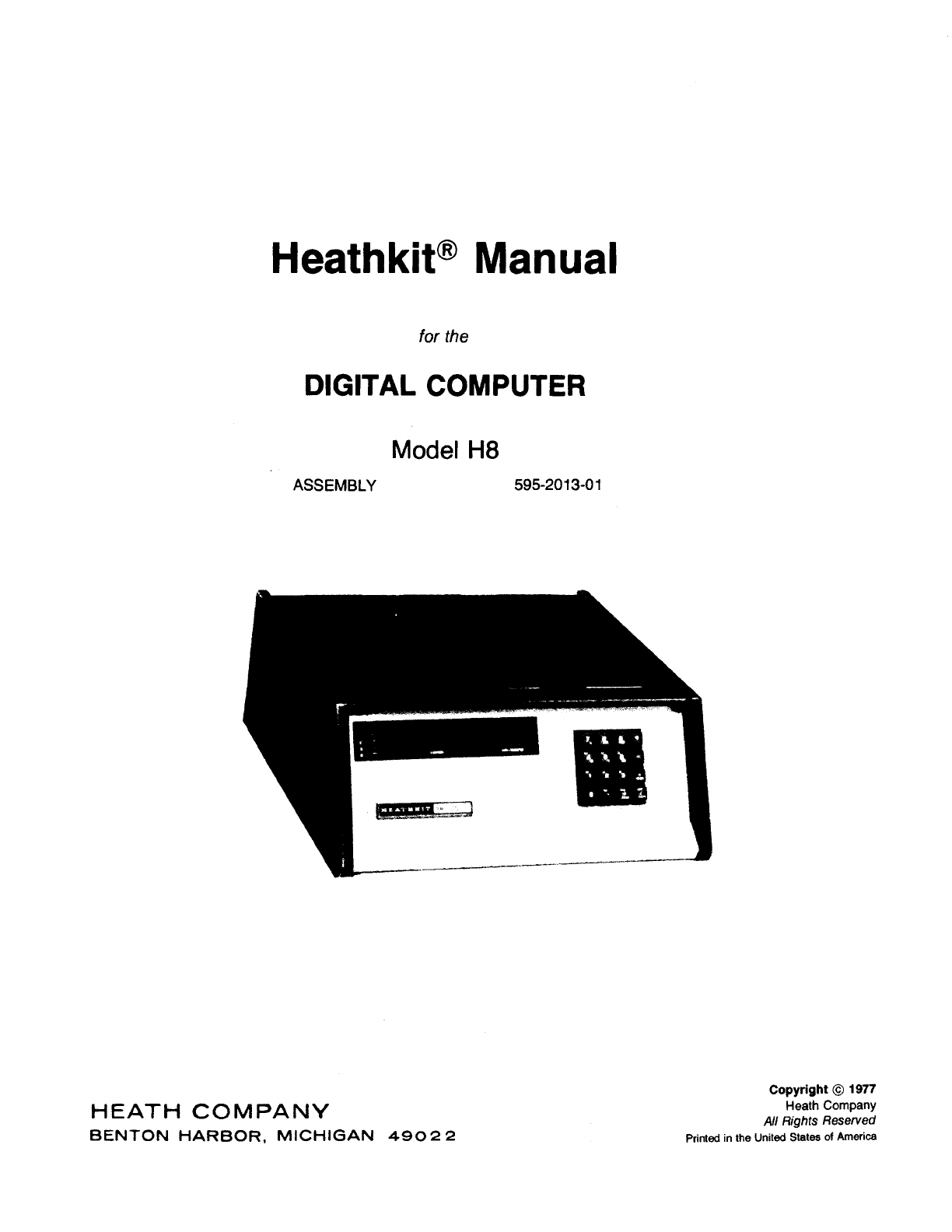

Heath Company Heathkit H8 User manual

Heathkit® Manual

for the

DIGITAL COMPUTER

Model H8

ASSEMBLY 595-2013-01

: --

--

HEATH

COMPANY

BENTON

HARBOR,

MICHIGAN

49022

Copyright

© 1977

Heath Company

All Rights Reserved

Printed

in

the United States of America

Page

2

TABLE OF CONTENTS

UNPACKING

................................

3 CONTROL CIRCUIT BOARD

Parts

List.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

34

Step-by-Step Assemlbly

.......................

37

ASSEMBLY NOTES . . . . . . . . . . . . . . . . . . . . . . . .

..

4 Circuit Board Installation

...................

"

55

Circuit Board Checks

.........................

56

CHASSIS ASSEMBLY

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

7

Step-by-Step Assembly

.......................

9

CPU CIRCUIT BOARD

Replacement Parts List

.....

. . . . . . . . . . . . . . . .

..

59

Circuit Board Installation

.....................

61

Mother Circuit Board Assembly

............

9 Circuit Board Check

..........................

61

Chassis

.................................

14

Power

Supply

Tests.

. . . . . . . . . . . . . . . . . . . . . . .

..

30 FINAL ASSEMBLY

..........................

62

UNPACKING

Your Digital

Computer

shipping

carton

contains

a

box

marked

"CPU

Circuit

Board"

and

a

smaller

box

marked

"Pack

#2."

After

you

remove

these

two

boxes,

the

remaining

parts

in

the

shipping

carton

form

the

Main

Pack,

which

are

items

too

large

to

fit

into

the

other

parts

packs

and

those

items

which

you

will

use

in

the

chassis

assembly

section.

Set

aside

the

boxes

marked

"CPU

Circuit

Board"

and

"Pack

#2"

until

one

of

these

packs

is

called

for

in

an

assembly

section. DO NOT

disturb

either

of

these

packs

yet.

Page 3

Each

assembly

section

of

this

Manual

contains

its

own

"Parts

List"

and

"Step-by-Step

Assembly"

in-

structions.

At

the

beginning

of

each

Parts

List,

you

will

be

instructed

which

parts

pack

to

locate

and

unpack.

You

may

also

be

directed

to locate

certain

required

parts

from

the

Main

Pack.

To

avoid

intermixing

parts,

do

not

remove

or

open

any

of

the

parts

packs

until

you

are

directed

to

do

so

at

the

beginning

of

one

of

the

"Parts

Lists."

Return

any

part

that

is

packed

in

an

individual

envelope,

with

the

part

number

on

it,

back

in

its

envelope

after

you

identify

it

until

that

part

is

called

for

in

a step.

Some

envelopes

have

one

transparent

side

so

you

can

iden-

tify

the

parts

inside

without

opening

the

envelope.

