HBK HBM Bruel & Kjaer AD103C User manual

AD103C

ENGLISH DEUTSCH

Operating Manual

Bedienungsanleitung

Hottinger Brüel & Kjaer GmbH

Im Tiefen See 45

D-64293 Darmstadt

Tel. +49 6151 803-0

Fax +49 6151 803-9100

www.hbkworld.com

Mat.:

DVS: A05895 01 X00 00

07.2022

EHottinger Brüel & Kjaer GmbH

Subject to modifications.

All product descriptions are for general information

only. They are not to be understood as a guarantee of

quality or durability.

Änderungen vorbehalten.

Alle Angaben beschreiben unsere Produkte in allge

meiner Form. Sie stellen keine Beschaffenheits- oder

Haltbarkeitsgarantie dar.

AD103C

ENGLISH DEUTSCH

Operating Manual

AD103C

TABLE OF CONTENTS

2

TABLE OF CONTENTS

1 Safety Instructions 3................................................

2 Markings used 5....................................................

2.1 Markings used in this document 5.....................................

2.2 Symbols on the device 6.............................................

3 Special features 7..................................................

4 Mechanical construction 8...........................................

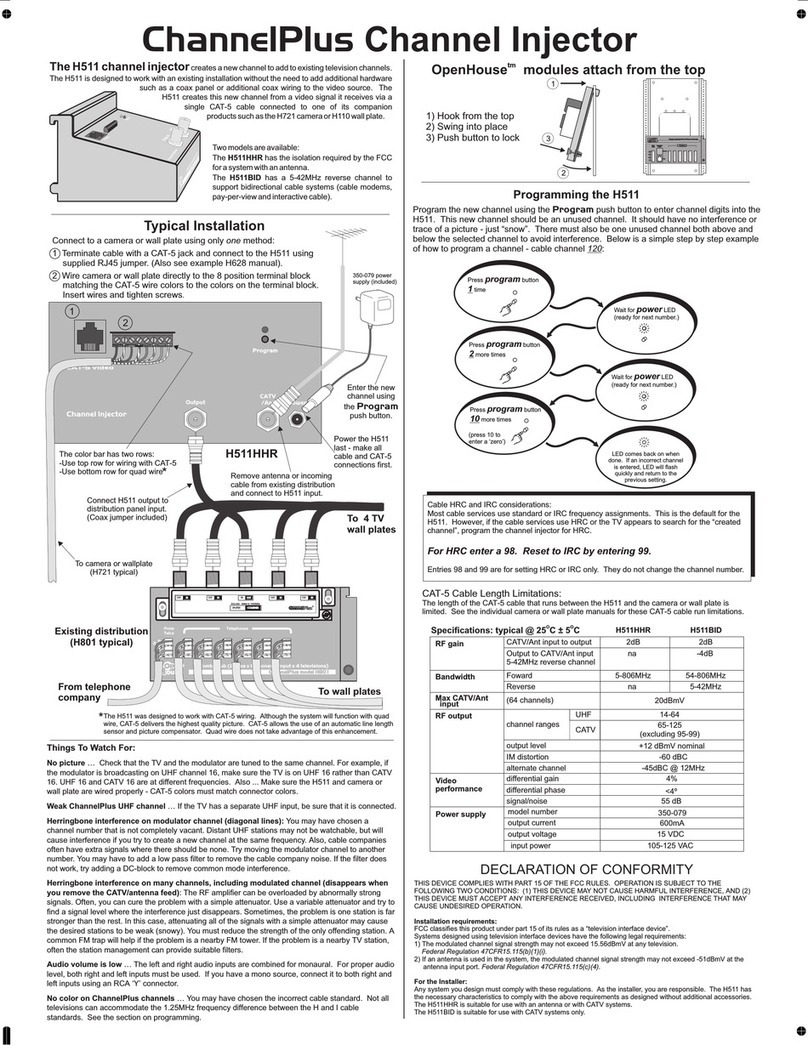

5 Amplifier board Electrical configuration 9..............................

5.1 Function 10.........................................................

5.2 Signal conditioning 11................................................

5.2.1 Triggering 12........................................................

5.2.2 Limit value outputs 12................................................

5.2.3 Control inputs 12....................................................

5.2.4 Extreme values 12...................................................

5.2.5 Filling control 13.....................................................

5.2.6 Diagnostic function 13................................................

6 Electrical connection 14..............................................

6.1 Transducer connection 14.............................................

6.1.1 Connection in a 6-wire configuration 14..................................

6.1.2 Connection in a 4-wire configuration 15..................................

6.2 Connecting the supply voltage 16.......................................

6.3 Connecting the RS232 serial interface 17................................

6.4 Connecting CAN bus or DeviceNet 18...................................

6.5 Connecting the diagnostic interface 19..................................

6.6 Hardware switch for parameter protection 19............................

6.7 Connecting the digital inputs/outputs 20.................................

6.7.1 Hardware connection, signal level 20....................................

6.7.2 Function of limit value outputs and control inputs 22.......................

6.7.3 Function of inputs/outputs for dosing control (IMD2) 23....................

Index 24...................................................................

