Haul-All Equipment SURE FLAME S100 Installation and user guide

PRODUCTS

Rev: 2.11 March 12, 2008

SERVICE AND MAINTENANCE MANUAL No. 934-6891

PLEASE RETAIN FOR FUTURE REFERENCE

A Division of Haul-All Equipment Ltd.

4115 - 18 Avenue North

Lethbridge, Alberta T1H 5G1

www.sureflame.ca

CONSTRUCTION HEATER

S100

Page LM P/N: 934-6891 S100 Manual, Rev: 2.1.1

S100 CONSTRUCTION HEATER

Failure to comply with the precautions and instructions

provided with this heater, can result in death, serious

bodily injury and property loss or damage from hazards

of fire, explosion, burn, asphyxiation, carbon monoxide

poisoning, and/or electrical shock.

Only persons who can understand and follow the

instructions should use or service this heater.

If you need assistance or heater information such as

an instruction manual, labels, etc. Contact the

manufacturer.

Fire, burn, inhalation, and explosion hazard. Keep solid

combustibles, such as building materials, paper or

cardboard, a safe distance away from the heater as

recommended by the instructions. Never use the heater

in spaces which do or may contain volatile or airborne

combustibles, or products such as gasoline, solvents,

paint thinner, dust particles or unknown chemicals.

Not for home or recreational vehicle use

WARNING

WARNING

GENERAL HAZARD WARNING

S100 Manual, Rev: 2.1.1 P/N: 634-6891 Page RM

READ THIS

WARNING

FIRST !

The heater is designed and approved for use as a construction heater

under CSA 2.14-2000 and ANSI Z83.7-2000. The primary purpose of

construction heaters is to provide temporary heating of buildings

under construction, alteration, or repair and to provide temporary

emergency heat. Properly used the heater provides safe economical

heating. Products of combustion are vented into the area being

heated.

The heater is not designed as an Unvented Gas Fired Room Heater

under ANSI-Z21.11.2 and should not be used in the home.

ANSI A119.2(NFPA 501C)-1987 Recreational Vehicle Standard

prohibits the installation or storage of LP-Gas containers even

temporarily inside any recreational vehicle. The standard also prohib-

its the use of Unvented Heaters in such vehicles.

Gas inspection authorities in Canada require that the installa-

tion and maintenance of heaters and accessories be accom-

plished by qualified gas fitters.

Installation must comply with local codes, or in the absence of

local codes, with the Natural Gas and Propane Installation Code

CSA-B149.1, the National Fuel Gas Code ANSI Z223.1/NFPA 54

and the Standard for the Storage and Handling of Liquified

Petroleum Gases ANSI/NFPA 58.

We cannot anticipate every use which may be made for our heaters.

CHECK WITH YOUR LOCAL FIRE SAFETY AUTHORITY IF YOU

HAVE QUESTIONS ABOUT LOCAL REGULATIONS.

Other standards govern the use of fuel gases and heat producing

products in specific applications. Your local authority can advise you

about these.

Page LM P/N: 934-6891 S100 Manual, Rev: 2.1.1

FOR YOUR SAFETY

DO NOT USE THIS HEATER IN A SPACE WHERE

GASOLINE OR OTHER LIQUIDS HAVING

FLAMMABLE VAPOURS ARE STORED OR USED.

S100 CONSTRUCTION HEATER

CONTENTS

Specifications .......................................................................................... 5

Installation ............................................................................................... 6

Installation Using A Propane Supply Tank ................................................ 7

Installation For Natural Gas Applications ................................................. 7

Operating Instructions ............................................................................. 8

Sequence Of Operation ........................................................................... 8

Common Installation And Operational Problems ..................................... 9

Safety Features ....................................................................................... 9

Design Related Additional Safety Features ............................................ 10

On-site Safety Problems ........................................................................ 10

Preventative Maintenance ..................................................................... 11

S100 Heater Parts ................................................................................. 12

