HeatPumps4Pools ThermoTec LCSPI-95BP Specification sheet

Swimming Pool Heat Pump

-Operation and Installation Manual -

Model:LCSPI-95BP,LCSPI-135BP,LCSPI-180BP,

LCSPI-220BP, LCSPI-280BP

TABLE OF CONTENT

INTRODUCTION…………...………………………………………………………………………………………………..... 2

This manual……………………………………………………………………………………………………………………...2

The Heat Pump………………………………………………………………………………………………………............... 2

SAFETY INSTRUCTIONS ……………………………………………………………………………………………………. 3

Warning ……………………………………………………………………………………………………………………….……. 3

Caution………………………………………………………………………………………………………………………………. 4

CONTENTS……………….…………………………………………………………………………………………….………... 4

OVERVIEW OF THE UNIT ……………………………………………………………………………………….…………. 5

EXPLODED VIEW ……… ……………………………………………………………………………………….………………6

INSTALLATION …………………………………………………………………………………………….…..….…….…….. 7

Installation guidelines …………………………………………………………………………………………….…..………. 7

Locating your Unit….……………………………………………………………………………….…………………………... 7

Water connection …………………………………………………………………………………..…………….…………….. 7

Electrical connection ……………………..……………………………………………………………………….….………… 8

Trial running …………………………………………………………………………………………….……..………………….. 8

OPERATING THE UNIT …………………………………………………………………………………………….…………. 9

Features and functions …………………………………………………………………………………………….…………… 9

User interface ……………………………………..………………………………………………………………………………. 9

Buttons …………………………………………………………………………………………….……………………….……. 10

PARAMETER CHECKING AND ADJUSTMENT…………………………………….……………….………………. 11

Parameter query table……………………………………………………………………………….………………………… 11

Parameter settings…………………………………………………………………………………….………………………… 11

SYSTEM PROTECTIONS/ERROR CODES……………………………….……………………………………………… 12

MAINTENANCE …………………………………………………………………….…………………………………………. 13

TROUBLESHOOTING …………………………………………………………….………………………………………….. 14

ENVIRONMENTAL INFORMATION ……………………………………….………………………………………….. 14

DISPOSAL REQUIREMENTS …………………………………………………………….………………………………… 15

WIRING DIAGRAM …………………………………………………………….………………………………………….….. 16

INVERTER SWIMMING POOL HEAT PUMP TECHNICAL SPECIFICATION…………………………… 17

READ THIS MANUAL CAREFULLY BEFORE OPERATING THE UNIT. DO NOT THROW IT AWAY.

RETAIN FOR FUTURE REFERENCE.

BEFORE OPERATING THE UNIT, ENSURE THE INSTALLATION HAS BEEN CARRIED OUT IN

ACCORDANCE WITH THESE INSTRUCTIONS. IF IN DOUBT CONSULT YOUR LOCAL DEALER.

1

INTRODUCTION

This manual

This manual includes the necessary information to safely install and maintain your Heat Pump. Please

read this manual carefully before you operate the unit.

The Heat Pump

The swimming pool heat pump is one of the most economical ways of heating your swimming pool

efficiently. Using the free renewable energy from the air,it is over 4/5 time more efficient than

traditional heating.The swimming pool heat pump extends your swimming season and gives you

comfort at high level.You could enjoy swimming not only in summer,but also in spring,autumn and

even winter time.

ECO Friendly

The Heat Pump uses R410A Refrigerant which is ozone friendly dramatically reducing Carbon

Emissions.

Titanium heat exchanger

The advanced titanium heat exchanger guarantees a longer life span, free of corrosion. It can be

used with all types of water treatment including chlorine, iodine, bromine and salt water.

Multiple functions

- Cooling and heating functions available

- Auto operation, Auto-restart, Auto defrost

- Auto timer on/off:no human attendance is required

- Wide ambient working range: -10°C to 43°C

Reliable operation

The Heat Pump has several built in safety features, which include insufficient water flow protection,

high/low pressure protection, overload protection, compressor protection.

Self-diagnosis

When there is malfunction,the swimming pool heat pump will make self-diagnosis by displaying

error code on the control panel.To identify the problem,please refer to ERROR CODES pages in this

manual.

2

SAFETY INSTRUCTIONS

To prevent injury to the user, other people or damage to property, the following instructions must be

followed.

Install the unit only when it complies with local regulations, by-laws and standards. Check the main

voltage and frequency. This unit must be earthed and have a supply voltage of 220 – 240 V ~ / 50Hz.

The following safety precautions should always be taken into account:

-Be sure to read the following WARNING before installing the unit.

-After reading these instructions retain for future reference.

Installing the Unit.

Incorrect installation could cause injury due to fire, electric shock or water damage. If in doubt consult

your local dealer or a qualified installer.

Securing the Unit.

The unit should be located on a solid, level, horizontal surface and securely fixed. Ensure free air-flow to

all sides of the unit.

Electrical Connections.