Page 4

ASSEMBLY NOTES

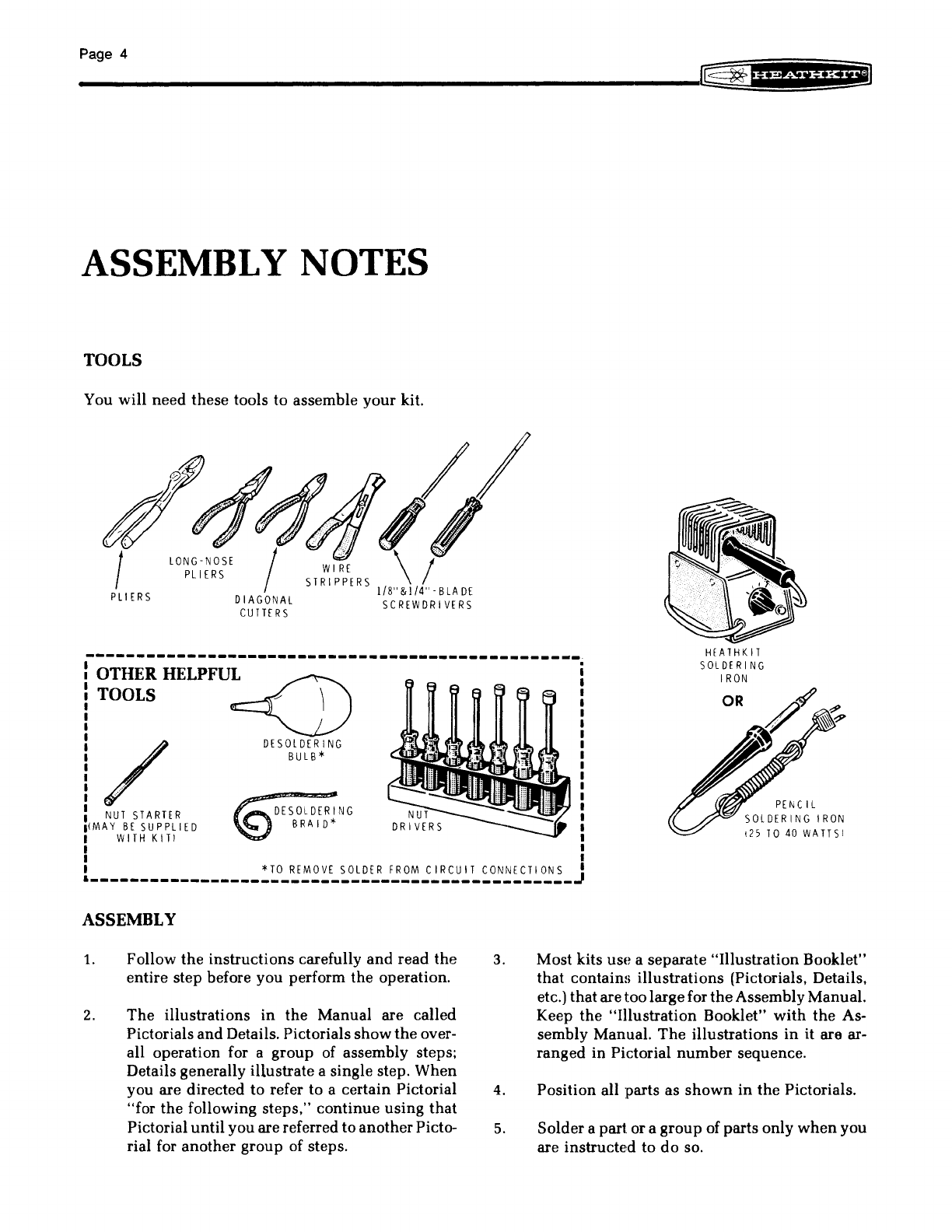

TOOLS

You

will

need these tools to assemble

your

kit.

~~

~-A(

d!

//

~

tf'J

rJ

tlJI

~

.....

I LONG-NOSE I

WI

RE

\ I

PLIERS STRI

PPERS

1/8"

&1/4"

-

BLA

DE

PLIERS DIAGONAL SCREWDRIVERS

CUTTERS

-------------------------------------------------

OTHER

HELPFU~

TOOLS

~

/ DESOLDERING

BULB*

NUT

STARTER

IIMAY

BE

SUPPLIED DESOLDERING

BRAID*

I WITH

KITI

I

I

HEATHKIT

SOLDERING

I

RON

OR

,25

TO

40

WATTSI

I

*TO

REMOVE

SOLDER

FROM

CIRCUIT

CONNECTIONS

I

________________________________________________

~

ASSEMBLY

1.

2.

Follow

the

instructions

carefully

and

read

the

entire step before you perform

the

operation.

The

illustrations in

the

Manual are called

Pictorials

and

Details. Pictorials

show

the

over-

all operation for a

group

of assembly steps;

Details generally illustrate a single step.

When

you are directed

to

refer to a certain Pictorial

"for

the

following

steps,"

continue

using

that

Pictorial

until

you are referred

to

another

Picto-

rial for

another

group of steps.

3.

4.

5.

Most kits use a separate

"Illustration

Booklet"

that contains illustrations (Pictorials, Details,

etc.) thataretoo largefor

the

AssemblyManual.

Keep

the

"Illustration

Booklet"

with

the

As-

sembly Manual.

The

illustrations

in

it are ar-

ranged

in Pictorial

number

sequence.

Position all parts as

shown

in

the

Pictorials.

Solder

a part or a

group

of parts only

when

you

are instructed to

do

so.

6.

= =

~

Each circuitpart

in

an

electronickit hasits

own

component number

(R2,

C4, etc.). Use these

numbers

when

you

want

to

identify

the

same

part

in

the

various sections of

the

Manual.

Thesenumbers,

which

areespeciallyuseful ifa

part has to be replaced, appear:

In

the

Parts List,

At

the

beginning of each step where a

component is installed,

In some illustrations,

In

the

Schematic,

In the section

at

the

rear

Df

the

Manual.

7. When you are instructed to

cut

something to a

particular length,

use

the

scales (rulers) pro-

vided at

the

bottom of

the

Manual pages.

SAFETY WARNING: Avoid eye

injury

when you

cut

offexcess lead lengths. Hold

the

leads

so

they

cannot

fly

toward

your

eyes.

Page 5

SOLDERING

Soldering is one ofthemost importantoperationsyou

will perform while assembling your kit. A good sol-

der connection will form

an

electrical connectionbe-

tween

two

parts, such as a component lead

and

a

circuitboard foil. A bad solder connectioncould pre-

vent

an

otherwise well-assembled kit from operating

properly.

It

is easy to make a good solder connection if you

follow a few simple rules:

1.

2.

Use

the

right type of soldering iron. A 25 to

40-watt pencil soldering iron

with

a 1/8" or

3/16"

chisel or pyramid tip works best.

Keep

the

soldering irontip clean. Wipe it often

on a wet sponge or cloth;

then

apply solder

to

the

tip

to

give

the

entire

tip

a wet look. This

process is calledtinning.

and

it will protect

the

tip

and

enable you

to

make good connections.

Whensolder

tends

to

"ball"

or does not stick

to

the

tip. the tip needs

to

be

cleaned

and

retin-

ned.

Page 6

PARTS

Resistors will

be

called

out

by

their

resistance

value

in

0 (ohms). kO (kilohms),

orMO

(megohms). Certain

types of resistors will have

the

value

printed

on

the

body, while others will be identified by a color code.

The

colors of

the

bands

and

the

value

will

be

given in

the

steps, therefore

the

following color

code

is given

for information only.

==

l/4-WATT

==fDIII~==

l/2-WATT

l-WATT

EXAMPLES:

==

..

~==

/

BROWN

__

GREEN

---

ORANGE

~

SILVER

5

1.000

±10%

15 x 1,000 =

15,0000

(15,000 OHMS),

or

"15 kO"

/ ORANGE 3

__

BLACK 0

---

GREEN

100,000

"'"

GOLD

::+:5%

30 x 100,000 = 3,000,000 0

(or

3 MO)

3

MO

= 3 MEGOHMS

2-WATT

TOLERANCE

RESISTOR COLOR CODE

II'.

*-----===i

Gold

5%

Silver 10%

.-~

l I No Band 20%

•

COLOR

1st

DIGIT

2nd

DIGIT

MULTIPLY

BY

BLAC K a a 1

BROWN I 1

10

RED

2 2

100

ORANGE l l

I,

000

YE

LL

OW

4 4

10

,000

GREEN

5 5 100,000

BLUE

6 6 1,000,000

VIOLET 7 7 10,000,000

GRAY 8 8 100,000,000

WH

IT[

9 q 1,000,000,000

GOLD

1

SI L

VE

R

01

Capacitors

will

be

called

out

by

their

capacitance

value

in,."F (microfarads) or pF (picofarads)

and

type:

ceramic,

Mylar·,

electrolytic,

etc_

Some capacitors

may

have

their

value

printed

in

the

following man-

ner:

EXAMPLES:

151K

=

15

x

10

=

150

pF

759

=

75

x

0.1

=

7.5

pF

First digit

of

capacitor's value: 1

--

__

....

Second

digit of

capacitor's value: 5

____

oJ

Multiplier: Multiply

the

___

--I

first & second digits by

the

proper value from the

Multiplier Chart.

To find the tolerance of

-----J

the capacitor, look

up

this

letter in the Tolerance

columns.

·DuPont

Registered

Trademark

NOTE:

The

letter

"R"

may be

used

at

timesto signify a

decimal point; as in: 2R2 = 2,2 (pF

or

,."F).

MULTIPLIER

TOLERANCE

OF

CAPACITOR

FOR

THE

MULTIPLY

lOp F

OR

LETTER

OVER

NUMBER

BY

LE5 S

10pF

0 I

to

1PF B

1

10

±0.25pF

C

2

100

to.

5pF

D

3 1000 ±I

OpF

F ±I %

4

10,000

±2

OpF

G ±

2'7,

5

100,000

H

±3'70

J t5%

g

0.01

K ±

10%

9

O.

1 M

±20%

Page

7

CHASSIS ASSEMBLY

PARTS LIST

( ) Locate

and

remove

all

of

the

partsfrom

the

main

pack

(parts left

in

the

shipping

carton). Be

sure

you

have

removed

the

items

from

the

carton

as

directed

in

the

"Unpacking"

section.

Unpack

these

parts

and

check

each part

against

the

following list.

The

key

numbers

correspond

to

the

numbers

on

the

"Chassis

Parts

Pictorial"

(Illustration Booklet,

Page

1).

Set

aside

any

re-

KEY

HEATH

No.

Part

No.

QTY.

DESCRIPTION

CIRCUIT

Compo No.

