HATO 535Y User manual

HATO 535Y

AUTOMATIC BARRIER

OPERATING MANUAL

Spis treści

RECOMMENDATIONS AND PRECAUTIONS...............................................................3

DECLARATION OF CONFORMITY..............................................................................4

BARRIER..................................................................................................................4

SPECIFIACTION........................................................................................................4

LIST OF ELEMENTS...................................................................................................5

DIMENSIONS...........................................................................................................5

ASSEMBLY AND ADJUSTMENT.................................................................................

E HELB11SZ ELECTRONICS......................................................................................11

SAFETY RECOMMENDATIONS................................................................................12

DEVICE DESCRIPTION.............................................................................................13

SPECIFICATION (electronics)..................................................................................14

DIMENSIONS.........................................................................................................14

DRIVER ASSEMBLY.................................................................................................15

CONNECTION DIAGRAM........................................................................................18

SETTINGS PROGRAMMING....................................................................................19

1.WARRANTY CONDITIONS....................................................................................24

Congratulations on your purchase of HATO 535Y automatic barrier and welcome to the

users of HATO products. Declarations of conformity and manuals for HATO TRADE SP. ZOO

products can be downloaded from our website: http://www.hato.com.pl

Before assembling and using the barrier for the first time, read the manual carefully and

eep them for future reference.

In accordance with the provisions of the Machinery Directive 2006/42 / WE, it is declared

that the product may not be put into operation until the final machine, into which it is built or a

subassembly of which it is built, obtains a declaration of compliance with the directives and

relevant regulations, which the final machine must meet.

RECOMMENDATIONS AND PRECAUTIONS

Before installing and using the drive, carefully read all warnings and safety rules. Incorrect

installation and non-compliance with the standards contained in the manual may result in serious

accidents.

All installation wor should be carried out in accordance with applicable regulations and

standards.

The driver installation may only be performed by qualified and authorized personnel.

Installation should be carried out with basic ESD protection.

Be especially careful during assembly! The controller uses 230Vac voltage (life and health

threatening).

All wor s related to the proper functioning of the device (connection, start-up, operation)

must be carried out in accordance with the applicable regulations in the field of electrical

equipment operation and in accordance with health and safety regulations.

Do not connect the drive to the power supply earlier than specified in the manual, failure

to do so may result in electric shoc .

Before starting the installation, chec the mechanical condition of the barrier: it should not

sway excessively, it should move easily and smoothly.

Before installation, remove unnecessary items and secure accessories, such as loc s.

During assembly, children, handicapped persons and motor vehicles must not be in the

vicinity of the barrier.

All fixed control elements should be located near the barrier, but away from moving parts

and out of the reach of outsiders.

Before repairing or removing any parts of the barrier, disconnect power.

Children and people with intellectual disabilities cannot control the barrier on their own.

Configuration of overload and thrust settings may only be performed by qualified

personnel.

Fluorescent lamps must not be used as traffic lights.

AUTOMATIC BARRIER IS NOT

INTENDED FOR PEDESTRIAN TRAFFIC

This product may only be used for its intended purpose. Improper use is improper and

dangerous. The manufacturer of the product is not liable for any damage caused by improper or

negligent use.

Failure to follow the instructions above may result in serious

injury or equipment damage. The manufacturer is not liable for

damage and malfunctions resulting from failure to observe these

installation and operating instructions.

In accordance with the regulations in force on the disposal of

waste equipment by private users in the European Union, items

bearing this symbol MUST NOT be disposed of with other rubbish. In

this case, the user is responsible for proper disposal by delivering the

device to a designated point, or to the manufacturer who will ta e

care of its further disposal. Separate collection and recycling of

unnecessary devices helps to protect the environment and ensures

that disposal is done in a way that protects human health and the

environment. This note also applies to waste batteries and

accumulators.

DECLARATION OF CONFORMITY

The HATO 535Y automatic barrier meets the requirements set out in the following regulations:

Complies with the conditions of the Machinery Directive 2006/42 / EC Annex II Section B as

amended.

Complies with the conditions of the following EU directives:

Directive on electromagnetic compatibility EMC 2014/30 / EU

Low Voltage Directive LVD 2014/35 / EU

The following harmonized standards have been applied:

EN60335-1: 2012, EN 60335-2-103: 2015-3, EN 55014-1: 2012,

EN 55014-2: 2015-06,

EN 61000-3-2-2014-10, EN 61000-3-3: 2013-10

the current declaration can be downloaded from the manufacturer's website www.hato.com.pl

