HEAT GLO Radius Series User manual

Radius

Series Wood Stoves

Australian Owner's Manual • Installation and Operation

HEAT GLO.

No one builds a better fire

NOTE: This product is designed as an intermittent wood burner and not intended to be used as a primary heat source

and Welcome to the Heat & Glo Family!

Hearth & Home Technologies welcomes you to our tradition

of excellence! In choosing a Heat & Glo appliance, you

have our assurance of commitment to quality, durability,

and performance.

This commitment begins with our research of the market,

including 'Voice of the Customer' contacts, ensuring we

make products that will satisfy your needs. Our Research

and Development facility then employs the world's most

advanced technology to achieve the optimum operation of

Serial Rating Plate Example

our stoves, inserts and fireplaces. And yet we are old-fash-

ioned when it comes to craftsmanship. Each unit is meticu-

lously fabricated and surfaces are hand-finished for lasting

beauty and enjoyment. Our pledge to quality is completed

as each model undergoes a quality control inspection.

We wish you and your family many years of enjoyment in

the warmth and comfort of your hearth appliance. Thank

you for choosing Heat & Glo.

INSTALLATIONS TO COMPLY WITH AS/NZS4013 AND

WILL REQUIRE A BUILDING CONSENT

IMPORTANT: Read all instructions carefully before starting installation. Failure to follow these

instructions may result in a fire hazard and will void the warranty.

Fig. 7.1,8.1,13.1,14.1,14.2 and Table 1,2 relate to installations with tested flue systems; as per

AS/NZS 2918:2001 - Appendix F, with a ceiling angle between 0° - 30° inclusive.

For installations with a ceiling angle greater than 30°, refer to Fig. 14.2 and AS/NZS 2918:2001 4.6.3(b)

Ceiling Plate may vary in size depending on ceiling angle. Please specify ceiling pitch prior to

ordering the ceiling plate.

Radius Hardwood Certified

Particulate Emissions = 0.8 g/kg Space Heating Efficiency = 64%

Radius Series

OVERALLAVERAGEEFFICIENCYBURNINGHARD-

WOOD

(WHEN TESTED IN ACCORDANCE TO AS/NZS4012)

64%

AVERAGEPARTICULATEEMISSIONFACTORBURN-

INGHARDWOOD

(WHEN TESTEDIN ACCORDANCE TO AS/NZS 4013)

0.8 g/kg

MAXIMUM AVERAGE HEAT OUTPUT BURNING

HARDWOOD

6.5 kw

APPROVED FUEL

BURN ONLY HARDWOODWITH A MOISTURE CON-

TENT LESS THAN 25% (dry basis).

Wetbacks are NOT an approved option and must

not be fitted.

NOTE: Performance may vary from test values

depending on actual operating conditions.

INSTALLATION DATE

/ /

This appliance has been TESTED TO

AS/NZS4013 for Hardwood by HRL Technology

Report # HCMG/14/066

Date tested:

7076-260 January 12, 2015

Table of contents

Technical data ............................................................................................. 4

Installation

Safety

Technical data and dimensions

Type plate

Dimension sketch for Radius - series

Installation & Assembly .................................................................................7

Positioning your wood burning stove

V e rt ic a l V e n t i n g H o r iz o nt al

V e nt in g L e ve l in g t h e U n i t

P o si t io n n e a r t o n o n -

f l a mma b le w a l ls

Distance to furniture

Distance to flammable walls

Removal of Radius from pallet

Component Pack

Instruction for use....................................................................................... 9

General Use

Lighting Instructions

Your First Fire

Fuels

Primary Air

Upper Air Control

Secondary Air

Airwash System

Front Door Handle Operation

Front Door Seal

Chimney System

Drafting

Maintenance................................................................................................13

Ash Drawer

Refractory

Baffle Material

For Proper burn

Coated Surfaces

Cleaning the Glass

Removal of Refractory

Troubleshooting........................................................................................ 15

Service Parts & Accessories .................................................................... 16

Warranty......................................................................................................18

Radius Series

7076-260 - January 12, 2015

Installation

The house owner is responsible for ensuring that all neces-

sary national and local safety measures are observed during

installation and fitting and also responsible for observing the

fitting and operating instructions detailed in this manual.

When you install any kind of fireplace or stove, you must

inform the local authorities. You are also responsible for

calling in a chimney sweep to inspect and authorize the

installation.

To ensure best-possible functionality and safety for your

installation, we advise you to call a professional fitter. Our

Hearth and Home Dealer will be able to recommend a

qualified fitter in your area. For information on Hearth and

Home Dealers, please go to www.hearthnhome.com.

All installations must comply with AS/NZS2918:2001.

This product was tested and ceritifed using a default flue kit

IMPORTANT: Read all instructions carefully before starting

installation. Failure to follow these instructions may result in

a fire hazard and will void the warranty.

Safety

Any changes made to the product by the dealer, installer or

user could result in the product and safety functions not

functioning as intended. The same applies to the fitting of

accessories or extra equipment not supplied by Hearth and

Home. This could also be the case if parts that are neces-

sary for the operation and safety of the stove are

dismantled or removed.

External surfaces of the appliance get hot during use and

can cause burns. Use caution around the unit even when

the unit does not appear to be in use. Different materials

can hold heat for different lengths of time.

In the event of a chimney fire, keep the front door closed,

close all air controls, evacuate the structure and call the

local authorities from a safe location.

