HARWI HVS User manual

--1--

MANUAL

HVS

Harwi Holland BV

Lage Dijk 28

5705 BZ Helmond

the Netherlands

Tel. 31 (0)492 543355

Fax 31 (0)492 522305

--2--

--3--

APPLIANCE

The saw bench type HVS is only to be used

for cutting wood and wood-like materials.

The cutting of other materials is not

allowed.

Maximum panel sizes are:

Height: 120 mm

Between saw-blade and fence: 760 mm

Length (not supported): 1000 mm

Cutting of material, which needs removal of

protections, is not allowed.

All other appliances except for the above

are improper use of the machine and

therefore prohibited. The producer cannot

be held responsible for damage as a result

of improper use. Damage will be recovered

from the user.

Proper use of the machine also implicates

following the instructions of the

manufacturer concerning use, maintenance

safety, replacing spares and electrics etc.

The machine may not be operated, used or

maintained by persons not acquainted with

the risks of the machine.

Permission for operating, using and

maintaining the machine have to be clearly

described by a person or persons

responsible within the organisation.

Maintenance has to be performed by the

manufacturer or customer service.

One has to be informed about and comply

with the country’s safety regulations.

Only original Harwi parts are to be used,

except the saw-blade. We cannot give

warranty or be held responsible for damage

caused by using non-original Harwi parts.

The manufacturer cannot be held

responsible for damage caused by changes

made to the machine by the user.

REMAINING RISKS

If the machine is used completely

according to all safety regulations there

still will remain some risks.

- Touching of the saw-blade

- Touching of the saw-blade when the

guard is removed.

- Breaking of the saw-blade or parts of it

hurtling out of the guard.

- Touching of parts under voltage while

junction box or switch is opened.

- Damage to the hearing by constant use

of the machine without ear protection.

- Throw out of harmful dusts or vapours

by using a dust extractor with bad

performance of no dust extractor at

all.

--4--

SAFETY REGULATIONS

Harwi Holland B.V. has bestowed great care

on compiling this manual.

Before operating the machine read the

complete manual carefully. Persons under

the age of 18 are not allowed to work on or

with the circular sawing machine, except for

a training program on a legal basis. The

machine may only be operated by educated

personnel or under supervision of educated

personnel.

To avoid touching with rotating saw-blades

make sure that:

- Clothing fits tightly to the body

- Work with closed fingers

- No rings or jewelry are worn

- A hairnet is used by long hair

Be careful when changing saw-blades. They

are sharp and cause injuries.

Do not remove woodchips when the blade

is running. Stop the machine first. Broken

saw-blades or deformed blades are not to

be used. Neither are HSS blades.

The applied saw-blade is to be used and

sharpened according to the directions of the

manufacturer. Sharpening only by

competent craftsmen. Stick to the max.

admissible r.p.m. mentioned on the blade.

Preferably use noise reduced saw-blades.

When cutting long pieces of wood take care

of support of the material. The safety guard

and other safety devices may not be

removed or put out of order. The riving

knife has to be used all the time and

adjusted correctly.

Mounting or repairs to the machine may

only be performed when the machine

cannot be switched on. Pull out the plug or

secure the main switch with a padlock.

On the lid of the dust collector a safety

door switch is mounted. This switch avoids

activating the machine when changing the

saw-blade or removing wood chips.

Repairs to the electricity supply are only to

be executed by skilled craftsmen.

When leaving the working area make sure

that the machine cannot be switched on

by incompetent persons. It is obligatory to

wear dust-mask, ear protection and safety

glasses.

Take care of a clean working area. The

machine has to be lighted. When using

strip lighting take into account the

stroboscopic effect. A rotating saw-blade

seems to be standing still.

--5--

GENERAL INFORMATION

MANUFACTURER

HARWI Holland B.V.

Lage dijk 28

5705 BZ Helmond Nederland

Tel: 04920 - 4 33 55

Fax: 04920 - 2 23 05

MACHINE

Building site machine

Type: HVS

Machine number:.................... (at the guiding strips of the height adjustment)

Manufactured:............................

EU DECLARATION OF CONFORMITY FOR MACHINERY

(according to Annex II A of the Machinery Directive)

We HARWI Holland B.V. Lage Dijk 28, 5705 BZ Helmond, the Netherlands herewith declare, on

our own responsibility, that the product:

HARWI BUILDING SITE MACHINE TYPE HVS.............. , MACHINE NUMBER..........................,

which this declaration refers to, is in conformity with:

Machinery Directive 89/392/EEG, 91/368/EEG.

In accordance with obligations of appendix 4 of the machine directive towards

TNO Certification, Laan van Westenenk501, Apeldoorn, Nederland.

EU type investigation number: 95 MI/01363/WAL

R. Visser

--6--

TECHNICAL SPECIFICATIONS

MEASURES AND WEIGHT

Height of cut mm 0-120

Width of cut mm 650

Saw-blade diameter mm Ø 400

Saw-blade bore mm Ø 30

Angle adjustment 0-45º

Table measures mm 945*715

Table height mm 850

Motor power kW 3

hp 4

Voltage V 380

Speed rpm 2800

Weight kg 120

NOISE INFORMATION

Used saw-blade: Leuco proline 101420/10005 ∅400 Z=28 d=30.

A-weighed Equivalent Continuous Noise Pressure

Idle dB(A) :80.7 dB(A)

Loaded dB(A) :83.3 dB(A)

Measuring performed according to DIN 45635 part 1659. Measured when cutting soft wood

thickness 75 mm, length 1.4 meter.

Safe deviation can be approx. 3 db(A).

The above mentioned values are radiated noise pressures and not necessarily noise pressures

to work safely with this machine. Supplementary measures for ear protection can be

necessary. The following can be of influence:

duration of operations

working area

other noises

Maximum value may vary per country. Above information can be used for better valuation of

dangers and risks subsequent to using this machine.

