Page 8

BBG-9

Air and Fuel Connections

1. Install the air piping to the burner body using a flexible connection. Avoid elbows and abrupt

directional changes in the piping where possible as turbulence can affect flow measurement

accuracy, and reduce pressure at the burner.

2. If necessary, the gas connection on direct spark ignited BBG_ 204 through _ 212 burners

can be rotated as follows:

a. Remove the screws and lock washers holding the gas inlet to the burner body.

b. Rotate the gas inlet until it is in the desired location.

c. Make sure the gasket between the gas inlet and the burner body is properly seated.

a. d. Replace the washers, hex nuts and securely tighten.

3. Install the gas line to the gas inlet using a flexible connection. Avoid elbows and abrupt

directional changes in the piping where possible as turbulence can affect flow measurement

accuracy, and reduce pressure at the burner.

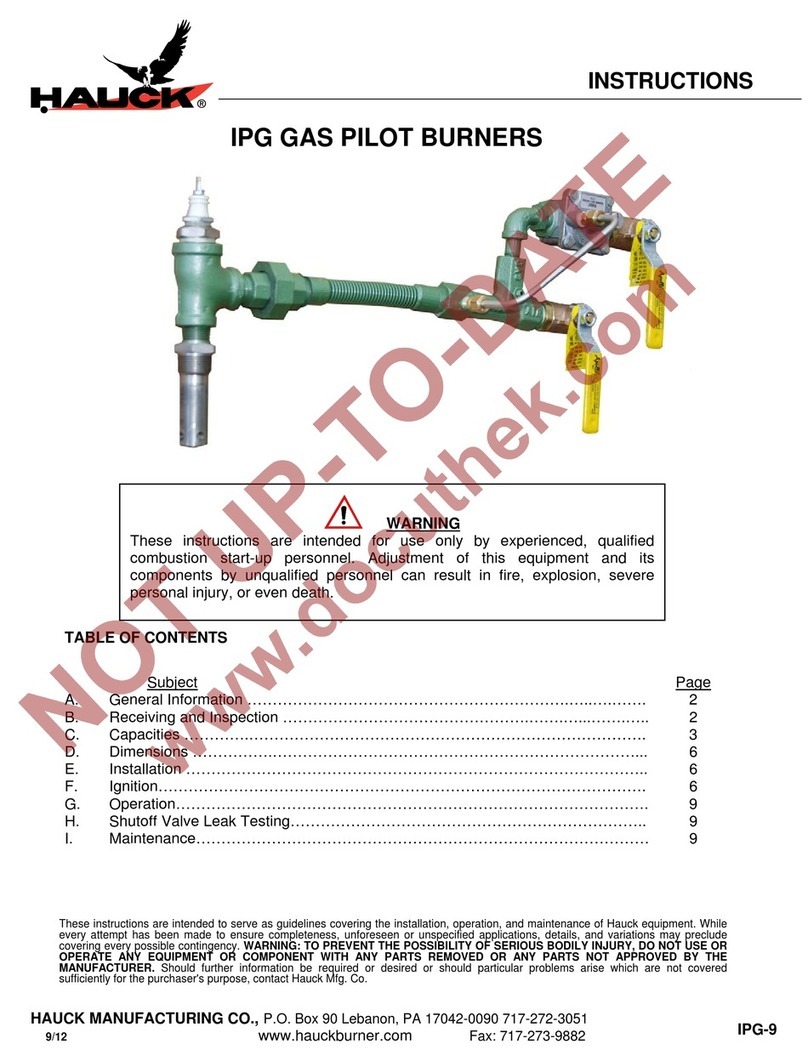

4. For BBG burners using gas pilot ignition: Consult the appropriate dimensional sheet and

instructions that accompany the pilot for additional information (IPG-9 or ZMI Literature).

a. BBG_104 through _118 IPG Gas Pilot

Install the pilot tip in the connection located above the burner center line on the burner

body. Connect pilot air and gas to the appropriate connections on the gas pilot.

b. BBG_104 through _BBG112 ZMI Gas Pilot

Install the ZMI Pilot in the connection located on the burner gas inlet tee.

c. BBG_124 Forced Air Premix Pilot

Install the air/fuel premix outlet of the pilot manifold assembly to the pilot assembly.

Connect pilot air and gas to the appropriate connections on the pilot manifold.

NOTE

All piping must be properly supported and aligned to avoid stresses on the burner

and associated equipment. Hauck recommends that flexible connections be used on

all air and fuel lines to isolate the burner from piping movement due to expansion,

contraction, and vibration.

NOTE

Size the pilot gas supply line to avoid excessive pressure drops. For

supply lines up to 25 ft (7.6m) use 1/2" (DN 15) pipe; from 25 to 100

ft (7.6 – 30m) use 3/4" (DN 20) pipe. Prior to connecting to the pilot

gas manifold, the gas line should be purged to remove debris.

NOTE

All burner models are provided with two sets of connections for observation port, pilot

and UV scanner mounting. Neither the pilot nor the UV scanner should be located below

the horizontal centerline of the burner, where they could be adversely affected by dirt

and debris.If the main air connection is at 6 or 12 o’clock, the accessory ports at either 3

or 9 o’clock can be used. However, both the IPG pilot and UV scanner must be in

adjacent ports on the same side of the burner. If the main air connection is at 3 or 9

o’clock, use the IPG pilot and UV scanner connection ports located 180° from the main

air connection. Scanner connection should be supplied with 1 psi of purge air.

NOTE

The BBG_124 UV scanner connections are positioned at 45°

and 225° clockwise from the main air connection center line.

Use guidelines in previous note to choose UV scanner port.