S100 Connection Wiring Diagram ......................................................... 14

S100 Ladder Wiring Diagram ................................................................ 15

S100 Manual, Rev: 2.1.1 P/N: 634-6891 Page RM

SPECIFICATIONS

Model No. S100 Construction Heaters

CSA Certified to CSA 2.14-2000 and ANSI Z83.7-2000 Gas Fired

Unvented Construction Heater

Gases: Natural or Propane

Capacity: 100,000 Btu/h (29 kW) maximum

Orifice Size: 43 DMS (x10)

Blower: 1,300 cfm (615 l/s)

Electrical Rating: 115 volts, 60 Hz., 4 amps, single

phase

Gas Supply:

Inlet Pressure Manifold Pressure

Max. W.C. Min.W.C. Max.W.C.

Propane 14" (3.5 kPa) 5" (1.25 kPa) 0.4" (100 Pa)

Natural 14" (3.5 kPa) 5" (1.25 kPa) 1.1" (275 Pa)

(Minimum inlet pressure is for purpose of input adjustment)

Page LM P/N: 934-6891 S100 Manual, Rev: 2.1.1

INSTALLATION

The Sure Flame Model S100 Construction Heater is a direct fired gas heater

intended to be used primarily for the temporary heating of buildings under

construction, alteration, or repair. Since all the products of combustion are

released into the area being heated, it is imperative that adequate ventilation

is provided. The flow of supply air and combustion gases must not be

obstructed in any way. Do not use the heater with ductwork as this will restrict

the flow of supply air.

1 Install the heater in a horizontal position at least 10 feet (3m) in

Canada or 6 ft. (1.83 m) in the U.S. from any LP-gas container. Allow

the following clearances from any combustible materials:

Front Outlet: 8 feet (2.4 m) Sides: 2 feet (0.6 m)

Intake: 2 feet (0.6 m) Top: 4 feet (1.2 m)

Front Outlet must not be directed at any LP-gas container within 20

feet (6 m).

Also make sure that no flammable vapours are present in the space

where the heater is being used.

2 When connecting the heater to a natural gas or propane supply line

ensure that the pressure at the heater inlet is within the specified range.

Excessive pressure (over 1/2" psi) will damage the controls and void the

warranty.

3 Visually inspect the hose assembly and ensure that it is protected from

traffic, building materials, and contact with hot surfaces. If it is evident that

there is excessive abrasion or wear, or the hose is cut, it must be replaced.

4 After installation, check the hose assembly for gas leaks by applying a

water and soap solution to each connection.

5 Connect the heater to an adequate 115 volt electrical supply as specified

on the rating plate. For protection against shock hazard the supply cord

must be plugged directly into a properly grounded three-prong recepta-

cle.

6 In all applications, install the heater in such a manner that it is not

directly exposed to water spray, rain and/or dripping water.

S100 Manual, Rev: 2.1.1 P/N: 634-6891 Page RM

INSTALLATION USING A

PROPANE SUPPLY TANK

1 When installing the heater for use with propane gas, set the gas selector

valve to “Propane”.

2 Arrange the propane supply system to provide for vapour withdrawal from

the operating container. Supplying liquid propane to the heater is danger-

ous and will damage the components. Another regulator must be

installed on the heater to reduce the pressure from this regulator to a

maximum inlet pressure of 1/2 psi.

3 Ensure that for the surrounding temperature the size and capacity of the

propane supply container is adequate to provide the rated Btu/h input to

the heater.

4 Turn off the propane supply valve at the container when the heater is not

in use.

5 The installation must conform with local codes, or in the absence of local

codes, with CSA-B149.1 Natural Gas and Propane Installation Code or

with the Standard for the Storage and Handling of Liquedied Petroleum

Gases, ANSI/NFPA 58.

6 When the heater is to be stored indoors the propane container must be

disconnected from the heater and the container moved away and stored

in accordance with the above National Standard.