--7--

SETTING UP THE MACHINE

MOVING

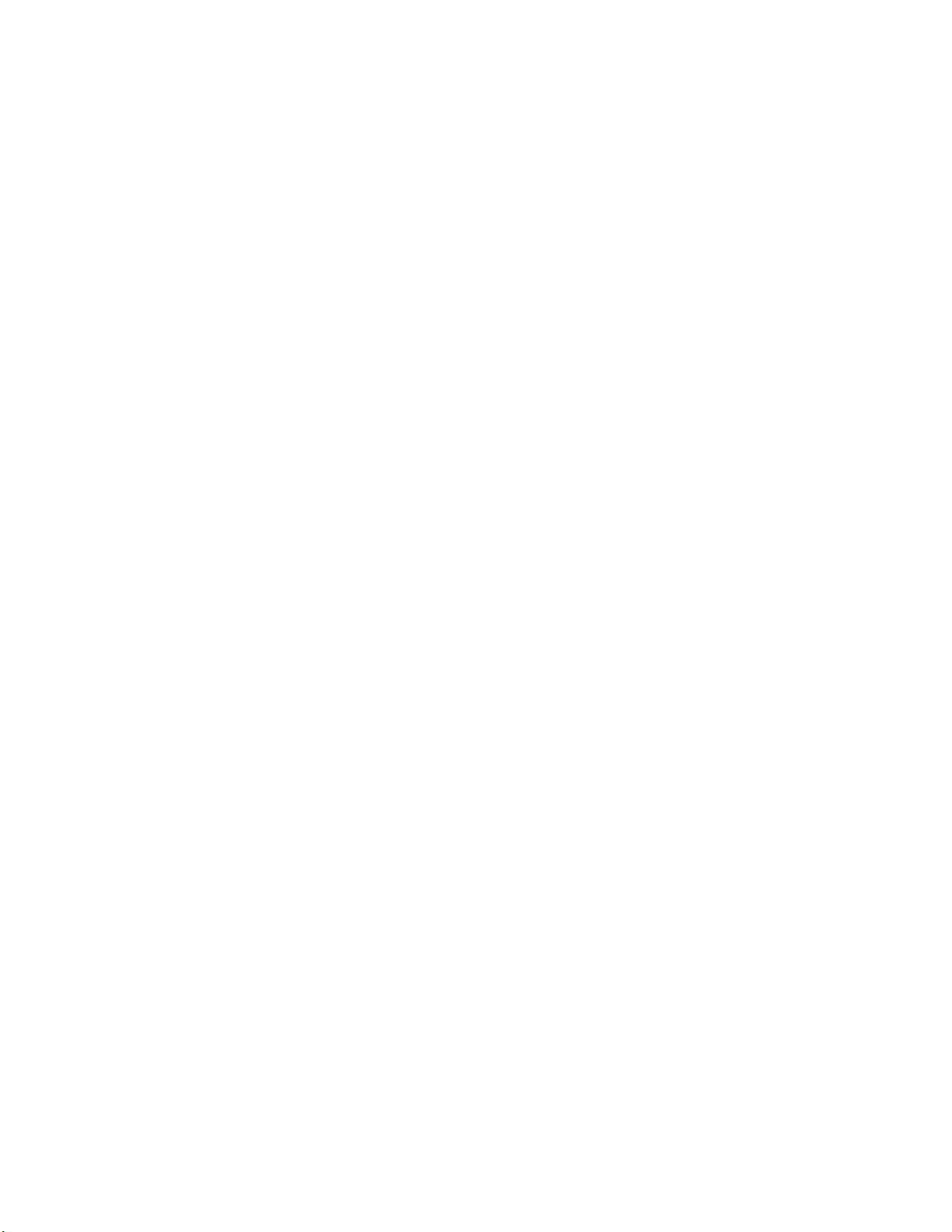

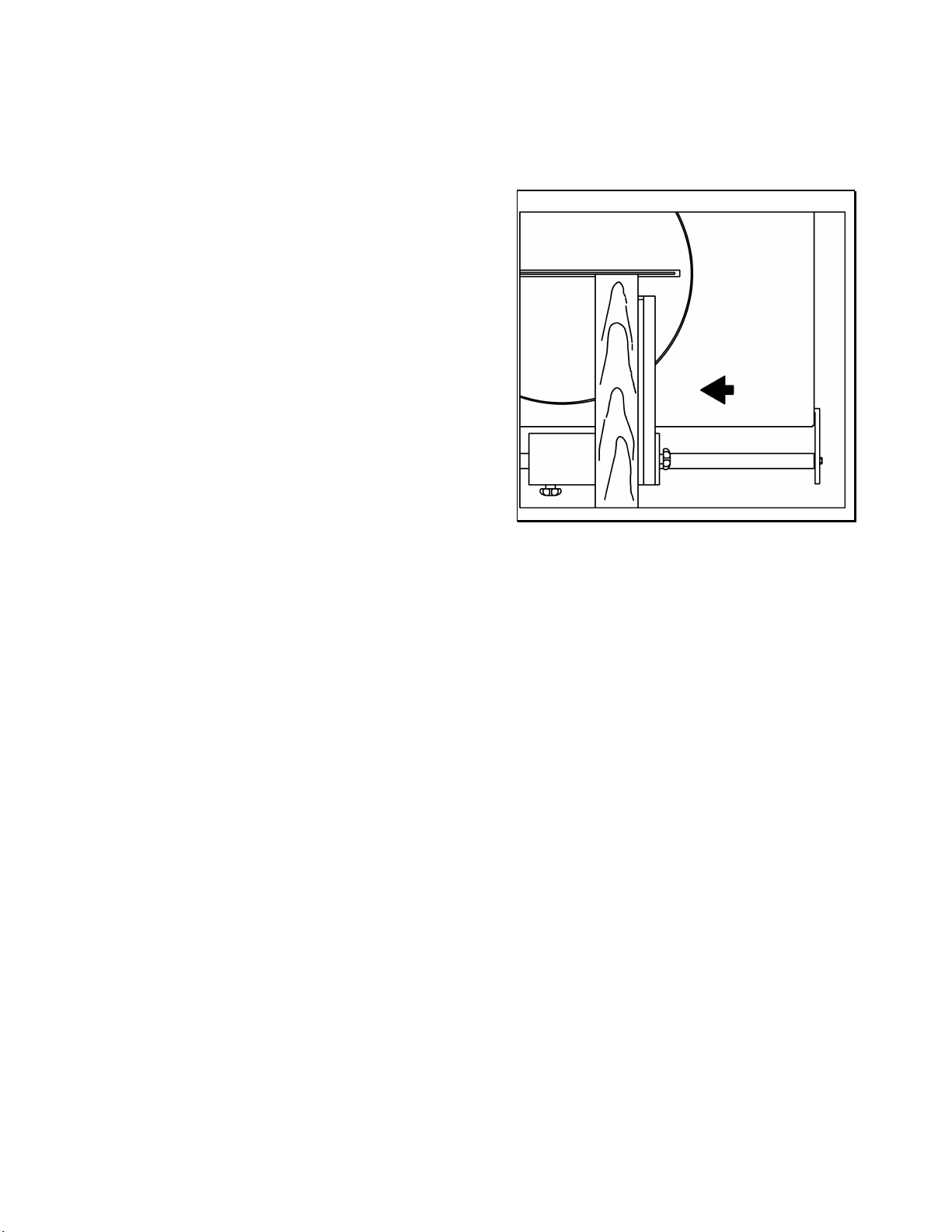

The machine can easily be moved by two

persons. Turnable grips are mounted at the

sides of the frame (fig. 1).

If the machine needs to be moved with a

crane, adjust the strops to the snap hooks

welded to each leg of the machine (fig. 2).

Also the machine can be easily transported

with a forklift truck (fig. 3).

INSTALLING THE MACHINE

The machine has to be put on a solid floor,

which has to be flat, dry and not slippery.

DUST EXTRACTION

The machine has to be connected to a dust

extraction. Connection for dust extracting

hose of 80 mm. The extracting capacity has

to be calculated in such a way that a

minimum air speed of 20 m/s is reached at