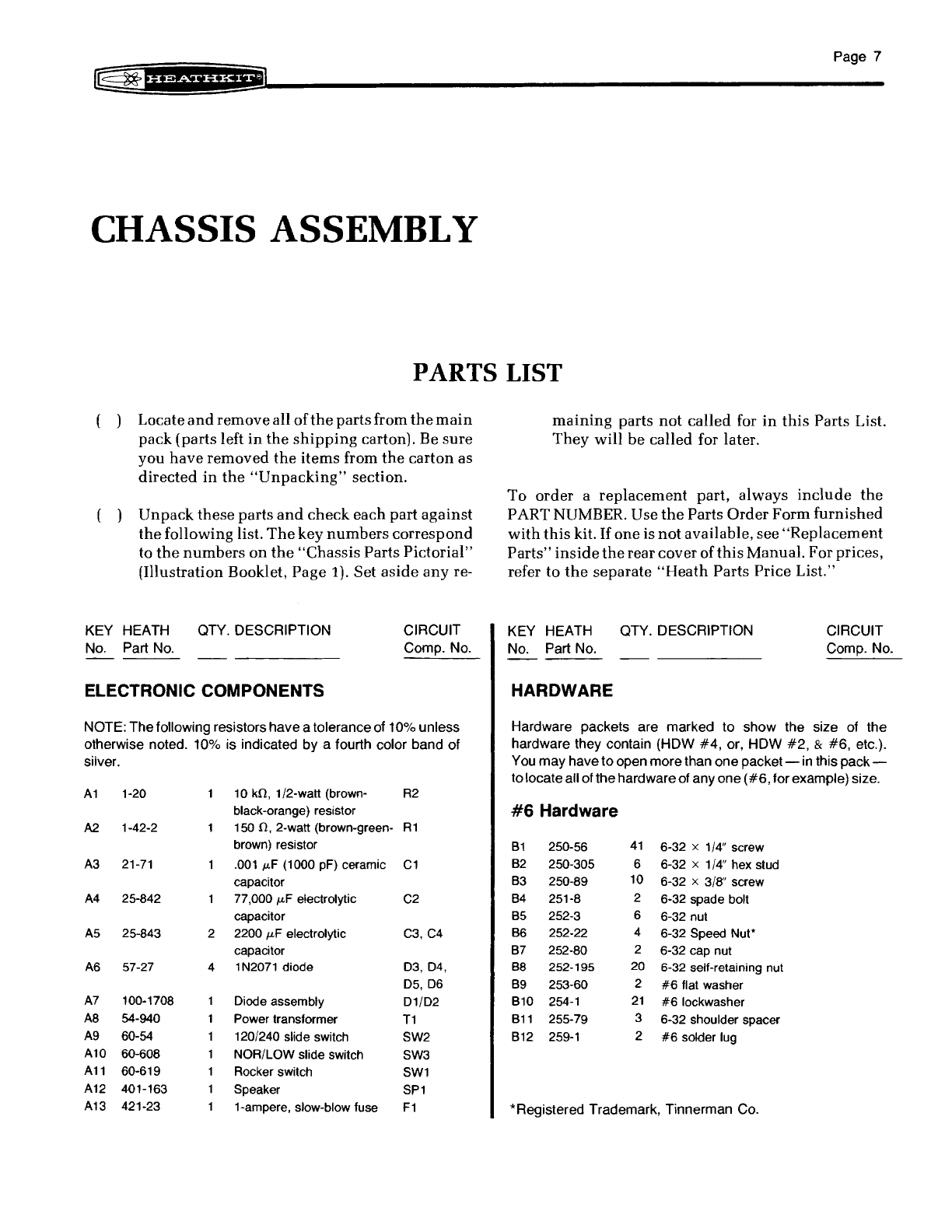

ELECTRONIC COMPONENTS

NOTE:

The

following resistors

have

a

tolerance

of

10%

unless

otherwise

noted.

10%

is

indicated

by

a fourth

color

band

of

silver.

A1

1-20

10

kfl,

1/2-watt (brown-

R2

black-orange) resistor

A2

1-42-2 150

fl,

2-watt (brown-green-

R1

brown) resistor

A3

21-71

.001

fotF

(1000

pF)

ceramic

C1

capacitor

A4

25-842 77,000

fotF

electrolytic

C2

capacitor

A5

25-843 2 2200

fotF

electrolytic

C3,C4

capacitor

A6

57-27 4 1

N2071

diode

03,04,

05,

06

A7

100-1708 Oiode assembly

01/02

A8

54-940 Power transformer

T1

A9

60-54 120/240 slide switch SW2

A10 60-608 NOR/LOW slide switch SW3

A11

60-619 Rocker switch

SW1

A12

401-163 Speaker

SP1

A13

421-23 1-ampere, slow-blow fuse

F1

maining

parts

not

called

for

in

this

Parts List.

They

will

be

called for later.

To

order

a

replacement

part, always

include

the

PART NUMBER. Use

the

Parts

Order

Form

furnished

with

this

kit.

If

one

is

not

available, see

"Replacement

Parts"

inside

the

rear

cover

of

this

Manual. Forprices,

refer to

the

separate

"Heath

Parts Price List."

KEY

HEATH

No. Part No.

HARDWARE

QTY.

DESCRIPTION

CIRCUIT

Compo No.

Hardware

packets

are

marked

to

show

the

size of

the

hardware

they

contain

(HOW

#4,

or,

HOW

#2,

&

#6,

etc.).

You

may

have

to

open

more

than

one

packet

-in this

pack-

to

locate

all of

the

hardware

of

anyone

(#6,

for

example)

size.

#6

Hardware

B1

250-56

41

6-32 x 1/4" screw

B2

250-305 6 6-32 x 1/4" hex stud

B3

250-89

10

6-32 x 3/8" screw

B4

251-8 2 6-32 spade bolt

B5

252-3 6 6-32 nut

B6

252-22 4 6-32 Speed

Nut'

B7

252-80 2 6-32 cap nut

88

252-195

20

6-32

self-retaining nut

B9

253-60 2

#6

flat washer

810

254-1

21

#6

lockwasher

811

255-79 3 6-32 shoulder spacer

812

259-1

2

#6

solder lug

*Registered

Trademark,

Tinnerman

Co.

PageS

KEY

HEATH

OTY.

DESCRIPTION

No.

Part

No.

Hardware (cont'd.)

#8

Hardware

Cl

250-98 6 8-32 x1/2" screw

C2 252-4 6 8-32 nut

C3 252-706 4 8-32 lock nut

C4 253-45 4

#8

flat washer

C5 254-2 6

#8

lockwasher

Other Hardware

Dl

250-1256 2 10-32 x 1/4" screw

D2

254-3 2 #

10

lockwasher

D3 259-26 4

#10

solder lug

D4

252-193 2 Push-on nut

D5 259-22 Spade lug

06

253-8 Brass flat washer

SHEET METAL PARTS

El

200-1296-1 Chassis

E2

203-1891-1 Top cover

E3

203-1892-1 1 Front panel

E4

204-2265 2 Circuit board mounting

bracket

E5 204-2267-1 Cable clamp

E6

204-2292 Tie bracket

E7 206-1249 AC shield

E8

206-1250 Capacitor shield

E9

207-98 Capacitor mounting strap

E10 207-622 Circuit board support clamp

WIRE

344-7 1'6" Large black wire

344-33

2'

Medium black wire

344-111 6'3" Orange wire

344-118 1'3" Large red wire

344-120 2'6" Small black wire

344-121 4' White wire

347-55 7'fJ' 8-wire cable

89-54 Line cord

0

y..

% %

(INCHES)

2

1'(8 I

3:8

I

5{B

I

7;8

I , I I I I I, I

I ! i I i !

"if

i

I"

i)

i I i

0 5 1

(eM)

2 3 4 5 6

CIRCUIT

Compo

No.

3

KEY

HEATH

OTY.

DESCRIPTION

CIRCUIT

No.

Part

No.

Compo

No.

PRINTED

MATERIIAL

Fl

390-1357 Model label

390-1415 Instruction card

F2 390-926 Warning label

F3 391-34 Blue and white label

F4 391-611 Nameplate

F5 390-1371 Keyboard label set

597-260 Parts Order Form

597-1656 Heath User's Group

(HUG) Application

597-1659 HUG return envelope

Assembly Manual (See

Page 1 for part number.)

Operation Manual (See

Page 1 for part number.)

Software Manual (See

Page 1 for part number.)

MISCELLANEOW,

G1

354-7 2 Large cable tie

G2 73-3 1 Rubber grommet

G3 261-20 4 Rubber foot

G4 352-31 Thermal compound*

G5 423-11 Fuseholder

G6 434-148 1 AC socket

G7 432-946 20 25-pin plug

G8 75-736 1 Strain relief

G9 432-120 2 PCB connector

Gl0

73-39

18"

Foam tape

G111

490-5 Nut starter

Gl'!

