Cambridge Air Solutions 8 SA-Series Technical Manual

INSTALLATION INSTRUCTIONS

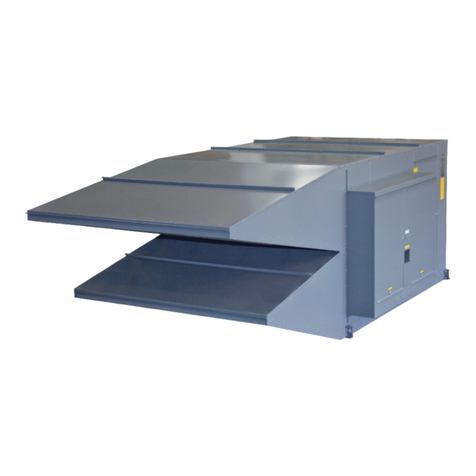

THRU WALL MOUNTING

WARNING:

It is recommended the heater mounting structure

be reviewed and approved by a qualified structural

engineer and the roof manufacturer before

installing this equipment.

IMPORTANT

Before proceeding with the installation, verify the

feasibility of the location selected with respect

to accessibility to the equipment for service and

maintenance functions.

IMPORTANT

To prevent contaminated air from being drawn

into the heater, install the heater’s inlet at least 10

feet from any building exhaust, process exhaust,

sewer stacks, or other sources that would allow

contaminants to be drawn into the heater. Consult

local codes for additional references.

1. For square duct - prepare wall penetration for

inlet collar to the dimensions below.

For round duct - prepare wall penetration to

accommodate the inlet duct (by others).

2. For square duct - Connect the inlet collar and the

rain hood to the unit prior to lifting the heater in

place.

For round duct - Attach the inlet duct to the rain

hood. Lift the rain hood and inlet duct into place

and attach to the wall.

3. Install hanging rods to adequate ceiling supports

and align with the hanging brackets on the unit.

Locate the hanging rods so that the weep holes

provided in the rain hood are located a minimum

of 3" beyond the outside wall surface.

4. Install the hanging brackets on the heater.

5. Use a forklift or comparable lifting device to

raise and position the heater. Take precautions

to prevent equipment damage (dents and/or

scratches) when the heater is being lifted into

position.

6. Use washers and double lock nuts to secure the

unit on the hanging rods.

7. For round duct - Attach the inlet duct to the

inlet transition.

IMPORTANT

The discharge end of the heater should be raised

slightly (1/8" above level) to slope the rain hood so

any ingested moisture will run outside the building.

8. Install fiberglass insulation in the gaps around

the wall opening. Apply enough material to

accommodate the full thickness of the wall.

9. Install finish trim pieces (by others) to the top,

sides and bottom of the wall opening on both the

inside and outside wall surfaces.

10. Apply silicone caulk at the joint between the top

of the rain hood and the outside wall surface.

Make certain this is a continuous bead and that it

runs the entire width of the rain hood. Caulk all

other exposed joints.

11. Install the directional elbows. Consult the job

layout for the orientation of the elbows.

Weight

Hanging Rods Wall Opening

Model Qty. Size A B H W

SA250 220 lbs. 4 3/8" dia. 53" 23.16" 23" 23"

SA350 550 lbs. 4 3/8" dia. 58" 33.25" 25" 27.5"