the connection. Air speed is 1500 m3 at a

depression bigger than 450 Pa. Preferably

simultaneously switched on with the

machine.

--8--

CONNECTING THE ELECTRIC SUPPLY

CONNECTING THE MACHINE

400v phase

1 Take a 5 core earthed cable suitable for

the power mentioned on the

identification plate.

2 Push female plug into CE-switch box of

the main switch box (fig. 4).

3 Connect to the mains supply.

Notice: use cartridges of minimum 16

ampere.

Notice: If you leave the machine

unattended, disconnect the machine and

lock it for instance with a padlock.

--9--

DIRECTION OF SPINDLE ROTATION

Open the lid of the saw guard and remove

the nut, the flanges and the saw-blade (see

chapter CHANGING THE SAW-BLADE)

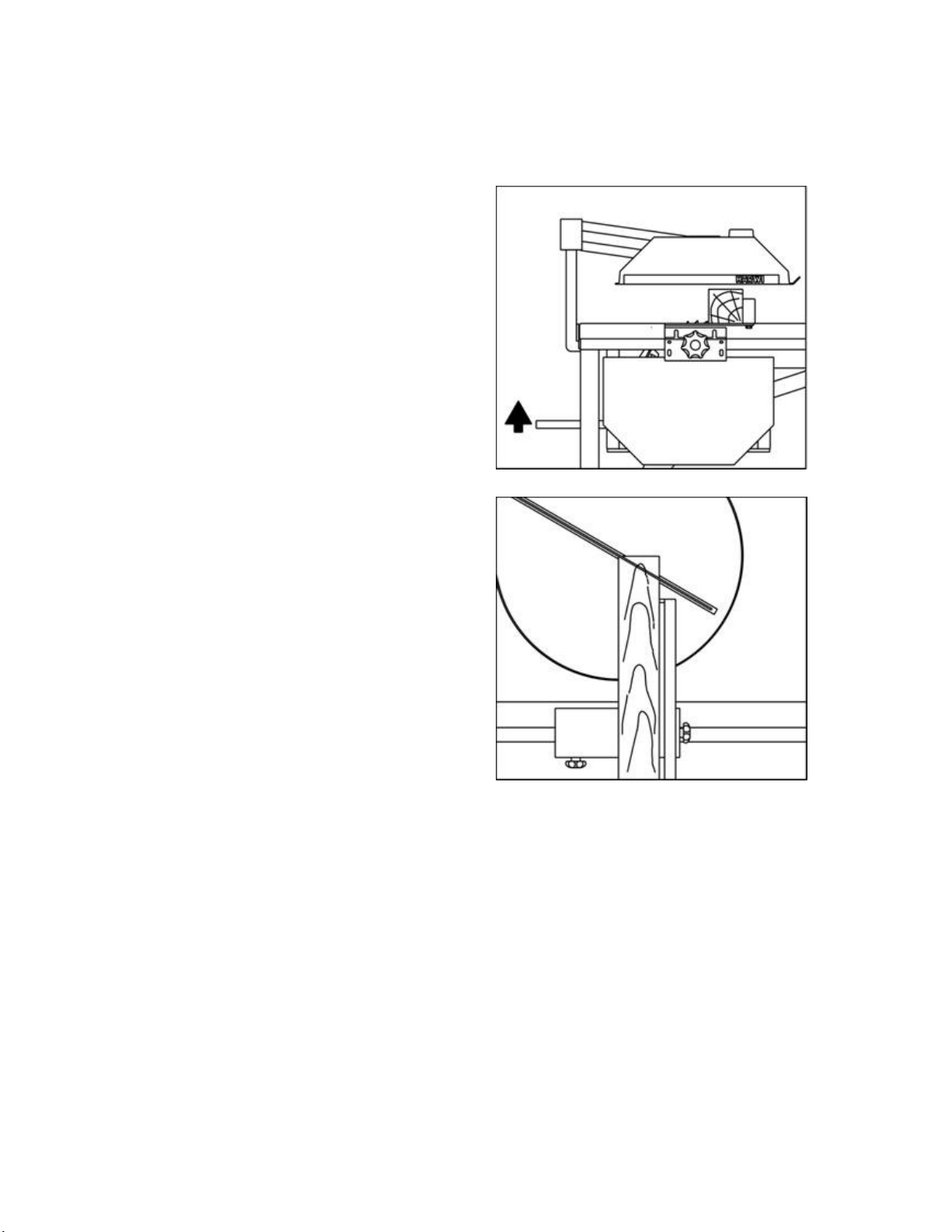

Put the motor in the highest position. And

close the lid.