3

AD103C

SAFETY INSTRUCTIONS

1 SAFETY INSTRUCTIONS

Intended use

AD103C digital transducer electronics are part of the AED component family that digitally

conditions signals from mechanical measurement sensors and networks them with bus

capability.

These include digital amplifier boards, basic devices and intelligent sensors with inte

grated signal processing. It is the task of these components to directly digitize and condi

tion the measurement signals at the transducer location. Using digital transducer elec

tronics, you can directly connect Strain Gage (SG) transducers in a full bridge circuit to a

controller or PC. This enables you to configure complete measurement chains quickly

and with little extra work.

The AD103C amplifier board can be operated independently from the basic devices.

The AED basic devices provide mechanical protection, shield the AD103C amplifier

boards (EMC protection) and also allow you to select other interfaces in addition to the

RS232 serial interface, such as RS485 (4-wire), Profibus, CANOpen and DeviceNet.

The signal conditioning functions of limit value monitoring, extreme value memory and

fast-settling digital filters open up the door to further areas of application. In addition, the

AD103C enables you to control the filling and dosing processes.

The free PanelX PC software is provided for easy setting of all parameters, displaying

dynamic measurement signals, and comprehensive analysis of the dynamic system.

In this document, the AD103C transducer electronics are also referred to by the abbrevia

tion AED (Aufnehmer-Elektronik-Digital, digital transducer electronics).

The AD103C commands are compatible with the AD103B amplifier. The calibration func

tion (CAL, ACL commands) to ensure the accuracy of the AD103C is no longer needed.

However, these commands are still implemented to ensure software compatibility. The

AD103C no longer needs measurement interruption to ensure measurement accuracy.

Operating conditions

The design and safety features of the device must not be modified. Any modification will

void our liability.

SThere are no hazards associated with this product, provided the notes and instruc

tions for project planning, installation, correct operation and maintenance are

observed.

SEach time before starting up the equipment, you must first run a project planning and

risk analysis that takes into account all the safety aspects of automation technology,

especially in relation to the protection of persons and equipment.

SCompliance with the safety and accident prevention regulations applicable to each

individual case is essential.

SInstallation and start-up must only be carried out by suitably qualified personnel.

AD103C

SAFETY INSTRUCTIONS

4

SDo not allow the equipment to become dirty or damp.

SDuring installation and when connecting the cables, take action to prevent electro

static discharge as this may damage the electronics.

SThe required power supply is an extra-low voltage (5V) with safe disconnection from

the mains.

SComply with the relevant safety requirements when connecting additional devices.

SShielded cables must be used for all connection cables. The whole surface of both

sides of the shield must be connected to earth.

The power supply and digital I/O connection cables only need to be shielded if the cables

are longer than 30 m or are routed outside closed buildings.

SBy way of the CE mark, the manufacturer guarantees that the product complies with

the requirements of the relevant EC directives (the Declaration of Conformity can be

found at http://www.hbm.com/HBMdoc

).

SIn accordance with national and local environmental protection and material recovery

and recycling regulations, old devices that can no longer be used must be disposed of

separately and not with normal household garbage.

If you require more information about disposal, please contact your local authorities or

the dealer from whom you purchased the product.

It is strictly forbidden to carry out any repairs and soldering work on the boards or to

replace any components. Repairs may only be carried out by persons authorized by Hot

tinger Brüel & Kjaer GmbH.

All the factory defaults are stored at the factory, where they are safe from power failure

and cannot be deleted or overwritten, and where they can be reset at any time using the

TDD0 command. For more information, see the PanelX Help AD103C; Standard com

mands.

The factory-set production number must not be changed.

The transducer connection must always be assigned. The connection of a transducer or

bridge model is essential for operation.

The AD103C is designed for a supply voltage (bridge excitation voltage) of 5 VDC.

After the voltage is switched on, the AD103C amplifier needs a warm-up time of 15 min

utes.

5

AD103C

MARKINGS USED

2 MARKINGS USED

2.1 Markings used in this document

Important instructions for your safety are highlighted. Following these instructions is

essential in order to prevent accidents and damage to property.

Icon Meaning

WARNING This marking warns of a potentially dangerous situa

tion in which failure to comply with safety require

ments could result in death or serious physical injury.

CAUTION This marking warns of a potentially dangerous situa

tion in which failure to comply with safety require

ments could result in slight or moderate physical

injury.

Notice This marking draws your attention to a situation in

which failure to comply with safety requirements

could lead to property damage.

Important

This marking draws your attention to important infor

mation about the product or about handling the prod

uct.

Tip

This marking indicates tips for use or other informa

tion that is useful to you.

