S400/S400T Manual 934-6638 - Page 15

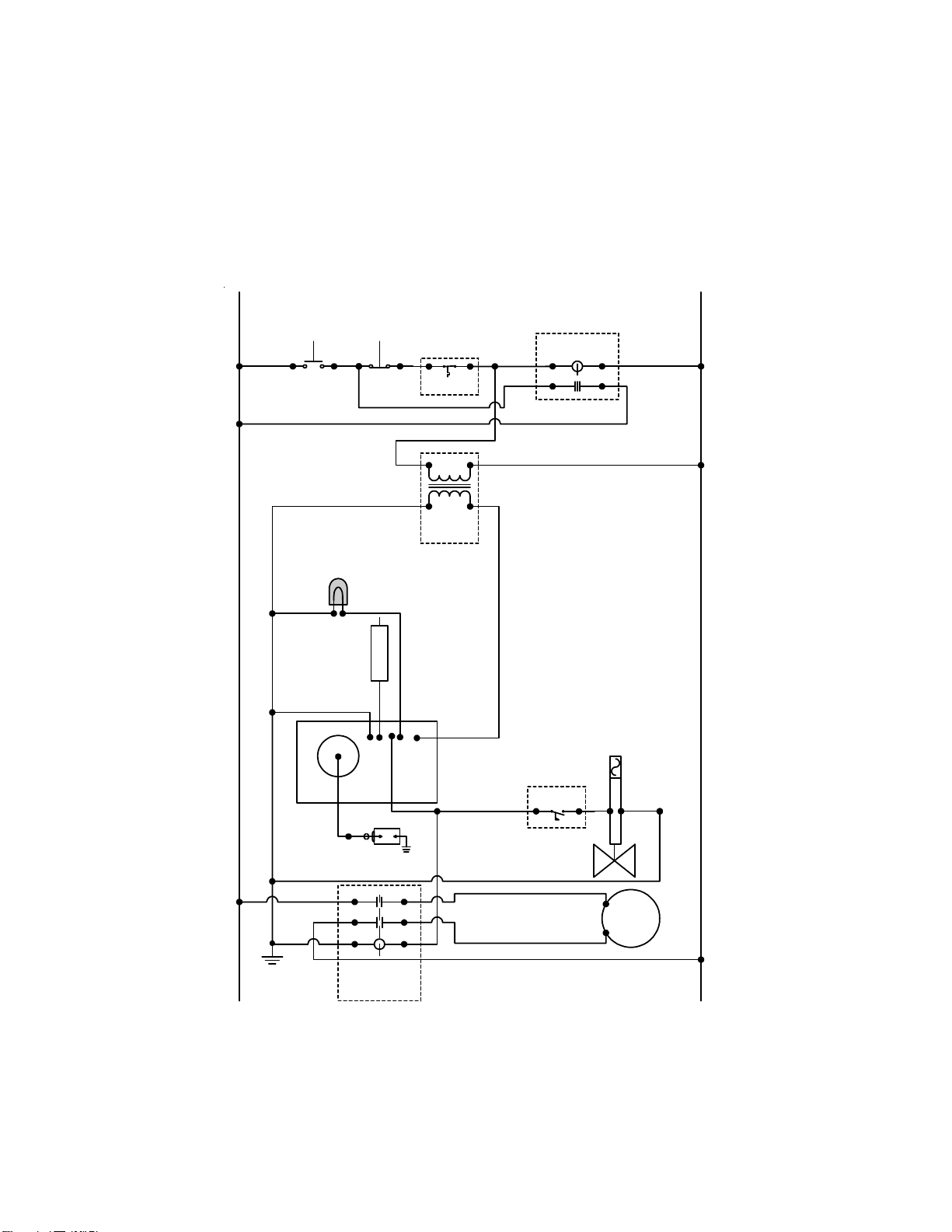

power present then check wire.

h) Turn thermostat knob to the extreme clockwise position, if 115V is

detected between the input terminals of the secondary transformer,

then transformer is faulty.

i) Ifthereisnot 24Vontheoutputside,andnot115V ontheoutputside

of the transformer then check the black wire on the input side of

transformer

j) If120Vispresentattheblackwireontheinputsideofthetransformer

then the transformer is faulty.

4Fan starts. If motor does not run check the following:

a) Check to see if the fan blade is turning freely.

b) If there is 115V between T1 & T2 on the motor starting relay then

there is a bad connection or broken wire between motor and relay.

c) If there is no power at T1 & T2 the contact points are dirty or the

relay is faulty.

d) Remove back plate on motor, if there is 115V between the incom-

ing white and black wires, then the connection to the motor is

incorrect or the motor is faulty.

5Fan reaches full speed and air switch closes, if air switch does not

close check:

a) If there is 24V on only one of the airswitch terminals while motor is

running, then airswitch is staying open, first check the airtubes.

b) If either upstream or downstream air tubes are plugged.

c) If both are free then check alignment ( tubes should be positioned

parallel to the air flow direction).

d) If above procedures do not correct problem, then the adjusting

screw located on the side of the airswitch can be rotated counter

clockwise, just enough so that fan stays running.

e) If this does not help then bypass the airswitch by joining the two

wires together, if heater now runs then the airswitch is faulty.

6Solenoid valve opens, if valve fails to open check:

a) If there is 24V between the wires of the solenoid valve and a sharp

click is not heard, then the coil of the solenoid valve is faulty.

b) If a sharp click is heard, then the valve body is faulty.

7Spark is generated, if no spark is present, check:

a) If the ignition wire is burnt, or cracked it may be shorting out to the