PROPER DIRECTION IS

CLOCKWISE (looking from the spindle to

the motor housing (fig. 5).

1 Switch motor on and off.

2 Check if direction is clockwise.

3 Assemble saw-blade, flanges and nut

(see chapter CHANGING THE SAW-

BLADE).

WRONG DIRECTION IS ANTI

CLOCKWISE (looking from the spindle to

the motor housing)

1 Switch motor on and off.

2 Direction is anti clockwise.

3 Disconnect the mains supply.

4 Open the switch box.

5 Interchange two phases.

6 Close the switch box.

7 Connect the mains supply.

8 Check rotation again before mounting

the saw-blade.

9 Assemble saw-blade, flanges and nut.

10 Close the lid of the saw-guard.

--10--

CHANGING THE SAW-BLADE

Notice: See to it that when changing the

saw-blade the machine cannot be switched

on. Disconnect the plug.

Noise reduced saw-blades are preferred.

Use the proper saw-blade. Enquiries at your

supplier or the manufacturer.

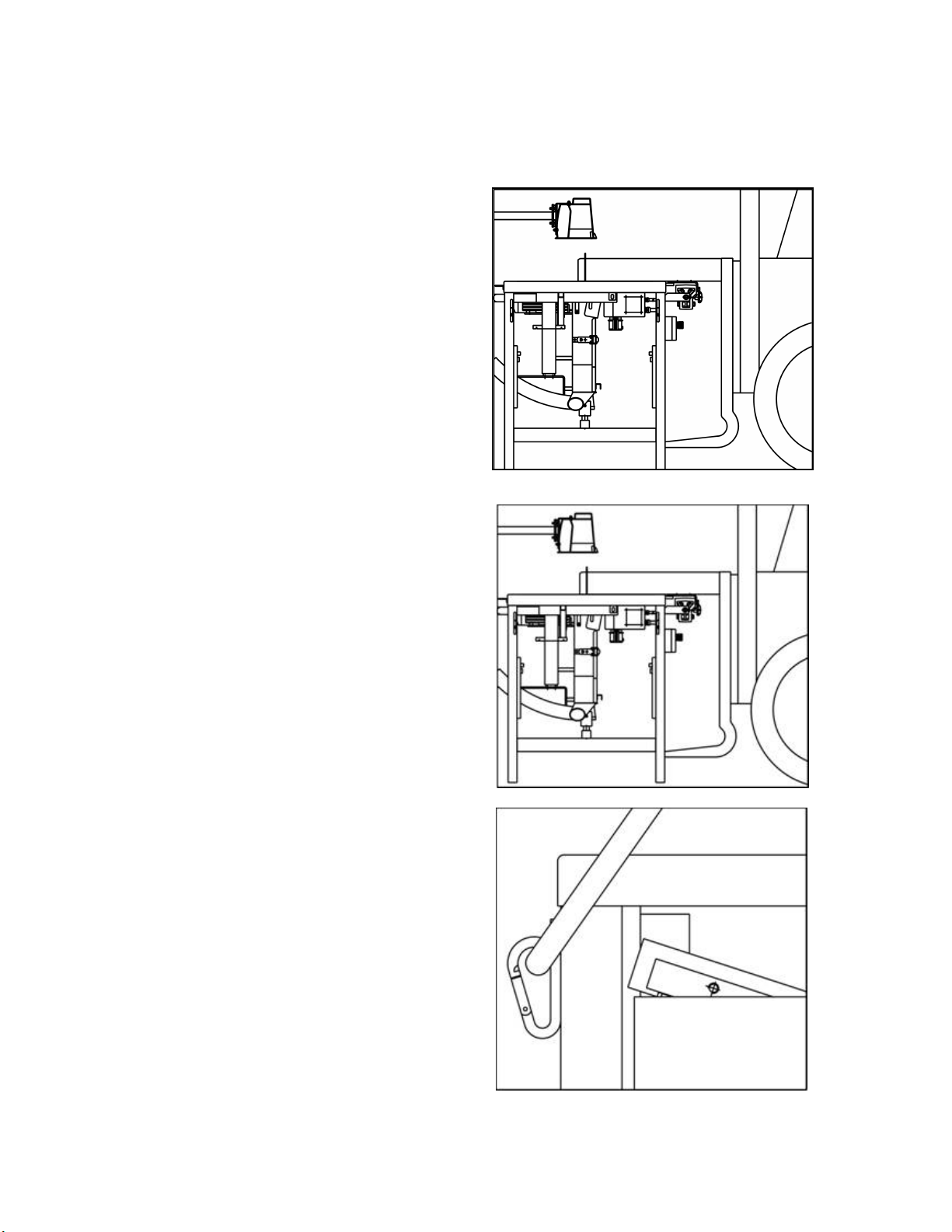

1 Open the saw-guard.

2 Block the saw-blade by putting an 8 mm

allen key in the spindle (fig. 6).

3 Loosen the nut of the spindle with the

30 mm flat spanner clockwise.

4 Remove the front flange.

5 Remove the saw-blade.

6 Assemble new saw-blade, flange and nut

in reversed order.

Notice: direction is clockwise.

7 Check position and thickness of the

riving knife.