Information

This marking draws your attention to information

about the product or about handling the product.

Emphasis

See …

Italics are used to emphasize and highlight text and

identify references to sections of the manual, dia

grams, or external documents and files.

Device -> New Bold text indicates menu items, as well as dialog and

window headings in the program environment. Arrows

between menu items indicate the sequence in which

the menus and sub-menus are opened.

Sample rate Bold text in italics indicates inputs and input fields in

the user interfaces.

uThis symbol indicates an action step.

AD103C

MARKINGS USED

6

2.2 Symbols on the device

CE mark

With the CE mark, the manufacturer guarantees that the product

complies with the requirements of the relevant EC directives (the

Declaration of Conformity can be found on the HBK website

(www.hbm.com) under HBMdoc).

Statutory waste disposal marking

In accordance with national and local environmental protection

and material recovery and recycling regulations, old devices that

can no longer be used must be disposed of separately and not

with normal household garbage.

7

AD103C

SPECIAL FEATURES

3 SPECIAL FEATURES

SSupply voltage 5 VDC ±5 %

STransducer excitation via external power supply.

SMeasurement input ohmic full bridges

SNominal (rated) sensitivity ±2 mV/V

SRS232 serial interfaces

SDigital filtering and scaling of the measurement signal

SCorrection of non-linearity

SPower failsafe storage of parameters

SIndestructible storage of factory defaults

SChoice of measured value output speed (max. 1200 M/s)

SAll settings made via the serial interface

SZero balance (±2 %)

SAutomatic zero tracking (0.5 d/s, ±2 %)

SAutomatic zero on start-up (±2 %...±20 %)

STrigger functions (level pre-/post-triggering, external pre-/post-triggering)

SFour limit switches

SExtreme value memory (MIN/MAX)

SFilling and dosing function

SHardware switch for parameter protection in legal-for-trade (LFT) applications

SDiagnostic bus

AD103C

MECHANICAL CONSTRUCTION

8

4 MECHANICAL CONSTRUCTION

AD amplifier boards are designed as plug-in boards and plug into the carrier board via a

25-pin sub-D connector.

The use of an AED basic device (not supplied with the AD103C) adds the following char

acteristics to extend the functionality:

SMechanical protection (IP65) via AED9101D, AED9201B, AED9301B, AED9401A or

AED9501A basic devices

SOverall bridge resistance (40) 80...4000 Ωvia the power supply to the basic devices

SAdditional interfaces RS232, RS422/RS485, Profibus, CAN bus, DeviceNet

SElectrically isolated digital inputs/outputs

SEMC protection (tested)

SCover for the ‘write protection’ switch and stamping point for LFT applications

SDiagnostic bus

The basic device features terminals for the transducer, power supply and PC connec

tions, switches for interface selection, and the voltage stabilizer. The connection cables

exit the housing via PG glands (see the respective operating manuals, Basic devices):

AED9101D basic device RS232/RS485 2- or 4-wire interface

AED9201B basic device RS232/RS485 4-wire interface

AED9301B basic device Profibus interface

AED9401A basic device CANOpen or DeviceNet interface

AED9501A basic device CANOpen or DeviceNet interface

The basic devices still differ in the following functionality:

AED9101D basic device Supports the input IN1

AED9201B basic device Supports the inputs IN1, IN2 and OUT1...6

AED9301B and AED9401A basic devices

Support the inputs IN1, IN2 and OUT1...4

AED9501A basic device Supports the input IN1

The AED9201B, AED9301B and AED9401A basic devices achieve complete electrical

isolation of the amplifier from the power supply, the serial interface and the digital

inputs/outputs.

All basic devices support the diagnostic bus.

9

AD103C

AMPLIFIER BOARD ELECTRICAL CONFIGURATION

5 AMPLIFIER BOARD ELECTRICAL CONFIGURATION

The digital transducer electronics circuit basically comprises the following function

groups:

SAmplifier

SAnalog/digital converter (A/D)

SEvaluation unit (μP)

SPower failsafe parameter storage (EEPROM)

SRS232 serial interface

SDigital inputs/outputs (HCMOS)

SPower supply

SHardware switch for write protection of LFT parameters

SBus connection for DeviceNet, CANOpen and diagnostic functions

CAUTION

The analog part is supplied with power via the external 5 VDC power supply, which is simul

taneously used as the bridge excitation voltage.

The supply voltage range of 5 VDC +5 % must not be exceeded.

The AED's external supply voltage must have low residual ripple (< 10 mV), as this supply

voltage must simultaneously be used as the bridge excitation voltage.