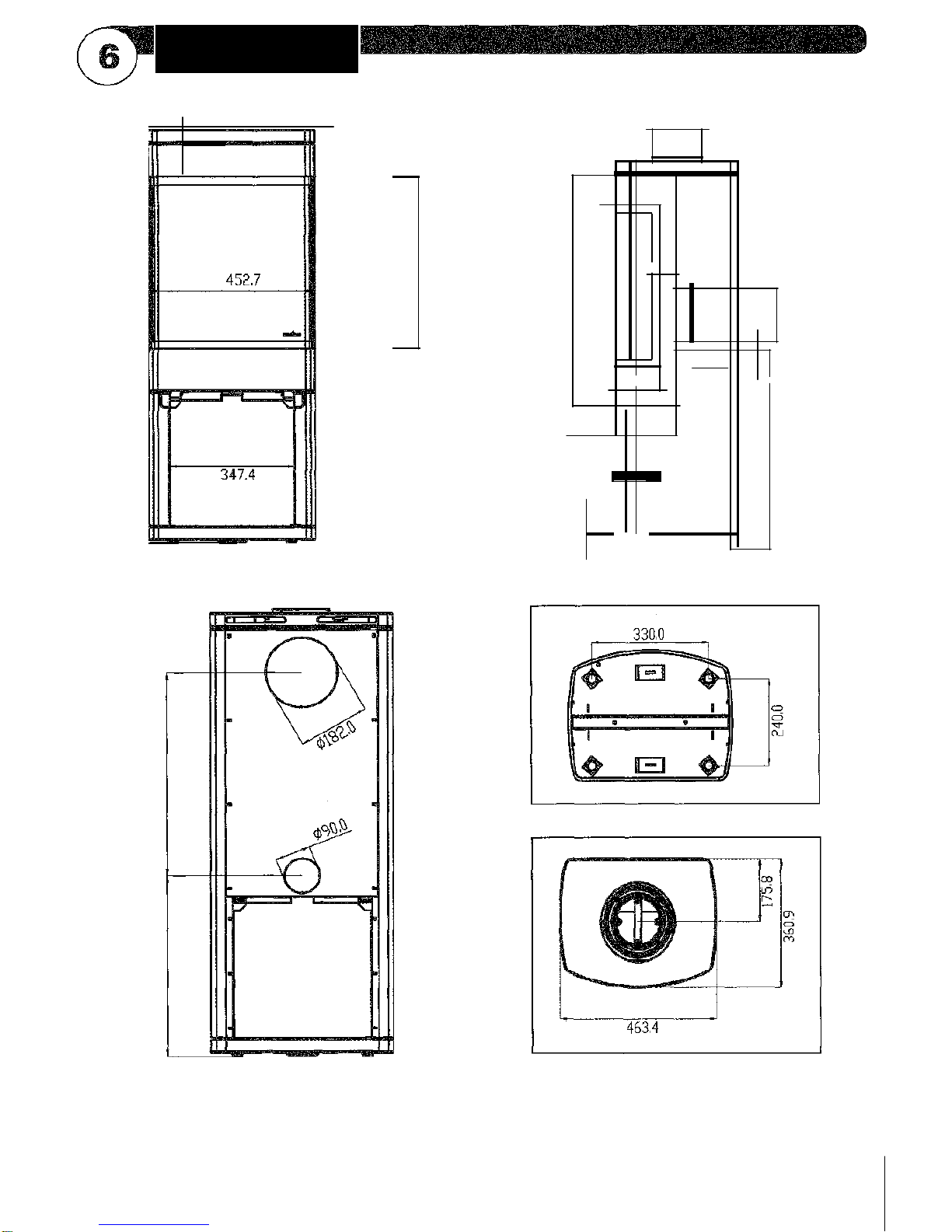

Technical data and dimensions

Materials: steel plate, cast iron, galvanized sheet, skamol

Max. wood length: 30 cm

Weight Radius 300: ca. 98 kg

Weight Radius 100: ca. 96 kg

Connecting piece internal diameter: 135 mm

Connecting piece external diameter: 148 mm

Emissions Test in compliance with AS/NZS

4012/4013

Basic data for the Radius - series

Overall Efficiency.......................................................................................... 64%

Average particulate emissions: .............................. 0.8 g/kg

Average Peak Power: ............................................ 8.9 kW

Average Power per setting:

High ................................................................. 6.5 kW

Medium............................................................ 6.0 kW

Low .................................................................. 5.1kW

Note: Be aware of the use of exhaust fans when operating

in the same room or space as the appliance, which could

affect the draft of the appliance.

Type plates

All Heat & Glo wood-burning stoves are fitted with a serial

plate, that specifies the approval standards.

NOTE: This product design intent is for intermittent use and

not as a primary heat source.

7076-260 • January 12, 2015

0144,0

353.0

co

Cb

Cu

CU

CO

Fig. 5.1: Front of Unit

cu

CO

Li)

Fig. 5.3: Right Side

Fig. 5.5: Bottom of Unit

Fig. 5.6: Top of Unit

Fig.5.2:Left Side

j

TECHNICAL DATA

Dimension Sketch - Radius 100

Cf,

ai

Cb

t

40,1

43,4

o5

Cu

Cu

Ui

179.8

CU

CO

Cu

C

O

Fig. 6.1: Front of Unit

Ca.

CO CO

"4-CO

'2,4

179.8

I 1r

Fig. 6.2: Side of Unit

Fig. 6.3: Back of Unit

Fig. 6.4: Bottom of Unit

Fig. 6.5: Top of Unit

TECHNICAL DATA

Dimension Sketch Radius 300

0144,0

,1

4

43.4

Cu

to

7076-260 • January 12, 2015

A. Positioning Your Wood Burning Stove

The wood burning stove must be set up so the stove, flue

connection, flue pipe, and chimney system can be cleaned

and serviced. Consideration should also be made when

locating the appliance in the home due to the supply of

combustion air requirements. Depending on the chosen

installation method, supplied combustion air may be taken

from the outside using the adapters provided, or through

the back of the unit by removing the cover plate on the inlet

hole. (To remove the cover or install the outside air

adapter, remove the back panel. The cover plate is located

near the bottom and retained with four screws.)

Out of the box, the appliance without the additional weight

of the venting system or fuel load weighs nearly 100

kilograms. Make considerations for the weight of the

system when locating the unit in the desired location. If the

load bearing characteristics of the structure are difficult to

determine or there is concern that the structure will not

adequately support the system, a distribution plate should

be used. Contact your Radius Wood Stove dealer with

questions.