8 Close the lid of the saw-guard.

Sharpening of the saw-blade has to be

performed by skilled craftsmen

--11--

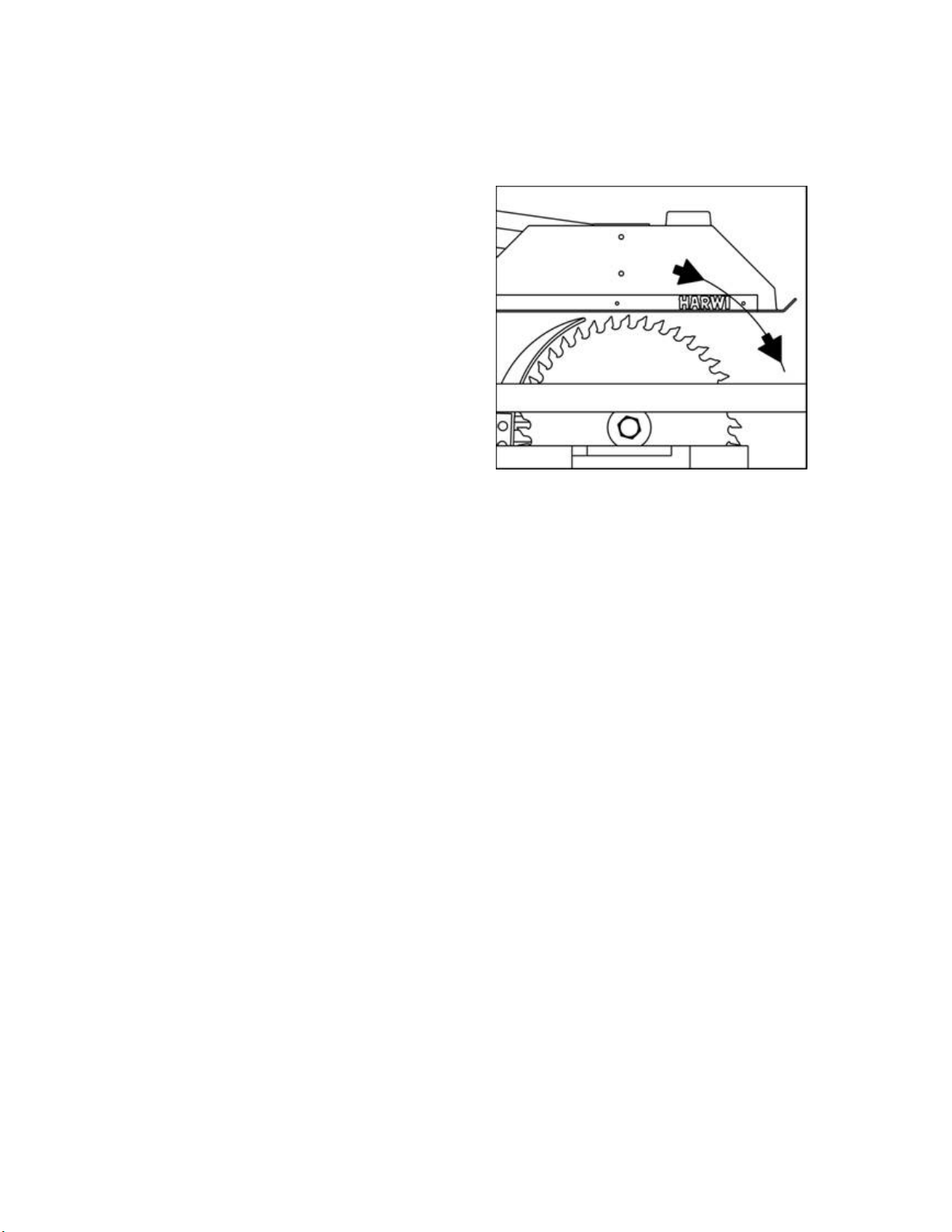

ADJUSTING THE RIVING KNIFE

Security

Check the thickness and dimensions of the

riving knife. The riving knife has to be

thicker than the mother blade but thinner

that the teeth of the saw-blade.

1 Disconnect the machine.

2 Put the saw-blade in the highest

position.

3 Open the lid of the saw-guard.

4 Slightly loosen the nut of the riving

knife.

5 Adjust the riving knife in such a way that

the distance of the inner circle and the

teeth of the saw-blade which rise above

the table top, is max. 3 mm. The highest

point of the riving knife has to be 3 to 5

mm below the highest point of the saw-

teeth (fig. 7).