AD103C

AMPLIFIER BOARD ELECTRICAL CONFIGURATION

10

5.1 Function

RS232

Digital I/O

AED9101D

SG transducer

AD103C

18...30 V

Power supply unit

Voltage

stabilizer

Calibration

Measurement

mode

Zero

RS485

4-wire

EEPROM

Production number

Linearization

Digital filter

Sample rate

Zero setting

Sensitivity

1200…115200 bauds

Computer

RS485

2-wire Diagnostic bus

RS485

2-wire

Fig. 5.1 AED9101D basic device with amplifier board (example)

The analog transducer signal is first amplified, then filtered and converted to a digital

value in the analog/digital converter. The digitized measurement signal is conditioned in

the microprocessor. The conditioned signal is forwarded to a computer via the serial

interface. All the parameters can be stored power failsafe in the EEPROM.

In the factory, the transducer electronics are adjusted by a calibration unit to the absolute

values 0 mV/V and +2 mV/V. From these measured values, the electronics use the com

mands SZA and SFA to determine a factory characteristic curve and map the subsequent

measured values over this curve. The following measured values are delivered, depend

ing on the output format (COF):

Output format Input signal Meas. values for

NOV = 0

Meas. values

for NOV > 0

Status on delivery

NOV = 0

Binary, 2 chars.

(integer)

0...2 mV/V 0 - 20000 digits 0 - NOV

Binary, 4 chars.

(long integer)

0...2 mV/V 0 - 5120000 digits 0 - NOV

ASCII 0...2 mV/V 0 - 1000000 digits 0 - NOV X

The unit of measurement mV/V reflects the ratio of the measuring voltage to the excita

tion voltage at the transducer bridge.

The factory setting for the SZA/SFA curve should not be changed.

11

AD103C

AMPLIFIER BOARD ELECTRICAL CONFIGURATION

With the pair of parameters LDW and LWT, you have the option of adapting the character

istic curve to meet your requirements (scale curve) and to standardize the measured val

ues to the required scaling value (e.g. 3000 d) using the NOV command.

The AD103C also offers you the option of setting different increments (1 d, 2 d, 5 d, 10 d,

20 d, 50 d, 100 d) using the RSN command.

5.2 Signal conditioning

FMD

ASF

Measuring

bridge Filter

Factory

calib-

ration

Sample

rate

Fine flow

Coarse flow

Net

RUN

BREAK

Dosing control

Ready

Alarm

Gross

measured

value

1 Trigger

2 Tare

Linear-

ization

User

scaling

Amplifier

ADC

SZA

SFA

NOV,RSN

LDW

LWT LIC

TAV,TAS

IMD

1...4

LIV

ICR

Limit

values

MIN/

Net

measured

value

MAX

Extreme

values

Fig. 5.2 Signal flow diagram of the AD103C amplifier

After amplification and A/D conversion, the signal is filtered by adjustable digital filters

(FMD, ASF commands). The ASF and FMD commands set the bandwidth for the

measurement signal (digital filters). The ICR command can be used to modify the output

rate (measured values per second), irrespective of the filter bandwidth. The HSM com

mand selects the ADU sample rate (600 Mw/s or 1200 Mw/s).

Various types of digital filter are implemented in the AED and these are selected using

the FMD command. With FMD0, filters are also available below the 1 Hz bandwidth. In the

FMD1 filter mode, fast-settling filters with high damping in the stop band are activated.

The signal conditioning functions described below are executed at the set output rate,

even if there is no communication via the serial interface.

The SZA and SFA commands are used to define the factory characteristic curve.

As a user, you can set your own characteristic curve with the LDW, LWT and NOV com

mands, without changing the working standard calibration (SZA/SFA). You can also

choose between gross/net (TAS, TAR command). The ZSE command activates auto

matic zero on start-up. There is also an automatic zero tracking function (ZTR) and zero

setting function (CDL).

AD103C

AMPLIFIER BOARD ELECTRICAL CONFIGURATION

12

The (LIC) command is available for linearization of the scale curve (with a third order

polynomial). Polynomial parameters can be defined using the HBK PanelX PC software.

The current measured value is read out using the MSV? command. The format of the

measured value (ASCII or binary) is set with the COF command. You can also use the COF

command to select automatic data output.

5.2.1 Triggering

The AD103C features four trigger functions to support functions in packaging machinery

and checkweighers:

SLevel post-/pre-triggering via an adjustable level

SExternal post-/pre-triggering via a digital trigger input (IN1)

Either the gross or the net measured value can be used as the trigger function input

(depending on the tare function, TAS).

This special measurement mode is activated via the TRC command. The established

measured value is read out using the MAV? command.

5.2.2 Limit value outputs

The AD103C provides four limit values, which are set via the LIV command. Limit value

outputs are available as hardware outputs on the 25-pin connector and as logical outputs

in the measured value status. As the input signal for limit value monitoring, you have a

choice between the gross value, the net value, the trigger result or the MIN/MAX extreme

values.

(also see section 5.6.2, Function of limit value outputs and control inputs)

5.2.3 Control inputs

You can activate 2 inputs (IN1/2) as control inputs via the IMD1; command.