INSTALLATION FOR

NATURAL GAS APPLICATIONS

1 When installing the heater for use with natural gas, set the gas selector

valve to the “Natural” position.

2 A regulator must be installed on the heater to ensure that the pressure to

the heater does not exceed 1/2 psi inlet pressure.

3 The installation of this heater to a natural gas supply must conform with

all applicable local codes, or in the absence of local codes, with CSA-

B149.1 Natural Gas and Propane Installation Code or with the National

Fuel Gas Code ANSI Z223.1/NFPA 54.

Page LM P/N: 934-6891 S100 Manual, Rev: 2.1.1

OPERATING INSTRUCTIONS

1 Set GAS SELECTOR VALVE to gas being used. The conversion shall

be done by the owner or lessor of the equipment.

NOTE: When using Propane Gas the Selector Valve must be in the

PROPANE position.

2 Ensure the MANUAL VALVE (blue knob at rear of heater) is in the “ON”

position.

3 Connect power - 115 volt supply.

4 Open gas supply.

5 Push START button AND HOLD FOR 5 SECONDS

6 To stop, turn gas off.

The appliance area should be kept clear and free from combustible materi-

als, gasoline, and other flammable vapours and liquids.

Ensure that the flow of supply air and combustion gases is not obstructed.

The installation and operation of the heater shall comply with the code

requirements specified by the authorities having jurisdiction.

General criteria for the use of construction heaters may be found in the

applicable sections of the Natural Gas and Propane Installation Code CSA-

B149.1.

THE INSTALLATION AND MAINTENANCE OF THE

HEATER MUST BE ACCOMPLISHED BY A

QUALIFIED SERVICE PERSON.

SEQUENCE OF OPERATION

1 Push start button AND HOLD FOR 5 SECONDS.

2 Relay closes.

3 Fan starts.

4 Fan reaches full speed and air switch closes.

5 Gas valve opens.

6 Spark is generated.

7 Flame rod senses flame, and then maintains flame.

S100 Manual, Rev: 2.1.1 P/N: 634-6891 Page RM

COMMON INSTALLATION AND

OPERATIONAL PROBLEMS

1 LOW VOLTAGE

This is one of the most common problems and is usually the result of the

supply cord having too small a wire gauge for its length. Low voltage

results in the motor overheating, burnt relay contacts, or a relay that will

not maintain contact.

2 SUPPLY LINE TOO SMALL

3 INSUFFICIENT VAPORIZATION AT SUPPLY

Normally caused by too small size of supply tank.

4 IMPROPER GAS SUPPLY PRESSURE

Usually a result of supply pressure being too high because of improper or

lack of regulation.

5 DIRTY GAS SUPPLY

Dirty gas can cause strainers to plug or form a build-up in the burner

orifice.

6 LACK OF PREVENTATIVE MAINTENANCE

Heaters must be cleaned as required, especially when used in a dirty

environment.

7 IMPROPER SUPPLY OF FRESH AIR

It is normally recommended that the intake air of the heater be taken from

outside the enclosed area. This provides a slight pressurization and

prevents any problems associated with recirculation.

SAFETY FEATURES

The Model S100 incorporates devices to detect the following:

1 LOSS OF FLAME Gas supply is shut off if flame is lost to

prevent raw gas from leaving the heater.

2 OVERHEATING High temperature limit switch in the com-

bustion chamber

3 LOSS OF POWER Total shutdown with manual restart re-

quired. Any one of the safety devices will

create a loss of power situation.

4 BLOCKED AIR SUPPLY A switch detects the differential pressure

in the combustion chamber and shuts down

when insufficient.

Page LM P/N: 934-6891 S100 Manual, Rev: 2.1.1

DESIGN RELATED ADDITIONAL

SAFETY FEATURES

1 LOW SKIN TEMPERATURE

Sure Flame Heaters are designed to have a low skin temperature. This

provides added safety in the workplace.