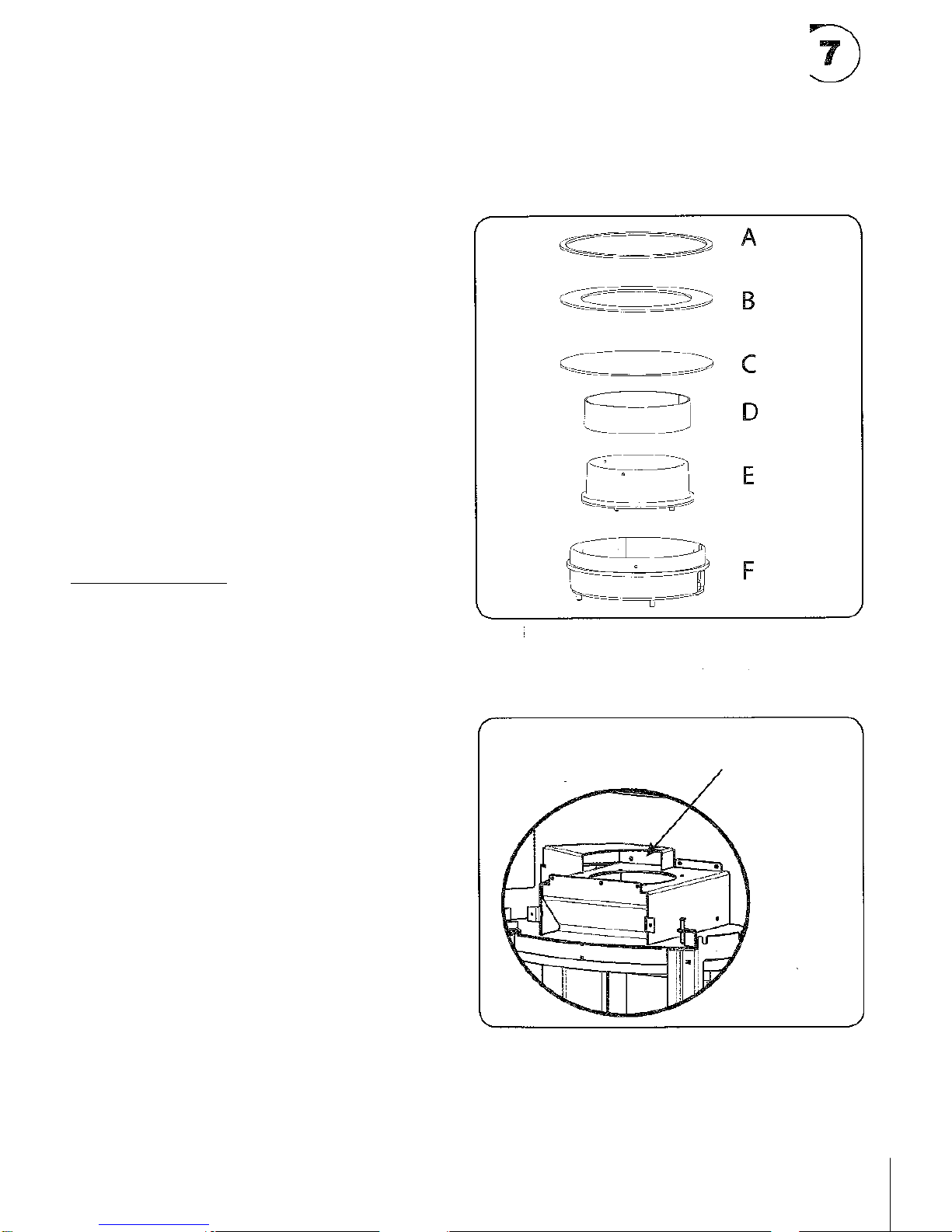

B. Vertical Venting & Combustion Air

When venting the appliance vertically, follow the venting

manufacturer's instructions and requirements. Slip the

cover ring down the flue and set on top of the appliance.

Vertical Venting Options (Fig. 7.1)

Standard 150mm Venting: E, B, F

Coaxial venting: F, E, D, A

(Use the items indicated for your installation. Use the bolts

provided to attach the components in the order shown.)

When installing F:

- If installing outside combustion air, turn F to cover the

opening at the top of the combustion air plenum.

- If using room combustion air or coaxial venting, turn F

to leave the opening at the top of the combustion air

plenum open.

(The outside air connection is located on the lower back

of the stove. The 75mm adapter is included in the

component pack.)

C. Horizontal Venting

When venting the unit horizontally, remove the back panel

of the unit. Next, remove the cast flue attachment ring in

the top of the appliance by removing the four bolts used to

secure it in shipping. Remove the rear cover plate that can

be seen in the back of the unit once the back panel is

removed. Install the rear cover plate over the vertical outlet

hole in the top of the unit using the four bolts that were

used to secure the cover plate when installed on the rear of

the unit. Install the cast flue attachment ring on the rear of

appliance using four bolts. Knock out the panel on the back

panel so the flue attachment ring can slip through it. Attach

the back panel back onto the appliance using

the same fasteners. Install the venting per the venting

manufactures specifications. Place the top cover plate

(item "C" in Fig. 7.1) from the component pack over the

hole in the top of the appliance for a finished look.

7076-260 • January 12, 2015

Fig.7.2

Opening at the top of the

combustion air plenum

Fig.7.1

This unit is suitable for installation in a shared flue.

Leveling the it

Four leveling bolts have come installed on the unit.

Following installation, adjustments can be made to the

heights of the four bolts from the top of the base pan. Use

a hex head bit to adjust the height of each of the four legs.

When in its final state, the unit should be secure and not

rock.

Position near to non-flammatla walls

When positioning near a non-flammable wall, we recom-

mend you keep a minimum distance of 50 mm between

the rear of the product and the wall for cleaning purposes.

Distance to furniture: 1000 mm

But please check to avoid furniture or other furnishings

being dried out due to being too close to the stove.

Distance to flammable walls

See. fig. 8.1.

UNIT

DIMENSIONS

HEARTH SIZE IN

FRONT

X (mm)

Y (mm)

Z (mm)

Radius 100

450

200

150

300mm

Radius 300

450

200

150

300mm

Fig. 8.1

7nimum Floor Protection Require-

ments

Component Pack

The component pack contains the following:

Manual

Gloves

Outside air connecting plate

Top adapter ring

Top flue cover plate

•Outside air screen

Removal of Radius from pallet

1. Remove the two 11 mm bolts holding the brackets in

the front and rear of the base on the unit, this requires

holding the bolt on the bottom side of the pallet as

shown in picture below on right

2. Tilt unit back unit the front bracket is able to tilt

forward and be removed from bottom of unit, repeat

tilting forward and removing rear bracket. (the brackets

need to swing down and slightly back in order to be

pulled from unit)

3. Unit can now be moved off pallet.

Fig. 8.3

INSTALLATION & ASSEMBLY

Fig. 8.2

Fig. 8.4

7076-260 • January 12, 2015

General Use

The Radius Series Wood Stoves are designed and tested

for intermittent use. This means that it is not designed for or

recommended to bum continuously for 24 hours.

This is a wood burning stove, the front, sides, and top will get

hot. Please use caution when you are near the fire especially

when it is burning.

Disposal of ashes and coals should always bein a non-com-

bustible container. Never put coals or embers into a flammable

container, even when they do not appear to be hot. Coals can

hold heat forextended periods of time and may cause damage if

improperly disposed of.

Prior to the start of the burn season or following extended periods

of non-use, you should inspect the firebox, flue connections, and

chimney system for debris and obstructions. Clean as necessary.

Contact your chimney sweep if needed.

Modification to your Radius appliance is prohibited, will void the

warranty, and may cause unsafe conditions during use. Certain

accessories are approved and available from your local Radius

Series Wood Stove Dealer.