A Low/High (0 V →5 V) edge at input IN1 initiates an external triggering process (TRC,

external triggering).

A Low level at input IN2 causes the measured value to be tared. For the tare input, the

Low level must be present for at least 20 ms (debounce time).

You can find more detailed information in the PanelX Help.

The IMD2 command activates the dosing function. This also switches the function of the

two control inputs:

IN1 = Stop (BRK) and IN2 = Start (RUN)

5.2.4 Extreme values

The AED includes an extreme value function, which can monitor either gross or net

measured values or trigger results (MAV). The two extreme values (MIN and MAX) are

13

AD103C

AMPLIFIER BOARD ELECTRICAL CONFIGURATION

output using the PVA command. The CPV command can be used at any time to clear the

extreme values. Activation is achieved via the PVS command.

5.2.5 Filling control

The filling and dosing function is activated via the IMD2; command.

In this case, the limit value function settings and the trigger function for the digital inputs/

outputs are meaningless.

5.2.6 Diagnostic function

A diagnostic function has been integrated in the AD103C to monitor dynamic measure

ments. This function includes a memory for 512 (binary) measured values and associ

ated status information. Different recording modes are available, so that the processes

can be analyzed without interrupting measurement.

The diagnostic function can be accessed in two modes:

SVia the main communication channel (RS232/RS485, Profibus, CAN bus or DeviceNet

SVia the diagnostic bus (RS485 2-wire)

The diagnostic output allows a display to be connected. Here, the measured values are

transmitted in encrypted form.

AD103C

ELECTRICAL CONNECTION

14

6 ELECTRICAL CONNECTION

6.1 Transducer connection

SG transducers with full bridge can be connected.

Bridge resistance RB= 40...4000 Ω(external excitation voltage). SG transducers must

operate at a bridge excitation voltage of 5 VDC.

Transducers with a bridge resistance >1000 Ωcan also be connected in principle. How

ever, this will increase the noise of the measurement signal (increased measurement

ripple).

Currentconsumption +≤90mA )ExcitationvoltageUB

BridgeresistanceRB

Important

Make sure that a low-noise constant voltage source is used for the excitation voltage, as

the quality of the power supply is directly reflected in the measurement result (see Calcula

tion).