6 Tighten the nut of the riving knife firmly

7 Close the lid of the saw-guard..

8 Connect to the mains supply.

--12--

OPERATING THE MACHINE

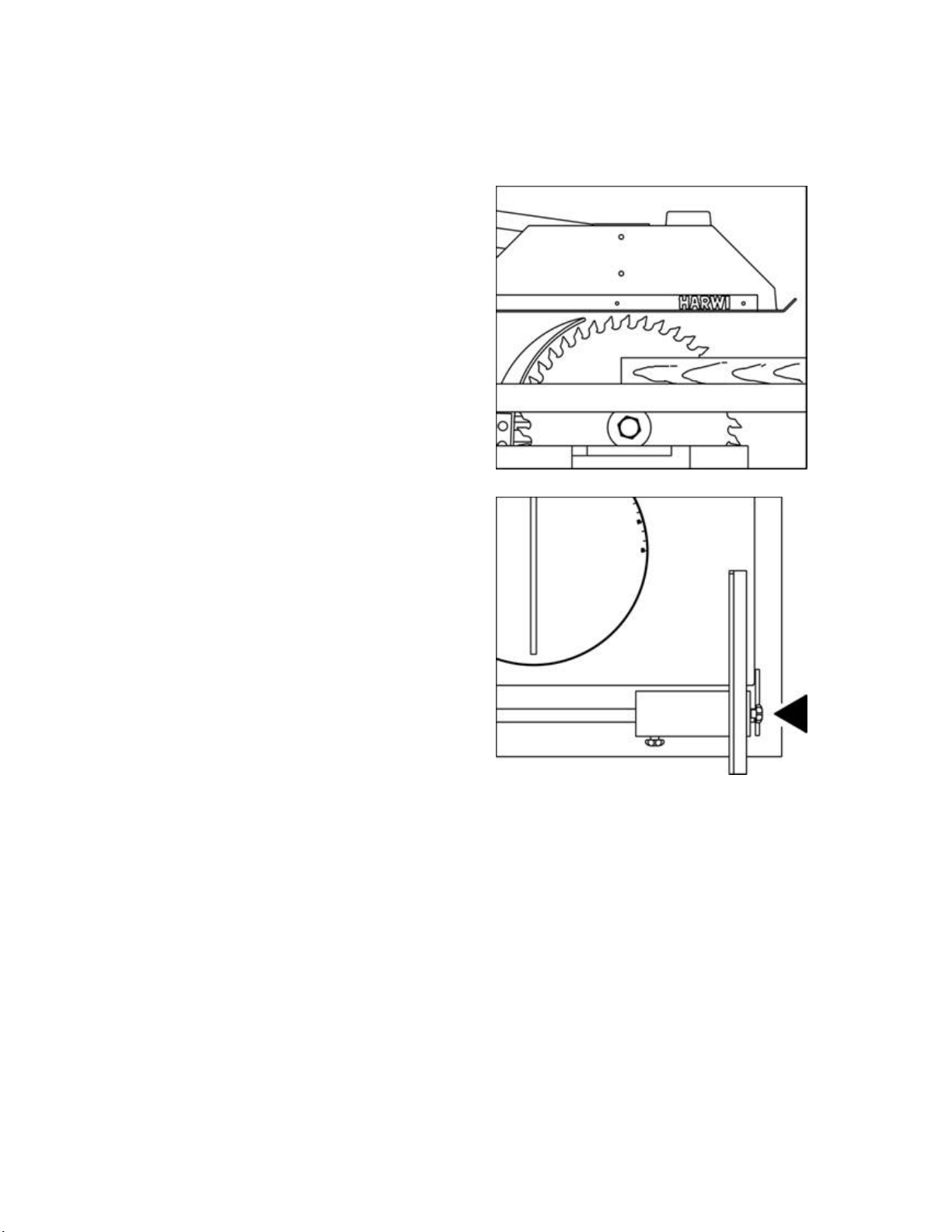

RIPPING

SAFETY

When ripping solid wood, put het saw-

blade as high as possible (fig. 8).

The sub-fence max. 10 mm pas the point

where the blade cuts the wood at full

height.

Adjusting the sub-fence properly prevents

the return shock of the wood or a part of

it.

Good support of the parts to be cut or

already cut is necessary.

When cutting small wood use a pushing

stick.

Adjusting the saw-guard.

1 Adjust the rip fence with the sub-fence

at the desired measure (fig. 9).

2 Check if the saw-blade can rotate freely.

3 Switch on the motor.

4 After cutting switch off the motor

immediately.

5 Remove the material after the saw-blade

has stopped.

Notice: When cutting small wood use a

pushing stick (fig. 10).

Notice: If the saw-blade stops because of

clamping of the wood, switch off the motor.

Hold the piece of wood tightly.

Notice: Never stand in the line of the saw-

blade. In case of a return shock you might

get hit.