Use only approved replacement parts available from your

Radius Series Wood Stove Dealer.

Lighting Instructions

Use paper or lighting briquettes and small pieces of wood to light

fire. Place the paper first in the bottom of the fire box and stack the

lighting briquettes orsmall pieces of wood on top of the paper. Do

not fill the firebox higher than the holes in the rear of the fire box.

(See Figures on next page).

Push in both air controls to open. Light the paper andleave the

door open slightly. As the small pieces of wood are burning add

slightly larger fuel on top of burning fuel and close the door. After

15-30 minutes or when good fireis established, close the lower

air control (it is located on the left side)by pulling it out

completely. When loading more wood during use, this control

may need to be pushed in to add more air under thefire.

Your First Fire

Duringthefirst firing ofthe Radiusitis tobe expected tosmoke and

give offunpleasantfumes.Thisiscausedbythepaint curingonthe

coatedsurfaces.Makesure the roomis wellventilatedto reducethe

inhalationofthesefumes.Afterthisfirstfirethe smokingand unpleas-

antsmell shouldgreatlydiminish.

As thepaint cures, therope seal onthedoormaysticktotheface

makingit difficultto open the front door. Toaidinthecuring process,

open thefrontdoorevery5 —10minutes forthefirstone totwo

hours.Thiswillkeepthesealfromforming abondtothefaceas the

coatingcurescompletely.

For the duration of this fire keep both air controls in the

completelyopenposition to ensure hotbumtocure stove.

Fuels

The Radius Series wood stoves are designed to burn a

wide range of firewood species. In general hardwoods are

better for heating since they burn more evenly. When

operating the unit with different types of fuels, refer to

operating the wood stove section for more information.

Consult the internet for specific heating values of different

species of firewood.

The optimal size of firewood for the Radius Series wood

stove is 25 cm long and 6 cm —12 cm in diameter when

split. Some varieties of fuels may perform better when split

smaller. When establishing a fire, it is helpful to have a

variety of different diameters in order to heat the flue up

quickly and establish the draft.

Fuels should be stored in locations protected from rain and

excessive moisture. Well seasoned firewood may take 1 -2

years to dry out. Well ventilated areas protected from

environmental elements aid in preparing the fuel faster. If the

fuel is stored outside, it is recommended that it is stored inside

a few days before use to allow the fuel to warm up to room

temperature.

Firewood and combustible items should NEVER be stored

below the firebox. Make sure the proper clearance to

flammable materials is maintained for all fuel storage. The

firewood used should have a moisture level less than

20%. The Radius Series wood stove will yield its best

performance if the moisture content is between 15% and

18%. Moisture levels above 20% can have adverse

environmental effects because of the inefficient burn.

Moisture levels below 15% will burn faster resulting in

shorter burn times. To determine whether your fuel is too

wet, knock it on a hard surface. If it is too wet, the sound

produced will be dull.

Burning wet wood reduces the amount of heat output into

your home because it is turning the water into steam and

venting it out your chimney rather than producing gases

that are burned up in the secondary system. It also

increases the amount of soot on the glass and in the

chimney system. It is inefficient and produces pollution.

Improper use including the use of illegal fuels may cause

pollution and can damage the appliance. Improper use will

void the manufactures warranty. Never burn treated or

painted wood, chipboard, glued or laminated materials,

wood from salt water, plastics, trash, or chemically treated

paper.

7076-260 • January 12, 2015

INSTRUCTION FOR USE

Fig.10: Proper Fill and Startup Configuration

Fig. 10.1: Add paper to back of firepot making sure to not

block lower air inlet with paper.

Fig. 10.2: Add small pieces of wood on top of paper

allowing for air flow between pieces.

Fig. 10.3: Add larger log on top of pile making sure it

does not go above the upper intake holes.

7076-260 • January 12, 2015

Primary Air (Lower it Control)

(Figure 11.1)

The primary air is controlled by the lever on the left side of

the appliance. When the control arm is pulled out, less air is

allowed into the firebox below the fire. When the control arm

is pushed in, maximum air is allowed in under the fire. This

lever is to be used during start up and refueling. If this air

control remains open (pushed in) then you will have

reduced burn times or a potential to overheat the appliance.

Upper it Control (Figure 11.1)

The upper air control is controlled by the lever on the right

side of the appliance. When the control arm is pulled out,

less air is allowed into the firebox through this system.

When the control arm is pushed in, maximum air is allowed

through the system. The function of this air control is to

regulate the burn rate of the fire and provide air for the air

wash system to keep the glass clean.

When the upper air control is closed and air is reduced to

the air wash system, the glass will soot up. This is normal

and to be expected. To help clean the glass off, add

additional fuel to the fire, pull out the upper air control and

pull out the lower air control lever for 15-30 minutes to

establish a hot fire. A hot fire with the upper air control

open will aid in cleaning the glass.

Fig. 11.1: Air Controls

Secondary Air (holes in rear of firebox)

This unit is equipped with a secondary combustion system

that cannot be regulated. The purpose of this secondary

system is to provide air that will mix with the combustion

gasses and burn them. This reduces the amount of debris

and gasses being let out into the environment ensuring a

clean burn.

Airwash System

An air wash system is built into the appliance and is

controlled by the air control lever on the right side of the

appliance. Even with this air wash system, the glass panes

will get dirty and have build up. This is normal and can be

cleaned using a simple glass cleaner. Alternate glass

cleaning products specifically designed for cleaning glass

panes on wood burning stoves may be available from your

dealer. Contact them directly for product availability.

Front Door Handle Operation

(Figure 11.2)

To open the front door, pull the lever located on the right

side of the unit upwards (be sure to wear the glove

provided if the unit is hot). Carefully swing the door open

from right to left. To close the door swing it shut from left

to right and close by pushing the handle down. When

securing the front door closed, make sure the roller on the

handle is beyond the ramp catch located on the side of the

unit.

1- Pull side of handle away 2- Then swing door open to the

from unit. left.

Fig. 11.2: Door Handle Operation

Lower (primary) Air Upper (secondary)

Intake Control Air Intake Control

7076-260 January 12, 2015

Front Door Se&

The front door has a non-combustible rope which creates a

tight seal for the firebox. The first time you open the front

door and close it, the gasket may be stiff and the door

difficult to close. Following the first fire, the gasketing will

relax which will allow the door to be closed easily for

normal use which provides a tight seal. This seal is critical

for proper air regulation in the firebox for safe and efficient

burn. Though this material is a high quality material

specifically designed for wood burning appliances, it is

subject to normal wear and tear and should be replaced if

burn times are reduced or there is concern of leakage. The

seal is subject to damage from excessive cleaning or by

debris being closed in the door.

