Heateflex PF2000 User manual

World Leaders in Ultra-Pure Heating

www.heateflex.com

405 E. Santa Clara St., Arcadia, CA 91006-7218

O

: (626) 599-8566

F

: (626) 599-9567

PF2000 CONTROLLER

for the

AQUARIUS® DEIONIZED WATER HEATING SYSTEM

Heateflex Corporation

405 E. Santa Clara St.

Arcadia, CA 91006-7218

TEL: (626)599-8566; FAX: (626)599-9567

Rev. 02.0 08/21/17, (PF2000)

World Leaders in Ultra-Pure Heating

www.heateflex.com

1

405 E. Santa Clara St., Arcadia, CA 91006-7218

O

: (626) 599-8566

F

: (626) 599-9567

TABLE OF CONTENTS

1. INTRODUCTION .......................................................................................... 3

2. BASIC TOUCH SCREEN FUNCTIONS ........................................................ 5

2.1. UTILIZING THE TEN KEY ............................................................................. 5

2.2. UTILIZING THE KEYBOARD .......................................................................... 5

2.3. UTILIZING THE SYSTEM SCREEN KEYS ........................................................ 7

2.4. UTILIZING THE FUNCTION KEYS ................................................................... 8

3. LOGIN ............................................................................................................ 9

4. DATE/TIME SET UP ................................................................................... 11

5. OPERATION .............................................................................................. 12

5.1. SYSTEM STATUS SCREEN ........................................................................ 15

5.2. MODE INDICATING LAMPS/LABELS ............................................................ 18

5.3. SYSTEM STATUS DISPLAY ........................................................................ 20

5.4. UNIT CHANGE KEY .................................................................................. 21

5.5. SYSTEM OPERATION KEYS ....................................................................... 21

5.6. SYSTEM SCREEN KEYS ............................................................................ 23

6. SYSTEM SET UP ....................................................................................... 24

6.1. SYSTEM SET UP MENU ............................................................................ 25

6.2. CONTROL SETTINGS SCREEN ................................................................... 26

6.3. ALARM SET POINTS SCREEN .................................................................... 28

6.4. OPTIONS SCREEN .................................................................................... 30

6.5. SYSTEM CALIBRATION SCREEN ................................................................ 32

7. ALARM MENU ........................................................................................... 34

8. ALARM HISTORY ...................................................................................... 48

9. SYSTEM INFORMATION ........................................................................... 50

9.1. SYSTEM INFORMATION MENU SCREEN ...................................................... 51

9.2. SYSTEM INFORMATION SCREEN ................................................................ 52

9.3. SYSTEM SPECIFICATIONS SCREEN ............................................................ 53

9.4. SYSTEM MAINTENANCE SCREEN ............................................................... 55

9.5. CONTACT INFORMATION SCREEN .............................................................. 56

10. TREND GRAPH .......................................................................................... 57

11. AUTO PURGE ............................................................................................ 58

12. RECIRCULATION ...................................................................................... 60

