòû

ìåæäó ëèñòàìè íåîáõîäèìî, ñ ïîìîùüþ,

íàïðèìåð, ðàñïîðíûõ âòóëîê èç íåãîðþ÷åãî

ìàòåðèàëà, îñòàâèòü çàçîð íå ìåíåå 30 ìì,

îáåñïå÷èâàþùèé ñâîáîäíóþ öèðêóëÿöèþ

âîçäóõà ìåæäó îáåèìè ïëàñòèíàìè çàùèòíîãî

ýëåìåíòà.

Çà áîëåå ïîäðîáíûìè èíñòðóêöèÿìè ìîæíî

îáðàòèòüñÿ â ìåñòíûå îðãàíû ïîæàðíîé

áåçîïàñíîñòè.

Radiation cover

Çàùèòà îò òåïëîâîãî

èçëó÷åíèÿ

Figure 3.

Ðèñóíîê 3.

min. 430 mm

ìèí. 430 ìì