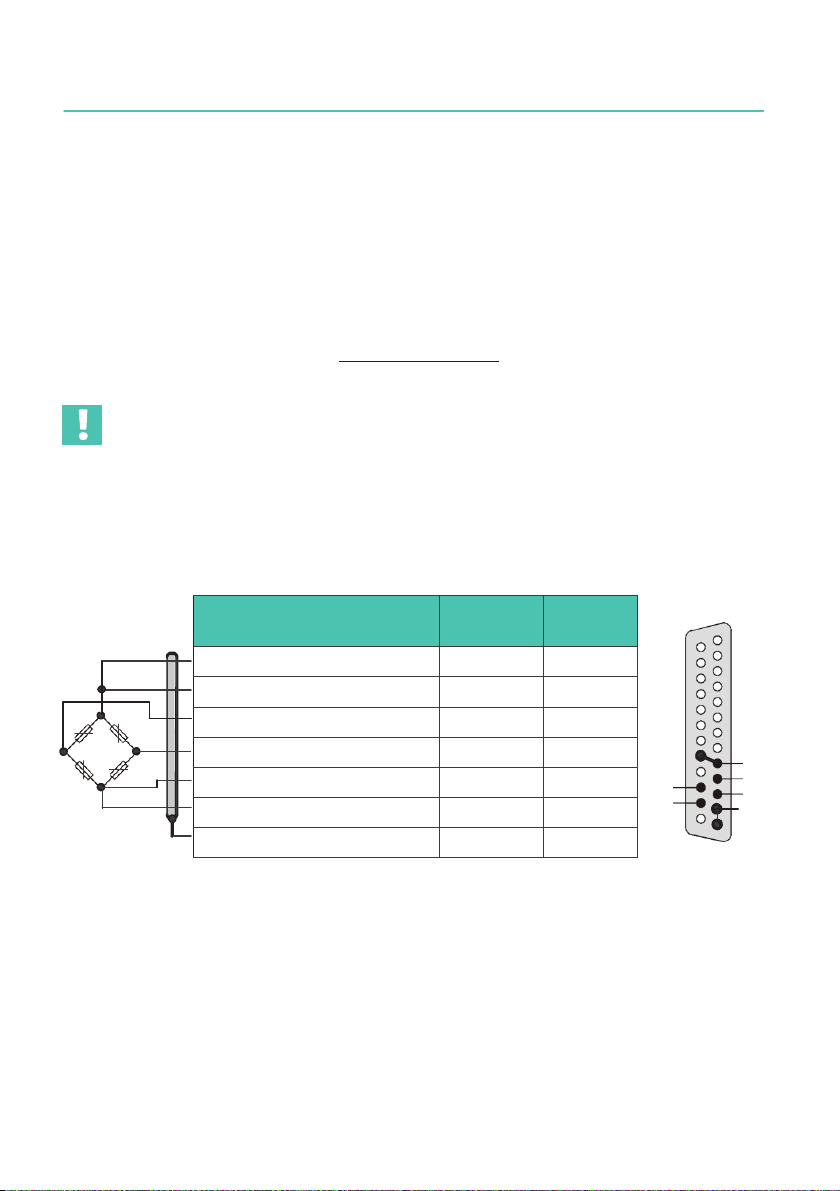

6.1.1 Connection in a 6-wire configuration

HBK color

code

Pin

socket

Bridge excitation voltage (+) bl 9/21

Sense lead (+) gn 10

Measurement signal (+) wh 24

Measurement signal (–) rd 11

Bridge excitation voltage (–) bk 12/13

Sense lead (–) gy 23

Cable shield ye Housing

Fig. 6.1 Transducer connection (6-wire) to the AD103C amplifier board

14 1

gy

wh

25

bl

gn

rd

bk

13

Bu1 amplifier

(back of connector)

15

AD103C

ELECTRICAL CONNECTION

6.1.2 Connection in a 4-wire configuration

Connection without an extension cable; sense lead bridged at the transducer electronics.

HBK color

code

Pin

socket

Bridge excitation voltage (+) bl 9/21

Sense lead (+) gn 10

Measurement signal (+) wh 24

Measurement signal (–) rd 11

Bridge excitation voltage (–) bk 12/13

Sense lead (–) gy 23

Cable shield ye Housing

Fig. 6.2 Transducer connection of supply leads and sense leads in a 4-wire

configuration without a cable extension

Information on the type of connection, cable length and cross-section

Voltage drops that can lower the bridge excitation voltage may occur, depending on the

bridge resistance of the load cell used, and the length and cross-section of the load cell

connection cable. The voltage drop at the connection cable is also dependent on temper

ature (copper resistance). Likewise, the output signal of the load cell changes in propor

tion to the bridge excitation voltage.

This is balanced out when connecting in a 6-wire configuration.

(See operating manuals of AED9101D, AED9201B, AED9301B, AED9401A or AED9501A

basic devices)

Bu1 amplifier

(back of connec

tor)