2 DURABLE CONSTRUCTION

The Model S100 uses a stainless steel burner for long life and consistent

performance.

In order to maintain the highly efficient combustion of the Sure Flame

Heater, the combustion chamber must remain as manufactured. Any

change or distortion could alter the fuel/air mixture and create unwanted

gases.

ON-SITE SAFETY PROBLEMS

1 SHORTING OUT OF DEFECTIVE COMPONENTS

This common problem saves short term expense at the risk of a large

future cost. Any heaters found in this condition should be removed

immediately.

2 IMPROPER ENCLOSURES

When heaters are installed partially to the outside for fresh air intake, strict

adherence must be made to the minimum clearance to combustibles

given on the instruction plate. Wood framing around a heater is a request

for trouble.

3 SUPPLYING LIQUID PROPANE TO HEATER

This problem has occurred from time to time. To minimize the damage,

and possible personal injury, shut off the gas supply and let the heater run

until all of the liquid in the lines has been vaporized.

S100 Manual, Rev: 2.1.1 P/N: 634-6891 Page RM

PREVENTIVE MAINTENANCE

Sure Flame Construction Heaters are built to withstand the rigours of

operating on construction sites, for mining applications, and a multitude of

other locations where heaters are used. To maintain the reliable perform-

ance required it is necessary to do a certain amount of regular maintenance.

A VISUAL CHECKS

The following items should be checked for excessive wear or damage:

1) Cords and Connectors

2) Wiring and Conduit

3) Heater Shell (including heat shield) and Control Box

It is recommended that units purchased as spares be rotated periodi-

cally, so that each unit will be placed in operation at least once every 90

days.

B BURNER

Flame Rod and Insulator - Clean with soap and water or solvent on a

routine basis. Any build up on burner

should also be removed at this time.

Spark Plug - Clean with solvent and check spark gap.

C CONTROL BOX

The inside of the control box should be cleaned using a dry cloth or by

blowing compressed air. Do not use any liquid or aerosol spray cleaners.

Also check that all electrical connections are snug and tight.

D MOTOR

The electric motor on the S100 Heater is fitted with sealed bearings and

no oiling is required. Keep the motor clean by blowing or wiping off dust

or dirt in order to prevent it from over heating.

E FAN

Check for dust or dirt build up on fan blades. Check the tightness of the

set screw and run the heater to check for fan vibration.