Ensure the correct sized Circuit Breakers, isolators and cables are used.All terminals should be tightly

secured and not prone to stress.

This unit must be earthed.

Materials.

To prevent fire, electric shock and other hazards all materials should be suitable for the specific use of

this unit.

Never use an extension cable to connect the unit to the electric power supply.

If there is no suitable earthed supply available, have one installed by a qualified electrician.

Do not move/repair the unit yourself.

Before carrying out any maintenance, service or repair work, the product must be isolated from the

mains electrical supply. To prevent possible injury, only qualified engineers should carry out these

works.

Do not install the unit in a place where there is a chance of flammable gas leaks.

If there is a gas leak and gas accumulates in the area surrounding the unit, it could cause an explosion.

3

Water Connections.

All plumbing connections should be carried out as per the instructions in this manual. Failure to do so

could result in water damage to property.

Cleaning the Unit.

To prevent injury always shut the power ‘OFF’ when cleaning or servicing the unit.

Error Codes.

If an error code occurs or you can smell burning, isolate the unit immediately and call your local installer.

Avoid contact with the fan when running as this will cause serious injury.

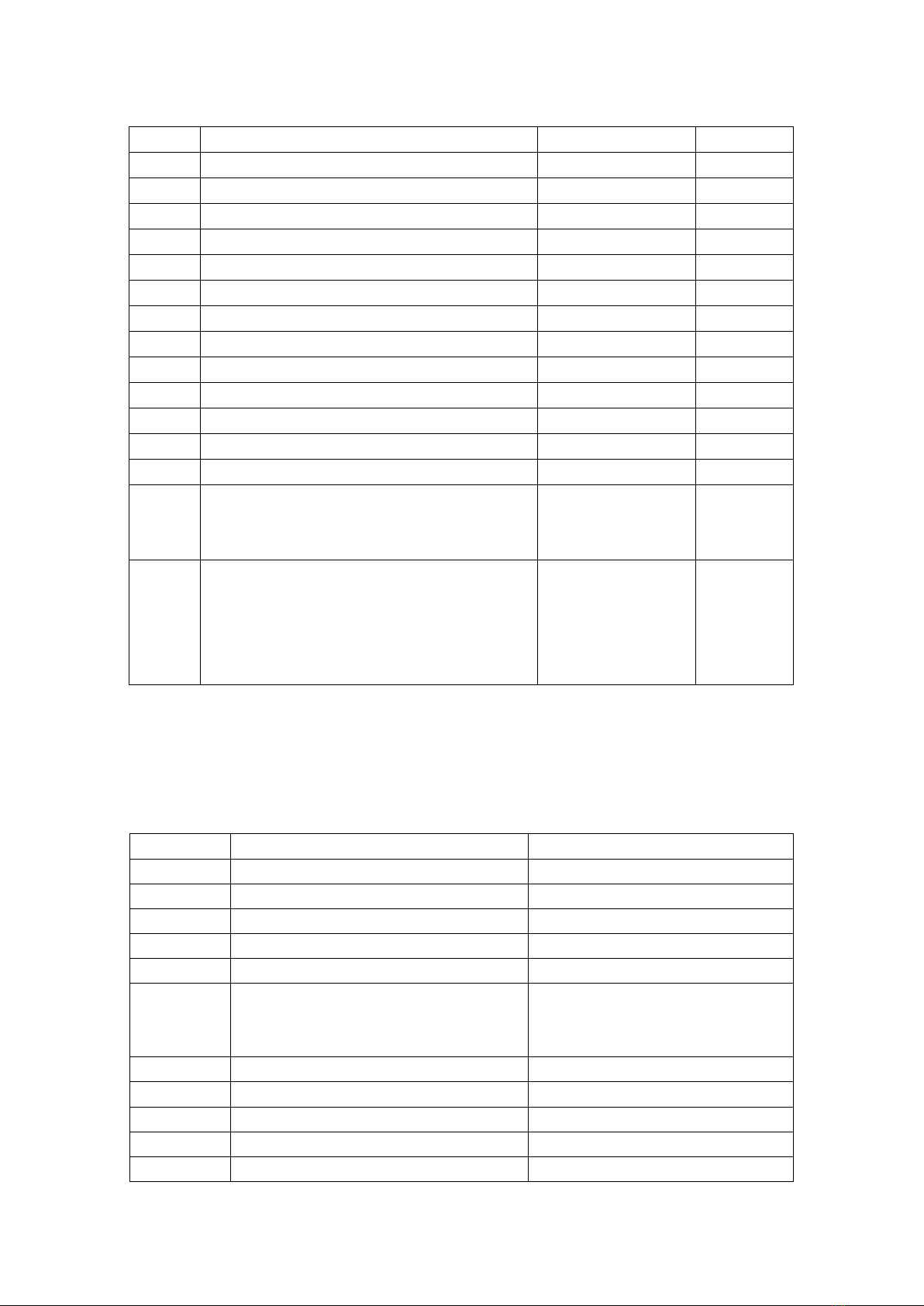

CONTENTS

Before starting the installation, please make sure that all items are found inside the box.

