28 Heat & Glo • VRTIKL-AU • 2123-900 • 7/07

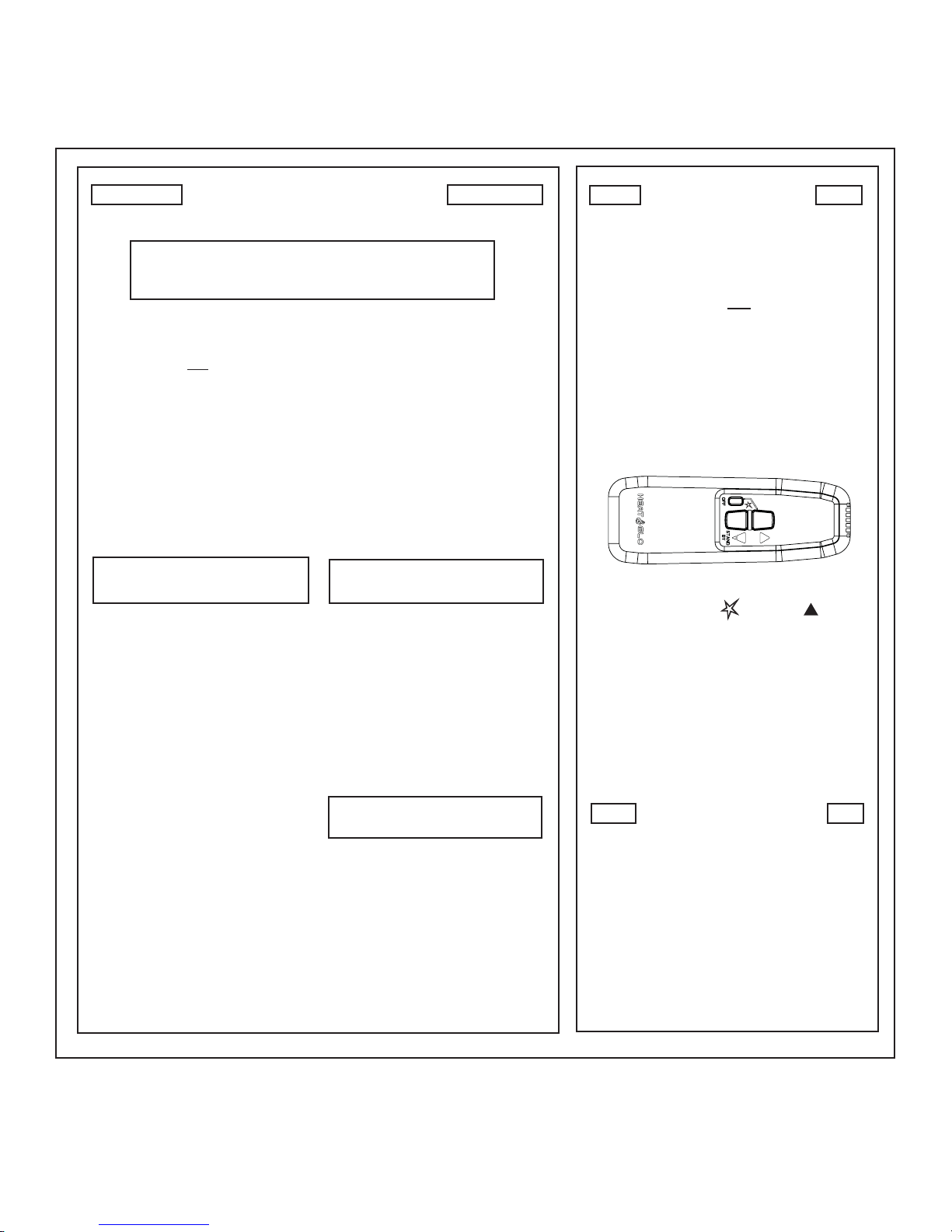

B. Lighting the Appliance

Electronic Ignition

LIGHTING

INSTRUCTIONS

TO TURN OFF

GAS TO HEATER

1. Push the ‘OFF’ button on remote.

2. Remove batteries from receiver.

FOR YOUR SAFETY

READ BEFORE LIGHTING

WARNING: If you do not follow these instructions

exactly, a fire or explosion may result causing property

damage, personal injury or loss of life.

A. This heater is equipped with an

electronic pilot ignition device

which automatically lights the

burner. Do not try to light the

burner by hand.

B. BEFORE LIGHTING, smell all

around the heater area for gas.

Be sure to smell next to the floor

becausesome gas is heavierthan

air and will settle on the floor.

WHAT TO DO IF YOU SMELL

GAS

• Do not try to light any appliance.

Improper installation, adjustment,

alteration, service or maintenance

can cause injury or property dam-

age.Refertotheowner’s information

manual provided with this fireplace.

This heater needs fresh air for safe

operation and must be installed so

there are provisions for adequate

combustion and ventilation air.

If not installed, operated, and main-

tained in accordance with the man-

ufacturer’s instructions, this product

could expose you to substances in

fuel or fuel combustion.

Keep burner and control compart-

ment clean. See installation and

operating instructions accompany-

ing heater.

CAUTION:

Hotwhilein operation. Do nottouch.

Keep children, clothing, furniture,

gasoline and other liquids having

flammable vapors away.

Do not operate the heater with

panel(s) removed, cracked or bro-

ken. Replacement of the panel(s)

should be done by a licensed or

qualified service person.

• Donottouchanyelectric switch; do

not use any phone in your building.

• Immediately call your gas supplier

from a neighbor’s phone. Follow

the gas supplier’s instructions.

• If you cannot reach your gas sup-

plier, call the fire department.

C. Do not use this fireplace if any part

hasbeenunderwater.Immediately

callaqualifiedservicetechnicianto

inspect the heater and to replace

any part of the control system and

any gas control which has been

under water.

NOT FOR USE

WITH SOLID FUEL

For use with natural or propane

gases.

WARNING:

1. This heater is equipped with an igni-

tion device which automatically lights

the burner. Do not try to light the

burner by hand.

2. Wait five (5) minutes to clear out any

gas. Then smell for gas, including

nearthefloor.If yousmell gas,STOP!

Follow “B” in the Safety Information

located on the left side of this page. If

you don’t smell gas, go to next step.

3. To light the burner, simultaneously

press the star and up arrow

buttons on the remote control until a

shortacoustic signalconfirmsthe start

sequence has begun.

4. Iftheheaterwillnot operate,check the

batteries then follow the instructions

“To Turn Off Gas to Heater” and call

your service technician or gas sup-

plier.