Page LM P/N: 934-6891 S100 Manual, Rev: 2.1.1

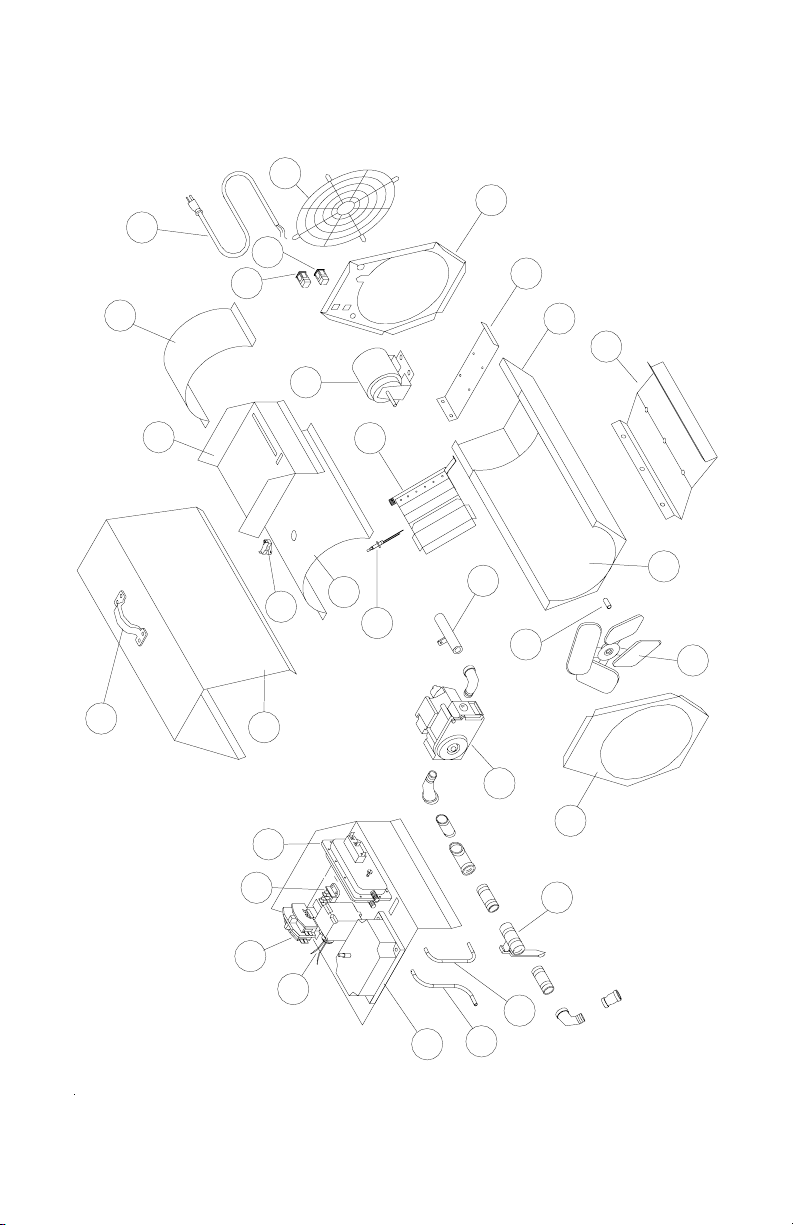

S100 HEATER PARTS

22

17

16

12

13

14

1

2

19

11

3

5

6

7

4

15

18

20

21

29

26

23

28

30

27

25

10

24

8

9

32

September 13, 2002

S100 Manual, Rev: 2.1.1 P/N: 634-6891 Page RM

S100 HEATER PARTS

Sept. 13, 2002

Ref. Part No Description

1 6897 Handle

2 S100-101 Top Shell

3 5124 Air Switch (0.2" W.C.)

4 5768 Terminal Block

5 4519 Motor Relay 24V

6 4511 Transformer 24V

7 8264 Direct Spark Ignition Control

8 S100-716 Downstream Airtube “S”

9 S100-715 Upstream Airtube “C”

10 S100-115 Front Top Heat Shield

11 2446 HI Limit Switch

12 S100-110 Control Box

13 S100-116 Top Rear Heat Shield

14 3868 24" Power Cord

15 S100-717 S100 Fan Guard

16 3337/8 OFF Switch (Red)

17 3337/9 ON Switch (Green)