The Unit Box

Item Image QTY Item Image QTY

Swimming pool

heat pump 1 Accessories 1(Set)

Operation and

Installation

Manual

1

4

OVERVIEW OF THE UNIT

5

EXPLODED VIEW

6

INSTALLATION

Installation guidelines

The following information is for guidance only.

Locating the Unit

The unit should be located on a solid, flat, horizontal surface. Ensure 3 metres of free air flow to the

discharge panel and 1 metre to the inlet panel. Ensure adequate access to the controller and for

maintenance purposes.

Precautions

--Avoid locating the unit close to bedrooms or other noise sensitive areas.

--Avoid a location which could create vibration i.e. secured to a solid wall.

--Try to avoid placing the unit under a tree or exposed to extreme conditions.

Water connection

The heat pump is connected to a filtration circuit with a by-pass.

It is imperative that the by-pass is placed after the pump and the filter.

The by-pass generally consists of 3 valves.

This makes it possible to regulate the water flow which passes through the heat pump and to isolate the

heat pump completely for any maintenance work, without cutting the flow of filtered water.

If your installation is equipped with a water treatment system (chlorine, bromine, saltetc) the by-pass must

be installed before the water treatment, with a non-return valve between the by-pass and water treatment

system.

7

Electrical connection

The Electrical supply must correspond to that indicated on the appliance.

All supply cables have to be sized according to the appliance power and installation requirements.

Please refer to below table:

The above are an indication only.Please refer to a qualified Electrician if in doubt.

Use the cable glands and grommets provided inside the heat pump to secure and route the supply cables.

Trial Running

After connecting the unit to the pool system, ensure your installation is complete, with a suitable by-pass

and electrical connections by a qualified engineer.

Be sure that:

1) Appliance is horizontal and on a firm base.

2) Water system has no leaks.

3) Electrical Installation is compliant with all local regulations and standards.

4) The installation requirements described previously have been strictly adhered to.

ATTENTION: THE HEAT PUMP ONLY OPERATES WHEN WATER FLOW IS PRESENT.

You can start up the heat pump following the procedure below:

-Open by-pass valves

-Start pool system pump

-Turn on pool heat pump

-Set controller

8

Features and functions

Basic controller functions

The basic controller functions are:

Turning the heat pump ‘ON’/’OFF’.

24 hour time clock.

Timer ‘ON’ and timer ‘OFF’.