12.1. ACTIVATING RECIRCULATION .................................................................... 62

12.2. DEACTIVATING RECIRCULATION ................................................................ 63

12.3. PUMP AIR COOLING SYSTEM CALIBRATION ............................................... 63

13. TEMPERATURE READY DEAD BAND (DB) SIGNAL ................................ 66

13.1. TEMPERATURE READY DEAD BAND SIGNAL WIRING .................................. 68

14. SECONDARY PROCESS TEMPERATURE SETPOINT ............................ 69

15. ANALOG INTERFACE ............................................................................... 73

15.1. ANALOG INTERFACE WIRING CONFIGURATION ........................................... 74

16. DISCRETE INTERFACE ............................................................................ 75

World Leaders in Ultra-Pure Heating

www.heateflex.com

2

405 E. Santa Clara St., Arcadia, CA 91006-7218

O

: (626) 599-8566

F

: (626) 599-9567

16.1. DISCRETE INTERFACE WIRING CONFIGURATION ......................................... 78

17. DRY CONTACT INTERFACE ..................................................................... 79

17.2. DRY CONTACT INTERFACE WIRING CONFIGURATION .................................. 82

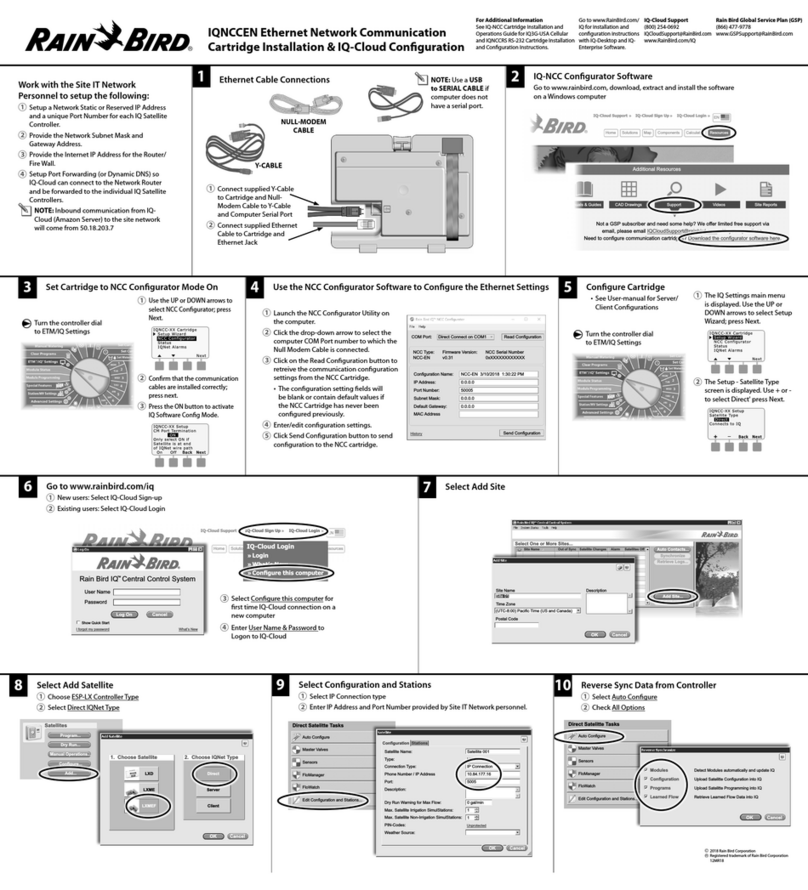

18. ETHERNET COMMUNICATIONS .............................................................. 84

18.1. ETHERNET SCREENS ................................................................................ 87

18.2. ETHERNET COMMUNICATIONS MENU ......................................................... 88

18.3. ETHERNET ALARM AND STATUS SIGNALS .................................................. 93

18.4. ETHERNET IP ADDRESS SET UP VIA WEB BROWSER.. ERROR! BOOKMARK NOT

DEFINED.

19. SPECIFICATIONS ...................................................................................... 96

20. LIST OF FIGURES ..................................................................................... 98

21. LIST OF TABLES ..................................................................................... 100

22. MANUAL REVISIONS .............................................................................. 101

World Leaders in Ultra-Pure Heating

www.heateflex.com

3

405 E. Santa Clara St., Arcadia, CA 91006-7218

O

: (626) 599-8566

F

: (626) 599-9567

PF2000 CONTROLLER for the

AQUARIUS® DEIONIZED WATER HEATING SYSTEM

1. INTRODUCTION

The Model PF2000 is a Programmable Logic Controller (Safety PLC) for the Heateflex

Corporation® Aquarius® DeIonized (D.I.) Water Heating Systems. It monitors and controls

all functions of the Aquarius® D.I. Water Heating Systems. Although its primary function

is to accurately control the temperature of the discharged D.I. water, it also provides

monitoring for incoming or input fluid temperature, output fluid temperature, fluid flow rate,

input voltage, input pressure, system alarms, and (optional) water resistivity.

The PF2000 receives data from various sensors in the Aquarius® Systems. Temperature

inputs are direct thermocouple connections. Separate individual thermocouples are used

for the input temperature of the ambient D.I. water, output temperature of the heated D.I.

water, and a thermocouple for each heating module in the Aquarius® D.I. Water Heating

Systems, serving as independent over-temperature safety interlock (HIGH LIMIT). A

liquid level sensor checks for the proper liquid level at the top of the final heating module.

A flow sensor checks the flow rate at the input of the first heating module (all heater

modules are configured in series). Pressure sensing is done with a pressure transducer

at the ambient D.I. water input. Incoming line voltage monitoring is done with a voltage

transducer at the step-down transformer at the power line. If the resistivity option is

present a resistivity sensor after the output module is also connected to the PF2000.