18 S100-106 Rear End Panel

19 6892 1/8 HP Motor

20 S100-107 Motor Mount

21 S100-102 Bottom Shell

22 BV2-502 Burner

23 6894 Triple Electrode

24 S100-109 Base

25 S100-103 Bottom Heat Shield

26 6901 Shaft Adapter

27 2419 Fan Blade

28 S100-105 Front End Panel

29 6895 Gas Valve

30 S100-707 Changeover Valve

32 S100-501 Pipe Weldment

Page LM P/N: 934-6891 S100 Manual, Rev: 2.1.1

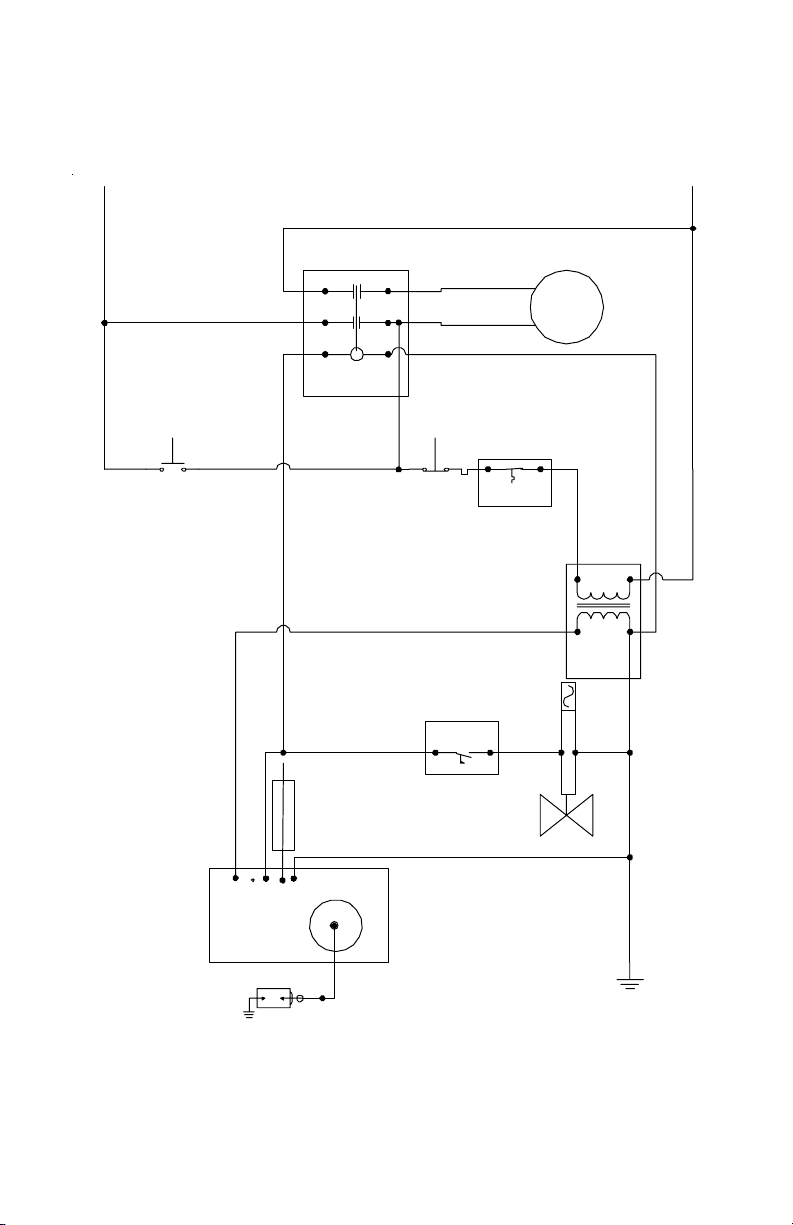

S100 CONNECTION WIRING

DIAGRAM

STOP

POWER

START

MOTOR

GAS

VALVE

BLU 15cm

GRN 7cm

TRANSFORMER

BLK 32cm

RELAY

POWER

BLK

GRN

WHT

T1

L1

A1

BLK 32cm

BLK 18cm

WHT 19cm

Motor Wire

Motor Wire

LINE

T2L2

A2

BLK 18cm

RED HT 64cm

RED HT 56cm

IGN 36cm

WHT 19cm

BLK 28cm

FLAME

ROD

CONTROL

IGNITION

2460D 601-002

FENWAL

G

S

V1

P

CONNECTOR

BLK 18cm

WHT 19cm

AIR SWITCH

BLK 30cm

LOAD

BLK 30cm

WHT 13cm

NC NO COM

BLK 28cm

SWITCH

HI LIMIT