490-111 IC lifter

Gl~1

490-185 Package of Soder Wick*-

203-1879 Set of side panels

containing:

G14

203-1877 Right side

panel

G1ti 203-1878 Left side

panel

G1E>

446-683 Window

GH

354-5 Small cable tie

85-1936-1 Mother circuit board

701-29 3-ring binder

703-12 Set of 5 tabs (for

binder)

880-1 System software

cassette tape (Assember,

Editor, Basic, Debug)

Solder

*Dow

Corning

thermal

heat

sink

compound

contains

Zinc

Oxides,

Si0

2,

and

slight

traces

of

CO

2,

**I~egistered

Trademark,

Solder

Removal

Company

4 5 6 7

iii

I ! I i

I I i I i I i Ii I

i i I

I ! i I I I i i I

I i i I i I I II i ! I I I

I

8 9

10

11

12

13

14

15

16

17

Page

9

STEP.BY·STEP ASSEMBLY

MOTHER CIRCUIT BOARD

ASSEMBLY

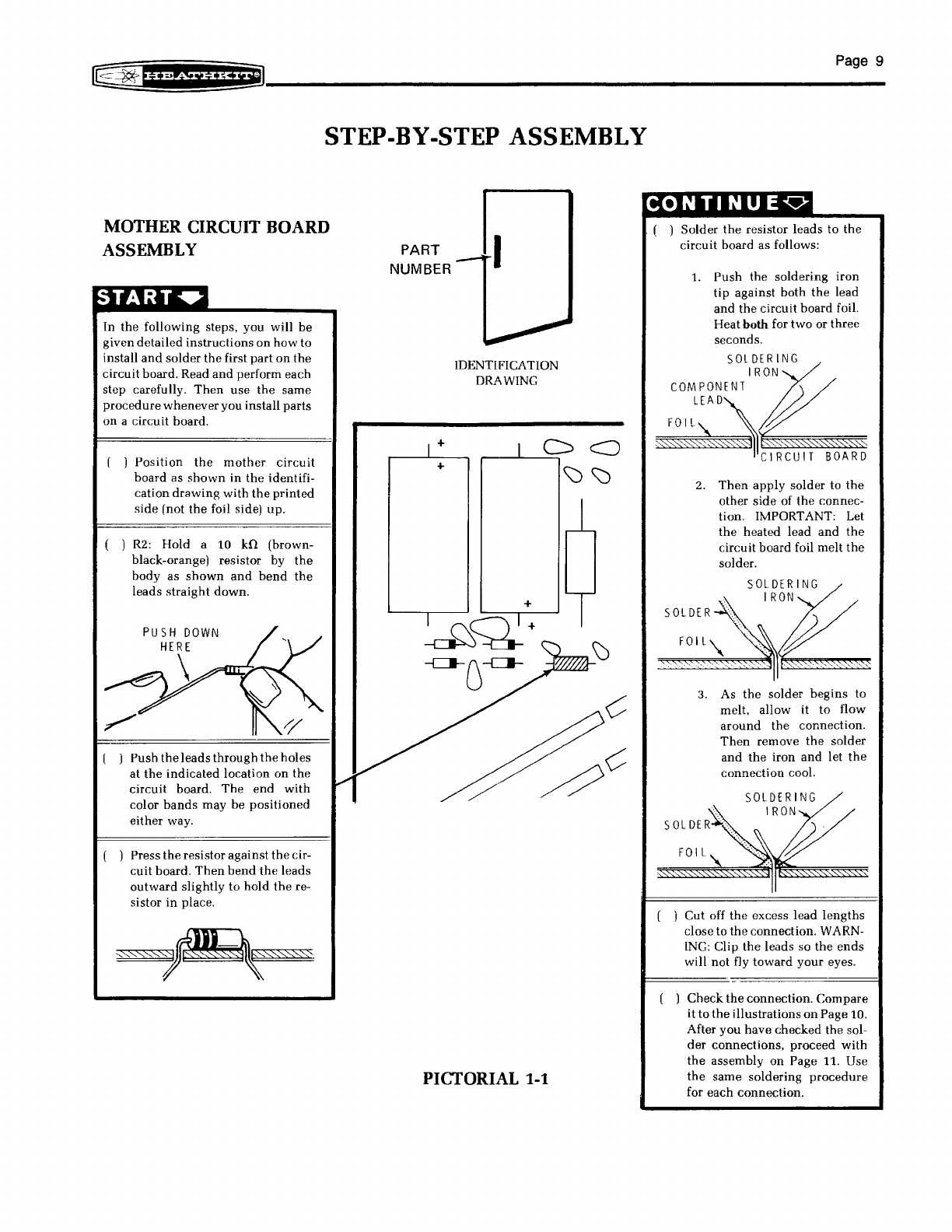

In

the

following

steps,

you

will

be

given

detailed

instructions

on

how

to

install

and

solder

the

first

part

on

the

circuit

board. Read

and

perform

each

step

carefully.

Then

use

the

same

procedure

whenever

you

install

parts

on

a

circuit

board.

[ )

Position

the

mother

circuit

board

as

shown

in

the

identifi-

cation

drawing

with

the

printed

side

[not

the

foil side)

up.

( )

R2:

Hold

a 10

kO

(brown-

black-orange) resistor by

the

body

as

shown

and

bend

the

leads

straight

down.

( )

Push

the

leads

through

the

holes

at

the

indicated

location

on

the

circuit

board.

The

end

with

color

bands

may

be

positioned

either

way.

( )

Press

the

resistor

against

the

cir-

cuit

board.

Then

bend

the

leads

outward

slightly

to

hold

the

re-

sistor

in

place.

PART

NUMBER

1+

+

I

IDENTIFICATION

DRAWING

+

PICTORIAL 1-1

CONTI

NUEv

. ( )

Solder

the

resistor

leads

to

the

circuit

board

as follows:

1.

Push

the

soldering

iron

tip

against

both

the

lead

and

the

circuit

board

foil.

Heatboth for

two

or

three

seconds.