If there is a concern of leakage, use a thin piece of paper,

place against the gasket in the area of concern, close the

door and latch shut, then gently tug on the paper. If the

paper comes right out without any resistance, the seal

should be replaced.

Chimney System

A chimney or flue system is required to run your wood

stove safely and efficiently. When a fire is started in the fire

box hot gases are released and exit the firebox into the

chimney system. These hot gases heat up the chimney

system and create a vacuum in the firebox or commonly

referred to as drafting. As a result, more air is pulled into

the firebox through the air openings. When more air is

pulled into the fire, the fire burns hotter and is a cleaner

burn. This also means that the burn time is shorter but

more heat is generated to heat the living space and the

glass stays cleaner. When the air controls are adjusted

and reduced, the fire will slow down. This lowers the draft

and as a result, the burn times are longer.

When lighting the appliance, it is important to get a hot fire

as quick as possible to establish the draft in the system for

an efficient and clean burn. There are many different types

of chimney systems, check with your local authority for

more details and follow all regulations in your area.

Drafting

Weather and chimney location can affect the draft of your

stove resulting in different performance settings. For windy

conditions, the draft may be higher which will result in

changing the air control settings for the same

performance. In areas where high wind is common, a

damper may need to be installed in the flue pipe to best

control the appliance. Performance can also be influenced

by changes in humidity including fog. Adjust the air

controls as needed to achieve the desired heat output of

your Radius wood burning stove.

Figure 12.1

Windward

Recommended:

Outside Air Intake

on windward side

NOT recommended:

Outside Air Intake

on leeward side

Multi-level Roofs

RecommendedLocation:

Recommended Location: • Above peak

Above peak • Inside heated space

Location NOT recommended:

Not the highest point of the roof

Windloadingpossible

Marginal Location:

Below peak

Recommended:

Insulated exterior chase

in cooler climates

Marginal Location:

Windloadingpossible

Location NOTrecommended:

Too close to tree

Below adjacent structure

Lower roof line

Avoidoutside wall

7076-260 • January 12, 2015

Ash Drawer

(Figure 13.1)

Before attempting any maintenance on the unit ensure that

the unit is cold and has no embers in the firebox. To access

the ash drawer open the front door. The drawer is located

under the firebox. Before removing pan empty ash from

firebox into the pan.

To do this open the grate at the bottom of the firepot by

pushing the primary air control lever on the left side all the

way in until all holes are open. Then gently sweep ash

through the grate into the ash drawer below. Then, pull the

primary lever forward to close the grate so that only the two

small holes in the back of the unit are open.

Then remove the ash pan drawer and empty into

noncombustible container. Never attempt to open ash pan

when stove is lit.

Figure 13.1: Ash Drawer Maintenance

1- Push in primary air control to

turn grate clockwise to open all

grate holes. After all holes are

open, push ash through grate to

drawer below.

Baffle Material

There are two baffle plates in the top of the unit. The

purpose of these plates is to restrict and direct the

combustion gases to allow for complete combustion of the

gasses prior to exiting the firebox and entering the flue.

The lower baffle plate is supported on each side by the

side refractory, it is notched on either side to allow proper

placement.

The upper baffle panel is supported by two brackets, one

on each side of the top of the firebox. During annual

chimney maintenance, these two baffle panels must be

removed prior to sweeping. Not doing so will result in

broken panels. Similar to the refractory panels lining the

inside of the firebox, the baffle panels are subject to wear

and tear and are subject to warranty limitations.

Fc-:.Proper Burn

Remove ash from firebox and ash pan regularly to

ensure proper air supply

Use only 1-3 pieces of wood quartered and placed to

optimize air flow (see Figure 10.2)

® Adjust the upper air control to ensure that enough air

is being supplied to the firebox, there should always

be a visible flame with minimal smoke

® Fuel should never be stacked above the upper air

inlets (see Figure 10.3)

Coated Surfaces

To clean the stove dust with a lint-free cloth or cleaning

device. If the topcoat is damaged it is possible to purchase

a repair spray from your local dealer. It is possible that this

spray may be slightly different from the original coat. For

best results, use repair spray in wide area in order to create

a subtle transition from one color to the next. For safety

purposes apply spray when stove is cold, the difference in

color may be very noticeable when first applied. However,

after firing again it should match very close to original color.

2- Remove drawer by pulling out

and empty into qualified

container.

Refractory

The firebox is lined with molded refractory firebrick. The

refractory protects the outside of the appliance and retains

the heat necessary for a clean efficient burn. The material is

a porous ceramic material that can break from abuse.

Occasionally, surface cracks may propagate from normal use

through the heating and cooling cycle. Surface cracks are

normal and should only be a concern when the crack causes

the refractory to not remain in place on its own.

Cleaning the Glass

This stove is designed to minimize soot build-up. To attain

this the stove must be burned properly, see section For

Proper Burn.

However even when burned properly a slight buildup of soot

can occur. To clean you can use dry cloth and regular glass

cleaner or specialized stove glass cleaning products.

7076-260 • January 12, 2015

3. Lift out the Firepot Plate and then the Firepot.

4. Lift Baffle (Top piece) slightly and remove left and

right sides then the Lower Back Refractory.

5.

Remove the Baffle by lowering the front and pulling out.

Be careful to not let the Upper Rear Refractory fall.

6. Remove the Upper Rear Refractory. If you are convert-

ing to rear vent, discard the Upper Rear Refractory

Installation is the reverse of the removal.

Removal of Radius refractory for

service or rear venting conversion.

Refractory that has been burned is fragile and must be

handled carefully to prevent breakage.

Remove Ash Drawer and set aside.

1. Using a pair of pliers; remove pin that secures

the Firepot

2. Plate to the Primary control damper. This can be

accessed in the ash drawer cavity below the firebox.

7076-260 • January 12,2015

Smoke escaping

Damp wood

Chimney not drawing properly

Chimney is not properly dimensioned for the stove

Check if the smoke gas pipe/chimney are blocked

Is the chimney the right height for its surroundings?

At rear outlet, check that the flue pipe does not obstruct

the chimney draught

Vacuum in room

The door is opened before the embers have

burned down sufficiently

Wood burning too quickly

The air valves are set incorrectly

The baffle plates are incorrectly mounted or missing

Inferior firewood (waste wood, pallets etc.)