Parameter adjustment

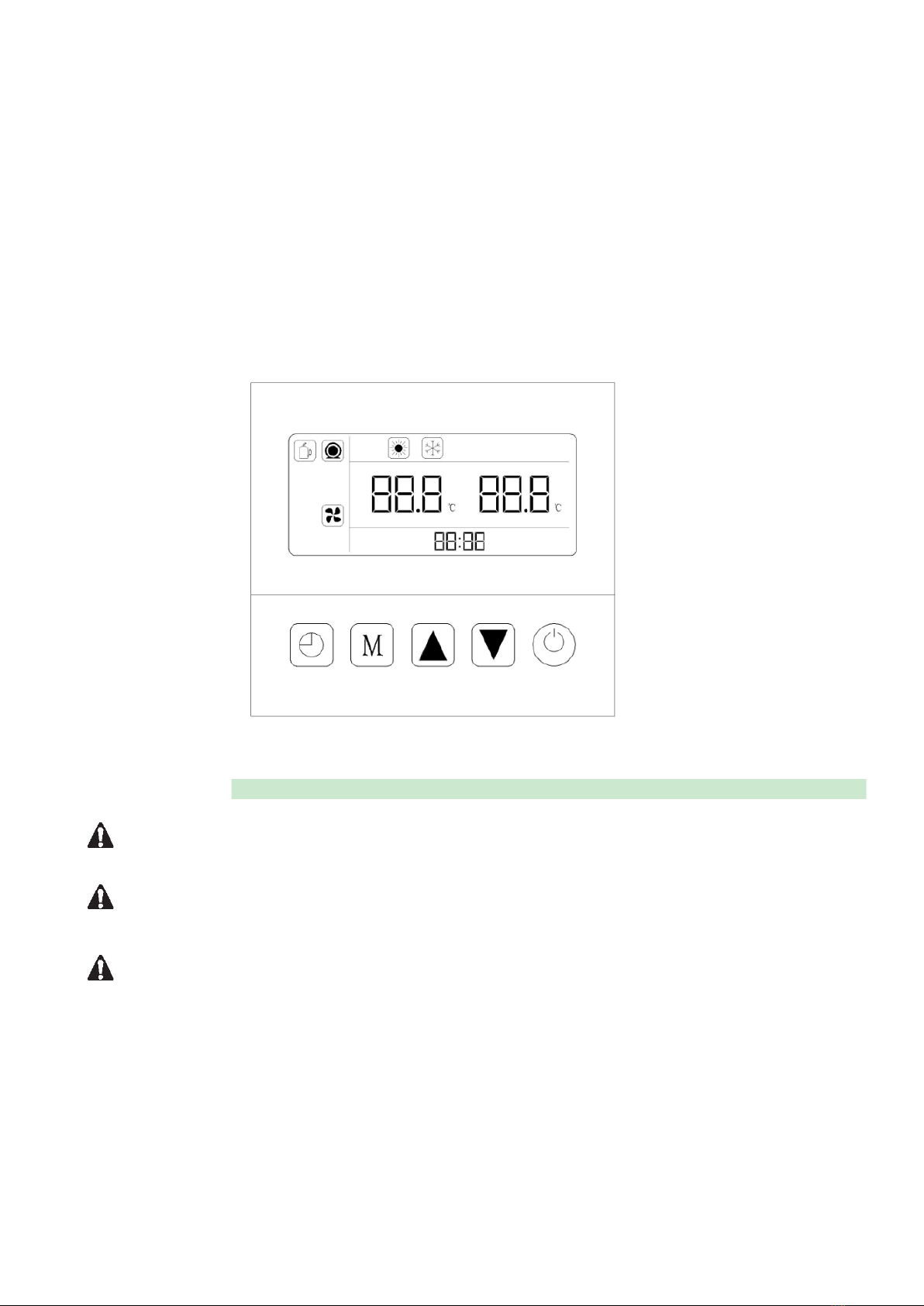

User interface

NEVER LET THE DIGITAL CONTROLLER GET WET. THIS MAY CAUSE AN ELECTRIC SHOCK OR FIRE.

NEVER PRESS THE BUTTONS OF THE DIGITAL CONTROLLER WITH A HARD, POINTED OBJECT.

THIS MAY DAMAGE THE DIGITAL CONTROLLER.

NEVER INSPECT OR SERVICE THE DIGITAL CONTROLLER YOURSELF. REFER TO A QUALIFIED SERVICE

ENGINEER.

9

Buttons

Unit ON/OFF button

Press this button for 3 second to switch unit ON/OFF.

Mode button

Under main operation interface when unit ON,press this button for 3 seconds to switch

heating or cooling modes.

and adjustment buttons

On main operation interface under heating mode,press and buttons to

set target outlet hot water temperature.

On main operation interface under cooling mode,press and buttons to

set target outlet cooling water temperature.

Clock/Timer button

Clock settings:Press for 3 seconds entering into clock flashing status,then press

entering into Clock Setting status:Firstly Hour-digit flashes,press and

to adjust number,press or each time will make number up or

down by one time,if press or for long time,Hour-digit will automatically

up or down.After finishing setting Hour-digit,press entering into Minute-digit

settings,which is same as Hour-digit settings.After Minute-digit settings finished,press

to exit.

Timer settings:Press entering into Timer selection,”Timer 1” will firstly

display,press or to choose different Timers.Then press again to

enter into“Timer1“ settings,press or to adjust target time,other Timers

settings are in same way.