SOLDERING

I

RON

COMPONENT

~

~~~ClRCUIT

BOARD

2.

Then

apply

solder

to

the

other

side

of

the

connec-

tion.

IMPORTANT: Let

the

heated

lead

and

the

circuit

board

foil

melt

the

solder.

3. As

the

solder

begins

to

melt,

allow

it

to

flow

around

the

connection.

Then

remove

the

solder

and

the

iron

and

let

the

connection

cool.

SOLDERING

I

RON

FO

IL

( ) Cut off

the

excess

lead

lengths

close

to

the

connection.

WARN-

ING: Clip

the

leads

so

the

ends

will

not

fly

toward

your

eyes.

Check

the

connection.

Compare

it

to

the

illustrations

on

Page

10.

After

you

have

checked

the

sol-

der

connections,

proceed

with

the

assembly

on

Page

11.

Use

the

same

soldering

procedure

for

each

connection.

Page

10

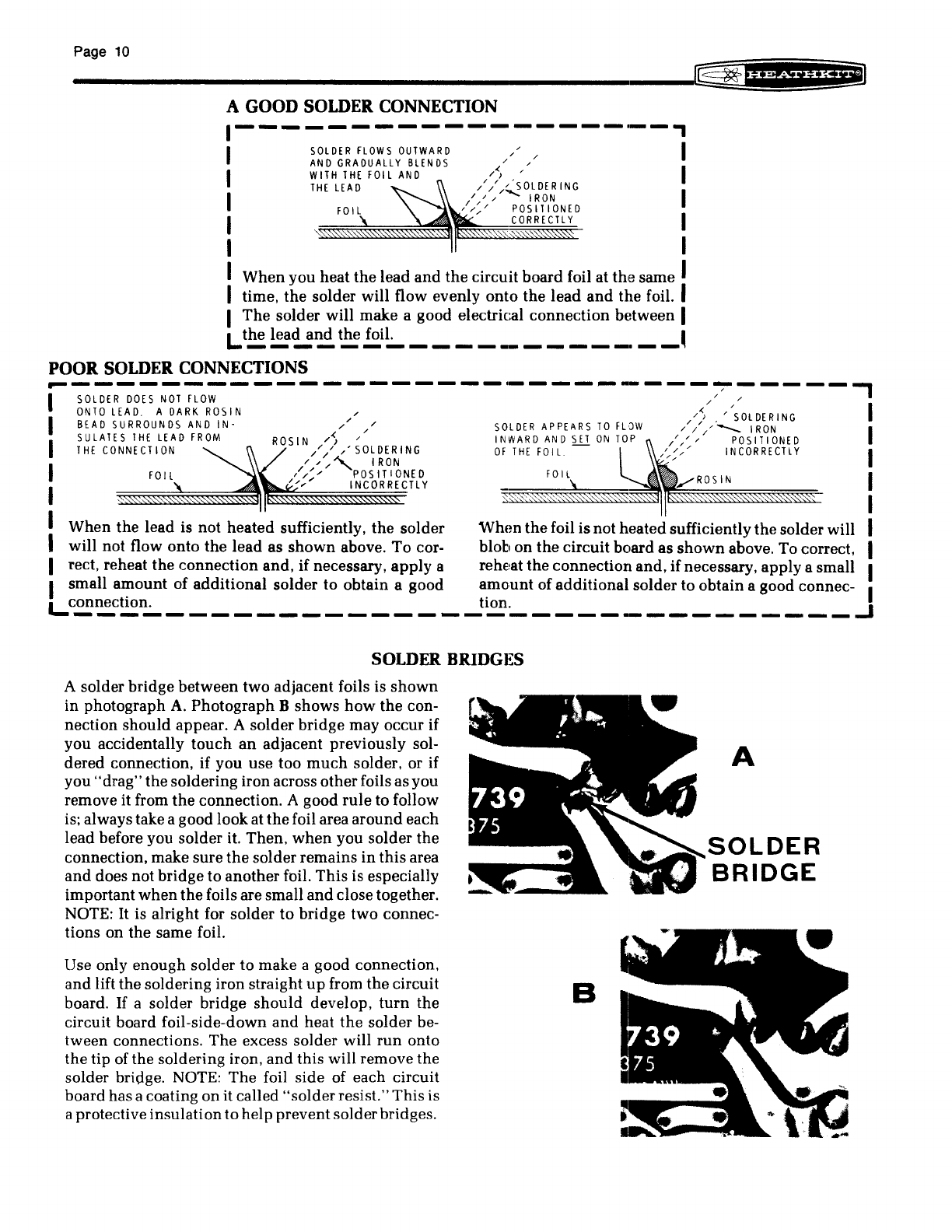

A GOOD SOLDER CONNECTION

1-------------------,

I

I

I

I

I

SOLDER

FLOWS

OUTWARD

AND

GRADUALLY

BLENDS

WITH

THE

FOIL

AND

THE

LEAD

I

I

I

I

I

I

When

you

heat

the

lead

and

the

circuit

board

foil at

the

same I

I time.

the

solder will flow evenly

onto

the

lead

and

the

foil. I

I

The

solder will make a good electrical

connection

between I

L.

t!!!:

~'!.!r!!,

~

.!!!i~

________

__

.

__

~

POOR SOLDER CONNECTIONS

-----------------------------~-----,

I

SOLDER

DOES

NOT

FLOW

,./

,.

I

ONTO

LEAD. A DARK

ROSIN,.

,.~

'/SOLDERING

I

BEAD

SURROUNDS

AND

IN-

,/

,./

SOLDER

APPEARS

TO

FLOW

///.---..

IRON I

SULATES

THE

LEAD

FROM

ROSIN

/~

/ INWARD

AND

SET

ON

TOP

///

/ POSITIONED

I

THE

CONNECTION

//

/ SOLDERING

OF

THE

FOIL. -l

////

INCORRECTLY I

///"'-

IRON

:

FOil

l:~"

1~~SoIJ~rNlDy

~;:;:;0W:;~':;::;Z'2&:§:'2""""""

VROSIN

I

I I

I

When

the

lead is not

heated

sufficiently.

the

solder

When

the

foil is not heated sufficiently

the

solder will

II

will not flow onto

the

lead as

shown

above.

To

cor- blob on

the

circuit board as

shown

above. To correct.

I

recto

reheat the

connection

and. if necessary.

apply

a reheat

the

connection and, ifnecessary.

apply

a small I

I small

amount

of

additional

solder

to obtain a good

amount

of

additional

solder to obtain a good connec- 1

Lconnection. tion. I

------------------------------------"

SOLDER

BRIDG)~S

A solder bridge

between

two

adjacent foils is

shown

in photograph

A.

Photograph

B

shows

how

the

con-

nection

should

appear. A solder bridge may occur if

you

accidentally

touch

an

adjacent previously sol-

dered

connection, if

you

use

too

much

solder. or if

you

"drag"

the

soldering iron across

other

foils asyou

remove it from

the

connection. A good

rule

to follow

is; always take a good lookat

the

foil area

around

each

lead before you solder it.

Then.

when

you solder

the

connection, make sure

the

solderremains

in

this

area

and

does not bridge to

another

foil.

This

is especially

important

when

the

foils aresmall

and

closetogether.

NOTE:

It

is alright for solder to bridge

two

connec-

tions on

the

same foil.

Use only

enough

solder to make a good connection.

and

lift

the

soldering iron straight

up

from

the

circuit

board.

If

a solder bridge

should

develop,

turn

the

circuit hoard foil-side-down

and

heat

the

solder be-

tween

connections.

The

excess solder will

run

onto

the

tip of the soldering iron.

and

this will remove

the

solder bridge. NOTE:

The

foil

side

of each circuit

board has a coating

on

it called

"solder

resist."

This

is

a protectiveinsulationtohelp preventsolderbridges.

B

A

SOLDER

BRIDGE

~

~f§f%i§B*fj]

Installtwo 25-pin

plugs

at each

of

the

following locations:

Pl0

..........................

.

P9

..........................

.

) P8.

P7

..........................

.

P6

..........................

.

) P5.

) P4

..........................

.

)

P3.

)

P2.

) P1.

) Visually

check

each

plug

for

solder bridges.

Page

11

PICTORIAL 1-2

Page

12

NOTE: Make

sure

you

have

installed

the

resistor

in

Pictorial 1-1.

( ) R1: 150 .0,

2-watt

[brown-

green-brown). Form

the

resistor

leads as necessary to fit

the

cir-

cuit

board

holes.

NOTE:

When

you install a

diode,

position its

banded

end

as

shown

in

the

Pictorial. A

circuit

will

not

oper-

ate

properly

if

the

diode

is

installed

backward.

~

0

\ I

V

.(

BANDED

END

D3: 1N2071

diode

(#57-27).

D6:

1N2071

diode

(#57-27).

D5: 1N2071

diode

(#57-27).

)

D4:

1N2071

diode

(#57-27).

y.

Solder

the

leads to

the

foil

and

cut

off

the

excess lead lengths.

Y2

%

(INCHES)

I

'(8

I

3;8

111'1"111

I

5i

B

I

i I