Chimney too large

Soot build-up on glass

Incorrect secondary airflow setting

Excessive primary air

Damp wood

Wood pieces too large on lighting

Inferior firewood (waste wood, pallets etc.)

Chimney not drawing sufficiently

Vacuum in room

Excessive soot build-up in chimney

Poor burning (more air required)

Damp wood

The surface of the stove is turning grey

Overheating (see instructions for heating)

Poor heating performance of stove

Damp wood

Not enough wood

Inferior wood quality with low fuel value

Baffle plates are not fitted correctly Odor coming from

stove

The lacquer on the stove hardens when you use the

stove for the first time; this can cause an odor. Open a

window or a door for ventilation, and make sure the stove

is heated up sufficiently to avoid odors later.

When heating up and cooling down, the stove may

make some clicking noises. These are due to the huge

temperature differences to which the material is

exposed and do not indicate any product defects.

Start Fire Problems

Possible Cause

Solution

Can't get fire started

Excessive smoke or

spillage Burns too slowly

Smolders, sizzles

Not enough kindling/paper or no

kindling/paper

Use dry kindling, more paper. Arrange kindling &

wood for air movement.

Not enough air for fire to ignite

Check for restricted cap/shroud

Open outside air kit (if installed).

Check for flue blockage.

Check for adequate vent height (refer to chimney

assembly section).

Wood condition is too wet, too

large

Use dry, seasoned wood (refer to wood fuel sec-

tion).

Bed of coals not established

before adding wood

Start with paper & kindling to establish bed of

coals (refer to starting fire section).

Flue blockage such as birds'

nests or leaves in termination cap

Have chimney inspected for creosote and cleaned

by a certified chimney sweep.

Down draft or negative pressure

Competition with exhaust devices

Do not use exhaust fans during start-up.

Open window below the appliance towards the

wind.

Fire burns too fast

Extremely dry or soft wood

Mix in hardwood.

Mix in less seasoned wood after fire is established

(refer to wood fuel section).

Overdrafting

Check for correct vent height; too much vertical

height creates overdrafting.

Check location of vent termination (refer to chim-

ney requirements section).

Ash pan may not be closed corn-

pletely

Close ash pan.

7076-260 • January 12, 2015

TROUBLESHOOTING

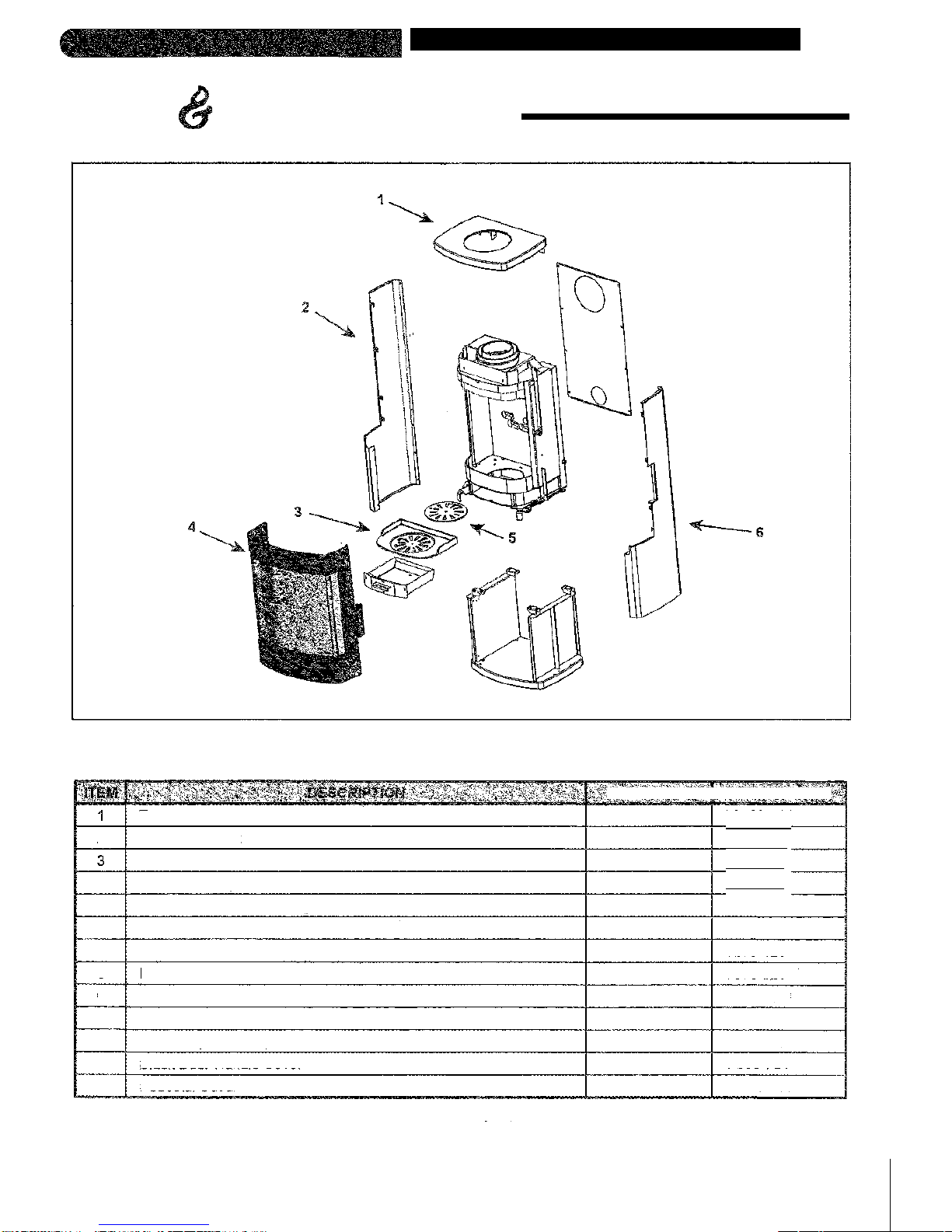

RADIUS-100

Beginning Manufacturing Date: Sept 2013

Ending Manufacturing Date: Active

IMPORTANT: THIS IS DATED INFORMATION. Parts must be ordered from a dealer or distributor. Hearth and Home Technologies does

not sell directly to consumers. Provide modelnumber and serial numberwhen requesting service parts from your dealer ordistributor.