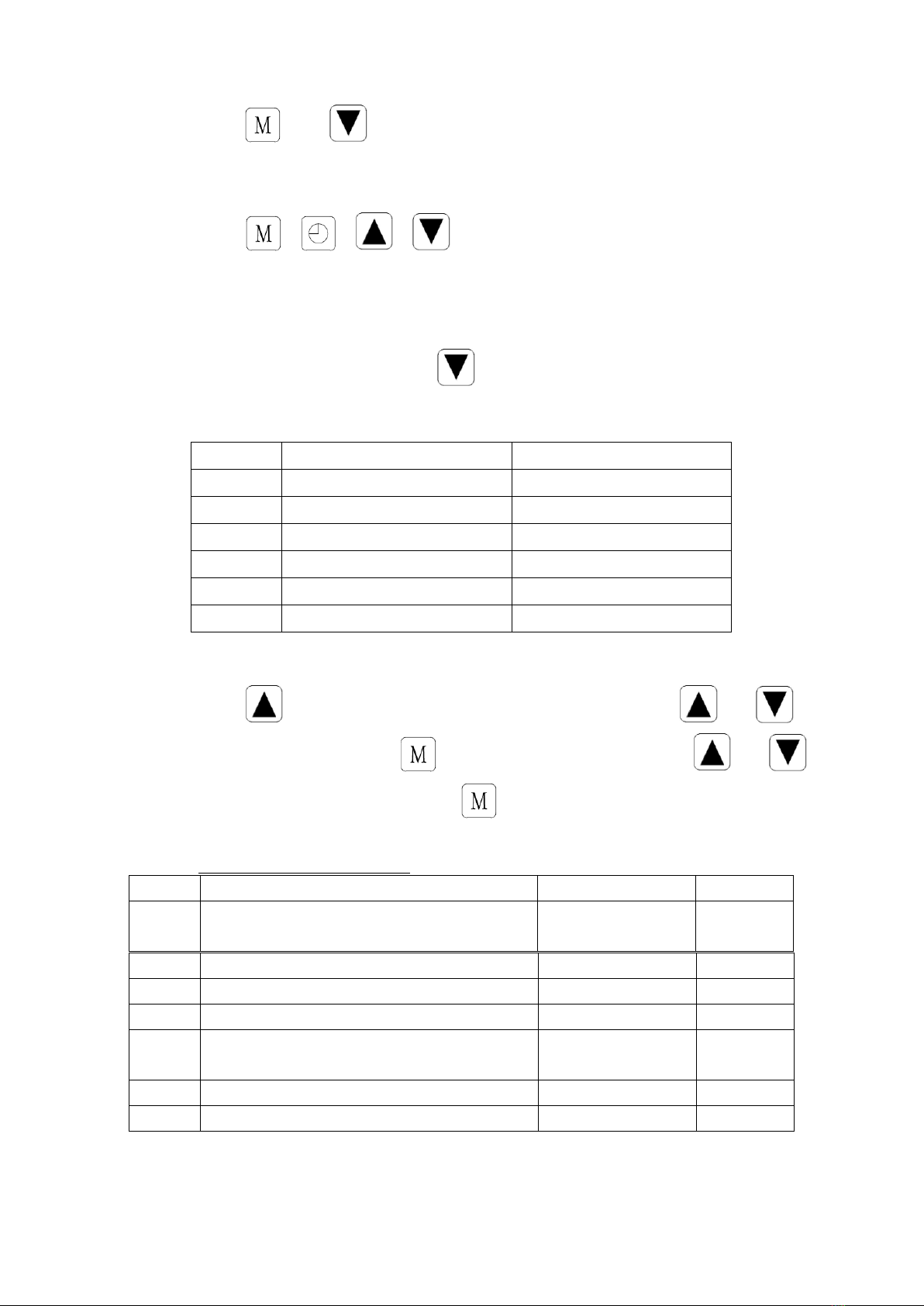

Mandatory defrost

10

Press and for 3 seconds entering into mandatory defrost mode.

Factory reset

Press + + + for 3 seconds entering into factory reset.

PARAMETER CHECKING AND ADJUSTMENT

Unit running status query

On main operation interface,press for 3 seconds to check temperatures,see the

following table:

Code

Temperature Name

Display Range

01

Inlet water temp

-20~99℃

02

Outlet water temp

-20~99℃

03

Ambient temp

-20~99℃

04

Exhaust gas temp

0~125℃

05

Return gas temp

-20~99℃

06

Coil temp

-20~99℃

System parameter query and settings

Press for 3 seconds entering into parameter query status,press or to

check parameters,then press to modify parameters by using with or ,

after modifications completed,press to confirm and exit.