The PF2000 also includes a Safety PLC which monitors the high limit thermocouples

values and status (all of which are Type J thermocouples), status of thermal cut-off

sensors and status of ground fault circuit interrupter (GFCI). The Safety PLC logic

determines if there is an output on the Heater Master Relay and/or the Heater Safety

Relay which sets the system into STANDBY mode if there is an unsafe condition.

World Leaders in Ultra-Pure Heating

www.heateflex.com

4

405 E. Santa Clara St., Arcadia, CA 91006-7218

O

: (626) 599-8566

F

: (626) 599-9567

A Human Machine Interface (HMI) Touch Screen is utilized to operate the system, display

the status of the unit and display various alarm conditions. Once the Aquarius® System

is powered ON the Main Menu screen will appear, which is illustrated by Figure 1-1. The

touch screen allows the user to set up and adjust the system parameters and set points.

The screen also allows the user to monitor the flow rate, system pressure, voltage,

incoming and process temperatures through the System Status screen (See Section 5.1)

and displays the various system alarms on the Alarm Menu screen (See Section 7).

Figure 1-1: Main Menu Screen

The System Set Up Menu (See Section 6.1) is used to access system settings and

troubleshooting. These settings include Control Settings, Alarm Set Points, System

Calibration, Factory Setup, Ethernet Interface, and Option Settings. Note: A factory

password is required to access the Trouble Shoot Menu and Factory Set Up Menu.

World Leaders in Ultra-Pure Heating

www.heateflex.com

5

405 E. Santa Clara St., Arcadia, CA 91006-7218

O

: (626) 599-8566

F

: (626) 599-9567

2. BASIC TOUCH SCREEN FUNCTIONS

2.1.

UTILIZING THE TEN KEY

The Ten Key is a keypad used to enter numeric data such as temperature set

points and parameters throughout the PF2000 screens. Once the Ten Key

window is accessed, type in the desired value ensuring that the value is within

the maximum and minimum values that are indicated at the top of the Ten Key

keypad. If a wrong entry is made, use either the Back Arrow key to backspace

or the Clear key to clear the entire entry. Once the desired value is entered

correctly, select the Enter key to submit the value into the controller as shown

in Figure 2-1. If a change is not desired select the Cancel key to cancel the

operation.

Figure 2-1: Ten Key Window

2.2.

UTILIZING THE KEYBOARD

The Keyboard is a keypad (shown in Figure 2-2 and 2-3) used to enter

alphanumeric data such as passwords or text. Once this Keyboard window is

accessed, type in the value or characters desired. The Shift key is used to

enter capital letters and special characters, as shown in Figure 2-3. If a wrong

World Leaders in Ultra-Pure Heating

www.heateflex.com

6

405 E. Santa Clara St., Arcadia, CA 91006-7218

O

: (626) 599-8566

F

: (626) 599-9567

entry is made, use either the Back-Arrow key to backspace or the Clear key

to clear the entire entry. Once the desired value or characters are entered

correctly, select the Return key to submit the value into the controller as shown

in Figure 2-2. If a change is not desired select the Cancel key to cancel the

operation.

Figure 2-2: Full Keyboard

Figure 2-3: Full Keyboard (Shift)

World Leaders in Ultra-Pure Heating

www.heateflex.com

7

405 E. Santa Clara St., Arcadia, CA 91006-7218

O

: (626) 599-8566

F

: (626) 599-9567

2.3.

UTILIZING THE SYSTEM SCREEN KEYS

The system screen keys are used to allow the user to easily navigate the

touch screen. These keys are shown on the upper right hand corner, lower

right hand corner and lower left hand corner. The keys that are shown are

dependent on the current screen and may vary from screen to screen.

Table 2-1: System Screen Keys

KEY DESCRIPTION COMMENTS

Login Window

This key is always visible and located on the

upper right hand corner of the screen. See

Section 3 for more details.

Main Menu The first screen that appears when the unit is

powered on.

System Setup

Menu Navigates to System Setup Menu screen

Alarm Menu

No Alarm

Indicates a No Alarm condition when green and

navigates to the Alarm Menu screen when

selected.

Alarm Menu

Critical Alarm

Indicates a Critical Alarm condition when red

and navigates to the Alarm Menu screen when

selected.

Alarm Menu

Non-Critical Alarm

Indicates a Non-Critical Alarm condition when

yellow and navigates to the Alarm Menu screen

when selected.