--13--

OPERATING THE MACHINE

MITRING WITH THE MITRE

FENCE

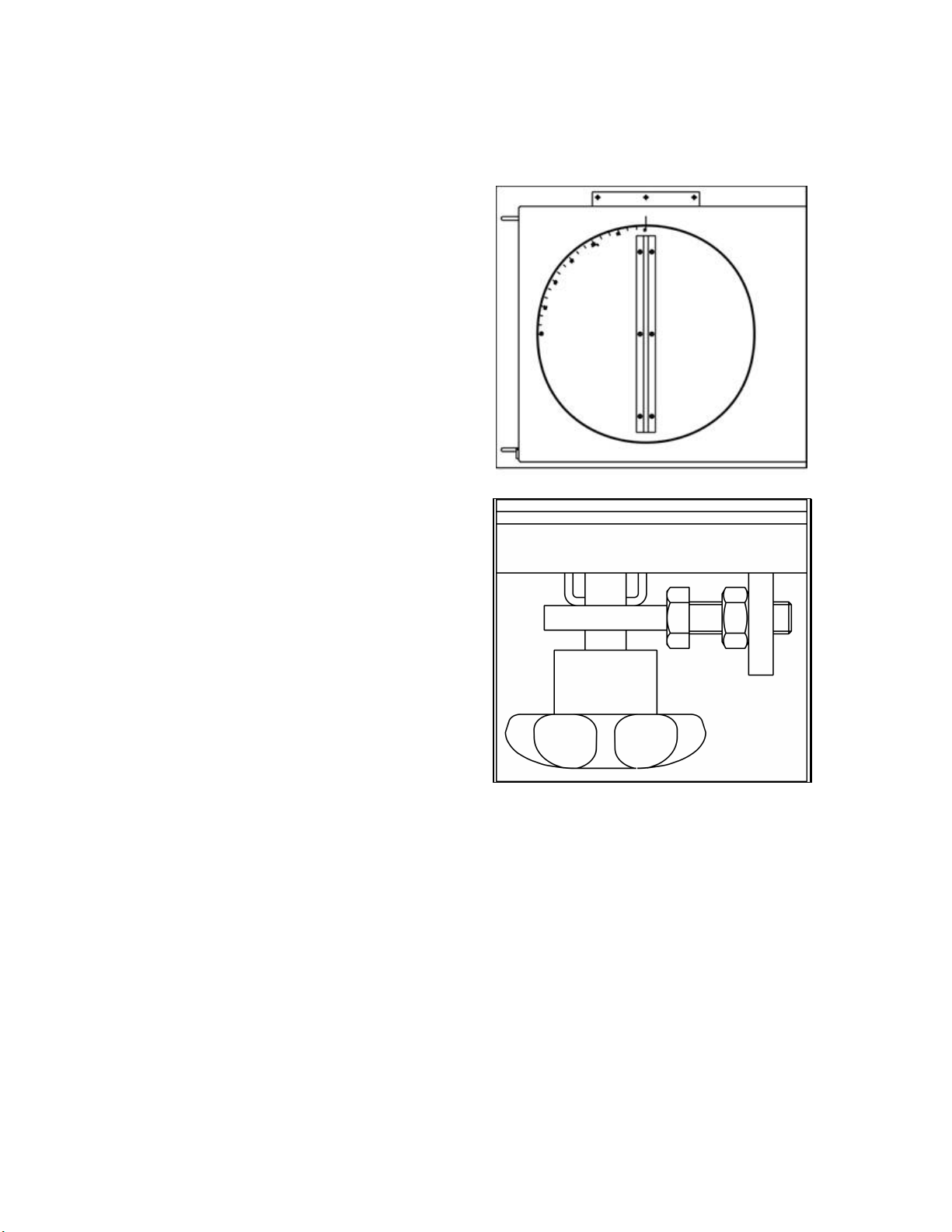

1 Turn the rotating table in such a position

that the saw-blade is square to the fence

and block the table with the knob

underneath the table top.

2 Put the saw-blade in the highest

position.

3 Put the material on the machine.

4 Push the wood against te fence.

5 Check if the wood does not touch the

saw-blade when starting the motor.

Notice: Support the wood properly.

6 Switch on the motor.

7 Move the fence and the wood forward at

a constant speed and cut the material

(fig. 11(.

8 Remove the material after the saw-blade

has stopped.

Notice: If the saw-blade stops because of

clamping of the wood, switch off the motor.

Hold the piece of wood tightly.

Notice: Never stand in the line of the saw-

blade. In case of a return shock you might

get hit.

--14--

OPERATING THE MACHINE

CUTTING AT AN ANGLE WITH

THE HEIGHT ADJUSTMENT

1 Put the saw-blade in the lowest position.

2 Turn the rotating table in such a position

that the saw-blade is square to the fence

and block the table with the knob.

3 Position the fence in such a way that the

wood is placed in the center of the saw-

blade.

4 Block the fence.

5 Push the material with the right hand

against the fence..

Notice: Support the material to be cut and

already cut properly.

6 Switch on the motor.

7 Move the saw-blade slowly and with a

constant speed upwards by means of the

lever (fig. 12)

8 If the material is cut lower the saw-blade

under the table top by means of the

lever.

9 Switch off the motor.

10 Remove the material.

CUTTING AT DIFFERENT ANGLES

B.M.O. THE HEIGHT

ADJUSTMENT

1 Put the saw-blade in the lowest position.

2 Adjust the rotating table at the proper

angle towards the fence. Angle scale

engraved in table top.l

3 Position the fence in such a way that the

wood is placed in the centre of the saw-

blade (fig. 13).

4 Block the fence.

5 Push the material with the right hand

against the fence.

Notice: Support the material to be cut and

already cut properly.

6 Switch on the motor.

7 Move the saw-blade slowly and with a

constant speed upwards by means of

the lever (fig. 12).

8 If the material is cut lower the saw-

blade under the table top by means of

the lever.

9 Switch off the motor.

10 Remove the material.

Notice: Saw-blade may not touch

aluminium sub-fence.