ITEM

DESCRIPTION

COMMENTS

PART NUMBER

1

Top

MG08-181

2

Side Panel, Left

7G08-551

3

Cast Firepot

7076-332

4

Door Assembly

7076-008

Door Handle Assembly

7076-018

Door Rope

IG08-041

Glass

IG08-011

5

Firepot Plate

7076-023

6

Side Panel, Right

MG08-551

Refractory Side Door

IG08-091

Refractory Assembly

MG08-511

Black Door Handle Cover

7G08-751

Pedestal Cover

MG08-501

7076-260 • January 12, 2015

Service Parts & Accessories List

Service Parts

Wood Stove

No one builds a better fire

IMPORTANT: THIS IS DATED INFORMATION, Parts must be ordered from a dealer or distributor. Hearth and Home Technologies does

not sell directly to consumers. Provide model number and serial number when requesting service parts from your dealer or distributor.

Service Parts & Accessories List

Service Parts

C3 11IMMIN--

Wood Stove

RArlUS-300

Beginning Manufacturing Date: Sept 2013

Ending Manufacturing Date: Active

HEAT

No one builds a better fire

Top

2

Side Panel, Left

Cast Firepot

4

DoorAssembly

Glass

7075-125

FirepotPlate

5

7076-023

6

MGOS-551

Side Panel, Right

Refractory b y

MG08-511

Black Door Handle Cover

7G08-751

C O M M E N T S A R T N U M B E R

Pedestal Cover

7076-260 - January 12, 2015

MG08-501

MG08-181

7G08-551

7076-332

7076-007

7076-018

1G08-041

Door Handle Assembly

Door Rope

H E A R T 1 1 6 - H O M E

technologies

AUSTRALIAN WARRANTY INFORMATION

Hearth & Home Technologies Inc (HHT)

1445 N. Highway I Colville, WA 99114 I (509-684-3745)

HHT extends the following manufacturer's warranty for HHT gas, wood, pellet, coal and electric hearth appliances that are purchased

from an HHT authorized dealer.

HHT warrants to the original owner of the HHT appliance at the site of installation, and to any transferee taking ownership of the

appliance at the site of installation within two years following the date of original purchase, that the HHT appliance will be free from

defects in materials and workmanship at the time of manufacture.

After installation, if covered components manufactured by HHT are found to be defective in materials or workmanship during the

applicable warranty period, HHT will, at its option, repair or replace the covered components. HHT, at its own discretion, may fully

discharge all of its obligations under this manufacturer's warranty by replacing the product itself or refunding the verified purchase price

of the product itself. The maximum amount recoverable under this warranty is limited to the purchase price of the product. This warranty

is subject to conditions, exclusions and limitations as described below.

Warranty coverage begins on the date of original purchase. In the case of new home construction, coverage under this manufacturer's

warranty begins on the date of first occupancy of the dwelling or six months after the sale of the product by an independent, authorized

HHT dealer/ distributor, whichever occurs earlier. The warranty period for this manufacturer's warranty shall commence no later than 24

months following the date of product shipment from HHT, regardless of the installation or occupancy date. The manufacturer's warranty

period for parts and labor for covered components is produced in the following table.

The term "Limited Lifetime" in the table below is defined as: 20 years from the beginning date of warranty coverage for gas appliances,

and 10 years from the beginning date of warranty coverage for wood, pellet and coal appliances. These time periods reflect the minimum

expected useful lives of the designated components under normal operating conditions.

Gas Wood Pellet

Labor

W o od Co al E lec tr ic V e nt in g

X

X

2years

Castings and baffles

5 years r 1 year

Manifold tubes,

HHT chimney

and HI-, ea

7 years 3 years

All replacement parts

urners, ogs an

Fireboxandheat

3years

90Days

7076-260 January 12, 2015

=15':Wiiirlin:111M1-17giTirAtif=iFigliMEMMMIATIMatitimilitivilff-I Is

Parts

All parts and material

except as covered by

Conditions, Exclusions,

and Limitations listed

X

X

X

X

X

1Year

Igniters, electronic

onnoopents, alass

actory-installed blowers

Molded refractory panels

3 ears X Fire ots and Burn ots

Components Covered

OTHER RIGHTS

The HHT manufacturer's warranty is in addition to other rights and remedies that you may have under Australian

law.

Our goods come with guarantees that cannot be excluded under the Australian Consumer Law. You are entitled to a

replacement or refund for a major failure and for compensation for any other reasonably foreseeable loss or damage.

You are also entitled to have the goods repaired or replaced if the goods fail to be of acceptable quality and the failure

does not amount to a major failure.

WARRANTY CONDITIONS AND EXCLUSIONS:

The HHT manufacturer's warranty only covers HHT appliances that are purchased through an HHT authorized dealer or distributor. A list of

HHT authorized dealers is available on the HHT branded websites.

This warranty is only valid while the HHT appliance remains at the site of original installation.

WARRANTY EXCLUSIONS:

This HHT manufacturer's warranty does not cover the following:

Changes in surface finishes as a result of normal use. As a heating appliance, some changes in color of interior and exterior surface

finishes may occur. This is not a flaw and is not covered under warranty.

Damage to printed, plated, or enamelled surfaces caused by fingerprints, accidents, misuse, scratches, melted items, or other external

sources and residues left on the plated surfaces from the use of abrasive cleaners or polishes.

Repair or replacement of parts that are subject to normal wear and tear during the warranty period. These parts include: paint, wood, pellet

and coal gaskets, firebricks, grates, flame guides, light bulbs, batteries and the discoloration of glass.

Minor expansion, contraction, or movement of certain parts causing noise. These conditions are normal and complaints related to this noise

are not covered by this warranty.

Damages resulting from: (1) failure to install, operate, or maintain the appliance in accordance with the installation instructions, operating

instructions, and listing agent identification label furnished with the appliance; (2) failure to install the appliance in

accordance with local building codes; (3) shipping or improper handling; (4) improper operation, abuse, misuse, continued operation

with damaged, corroded or failed components, accident, or improperly/incorrectly performed repairs; (5) environmental conditions,

inadequate ventilation, negative pressure, or drafting caused by tightly sealed constructions, insufficient make-up air supply, or

handling devices such as exhaust fans or forced air furnaces or other such causes; (6) use of fuels other than those specified in the

operating instructions; (7) installation or use of components not supplied with the appliance or any other components not expressly

authorized and approved by HHT (8) modification of the appliance not expressly authorized and approved by HHT in writing; and/or (9)

interruptions or fluctuations of electrical power supply to the appliance.

Non HHT venting components, hearth components or other accessories used in conjunction with the appliance.

Any part of a pre-existing fireplace system in which an insert or a decorative gas appliance is installed.

Removal, installation, reinstallation, set up or any other costs associated with a claim including travel and shipping charges for parts

HHT's obligation under this warranty does not extend to the appliance's capability to heat the desired space. Information is provided to

assist the consumer and the dealer in selecting the proper appliance for the application. Consideration must be given to appliance location

and configuration, environmental conditions, insulation and air tightness of the structure.