System Status Navigates to the System Status screen.

Alarm History Navigates to the Alarm History screen.

Trend Graph Navigates to the Trend Graph screen.

Previous Screen

Navigates to the screen that was previous to

the current screen. Can be pressed multiple

times to navigate through multiple previous

screens.

Next Screen Navigates to the “Next” screen of a series.

Silence Alarm The Silence Alarm key is used to silence the

buzzer only. It does not clear the alarm.

Alarm Reset

The Reset Alarm key is used to clear an alarm

condition when the alarm condition has been

resolved. If the alarm condition is not resolved,

the alarm does not clear

.

World Leaders in Ultra-Pure Heating

www.heateflex.com

8

405 E. Santa Clara St., Arcadia, CA 91006-7218

O

: (626) 599-8566

F

: (626) 599-9567

2.4.

UTILIZING THE FUNCTION KEYS

The Function keys allow the user to easily navigate the touch screen. They

are the three circular keys located on the bottom bezel of the touch screen.

The leftmost function key with one dot will navigate to the Main Menu screen.

The middle function key with two dots will navigate to the System Status

screen. The rightmost function key with the three dots will navigate to the

screen previous to the current screen. These keys will always be available

and will not change function.

Figure 2-4: Function Keys

Previous Screen

System Status Screen

Main Menu Screen

World Leaders in Ultra-Pure Heating

www.heateflex.com

9

405 E. Santa Clara St., Arcadia, CA 91006-7218

O

: (626) 599-8566

F

: (626) 599-9567

3. LOGIN

In some cases, it may be desirable to restrict access to the Aquarius® settings,

parameters and set points. With that in mind a Password System is incorporated into the

Aquarius® D.I. Water Heating Systems to limit access, prevent unauthorized access or

prevent unintentional changes to the system.

A username and password is required to access some of the parameters and set points

of the System Set Up submenus (Control Settings, Alarm Set Points, Options (if

available), and System Calibration). When a user level access is required, the user

must select the Login key at the upper right hand corner of the screen (see table 2-1 for

icon) to bring up the Login window. The user must enter the correct User Name and

Password with the proper credentials. Touch the input boxes within the Login window,

shown in Figure 3-1 below, to access the Keyboard window so that the User Name and

Password can be entered. (For instructions on how to use the Keyboard see Section

2.2) Once the correct User Name and Password are entered, select the Return key on

the Keyboard window and then select the OK key on the Login window. When the User

Name and Password is entered, the operator will gain access to the different settings,

parameters, and set points associated with the password level entered. The active User

Name will be shown at the upper right hand corner of the screen (See Figure 1-1). If the

controller is left idle for over one minute, the “password lock” will be activated which will

require the operator to re-enter the User Name and Password for access.

Figure 3-1: Login Window

World Leaders in Ultra-Pure Heating

www.heateflex.com

10

405 E. Santa Clara St., Arcadia, CA 91006-7218

O

: (626) 599-8566

F

: (626) 599-9567

Figure 3-2 – Close Up of Active User Name, Date and Time

The password is eight digits alpha-numeric. This password will allow the user to modify

the parameters and set points within the Control Settings, Alarm Set Points, System

Calibration, and Options (if options are available). In addition, the User Password is

required in order to clear the information on the Alarm History screen and in order to

activate the GFCI TEST key for the GFCI Alarm.

Note: The User Password will not grant access to the Factory System Menu screen.

This menu is for Factory Use Only and a Factory Password is required to access these

screens.

Active User Name

Date and Time

World Leaders in Ultra-Pure Heating

www.heateflex.com

11

405 E. Santa Clara St., Arcadia, CA 91006-7218

O

: (626) 599-8566

F

: (626) 599-9567

4. DATE/TIME SET UP

To change the date or the time, select the System Information Key from the Main Menu

Screen. Next select System Clock Set Up. This is shown in Figure 4-1 below.

Figure 4-1: System Clock Set Up Screen

The system will prompt you to enter the User Password. Once the correct password is

entered, the date and time can be modified.

To change the date and time, select the white area next to the SET key. The Set NA

Calendar/Clock window will display. The date and time can be entered using the drop-

down menus labeled Day, Month, Year, Hour, Minute, and Second.

To change the date, enter the date in the following format “mm/dd/yyyy”.

Press the Enter key to accept the changes.

To change the time, enter the time in the following “24 hour” format “hh:mm:ss”.

