HearthStone Quality Home Heating Products MODEL Sterling “G” B-Vent

Warnings -Cautions -Safety Information

NOTE

This gas appliance must be installed and

maintained by qualified service personnel. Failure

to properly install, adjust and maintain this gas

appliance may result in an unsafe or hazardous

condition which may lead to carbon monoxide

poisoning, fire, explosion, personal injury and loss of

life.

CAUTION

This gas appliance must be operated and maintained

according to the instructions contained in this owner's

manual. The unit must be inspected before use and at

least annually by qualified service personnel. More

frequent cleaning may be required due to excessive

lint from carpeting, bedding material, etc. It is

imperative that control compartments, burners, and

circulating air passageways of the appliance be kept

clean.

WARNING

Do not use this appliance if any part has been under

water. Immediately call qualified service personnel to

inspect the appliance and to replace any part of the

control system and any gas control which has been

under water.

HAZARD

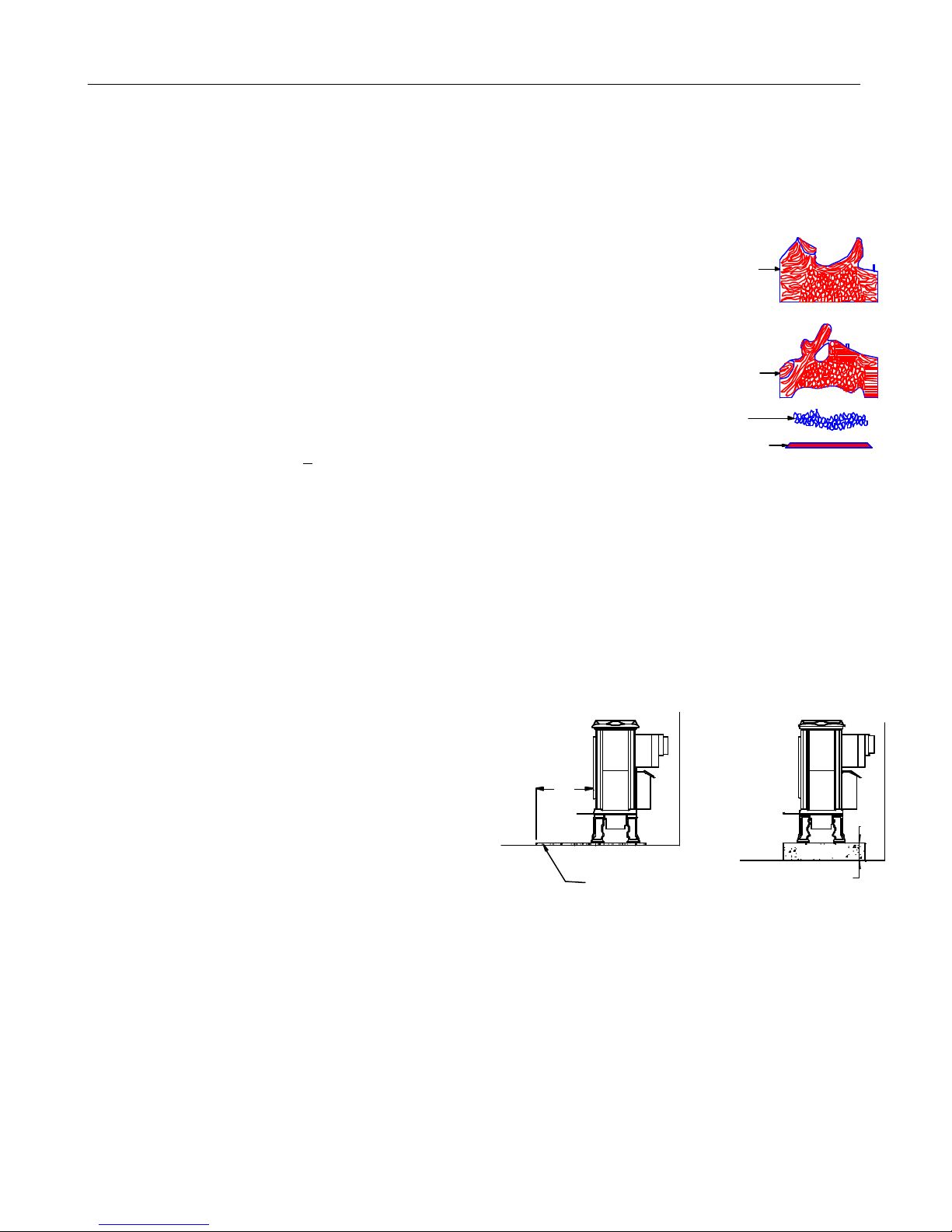

This gas appliance must be connected to a properly

installed and maintained venting system (chimney).

This appliance is equipped with a down draft sensor

switch (vent spill switch). Tampering, modifying,

disconnecting or overriding the vent safety shutoff

system may result in an unsafe or hazardous condition

which may lead to carbon monoxide poisoning and

loss of life.

HOT SURFACES

Certain exposed surfaces of the Sterling will reach

high temperatures during normal operation. Clothing

or other flammable material should not be placed on or

near the appliance. Do not place objects that may

obstruct air circulation on, under or near this heater.

Clearances to combustibles must be maintained as

specified elsewhere in this manual. The Sterling

should be located out of traffic and away from

furniture, draperies, clothing and flammable material.

Children and adults who are unfamiliar with heaters of

this type should be alerted to the hazards of high

surface temperatures and warned that they should stay

away to avoid burns to skin or clothing ignition.

Children should be carefully supervised when in the

same area as the Sterling heater. Do not leave children

unattended in the vicinity of this unit.

FIRE HAZARD

Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this appliance.

Clean the area around, under and behind the unit on

a regular basis to prevent the accumulation of dust

and lint.

ELECTRICAL HAZARD

This appliance is equipped with a three-prong

grounded plug if equipped with an optional blower fan.

The three-prong grounded plug must be plugged

directly into a properly grounded three-prong

receptacle. Do not cut or remove the grounding prong

from the plug or otherwise attempt to circumvent the

grounding protection provided with the unit. The

appliance must be electrically connected and grounded

in accordance with local codes or, in the absence of

local codes, with the current NFPA 70-National

Electric Code or CSA C22.1-Canadian Electrical Code.

CAUTION

This unit has a standing pilot light which is lit using

a piezoelectric spark generator as described elsewhere

in this manual. Never attempt to light the pilot light or

main burners by hand with a match or lighter. If, after

repeated attempts, the pilot light fails to light,

discontinue operation, turn off the gas at the Sterling

gas control valve and immediately contact qualified

service personnel for assistance.

FUEL WARNING

This unit is designed to burn either natural gas or

liquid propane as specified. Do not place candles on

top or above the stove. Never burn paper, wood or any

other materials in this unit, failure to comply may

result in property damage or personal injury.

SAFETY INFORMATION

This unit is supplied with decorative ceramic fiber

logs. If the decorative ceramic fiber become damaged

or broken they must be replaced with similar, approved

decorative ceramic fiber logs supplied by the

manufacturer. Do not replace the manufacturer-