--15--

PUTTING SAW-BLADE AT AN

ANGLE

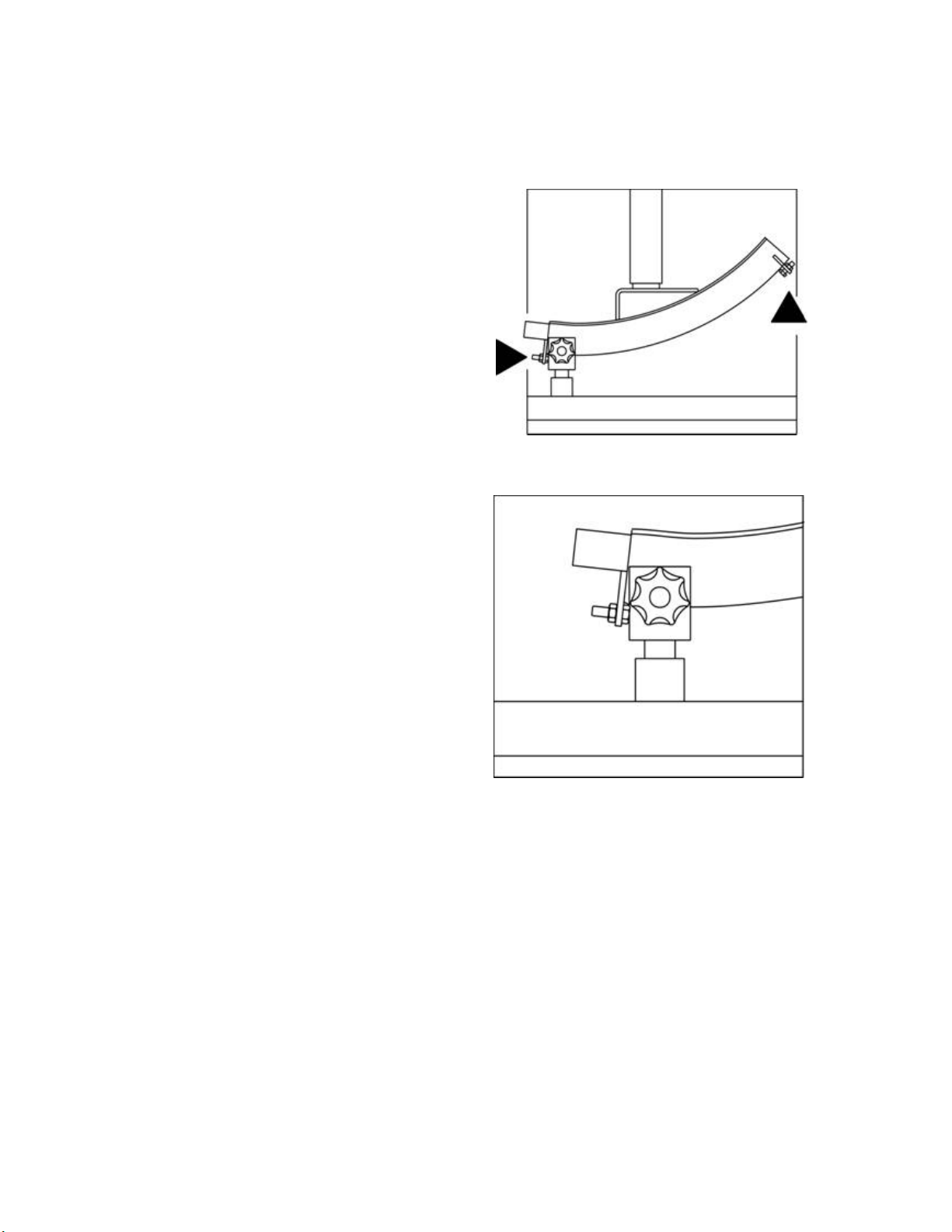

1 Adjust the right angle b.m.o. the handle

and the knob at the bottom of the

machine (fig. 14).

2 Check the angle adjustment with a

bevel. (90 E and 45E

are fixed stops).

3 Block the angle

adjustment with the

knob.

Notice: Support the

material to be cut and

already cut properly.

Notice: Adjust the sub-

fence in such a way that

it cannot touch the saw-

blade.

Notice: Use a pushing

stick when cutting small

wood.

Notice: If the saw-blade stops because of

clamping of the wood, switch off the motor.

Hold the piece of wood tightly.

Notice: Never stand in the line of the saw-

blade. In case of a return shock you might

get hit.

--16--

MALFUNCTIONS

SAFETY

Disconnect the machine of the mains

supply before adjusting the machine or

removing malfunctions.

See to it that all damagerd parts are

replaced before operating the machine.

MALFUNCTION:

-STOPS FOR CUTTING 90º AND 45º ARE

OUT OF ADJUSTMENT.

ADJUSTING THE TURN TABLE

ADJUSTING STOPS 0-90º

1 The table top is marked.

2 Rotate the turntable in such a way that

90º exactly aligns with the notch in the

top (fig. 15).

3 Adjust the bolt with the counter nut at

the stop (fig. 16).

4 Check the adjustment.

5 lmmediately adjust the sub-fence.

(see chapter checking

malfunctions, adjusting sub-fence.

6 Block the sub-fence.

7 Put a square against the sub-fence langsgeleider

8 Adjust the saw-blade b.m.o. the turn

table against the square.

9 Adjust the bolt with the counter nut at

the stop.

10 check the adjustment.

--17--

MALFUNCTIONS

SAFETY

Disconnect the machine of the mains

supply before adjusting the machine or

removing malfunctions.

See to it that all damaged parts are

replaced before operating the machine.

MALFUNCTION:

- BURN OF SAW-BLADE AT THE FENCE

SIDE

- WOOD CLAMPS BETWEEN SAWBLADE

AND FENCE

- WOOD CLAMPS ON RIVING KNIFE

CHECKING AND RE-ADJUSTING

OF THE SUB-FENCE.

1 Check if turn table is adjusted at 0º. If

not, see chapter adjusting turn table

first.

2 Put the saw-blade in the highest position

an square on the table.

3 Put a lath against the saw-blade.

4 Push the sub-fence against the lath and

block the fence.

5 Check the distance between the saw-

blade and the sub-fence at two positions

(fig. 17).

6 Loosen the two bolts of the fence (fig.

18).

5 Adjust the sub-fence parallel to the lath.

6 Tighten the nuts firmly.

7 Check if the sub-fence is parallel tot the

lath.

8 Remove the lath.

CHECKING OF RIVING KNIFE

Check thickness, measure and position of

riving knife (see chapter adjusting riving

knife).

--18--

MALFUNCTIONS

SAFETY

Disconnect the machine of the mains

supply before adjusting the machine or

removing malfunctions.

See to it that all damaged parts are

replaced before operating the machine.

MALFUNCTION:

- STOPS OF ANGLE ADJUSTMENT OF

THE SAW-BLADE FOR CUTTING AT 0º

& 90º ARE OUT OF ADJUSTMENT.

ADJUSTING STOP 0º

1 Put the saw-blade in the highest

position.

2 Adjust the saw-blade with a square.

3 Loosen the counter nut of the bolt and

4 Block the bolt with the counter nut.

5 Check the adjustment.

AJUSTING STOP 45º

1 Put the saw-blade in the highest

position.

2 Adjust the saw-blade with a square

3 Loosen the counter nut of the bolt

and adjust it against the stop (fig. 20).

4 Block the bolt with the counter nut.

5 Check the adjustment.

--19--

MALFUNCTIONS

SAFETY

Disconnect the machine of the mains supply

before adjusting the machine or removing

malfunctions.

See to it that all damaged parts are

replaced before operating the machine.

MALFUNCTION:

- BRAKE DOES NOT WORK

1 Put the machine out of order and contact

a skilled electrical engineer.

- SAW-BLADE DOES NOT ROTATE

1 Disconnect the machine.

2 Check if the saw-blade can run freely.

3 Check if the saw-blade is mounted

correctly (see chapter changing saw-

blade).

4 Check if the lid of the guard is closed.

5 If the problem is not solved after

checking the above contact a skilled

electrical engineer.

--20--

MAINTENANCE

CLEANING, LUBRICATING AND

GREASING

Perform following maintenance every 40

productive hours.

1 Clean height adjustment and lubricate

slightly.

2 Clean tube of fence.

3 Clean angle adjustment.

4 Brush the air inlet and parts of the motor

and check if not obstructed

Perform following maintenance every 160

productive hours.

5 Wear and tear of cables.

6 Broken or torn parts of the electric

circuit.

7 Brake time of the saw-blade (has to be

less than 10 seconds).

8 Operation of micro switch on dust

collector.

9 Operation and condition of safety guard.

Perform following check every 1000

productive hours.

10 The bolt connections of height and angle

adjustment.

11 Saw-spindle on excessive play.

Table of contents