Press the Enter key to accept the changes.

World Leaders in Ultra-Pure Heating

www.heateflex.com

12

405 E. Santa Clara St., Arcadia, CA 91006-7218

O

: (626) 599-8566

F

: (626) 599-9567

5. OPERATION

The basic function of the PF2000 Controller is to provide hot D.I. water on demand. The

unit continually monitors the flow sensor and once flow is detected by the flow sensor the

heaters are turned on to a proportional power level that is calculated by the following

formula:

GPM x T°C

KW = 3.79

This formula utilizes the input thermocouple temperature and process set point

temperature to calculate ToC. The flow value in GPM is taken from the flow meter

reading and the power or KW is adjusted by time proportioning the “on time” of the heaters

in ratio to the time base set in the “Cycle Rate” (CR) parameter.

This value becomes the maximum KW that the system may utilize. Additionally, the actual

percentage of power that is utilized is determined by the temperature control section

utilizing the output thermocouple.

The temperature control section operates as an adjusting mechanism to the power

requirement. It monitors the discharge temperature and compares it against the required

set point. Based on the “Power Reset” (PR) parameter, it will adjust the power that is

applied to the unit to bring the discharge temperature into complete compliance with the

requirements. The “Dead Band” (DB) setting is utilized to establish a range above and

below the set point in which the temperature control section will take no further action.

This means that the PR parameter will adjust the power on a periodic basis and examine

the temperature output to determine whether the temperature is within the customer

specified control band. If the temperature is within this DB, it will leave the power alone.

If the temperature is outside this DB, it will continue to adjust the power until the

temperature is within the DB.

The PF2000 has a large number of inputs and outputs. The main output is the silicon

controlled relay drive to the heaters. This is a 12 VDC output signal that is active high. It

has sufficient capacity to drive 10 solid-state relays. The alarm output is an open collector

transistor that may be interfaced with an external alarm. The purge valve output is a form

C relay. It will close either on automatic or manual purge.

World Leaders in Ultra-Pure Heating

www.heateflex.com

13

405 E. Santa Clara St., Arcadia, CA 91006-7218

O

: (626) 599-8566

F

: (626) 599-9567

When the system is powered ON, the Main Menu screen will appear and the unit will be

in STANDBY mode. In this mode, all the keyboard operational features are active, the

Heater Master Relay is inactive (normally open), and the Heater Safety Relay is active

(normally closed). The Aquarius® D.I. Water Heating System is ready to process provided

that all the installation requirements have been fulfilled, including water flow through the

unit system, the desired process temperature has been entered, and there are no “critical

alarms” present. The “critical” alarms in the system are designated as manual reset

alarms. When any of these “critical” alarms are triggered, the unit will go into STANDBY

mode and the heaters will be disabled. The unit will not return to normal operation until

the system has been manually reset by pressing the ALARM RESET key (located on the

Alarm Menu screen or Alarm submenu screens) and/or the alarm condition resolved.

“Non-critical” alarms do not affect the system and serve only as a warning to the user.

Under normal operating conditions a minimum flow rate is required based on the size of

the Aquarius® D.I. Water Heating System plumbing in order to process fluid (0.5 GPM for

standard plumbing sizes). The Aquarius D.I. Water Heating System has a special feature

called “Automatic Reset” (Auto Reset) which allows the user to disable this minimum

flow rate requirement. When the Auto Reset parameter is set to ON, the Low Flow

Alarm will be disabled and the “Low Flow Alarm Set Point” will temporarily be set to 0

GPM. The system will automatically go from STANDBY mode to ACTIVE mode and start

HEATING (indicated by the flickering light) when the system detects a flow rate provided

there are no critical alarms present. The unit will remain in STANDBY mode when a flow

rate of 0.5 GPM or lower exists. In addition, when the AR parameter is set to ON, the

previous “Low Flow Alarm Set Point” will be stored and re-entered once the AR

parameter is set to OFF. In order to process fluid in the “Automatic Reset” mode the

AR setting must be set to ON and the RUN key must be pressed.

The PF2000 has two redundant relays dedicated to the Master System Contactor coil.

This Heater Master Relay which is linked to the Safety PLC and is interlocked with a

number of intelligent alarms. Depending on the type of “critical alarm”, the Heater Master

Relay will open (if the system is processing) thus opening the Master System Contactor

and disabling power to the heaters. In addition, if the unit is turned off, the power to the

Master System Contactor will be disrupted, opening the Heater Master Relay and

disabling power to the heaters. The Safety PLC is wired to two independent contact relays

with relays wired in series to the Master System Contactor. This redundancy is to

prevent a false contact condition.