7

~8

I

I I I I I I I

0 5 ,

(eM)

2 3 4

2

I

I

5

I i Ii I i

6

PICTORIAL 1-3

3 4

I II i I I

I I I I I I II I

I I

8 9

10

"

'2

CONTINUE

0-

I

NOTE: As you

wire

this kit, you will

be

instructed

to

prepare

lengths

of

wire

ahead

of time, as

in

the

follow-

ing step.

To

prepare

a wire,

cut

it to

the

indicated

length

and

remove

1/4"

of

insulation

from each end.

Then

melt

a

small

amount

of

solder

on

the

bare

wire

ends

to

hold

the

small

strands

of

wire

together.

( )

Prepare

the

following wires:

11" large

red

11"

large black

Install

the

prepared

wires

in

the

fol-

lowing steps.

Solder

each

wire

to

the

foil as you install it

and

cut

off

the

excess wire end.

The

other

end

of

the

wire

will be

connected

later.

11"

red.

11"

black.

5 6

I I I i I I I i I

i i I I II I I I I

'3

'4

'5

'6

17

7

I

NOTE:

When

you

install

an

elec-

trolytic capacitor, always

position

the

plus

(+)

marked

end

of

the

capacitor

toward

the

plus

mark

on

the

circuit

board.

( ) C3:

2200

f.LF

electrolytic

capacitor.

( ) C4:

2200

f.LF

electrolytic

capacitor.

( )

Solder

the

leads

to

the

foil

and

cut

off

the

excess

lead

lengths.

PICTORIAL 1-4

Page

13

CONTINUEQ

( )

Thread

a large cable

tie

through

the

holes in

the

circuit

board

and

around

capacitor C4. Make

sure

the

rough

side

of

the

cable

tie

is

toward

the

capacitors.

Then

pull

the

cable

tie

tight

and

cut

off

the

excess length.

CABLE

TIE

In

the

same

manner,

install a

large cable

tie

around

capacitor

C3.

( ) Use

an

ohmmeter

to

check

for

unwanted

shorts

between

each

adjacent

pin

at

any

of

the

50-pin

plugs

(two

25-pin

plugs).

NOTE:

Pins

0

and

1,

and

pins

48

and

49

are

connected

together;

these

should

show

up

as shorts.

CIRCUIT BOARD CHECKOUT

Carefully

inspect

the

foil

side

of

the

circuit

board

for

the

following most

commonly

made

errors.

Unsoldered

connections.

Poor

solder

connections.

Solder

bridges

between

foil pat-

terns.

( )

Protruding

leads

which

could

touch

together

or

the

chassis

when

the

circuit

board is instal-

led later.

Refer to

the

illustrations

where

the

parts

were

installed

as you

make

the

following

visual

checks.

( ) Electrolytic capacitors for

the

correct position

of

the

positive

(+)

mark.

( ) Diodes for

the

correct orienta-

tion.

Set

the

circuit

board

aside

until

it is

called

for

in

a step.

FINISH

Page

14

CHASSIS

RUBB

ER

FOO

T

8-32

x

ll2

"

SC

RE

W

Detail

2~lA

Refer to Pictorial

2-1

(Illustration Booklet. Page

3)

for

the following steps.

( ) Position the chassis as

shown

in the Pictorial.

NOTE:

When a step calls for hardware.onlythescrew

size is given. For instance, if"6-32 x 3/8" hardware"

is called for, it means you should use a 6-32 x 3/

8"

screw, one or more lockwashers, and a 6-32

nut

at

each mounting hole.

The

detail referred to in the step

shows

the

proper

number

and

placement

of

lockwashers.

( ) Refer to Detail2-1A and

mount

a rubber foot on

the bottom ofthe chassis at AA. Use 8-32 x 1/

2"

hardware_

( ) Similarly. mount rubber feet on

the

bottom of

the chassis at

AB, AC,

and

AD.

Use 8-32 x 1/2"

hardware.

( ) Scrape or sand any excess paint from around

holes

AE

and AF on the

inside

of the chassis.

Detail 2-18

NOTE:

Use the plastic

nut

starter supplied with this

kit to hold and start 4-40

and

6-32 nuts on screws.

( ) Refer to Detail2-1B

and

mount a

#6

solder lug

at

AE.

Use

6-

32 x 1/

4"

hardware and be sure to

position the solder lug as shown in the Picto-

rial.

( ) Similarly, mount a

#6

solder lug at AF with

6-32 x 1/

4"

hardware.

( ) Refer to Detail2-1C and mount thecable clamp

on

the

rear of the chassis at

AG.

Use two 6-32 x

3/8" screws and two

#6

flat washers. Be sureto

position the lip on the clamp as shown.

Slide

the clamp down as far as possible before you

tighten the screws.

Detail 2-1C

6-32x3/S

"

SC

REW

•

•

•

Page

15

f6-32xIl4"

SCREW

~

#6 LOCKWASHER

~

:

CIRCUIT

BOARD

6-32 SELF-

'"

.'

I '" MOUNTING BRACKET

RET~~~IEN~)

NUT~

I

"

r9

~-l

Ii

(21

~,

t

~~LEFT

~~t:'

p SIDE PANEl

//' '

~(B~:~

______________________

~

Detail2-1D

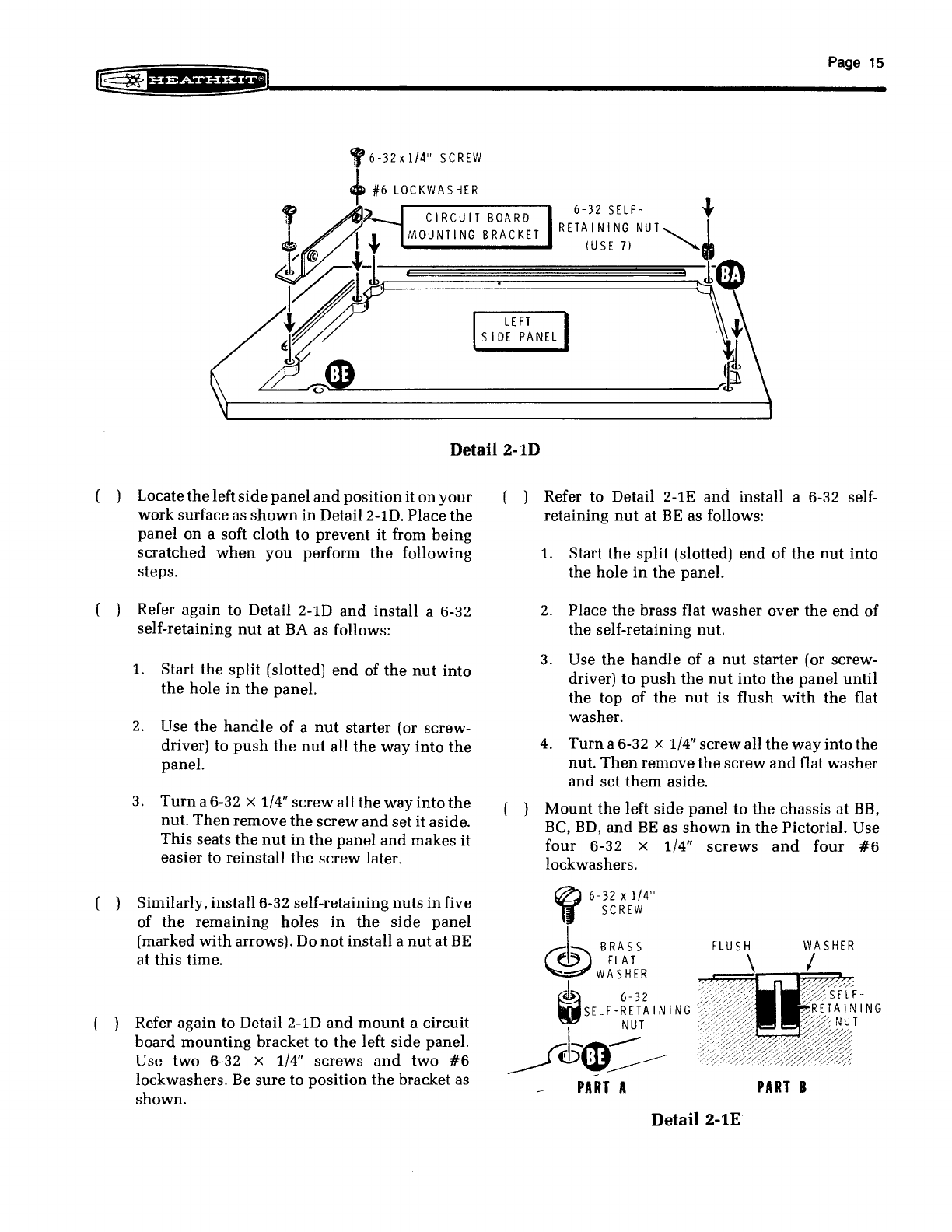

( ) Locate

the

left

side

panel

and

position

it

on

your

work

surface as

shown

in

Detail 2-1D. Place

the

panel

on

a soft

cloth

to

prevent

it from

being

scratched

when

you

perform

the

following

steps.

( ) Refer

again

to Detail 2-1D

and

install a 6-32

self-retaining

nut