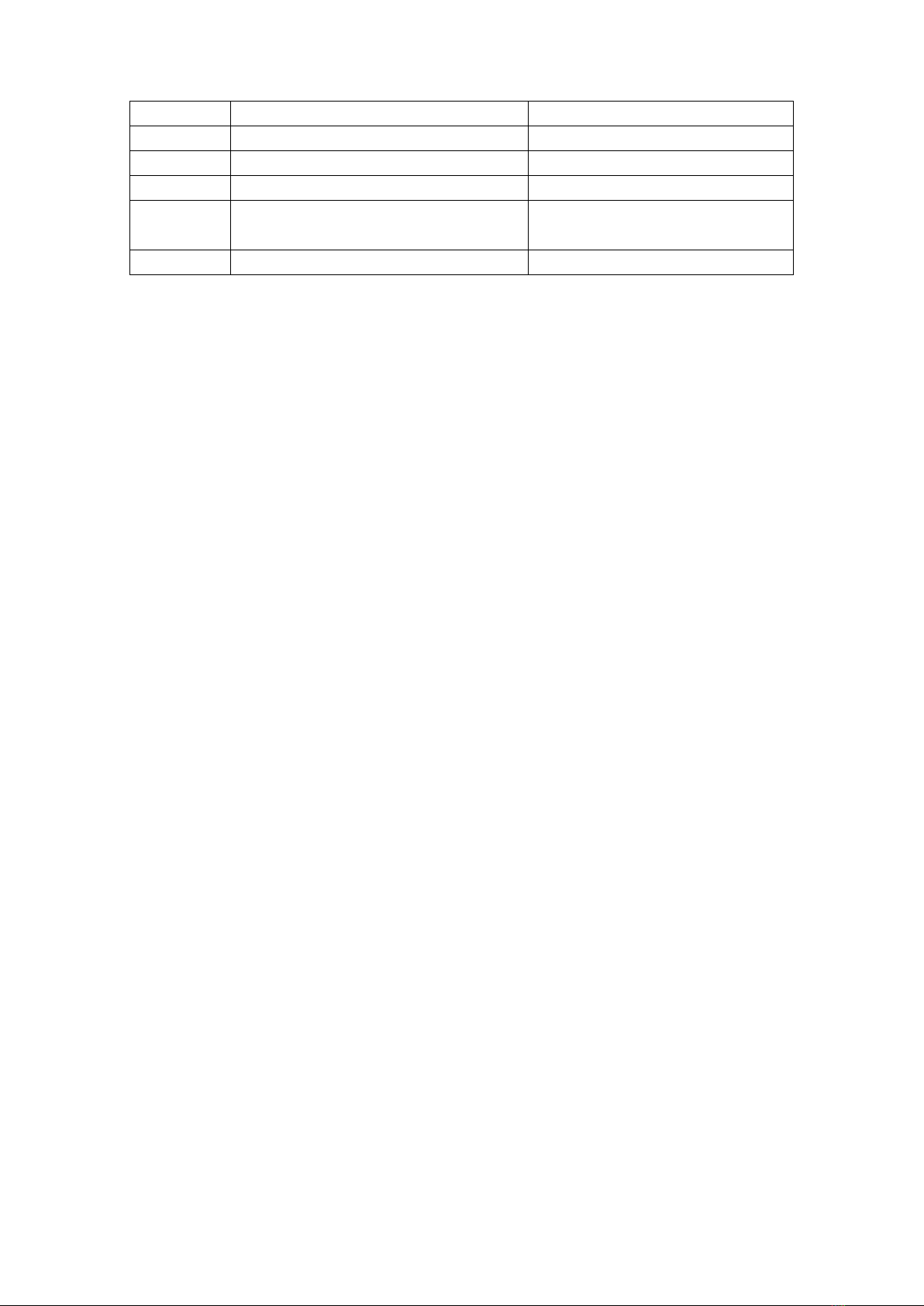

SYSTEM PARAMETER TABLE

Code

Parameter Name

Adjustment Range

Default

P01 Target/inlet water temp difference

to start compressor

2℃~18℃2℃

P04 Target cooling water temp 7℃~30℃12℃

P05 Target hot water temp 15℃~50℃35℃

P06 Exhaust gas overheat protection gas temp 80℃~125℃120℃

P07 Exhaust gas overheat protection exit

gas temp 50℃~100℃95℃

P08 Compressor current protection 2A~50A 20A

P09 Inlet water temp compensation -5℃~15℃0℃

11

P11

Defrost cycle

20MIN~90MIN

45MIN

P12

Defrost entry coil temp

-15

℃

~-1

℃

-3

℃

P13

Defrost duration time

5MIN~20MIN

10MIN

P14

Defrost exit coil temp

1

℃

~40

℃

20

℃

P15

Ambient/coil temp difference for defrost entry

0

℃

~15

℃

5

℃

P16

Ambient temp for defrost entry

0

℃

~20

℃

17

℃

P17

EEV action cycle

20S~90S

30S

P18

Heating EEV action factor

-5

℃

~10

℃

3

℃

P19

Exhaust gas temp to trigger EEV adjustment

70

℃

~125

℃

95

℃

P20

Defrost EEV open angle

20~450

400

P21

EEV min. open angle

50~150

80

P22

EEV mode option

0:manual/1:auto

1

P23

EEV manual step

20~450

350

P24

Cooling EEV action factor

-5

℃

~10

℃

3

℃

P27 Cooling EEV working mode 0=Ambient temp;

1=Cooling EEV

action factor

0=Ambient

temp

P28 Water pump working option 0=Stop when target

water temp reached

/1=NOT stop when

target water temp

reached

0=Stop

when

target

wate temp

reached

SYSTEM PROTECTIONS/ERROR CODES

When an error occurs or the protection mode is set automatically,the wired controller will display an

error code as below.

Error code

Error Name

Remark

Er 03

Water flow failure

Er 04

Winter anti-freeze protection

Er 05

High pressure failure

Er 06 Low pressure failure

Er 09 Communication failure

Er 10

Inverter module communication

failure(Communication failure

btw. PCB and inverter module)

Er 12

Exhaust gas over-heat protection

Er 15

Inlet water temp sensor failure

Er 16

Coil temp sensor failure

Er 18

Exhaust gas temp sensor failure

Er 20

Inverter module abnormal run protection

12

Er 21

Ambient temp sensor failure

Er 23

Outlet cooling water over-cold protection

Er 27 Outlet water temp sensor failure

Er 29 Return gas temp sensor failure

Er 32 Outlet hot water over-heat

protection

Er 35 Compressor current protection

MAINTENANCE

To protect the paintwork, avoid leaning or putting objects on the shell. External Heat Pump parts can be

wiped with a damp cloth and domestic cleaner. (Warning: Never use cleaning agents containing sand,

soda, acid or chloride as these can damage the surfaces.)

To prevent blockages in the titanium heat exchanger, ensure that the system incorporates a water and

filter treatment facility. In the event of a problem occurring due to contamination, the system should be

cleaned as described below. (Warning: the fins on the finned tube heat exchanger are sharp!).

Cleaning the Heat Exchanger and Pipework

Contamination in the pipes and heat exchanger can reduce the performance of the heat pumps’

titanium heat exchanger. If this is the case, the pipe system and heat exchanger must be cleaned by a

technician.