World Leaders in Ultra-Pure Heating

www.heateflex.com

14

405 E. Santa Clara St., Arcadia, CA 91006-7218

O

: (626) 599-8566

F

: (626) 599-9567

The Heater Safety Relay is also interlocked with a number of intelligent alarms. Each of

the “critical alarms” has the capability of disabling the Heater Safety Relay. As a result,

when any of the “critical” alarms are triggered, they not only shut down the intelligent drive

to the Silicon Controlled Rectifier (SCR), disable the Heater Safety Relay to provide an

additional element of protection by mechanically eliminating the signal which controls

power to the heaters.

The PF2000 has an additional safety interlock feature that is transparent to its normal

operation. If for some reason, the discharge temperature reaches 5oC higher than the

process temperature set point, the heaters will be disabled. This is not announced as an

alarm unless this temperature exceeds “High Temperature Alarm” setting. However, it

is provided to ensure that the set point has overriding control over all of the automatic

calculations. This provides additional first line protection against erroneous heater output

due to conditions such as bad voltage or current sensors.

The Aquarius® D.I. Water Heating System has an optional Auto Purge feature that

flushes or purges the unit after a programmable period of time where there is no demand

for D.I. water. Auto Purge monitors the amount of time elapsed since leaving ACTIVE

mode (i.e.: "No Flow Time"). If this amount of time exceeds the programmed “Auto Purge

Period” (AP) parameter, the system is purged for the amount of time programmed in the

“Auto Purge Duration” (AD) parameter. This cycle will continue until the Auto Purge

feature is disabled or turned off. The system will continue to purge even if flow is detected

while the unit is in AUTO RESET mode or MANUAL mode. Once the “Auto Purge

Period” has elapsed, the unit will return to AUTO RESET mode. The purge cycle may

be terminated prematurely by pressing the PURGE key located on the System Status

screen. Note, to access the Purge Key, select the AP option key to display the Auto

Purge User Selected Display. (The PF2000 also supports a remote Auto Purge switch,

which is available in the standard Ethernet Communications and Discrete Interface

Package Option of the Auto Purge Option.) Please note that the heaters will be disabled

during “Auto Purge Duration” time.

A Resistivity option is offered for the Aquarius® D.I. Water Heating Systems. The

Resistivity option utilizes a standard Resistivity sensor with a cell constant of 0.01. It

excites the sensor with an AC signal to prevent any interference due to electrolysis or

secondary reactions with the electrode material. The standard cell has an extremely non-

linear characteristic with respect to temperature. The transmitter has an extensive

compensation algorithm to handle the standard 3D curve. It should be noted, that while

the cell has an internal temperature sensor, this sensor is not utilized in the system. The

Low Resistivity Alarm is considered a non-critical alarm and will not affect the heaters.

World Leaders in Ultra-Pure Heating

www.heateflex.com

15

405 E. Santa Clara St., Arcadia, CA 91006-7218

O

: (626) 599-8566

F

: (626) 599-9567

The Aquarius® D.I. Water Heating Systems incorporate a large red emergency power off

switch (EMO) and an optional remote emergency power off switch is also supported (See

Discrete Interface Package Option). Each of these switches will produce the same effect.

When the switch is pressed, the normally closed contacts will open which causes the

Safety Relay to POWER OFF the entire system therefore interrupting power to the Master

Contactor holding coil, and disabling the heaters.

5.1.

SYSTEM STATUS SCREEN

The System Status screen shown below is used to monitor and operate the

system. The Mode Indicating Lamps are used to distinguish the different

system modes. In addition, the operator will also be notified of any alarm

conditions that are present on this screen. When an alarm condition is

present the alarm icon will be illuminated red. When the alarm is reset the

alarm icon will be illuminated green. The System Status Displays provide

values for the Voltage, Power, Purge (optional), Resistivity (optional),

Recirculation (optional), Flow Rate, Pressure, Process Temperature, Set

Point Temperature, and Incoming Temperature. The Unit Change Keys are

used to easily switch from English units to metric or SI units or vice versa.