at

BA

as

follows:

1.

Start

the

split

(slotted)

end

of

the

nut

into

the

hole

in

the

panel.

2.

Use

the

handle

of a

nut

starter (or screw-

driver) to

push

the

nut

all

the

way

into

the

panel.

3.

Turn

a 6-32 x 1/4"

screw

all

the

way

into

the

nut.

Then

remove

the

screw

and

set

it

aside.

This

seats

the

nut

in

the

panel

and

makes

it

easier to reinstall

the

screw

later.

( ) Similarly, install 6-32 self-retaining

nuts

in

five

of

the

remaining

holes

in

the

side

panel

(marked

with

arrows). Do

not

install

a

nut

at

BE

at

this

time.

( ) Refer

again

to Detail 2-1D

and

mount

a circuit

board

mounting

bracket to

the

left

side

panel.

Use two 6-32 x 1/4"

screws

and

two

#6

lockwashers. Be

sure

to

position

the

bracket as

shown.

( ) Refer to Detail 2-1E

and

install a 6-32 self-

retaining

nut

at

BE

as follows:

1. Start

the

split

(slotted)

end

of

the

nut

into

the

hole

in

the

panel.

2.

Place

the

brass flat

washer

over

the

end

of

the

self-retaining nut.

3.

Use

the

handle

of a

nut

starter (or screw-

driver) to

push

the

nut

into

the

panel

until

the

top

of

the

nut

is flush

with

the

flat

washer.

4.

Turn

a 6-32 x 1/4"

screw

all

the

way

into

the

nut.

Then

remove

the

screw

and

flat

washer

and

set

them

aside.

( )

Mount

the

left

side

panel

to

the

chassis

at

BB,

Be,

BD,

and

BE

as

shown

in

the

Pictorial. Use

four

6-32 x 1/4"

screws

and

four

#6

lockwashers.

~

6-32 x

1/4"

11

SCREW

®

BRASS

~

FLAT

WA

SHER

~')

6-32

gSELF

-RETA

INI

NG

NUT

Jth--OC:--

PART

A

FLUSH

WASHER

PART

B

Detail 2-1E

Page 16

Detail 2-1F

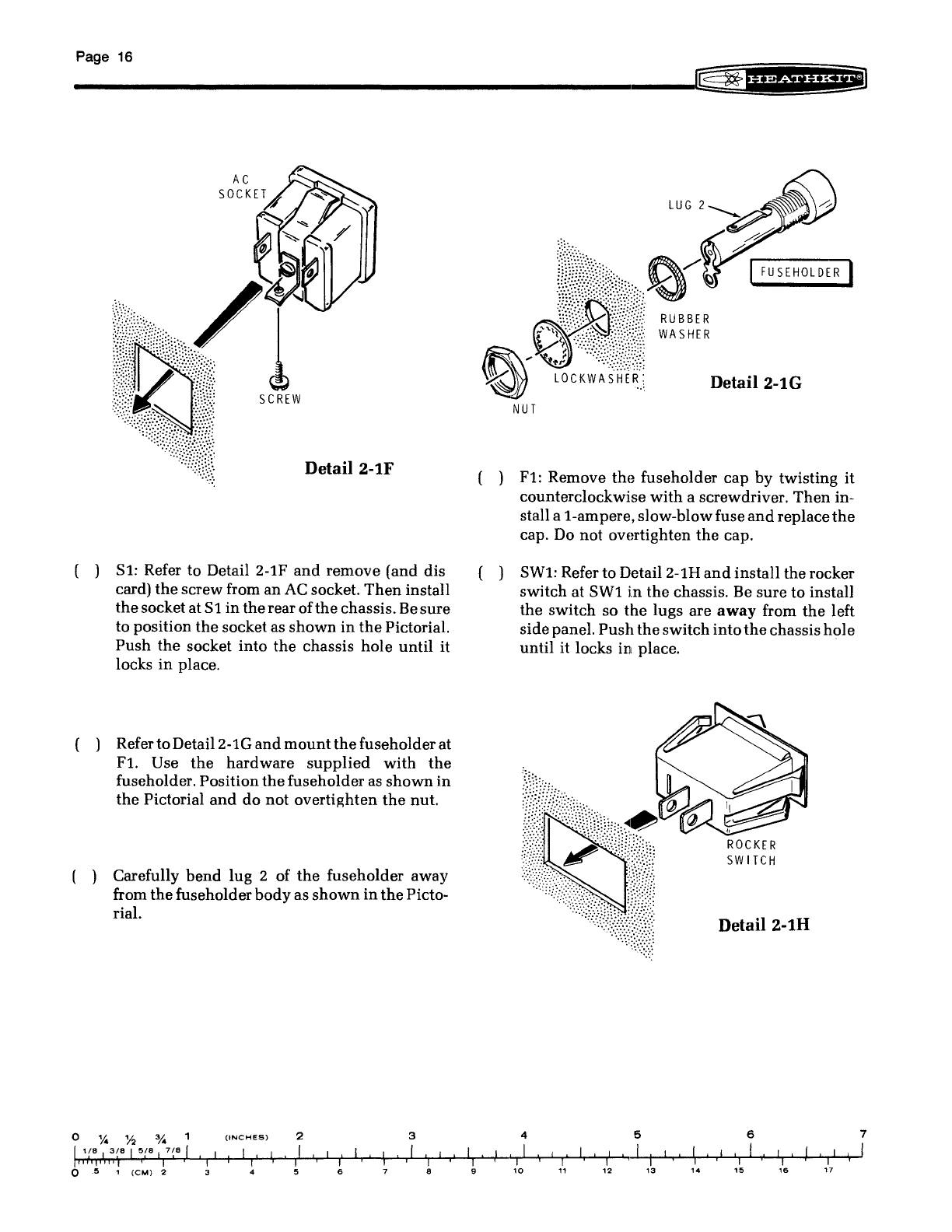

( )

Sl:

Refer to Detail 2-1F

and

remove (and dis

card)

the

screw from an

AC

socket.

Then

install

the

socketatS1

in

the

rear ofthe chassis.

Be

sure

to position

the

socket as

shown

in

the

Pictorial.

Push

the

socket

into

the

chassis hole

until

it

locks

in

place.

( ) RefertoDetail2-1G

and

mount

the

fuseholder at

Flo

Use

the

hardware

supplied

with

the

fuseholder. Position

the

fuseholder as

shown

in

the

Pictorial

and

do

not

overtighten

the

nut.

( ) Carefully bend lug 2 of

the

fuseholder away

from

the

fuseholder

body

as

shown

in

the

Picto-

rial.

o

'l4

'h

3;"

1

(INCHES)

l'

(8

I

3(8

I

5(8

I 7

(8

I

'I

I I I I '

2

I

'I

I ,

, I I I I

"Ii,

II

i

'i

ii'

o 5 1

(CM)

2 3 4 5 6 8 9

FUSEHOLDER

LOCKWASHER:

.,',

Detail2-1G

NUT

( )

Fl:

Remove the fuseholder cap

by

twisting it

counterclockwise

with

a screwdriver,

Then

in-

stall a

i-ampere.

slow-blowfuse

and

replace

the

cap. Do

not

overtighten

the

cap.

( ) SW1: Refer to Detail2-1H

and

install the rocker

switch at

SWl

in

the

chassis. Be sure to install

the switch so

the

lugs are

away

from

the

left

sidepanel.

Push

the

switch

into

the

chassishole

until

it

locks

in

place.

4

I I

,

10

ROCKER

SW

ITCH

Detail 2-1H

5 6

I ' I I I

"I

I

I,

I I I I I I

I I I 1 I ,

11

12

13

14

15

16

I

I'

17

7

I

=:

ill

Detail2-2A

Refer to Pictorial 2-2 (Illustration Booklet,

Page

4)

for

the

following steps.

( ) Refer

to

Detail2-2A

and

prepare

the

line

cord

as

follows:

1.

Remove

the

outer

insulation

of

the

line

cord

for

2".

2.

Twist

together

the

fine

wire

strands

at

the

end

of

each

lead.

Then

melt

a

small

amount

of

solder

to

the

end

of each

lead

to

hold

the

strands

together.

NOTES:

1.

When

you

are

directed

to

"make

a

mechanically

secure

connection,"

as

in

the

following steps,

refer

to

the

inset

drawing

on

the

Pictorial.

2. In

the

following steps, (NS)

means

not

to

solder

because

other

wires

will

be

added

later.

"S-"

with

a

number

following it,

such

as (S-3),

means

to

solder

the

connection.

The

number

following

the

"S-"

tells

you

how

many

wires are at

the

connection.

( ) Route

the

end

ofthe

line

cord

through

hole

AJ

in

the

chassis.

Then

connect

the

green

line

cord

lead

to solder

lug

AE (S-l). Make a

mechani-

cally

secure

connection.

( )

Connectthe

black

line

cord

lead

toAC

socket

Sl

lug 1 (NS).

Make

a

mechanically

secure

connec-

tion.

PLACE

THE

LI

NE

CORD

IN

THE

SLOT.

SQUEEZE

THE

TWO

SEGMENTS

TOGETHER.

Detail 2-2B

Page

17

INSERT

THE

REAR

HALF

I

NTO

THE

HOLE.

( )

Connect

the

white

line

cord

lead

to

AC socket

Sllug

2 (NS). Make a

mechanically

secure

con-

nection.

( ) Install

the

strain

relief

on

the

line

cord

at

AJ

as

shown

in