14 1

bl

wh

25 bk

13

rd

AD103C

ELECTRICAL CONNECTION

16

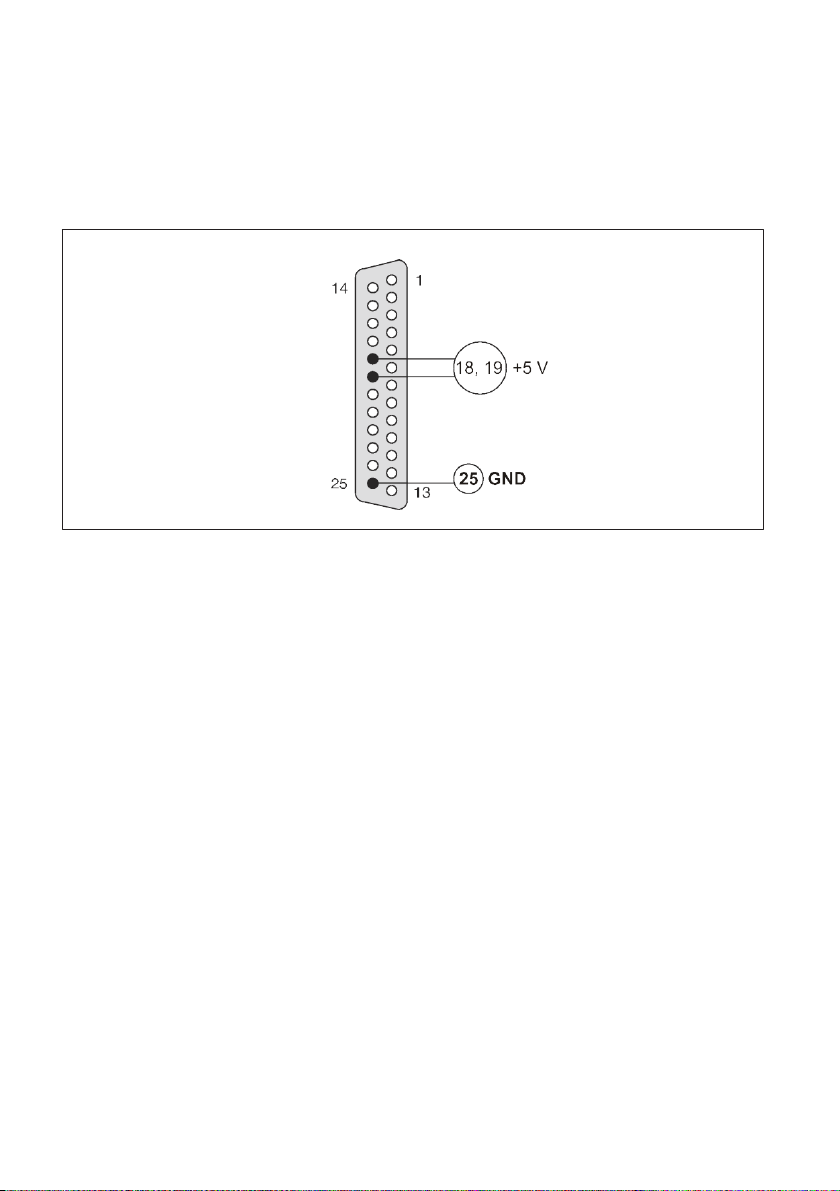

6.2 Connecting the supply voltage

The supply voltage must meet the following requirements:

Regulated DC voltage +5 V ±5 %

Residual ripple <10 mV (peak-to-peak)

AD103C current consumption <120 mA (without SG bridge)

AD103C

Fig. 6.3 Connecting the supply voltage to the amplifier board

17

AD103C

ELECTRICAL CONNECTION

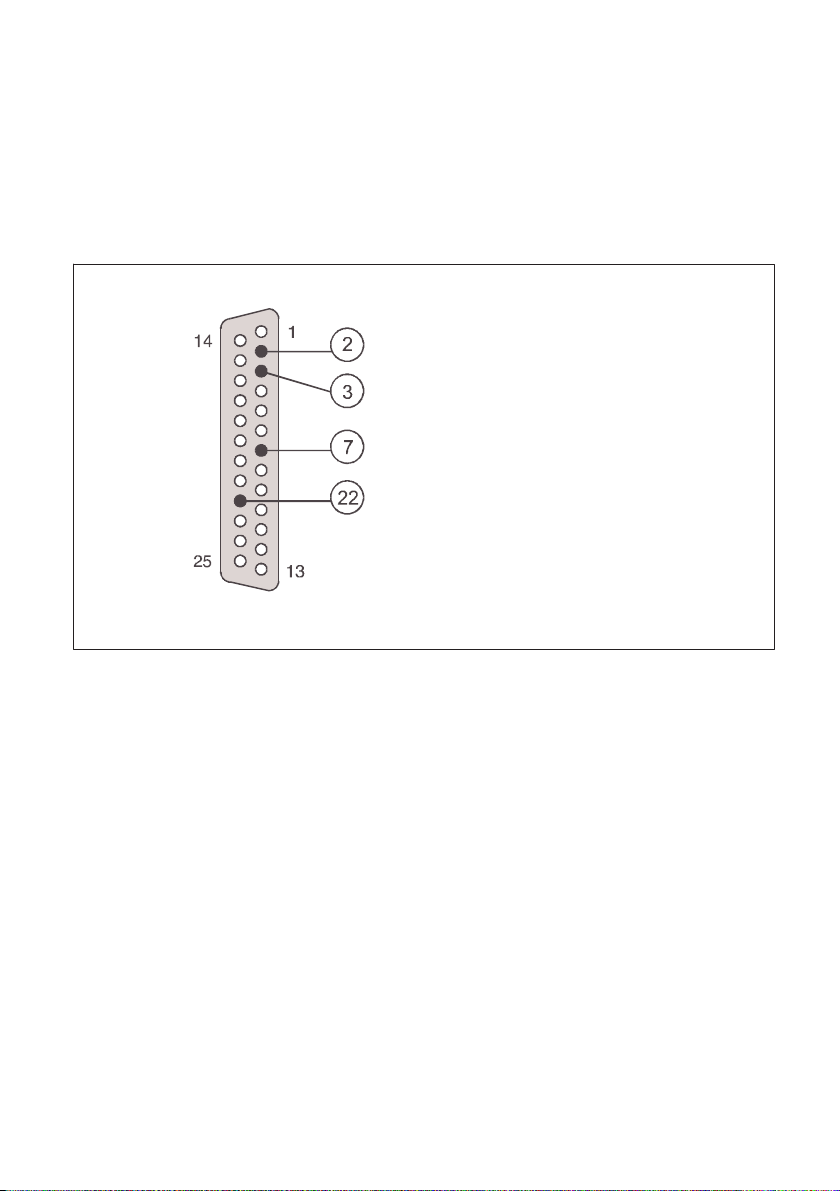

6.3 Connecting the RS232 serial interface

The amplifier board is equipped with an RS232 interface as standard. Baud rates of

1200...115200 bit/s are available for this serial interface. In addition to the RxD (Receive

Data) and TxD (Transmit Data) interface lines, a DTR (Data Terminal Ready) control line is

also available for triggering bus driver modules (e.g. LTC485). When the amplifier board

is installed in a basic device, the RS422 (factory default), RS485 and RS232 interfaces are

directly available.