The units GPM, PSI, and F can be changed to LPM, kPA, and C by clicking

on the unit label. The System Operation Keys are used to “RUN” the

system or alternatively to “STOP” the system from heating, manually initiate

Auto Purge (if available), and enable Recirculation (if available). See Table 5-

3 for more information. Note, Auto Purge, Resistivity, and Recirculation are

optional features. These sub-menus can only be accessed if the option is

available. Furthermore, the sub-menus for Power, Purge, Resistivity, and

Recirculation cannot be displayed concurrently. The System Screen Keys

are used to easily navigate to various system screens. See Figure 5-1 below

for more detail.

World Leaders in Ultra-Pure Heating

www.heateflex.com

16

405 E. Santa Clara St., Arcadia, CA 91006-7218

O

: (626) 599-8566

F

: (626) 599-9567

Figure 5-1: System Status Screen

Figure 5-2: System Status Screen User Selection Keys

Power Display

Purge Display

Res

istivity Display

Recirculation Display

Please note that the appearance of the System Status screen may vary

depending on the Aquarius® D.I. Water Heating System options such as the

Resistivity, Auto Purge, Discrete Interface, Analog Interface Package

(Remote Temperature Set Point), Secondary Process Temperature Set

Point and Recirculation that are present. Figure 5-3 through 5-5 illustrate a

typical Aquarius® System Status screen with Auto Purge, Resistivity, and

Recirculation options.

System Status

Display

Unit Change

Key

(LPM

-

GPM)

User Selected

Options

Unit Change

Key

(kPa – PSI)

System

Screen Keys

See 6.6

Mode Indicating

Lamp/Labels

See 6.2

System

Operation Keys

See 6.5

Unit Change Key

(C – F)

World Leaders in Ultra-Pure Heating

www.heateflex.com

17

405 E. Santa Clara St., Arcadia, CA 91006-7218

O

: (626) 599-8566

F

: (626) 599-9567

Figure 5-3: System Status Menu Screen w/ Auto Purge Selected

Figure 5-4: System Status Menu Screen w/ Resistivity Selected

Figure 5-5: System Status Menu Screen w/ Recirculation Selected

World Leaders in Ultra-Pure Heating

www.heateflex.com

18

405 E. Santa Clara St., Arcadia, CA 91006-7218

O

: (626) 599-8566

F

: (626) 599-9567

5.2.

MODE INDICATING LAMPS/LABELS

There are two primary modes which are indicated by lamps and labels on the

System Status screen which are STANDBY/ACTIVE and HEATING.

Additional mode indicating lamps/labels will appear based on the Aquarius®

D.I. Water Heating System options. See Table 5-1 for a complete list of

system status mode descriptions.

Table 5-1: System Status Modes

MODE LAMP DESCRIPTION

STANDBY

When the system is first powered ON the unit will

load into the STANDBY mode. In this mode, all of

the keyboard operational features are active, but the

Heater Master Relay is inactive (disabling all power

to the heaters), and the Heater Safety Relay is

active provided that there are no critical alarms

present. The system is "standing by" and is ready to

go into

ACTIVE

mode

.

ACTIVE

This is the normal operating mode for the system. In

this mode, if there are no critical alarms present and

the required minimum flow rate is detected, the

control system will meter power to the heaters to

raise the output D.I. water temperature to the

“Process Temperature Set Point” parameter. This

mode is initiated by pressing the RUN key while in

STANDBY mode. The STANDBY label will

automatically switch to the ACTIVE

label and a green

indicating lamp will illuminate.

HEATING

This mode lamp indicates the status of the heaters.

When the heaters are ON the lamp will flicker amber.

This lamp will cycle as required by the system

parameters.

AUTO RESET

This mode lamp is active if the AUTO RESET mode

is enabled. This mode allows the user to disable the

minimum flow requirement. The Low Flow Alarm is

disabled, and the Low Flow Alarm Set Point is

temporarily set to zero. The system will

automatically reset when there is flow and no critical

alarms are present.

World Leaders in Ultra-Pure Heating

www.heateflex.com

19

405 E. Santa Clara St., Arcadia, CA 91006-7218

O

: (626) 599-8566

F

: (626) 599-9567

MODE LAMP DESCRIPTION

REMOTE STOP

(Optional)

This mode lamp is active only if the Discrete

Interface Package option is available. This mode

lamp notifies the user when the unit is remotely

stopped or placed into STANDBY. When the

Remote Stop function is active this mode lamp will

illuminate green.