NOTES: ALL WIRES 18GA. STR TEW 600V

UNLESS OTHERWISE SPECIFIED

NC

NO

COM

NO

COM

NC

CORD

TYPE STJW

14/3 61cm

24VAC

120VAC

BLK 20cm

WHT 20cm

18 Aug 2006

S100 Manual, Rev: 2.1.1 P/N: 634-6891 Page RM

S100 LADDER WIRING DIAGRAM

S1

FENWALL

#2460D-XXX-XXX

V1

NC

G

Power

SP

STARTBUTTON STOPBUTTON

M

AIRSWITCH

HILIMITSWITCH

POWER/MOTORRELAY

FLAME ROD

110V-24V

STEPDOW N

TR AN SF OR ME R

SOLENOIDVALVE

L

N

Table of contents

Other Haul-All Equipment Heater manuals

Popular Heater manuals by other brands

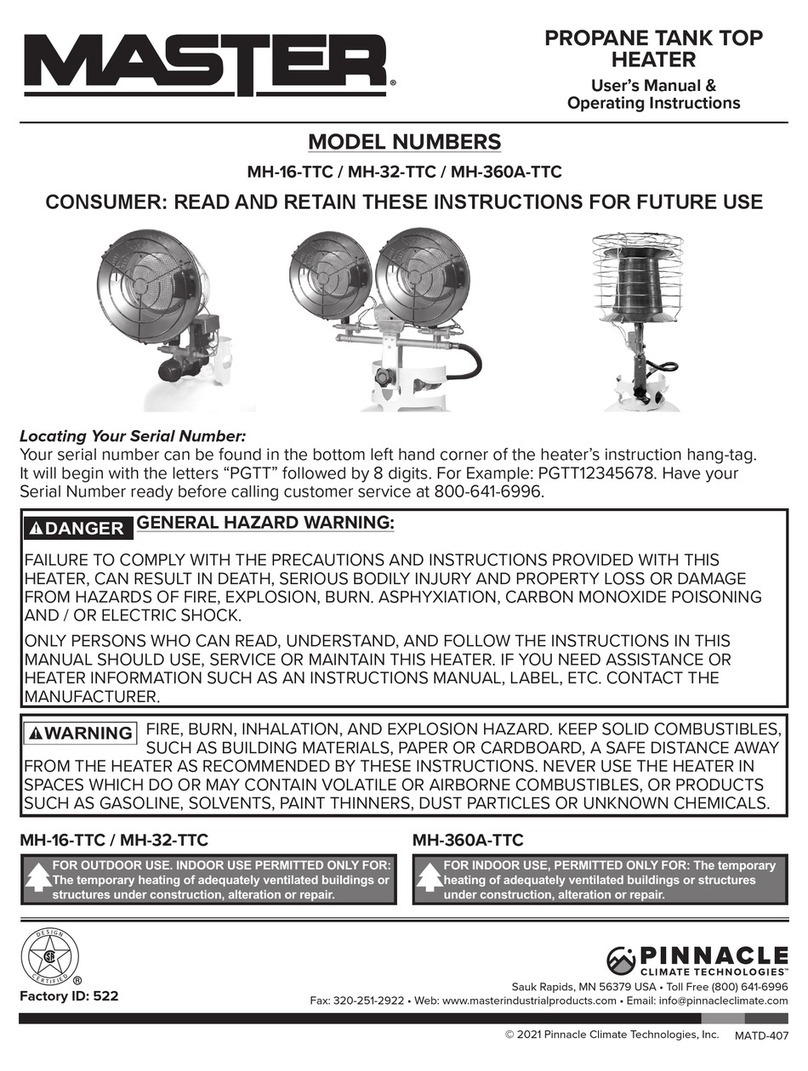

Pinnacle

Pinnacle MASTER MH-360A-TTC User's manual & operating instructions

Toyotomi

Toyotomi Radiant 101 Type A user guide

Chromalox

Chromalox NOR FOUND PD445 Installation and maintenance instructions

Scarlett

Scarlett SC-054 instruction manual

Holmes

Holmes HFH105 owner's guide

IRSAP

IRSAP THE RADIATOR COMPANY ISEO TRC-IS-O30 Fitting instructions