AD103C amplifier

Bu1

(back of connector)

RxD, RxD < -3 V -> quiescent level

TxD, TxD < -3 V -> quiescent level

GND, interface

DTR, DTR < -3 V -> quiescent level

DTR, DTD > +3 V -> transmitter active

RS232:

Fig. 6.4 Pin assignment for the RS232 interface on the amplifier boards

AD103C

ELECTRICAL CONNECTION

18

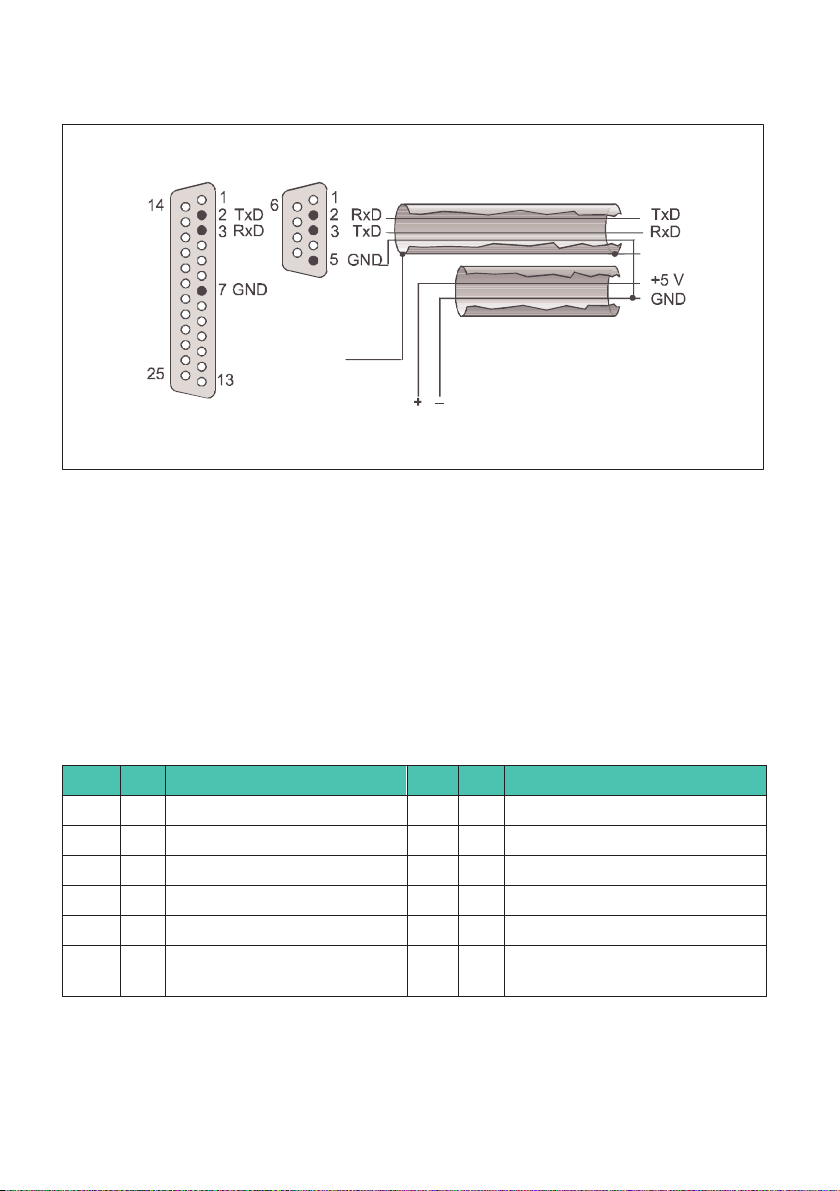

Connecting the AED to a computer via the RS232 interface

Computer

RS232

AD103C

RS232

9-pin socket

(solder view)

Housing

Power supply

unit

25-pin socket

(solder view)

Housing

Fig. 6.5 Connecting the AD103C to a PC or controller via RS232 and supply voltage

(5VDC only!!)

Multi-channel measurement is only possible with appropriate bus drivers (RS485) (see

operating manuals of the AED9101D, AED9201B, AED9301B, AED9401A or AED9501A

basic devices).

6.4 Connecting CAN bus or DeviceNet

The AD103C amplifier has an additional 12-pin connector for providing another connec

tion to the AED basic device. The following signals are directed via this two-row connec

tor:

PIN I/O Signal PIN I/O Signal

1 - GND 2 - Not connected

3 - Not connected 4 I DRxD (diagnosis)

5 I CRxD (CAN/DeviceNet) 6 O CTxD (CAN/DeviceNet)

7 O DDTR (diagnosis) 8 O DTxD (diagnosis)

9 - Not connected 10 - Not connected

11 I CDS (CAN/DeviceNet selec

tion)

12 I DIAG (digital outputs), for HBK

only

I/O – input/output

Table of contents

Languages:

Other HBK Amplifier manuals