Use only pressurized drinking water for cleaning.

Cleaning the air system

The finned heat exchanger, fan and condensate outflow should be clear of all obstructions (leaves,

twigs, etc.) before each new heating season. These can be manually removed using compressed air or

by flushing with clean water.

It may be necessary to remove the unit cover and air inlet grid first.

Attention: Before opening the unit, ensure that all electrical supplies are isolated.

To prevent the evaporator and the condensate tray from being damaged, do not use hard or sharp

objects for cleaning.

Under extreme weather conditions (e.g. snow drifts), ice may form on the air intake and exhaust air

outlet grids. If this happens, the ice must be removed in the vicinity of the air intake and exhaust air

outlet grids to ensure that the minimum air flow rate is maintained.

Winter Shutdown.

To prevent frost damage to the unit when not in use the Heat Pump should be drained of all water.

Failing this another form of frost protection should be considered and actioned.

Attention: The warranty does not cover damage caused by inadequate frost protection measures

during the winter.

13

TROUBLESHOOTING

This section provides useful information for diagnosing and correcting certain prolems which may occur.

Before starting the troubleshooting procedure, carry out a thorough visual inspection of the unit and

look for obvious defects such as loose connections or defective wiring.

Before contacting your local dealer, read this chapter carefully.It could save you time and money.

WHEN CARRYING OUT ANY MAINTENANCE ENSURE ADEQUATE PRECAUTIONS ARE TAKEN TO

PREVENT AN ELECTRIC SHOCK .

The hints below are for guidance only. If you cannot solve the problem, consult your installer/local

dealer.

The Heat pump will not run.

Please check:

There is a supply voltage (tripped fuse, power failure).

The switch on the wired controller is switched on, and whether the correct set point temperature

has been set.

The set temperature level cannot be reached.

Please check whether:

The permissible operating conditions for the heat pump have been adhered to (air temperatures

too high or too low).

The air inlet or outlet area is blocked, restricted or very dirty.

There are closed valves or stop-cocks in the water pipes.

The timer works but the programmed actions are executed at the wrong time (e.g. 1 hour too late or

too early).

Please check whether:

The clock and the day of the week are set correctly, adjust if necessary.

If you cannot correct the fault yourself, please contact your after-sales service technician.

Work on the heat pump may only be carried out by authorized and qualified after-sales service

technicians.

ENVIRONMENTAL INFORMATION

This equipment contains fluorinated greenhouse gases covered by the Kyoto Protocol. It should only be

serviced or dismantled by professional trained engineers.

This equipment contains R410A refrigerant in the amount as stated in the specification. Do not vent

R410A into the atmosphere: R410A, is a fluorinated greenhouse gas with a Global Warming Potential

(GWP) = 1975.

14

DISPOSAL REQUIREMENTS

Dismantling of the unit, treatment of the refrigerant, of oil and of other parts must be carried out in

accordance with relevant local and national legislation.

Your product is marked with this symbol. This means that electrical and electronic products

should not be mixed with unsorted household waste.

Do not try to dismantle the system yourself: the dismantling of the system, treatment of the refrigerant,

of oil and other parts must be done by a qualified installer in accordance with relevant local and

national legislation.

Units must be treated at a specialized treatment facility for re-use, recycling and recovery. By ensuring

that this product is disposed of correctly, you will help to prevent potential negative consequences for

the environment and human health. Please contact the installer or local authority for more information.

15

WIRING DIAGRAM

Please refer to the wiring diagram on the electric box.