Detail 2-2B.

( )

Cl:

Cut

both

leads

of a .001

/-tF

(1000 pF)

ceramic

capacitor to 1/2".

Then

connect

the

capacitor

between

AC socket

Sllugs

1 (NS)

and

2 (NS). Make

mechanically

secure

connections.

NOTE:

When

wiring

this

kit,

you

will

be

directed

to

prepare

the

wires

ahead

of time, as

in

the

following

step. To

prepare

a wire,

cut

it

to

the

indicated

length

and

remove

1/4" of

insulation

from each

end.

Then

melt

a

small

amount

of

solder

on

the

bare

wire

ends

to

hold

the

fine

wire

strands

together,

if

not

already

done.

The

wires are

listed

in

the

order

in

which

you

will

use

them.

( )

Prepare

the

following

medium

black

wires:

2-1/2"

1-3/4"

1-1/2"

NOTE:

Make mechanically secure connections

when you connect the prepared wires

in

the

next three steps.

l )

Connect

the

2-1/2"

wire

from

solder

lug AF (S-l)

to

AC socket

Sl

lug

3 (S-l).

( )

Connect

the

1-3/4"

wire

from AC socket

Sllug

1

(S-3) to

fuseholder

Fl

lug

1 (S-l).

( )

Connect

the

1-1/2"

wire

from

fuseholder

Fllug

2 (S-l)

to

switch

SWl

lug

1 (S-l).

Page 18

Refer to Pictorial 2-3 for

the

following steps.

( ) SW2: Locate

the

120/240

slide

switch

(#60-54)

and

position

it

as

shown

in

the

Pictorial. (Note

the

position

of

the

bare

jumper

wire

connected

between

lugs 5

and

6

on

the

switch.)

( )

Prepare

the

following

medium

black

wires:

One

5/1

One

4/1

Two

1-1/2"

NOTE:

Make

mechanically

secure

connections

when

you

connect

the

wires

to

the

switches

in

the

following

steps.

( ) Connect

one

end

of

the

5/1

black wire

to

switch

SW2 lug 1 (NS).

The

other

end

will

be

con-

nected

later.

( )

Connect

one

end

of

the

4"

black

wire

to

switch

SW2

lug

2 (NS).

The

other

end

will

be

con-

nected

later.

( ) Connect

one

end

ofa

1-1/2/1

wire to

switch

SW2

lug 3 (S-l).

The

other

end

will

be

connected

later.

( ) Connect

one

end

of

the

other

1-1/2/1

wire

to

switch

SW2 lug 4 (S-l).

The

other

end

will

be

connected

later.

( ) Locate

the

power

transformer.

Then

slide

a rub-

ber

grommet over

the

black, black-red, black-

green, black-yellow, black-white,

and

black-

gray transformer leads.

( )

Connect

the

black transformer

lead

to

switch

SW2 lug 1

(S-2:).

( )

Connect

the

black-red transformer lead to

switch

SW2 lug 2 (S-2).

( ) SW3: Locate

the

NOR/LOW

slide

switch

(#60-

608)

and

position

it

near

slide

switch

SW2 as

shown.

Refer to

the

printing

on

the

front of

the

switch

and

the

inset

drawing

on

the

Pictorial to

properly

orient

the

switch.

( ) Connect

the

black-white

transformer

lead

to

switch

SW3 lug 5 (S-l).

( ) Connect

the

black-gray transformer lead to

switch

SW3 lug 6 (S-l).

( ) Connect

the

free

end

of

the

black

wire

coming

from

switch

SW2

lug

3

to

switch

SW3

lug

3

(S-l).

( ) Connect

the

free

end

of

the

black

wire

coming

from

switch

SW2 lug 4 to

switch

SW3 lug 4

(S-l).

( )

Connect

the

black-green transformer

lead

to

switch

SW3 lug 1 (S-l).

( )

Connect

the

black-yellow transformer

lead

to

switch

SW3 lug 2 (S-l).

POW

ER

TRANSFORMER

PICTORIAL 2-3

INS:f\

I~B

(})

Page

19

Page 20

___________________________________________________________________

~

~fif&6Siifii*~

6-32 5

PEED

NUT

IACSHIELDI

Detail

2-4A

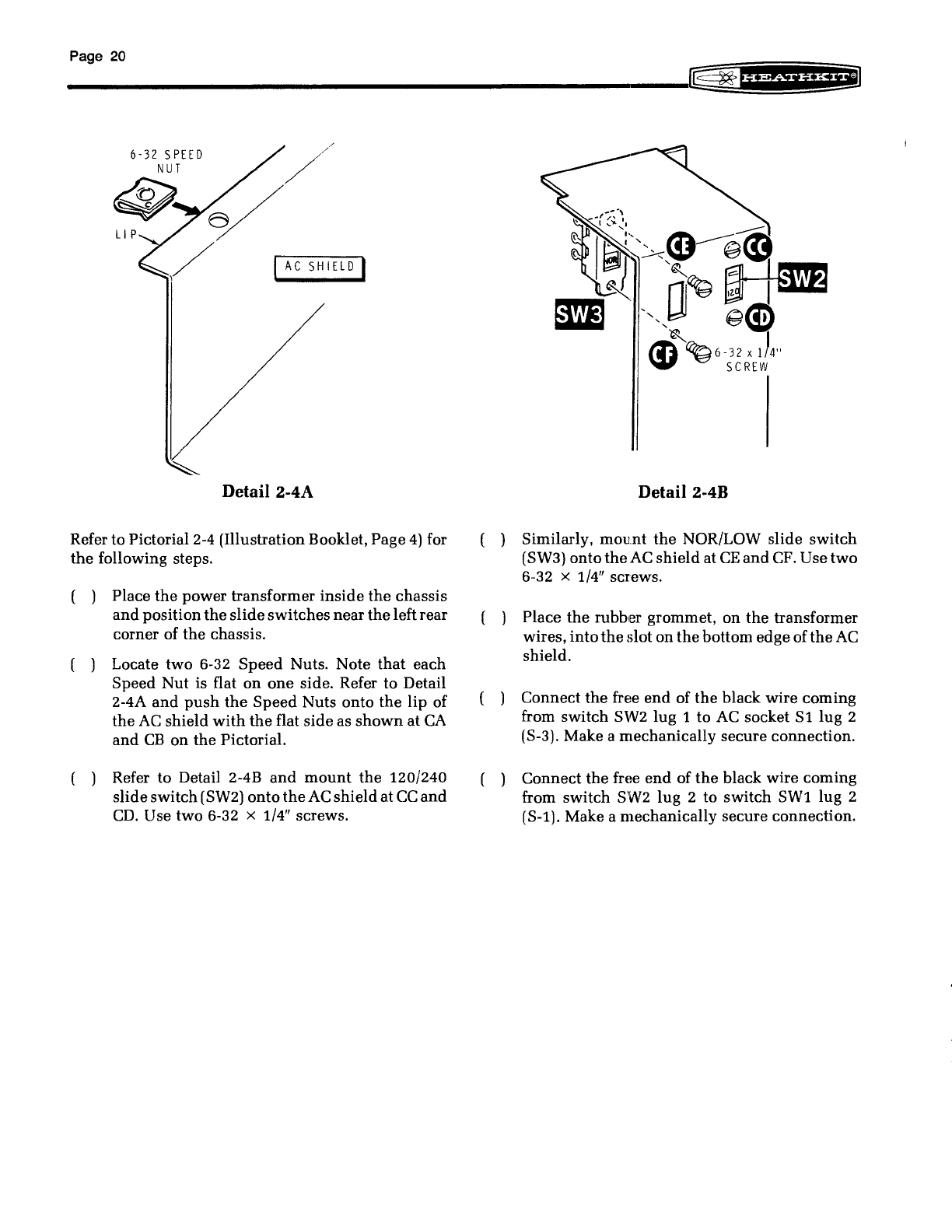

Refer to Pictorial

2-4

(Illustration Booklet, Page

4)

for

the

following steps.

( ) Place

the

power transformer

inside

the

chassis

and

position

the

slideswitches near

the

leftrear

corner of the chassis.

( ) Locate two 6-32 Speed Nuts. Note

that

each

Speed Nut is flat

on

one

side. Refer to Detail

2-4A

and

push

the

Speed

Nuts onto

the

lip of

the

AC

shield

with

the

flat side as

shown

at

CA

and

CB

on

the

Pictorial.

( ) Refer to Detail 2-4B

and

mount

the

120/240

slideswitch(SW2) onto

the

AC

shieldat

CC

and

CD.

Use two 6-32 x 1/4" screws.

Detail2-4B

( ) Similarly,

mount

the

NOR/LOW slide switch

(SW3) onto

the

AC

shield

at

CE

and

CF.

Use two

6-32 x 1/4" screws.

( ) Place

the

rubber grommet, on

the

transformer

wires,

into

the

slot on thebottom edge of

the

AC

shield.

( ) Connect

the

free

end

of

the

black wire coming

from switch SW2 lug 1 to

AC

socket

Sl

lug 2

(S-3). Make a mechanically secure connection.

( ) Connect

the

free

end

of

the

black wire coming

from switch SW2 lug 2 to switch

SW1

lug 2

(S-l). Make a mechanically secure connection.

Table of contents

Other Heath Company Desktop manuals