BARRIER

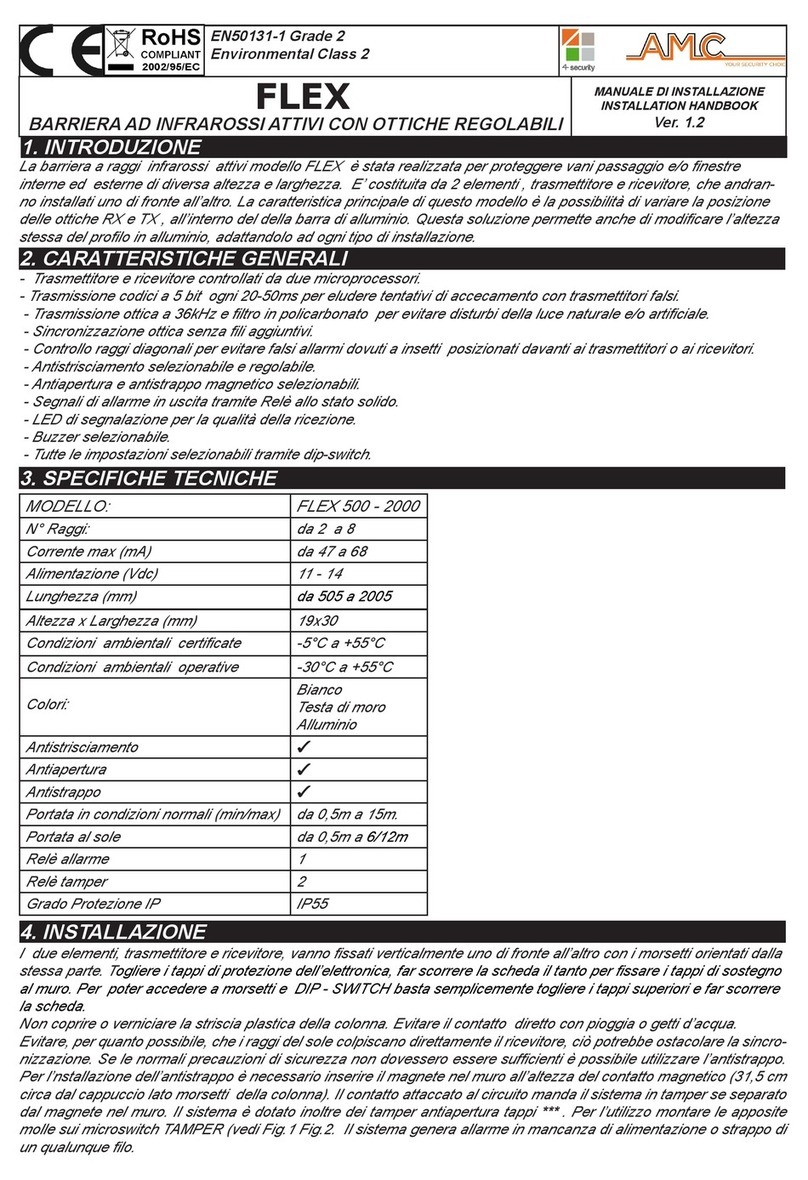

SPECIFIACTION

Model HATO 535Y

Power supply 220×(1±10%)V 50Hz

Engine power 180W

Lowering/lifting time 3.5s

Wor ing range of time 30m

Noise ≤62dB

Operating temperaturę -20ºC~+45ºC

Dimensions 360﹡230﹡1050

Max. arm length 5m

Weight 60 g

Number of cycles per hour 200

LIST OF ELEMENTS

No

.

Description Quantity

1 Barrier 1

2 Mounting plate for the barrier arm 1

3 Barrier mounting cover 1

4 Handle 1

5 Remote control 1

6 M12 dowel pin 4

7 M10 x 16 the bolt securing the barrier 4

8 M4 x 5 cover fixing bolt 3

9 M12 washer 4

10 Key 2

11 Manual 1

DIMENSIONS

The LEFT barrier is shown in the diagram above.

ASSEMBLY AND ADJUSTMENT

REQUIRED TOOLS:

- set of eys

- set of screwdrivers

- drill

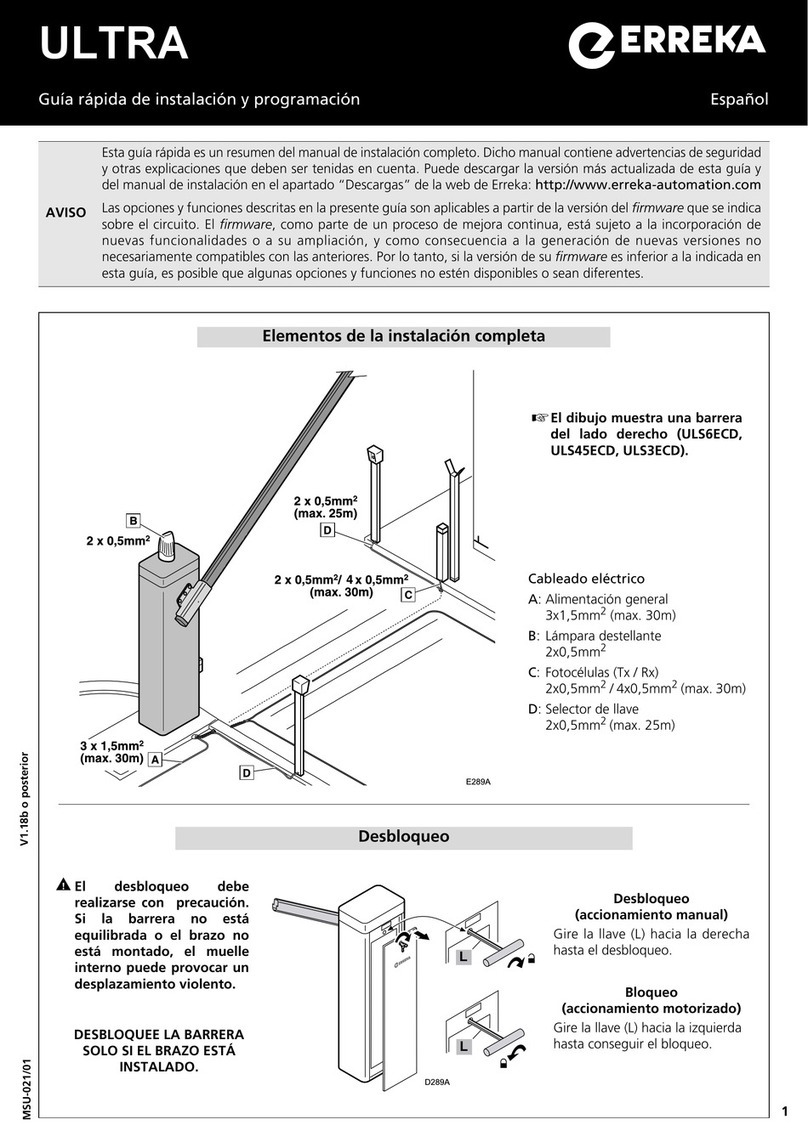

CORDS:

- power cord 1,5mm2

- signal cord 0,5mm2

FOUNDATION:

When the foundation is poured under the barrier, a PVC pipe should be placed in it (min. 12mm

diameter). This way we can secure the cords brought to the barrier in front of the mechanical

device. Diagram above. Power and signal cord should always be separated.

BARRIER (fastening):

Four M12 fixing bolts can be inserted into the foundation during pouring or alternatively you can drill holes in the

foundation and use expansion plugs (supplied).

Hole spacing: 150mm x 260mm. To do this, place the barrier on the foundation and mar the holes. Then move the

barrier and drill the holes. Put expansion plugs into the drilled holes or instert the screws into the still wet concrete.

Place barrier over the bolts and tighten using the washers and nuts provided.

BARRIER ARM:

Fit the barrier arm to the barrier and fasten it with four M10x16 screws.

Then mount the barrier cover with three M4x5 screws.

EMERGENCY OPENING:

In case of a power failure, use the handle to manually open or close the barrier.

Before starting manual operation of the barrier, it is necessary to:

- disconnect the power supply to avoid accidental activation of the barrier.

- put the handle in the designated place, covered with a plastic cover.

- turn the handle in the appropriate direction to open or close.

- pull out the handle before turning on the power

LIMIT SWITCH (normally open)

Regulowane wyłączni i rańcowe służą do zatrzymania szlabanu w pozycji otwartej lub zam niętej.

INITIAL ADJUSTMENT

- Use the handle to manually set the barrier in the opening position. Loosen the M4 screw of the opening cam and

turn the cam until the green indicator light for limit switch open comes on, then tighten the M4 screw.

- Use the handle to manually set the barrier to the closed position. Loosen the M4 screw of the closing cam and turn

the cam until the red indicator light for limit switch closed is on, then tighten the M4 screw.

FINAL ADJUSTMENT

- After adjusting the cams of the limit switch, activate the barrier and chec that the pre-adjustment of the position is

correct. In a situation when the end positions deviate from the desired ones, already on the attached barrier, it is

necessary to precisely adjust the limit switches.

SPRING BALANCING:

Correct adjustment of the balancing spring is crucial for the proper operation of the barrier. The barrier is

adjusted in the open position, when the balance spring is loose.

Dźwignia napędu posiada cztery otwory Ø15, szlaban oryginalnie dostarczany jest z sprężyna balansującą

zamontowaną w pierwszym otworze (5-6m), w sytuacji gdy szlaban jest rótszy niż 5m., należy zamontować

sprężynę w odpowiedni otwór.

To do this you need to;

• Loosen the spring, bringing the barrier to the open position.

• Loosen the nut and the turnbuc le (turn cloc wise)

• Pull out the cotter pin and disassemble the spring mount to the drive lever.

• Select the appropriate hole corresponding to the length of the barrier, install the spring mount and the

cotter pin.

• Final adjustment is done with a turnbuc le.

• Tighten the nut

Table of contents