REMOTE SET POINT

(Optional)

This mode lamp is active only if the

Ethernet Remote

Set Point (available standard), Analog Remote Set

Point (option) or Secondary Set Point (option) is

active. This mode lamp notifies the operator whether

the “Process Temperature Set Point” is being

controlled locally or remotely. When the “Process

Temperature Set Point” is being controlled locally

the REMOTE SET POINT mode lamp will not be

illuminated. When the system is being controlled

remotely the REMOTE SET POINT mode lamp will

illuminate green.

PURGE STATUS

(Located in User

Selected Option Area

when AP is selected)

This mode lamp is active only if the Auto Purge

option is available. This mode lamp notifies the user

as to the current status of the purging feature of the

unit. When the system is automatically (Auto Purge)

or manually purging this mode lamp will illuminate

green.

ISOLATION STATUS

(Optional)

This mode lamp is active only if the Water Leaks

option is available. This mode lamp notifies the user

when the isolation valves are active as a result of the

detection of leaks.

DEMAND, VENTING,

RECIRCULATION

(Located in User

Selected Option Area

when ∞ is selected)

The following mode lamps are only accessible if the

Recirculation option is available.

DEMAND: This mode lamp/label notifies the

operator that the unit is in DEMAND mode

and will illuminate green when active.

VENTING: This mode lamp/label notifies the

operator that the unit is in VENTING mode

and will illuminate green when active.

RECIRCULATION: This mode lamp/label

notifies the operator that the unit is in

RECIRCULATION mode and will illuminate

green when active.

Table of contents

Popular Controllers manuals by other brands

M2 Antenna Systems

M2 Antenna Systems RC2800PRKX1SU manual

Mitsubishi Electric

Mitsubishi Electric MELSEC iQ-F FX55-ASL-M user manual

Mitsubishi

Mitsubishi MELSEC-A AJ35PTC-CNV user manual

Nice

Nice PLUTO PL 4000 Instruction manual and spare parts catalogue

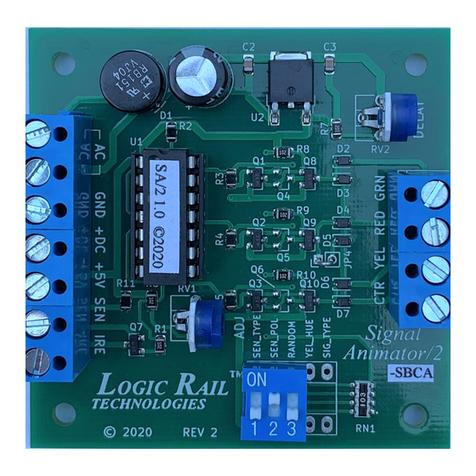

LOGIC RAIL

LOGIC RAIL Block Animator/2-SBCA Series instructions

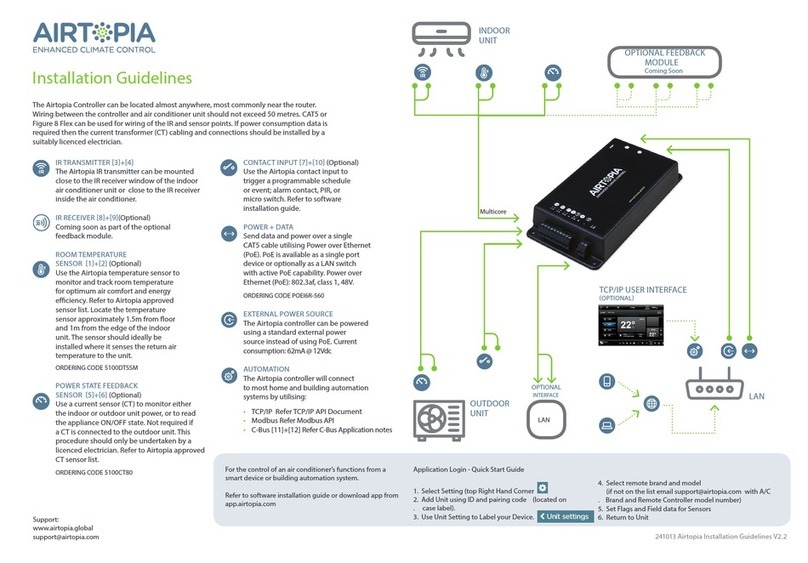

Airtopia

Airtopia KIT-T01 Installation guidelines