This warranty is void if:

The appliance has been over-fired or operated in atmospheres contaminated by chlorine, fluorine, or other damaging chemicals. Over-firing

can be identified by, but not limited to, warped plates or tubes, rust coloured cast iron, bubbling, cracking and discoloration of steel or

enamel finishes.

The appliance is subjected to prolonged periods of dampness or condensation.

There is any damage to the appliance or other components due to water or weather damage which is the result of, but not limited to, improper

chimney or venting installation.

HOW TO CLAIM

To make a claim against this warranty, contact your local distributor during regular business hours. See addresses below

for a dealer nearest you. (Vic) Pty Ltd ACN 005 872 159 (Jetmaster).

Additional service fees may apply if you are seeking warranty service from a dealer other than the dealer from whom you

originally purchased the product.

Check with Jetmaster in advance for any costs to you when arranging a warranty call. Travel and shipping charges for

parts are not covered by this manufacturers' warranty.

HHT and Jetmaster will assess your claim. HHT or Jetmaster may need to inspect the product as part of the assessment of your claim.

If the product requires inspection, HHT or Jetmaster will discuss with you the best way for this to occur.

To make a claim under this manufacturer's warranty, you must be able to prove when you purchased the product. The easiest way to

do this is through your original proof of purchase, for example your invoice or receipt. However, if you do not have your original proof of

purchase HHT or Jetmaster may accept other evidence of the date of purchase.

Local Distributors:

Melbourne

Jetmaster

44 Swan Street

Richmond 3121

(03) 9429-5573

Perth

Fireplace Corner

277 Lord Street

East Perth 6000

(08) 9228-2600

Sydney

Jetmaster

10 Martin Avenue

Arncliff 2205

(02) 9597-7222

7076-260 • January 12, 2015

We recommend that you record the following pertinent information

for your heating appliance.

Date purchased/installed: ________________________________________

Serial Number: __________________________________________________ Location on appliance: ___________________

Dealership purchased from: ________________________________________ Dealer phone: __________________________

Notes: ________________________________________________________________________________________________

H F A I : T H & H O _

technologies

CONTACT INFORMATION:

Hearth & Home Technologies

1445 North Highway

Colville, WA 99114

Division of HNI INDUSTRIES

This product may be covered by one or more of the following patents: (United States) 5341794, 5263471, 6688302, 7216645,

7047962 or other U.S. and foreign patents pending.

H E A R T H & H O M E

technologies

7076-260 • January 12, 2015

Table of contents

Popular Wood Stove manuals by other brands

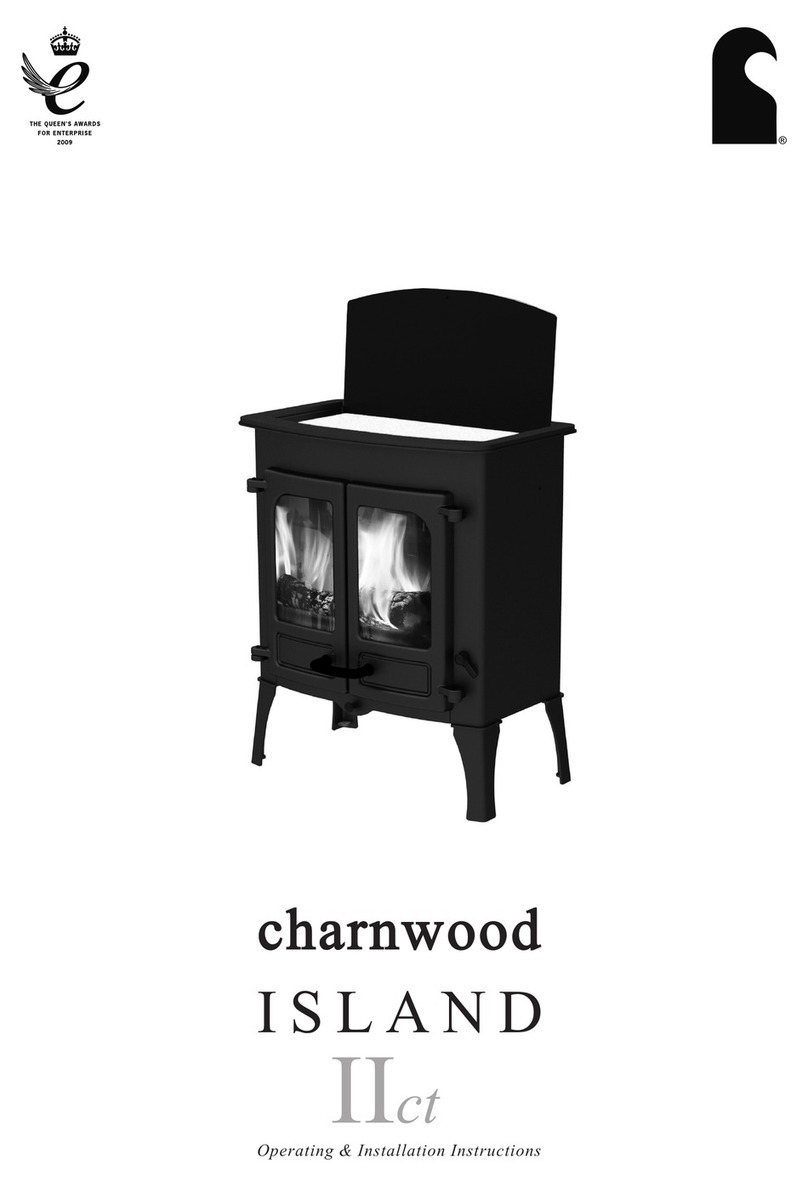

Charnwood

Charnwood I S L A N D Operating & installation instructions

Harvia

Harvia Legend 150 Instructions for installation and use

pleasant hearth

pleasant hearth PH35PS-B owner's manual

Jøtul

Jøtul F 400 Castine Installation and operation instructions

Regency

Regency Classic F2450M Owners & installation manual

Lotus

Lotus 2000 Series Mounting and user instructions

Vogelzang International

Vogelzang International PONDEROSA TR007 owner's manual

RAIS

RAIS RONDO user manual

Palazzetti

Palazzetti Cindy Instructions for use and maintenance

Beltane Stoves

Beltane Stoves HOLFORD Installation and operating instructions

Morso

Morso 7370 Installation

ACR STOVES

ACR STOVES Wychwood WYC1WB Technical manual