16

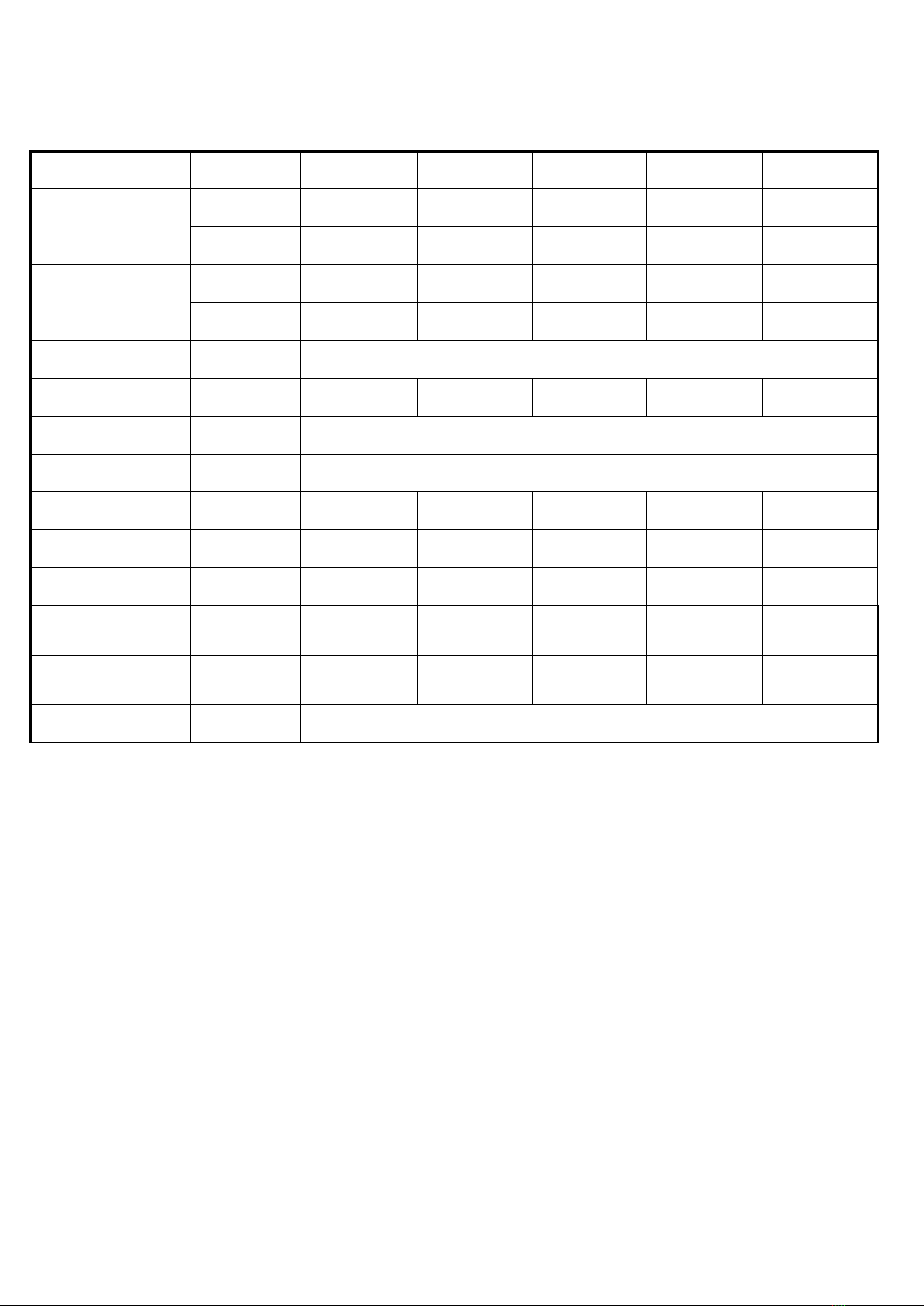

LCSPI-135/180/220BP

Inverter Swimming Pool Heat Pump Technical Specification

Model LCSPI-95BP LCSPI-135BP LCSPI-180BP LCSPI-220BP LCSPI-280BP

Air 27℃,Water

inlet/outlet:26℃

/28℃, Humidity 80%

Capacity(kW) 10.23~2.55 14.11~3.52 19.12~4.78 22.79~5.69 28.68~7.16

COP 16.11~6.14 16.23~6.19 16.18~6.15 16.09~6.12 16.07~6.11

Air 15℃,Water

inlet/outlet:26℃

/28℃, Humidity 70%

Capacity(kW) 8.06~2.01 11.02~2.75 14.11~3.52 17.18~4.29 21.53~5.38

COP 8.16~4.72 8.22~4.75 8.19~4.73 8.11~4.63 8.05~4.61

Power supply 230V/1Ph/50Hz

Rated power input kW 1.71~0.16 2.32~0.21 3.12~0.29 3.72~0.35 4.71~0.45

Evaporator Hydrophilic fin and copper tube

Heat exchanger Titanium in PVC shell

Water flow volume m³/h 3.5 4.8 5.9 7.5 9.6

Package dimensions mm( L*W*H) 662*724*950 662*724*950 757*826*1080 757*826*1080 757*826*1080

Unit net dimensions mm( L*W*H) 650*688*823 650*688*823 745*792*954 745*792*954 745*792*954

Sound pressure at

1m dB(A) 39~48 40~49 43-52 45~54 45~55

Sound pressure at

10m dB(A) 19~28 20~28 23~32 24~34 25~36

Water proof level IPX4

17

This manual suits for next models

4

Table of contents

Other HeatPumps4Pools Heat Pump manuals

Popular Heat Pump manuals by other brands

STIEBEL ELTRON

STIEBEL ELTRON HSBC 200 S Operation and installation

Glen Dimplex

Glen Dimplex LIK 8TES Installation and operating instruction

Riello

Riello A2WHPR32M/004 manual

evoheat

evoheat EVO 270 manual

Regulus

Regulus CSE2 MIX F W 1F Installation and operation manual

Oilon

Oilon S 180 Installation and operation manual

Dimplex

Dimplex LA 11TAS Installation and operating instructions

Daikin

Daikin FTXR28EV1B9 Service manual

Viessmann

Viessmann VITOCAL 300-G Operating and service instructions

GE

GE AUH2436ZGDA installation instructions

Swim & Fun

Swim & Fun Xpress8 1299 Installation and instruction manual

Daikin

Daikin EGSQH10S18AA9W installation manual