Heatrae Sadia Aquatap Assembly Instructions

INSTALLATION & USER INSTRUCTIONS (BOIL)

the nation’s favourite for

PLUMBING & HEATING SUPPLIES

SECURE PAYMENTS

shop online with confidence

FREE SHIPPING

on all orders over £100 to mainland UK

FINANCE AVAILABLE

spread the cost with low interest rates

PRICE MATCH

always get the best deals available

Boilers

Radiators

Heating controls

Cylinders

Fires

Renewable energy

Bathroom suites

Kitchen sinks & taps

Showers

Wet rooms

Towel warmers

Bathroom furniture

& much more

HUGE REDUCTIONS

we have

ON THOUSANDS OF ITEMS

0844 800 3460

CALL US ON

visit our website

plumbnation.co.uk

CONTENTS

SECTION PAGE

1.0 INTRODUCTION 3

2.0 TECHNICAL SPECIFICATION 4

3.0 INSTALLATION - IMPORTANT INSTALLATION POINTS 7

4.0 INSTALLATION - MOUNTING THE WATER HEATING UNIT 8

5.0 INSTALLATION - WATER SUPPLY 9

6.0 INSTALLATION - VENT PIPE 10

7.0 INSTALLATION - DISPENSING TAP MOUNTING 10

8.0 INSTALLATION - DISPENSING TAP CONNECTION 12

9.0 INSTALLATION - ELECTRICAL REQUIREMENTS 14

10.0 COMMISSIONING 14

11.0 USER INSTRUCTIONS 17

12.0 MAINTENANCE 18

13.0 FAULT FINDING 20

14.0 SPARE PARTS 22

GUARANTEE 27

ENVIRONMENTAL INFORMATION 27

15.0 COMMISSIONING RECORD 28

16.0 SERVICE RECORD 29

17.0 SPARES STOCKISTS 32

2

BOILING WATER MODEL

1.0 INTRODUCTION

Thank you for purchasing a Heatrae Sadia AQUATAP unit. This unit is manufactured to the

highest standards and has been designed to meet all the latest relevant constructional and safety

TheAQUATAP unit must be installed (see Sections 3.0, page 7 to 9.0, page 14), commissioned (see

Section 10.0, page 14 ) and maintained (see Section 12.0, page 18) by a competent person. Please

read and understand these instructions prior to installing your AQUATAP unit. Following installation

and commissioning of the unit, the operation of the AQUATAP should be explained and demonstrated

to the user. Instructions for use are explained in Section 11.0, page 17. These instructions should

be left with the user for future reference.

This appliance is not intended for use by persons (including children) with reduced physical, sensory

or mental capabilities, or lack of experience and knowledge, unless they have been given supervision

or instruction concerning the use of the appliance by a person responsible for their safety. Children

should be supervised to ensure that they do not play with the appliance.

IntelliboilTMPlus

It regularly brings the contents of the water container to boil in response to ongoing user demand.

However, when there has been no draw off for a period of one hour, IntelliboilTMPlus steps back the

stored water temperature. This avoids unnecessary boiling - possibly for a number of hours or even

days - until there is renewed user demand. When this occurs, the boiling cycle resumes.

The appliance is intended to be used in commercial applications such as:

COMPONENT CHECKLIST

Before commencing installation please check that all the following components have been supplied

in the packaging:

3

2.0 TECHNICAL SPECIFICATION

AQUATAP HEATER

Model reference 95200261

Electrical rating 2.3kW @ 230 V ~

2.5kW @ 240 V ~

Nominal capacity 5.0 litres

Weight (full) 17.5kg

Rated pressure 0 MPa ( 0 bar )

Minimum supply pressure 0.05 MPa ( 0.5 bar )

Maximum supply pressure 1.0 MPa ( 10 bar )

Enclosure rating IPX2

Nominal commissioning 24

time (minutes) to temperature

ready

FIGURE 1 : AQUATAP HEATER

INLET

MAINS (ELECTRICAL SUPPLY)

TAP ELECTRICAL CONNECTION

VENT

OUTLET

480mm

269mm

150mm 150mm

150mm

Minimum clearance needed around the heater unit

150mm

Minimum clearance needed around the heater unit

350mm

4

HEATING ELEMENT

TRANSFORMER

MAIN PCB

STEAM

CONDENSING TRAP

PUMP

INLET SOLENOID

FIGURE 2: AQUATAP HEATER - IMPORTANT FEATURES

LEVEL SENSOR ASSEMBLY

THERMAL CUT-OUT

DRAIN

5

6

FIGURE 3: AQUATAP WATER HEATER SCHEMATIC

INLETOUTLET VENT

STEAM CONDENSING TRAP

HEATING ELEMENT

HOT WATER STORE

PUMP

OVER

TEMPERATURE

SENSOR

LEVEL

SENSOR

SOLENOID

VALVE

3.0 IMPORTANT INSTALLATION POINTS

Regulations (England and Wales), The Building Regulations (Scotland) or

The Building Regulations (Northern Ireland). In territories other than those listed

the local regulations in force must be complied with.

Ireland) or The Water Byelaws in Scotland.

3.2 The AQUATAP stores and dispenses water at or close to boiling point whilst

switched on. Due caution must be taken when choosing a location for the product to

minimise any possible misuse. The dispenser tap should be located such that it

discharges over a sink or mounted on its own purpose designed drip tray (available as

an accessory, Product Code 95970138).

3.3 The AQUATAP is a vented water heater. The vent pipe must never be blocked,

obstructed or removed. Warning, in the event of a unit malfunction, steam may vent

from the vent pipe for a short period of time (see FIG. 5, page 11 for position of vent

pipe).

3.4 Wherever possible the AQUATAP should be supplied directly from the cold mains

supply. If fed from a cold water feed cistern, the cistern must comply with the

be reduced when supplied from a cistern and additional pre-treatment of the water

NOTE: In order to meet the minimum supply pressure requirements of the

AQUATAP, any cold feed cistern must be a minimum of 5 metres above the unit.

3.5 In hard water areas, heated water will produce limescale which will be deposited in

the heater. If this is not regularly removed it will impair the operation of the AQUATAP

unit. Where rapid and excessive scale build up is likely to occur the use of a

3.6 The AQUATAP unit will adjust for ambient air temperatures of between 1°C and 40°C

3.7 The unit must not be installed where it is liable to freeze. If the unit is thought to be frozen

it must not be switched on. It should be allowed to thaw and must then be thoroughly

inspected to ensure it is undamaged.

3.8 The unit is not suitable for installation in an area where a water jet could be used.

7

4.0 INSTALLATION – MOUNTING THE WATER HEATING UNIT

4.1 The AQUATAP water heating unit is free standing and must be mounted on a level

surface. If being mounted in a cupboard, on a shelf or false base, ensure that

the supporting surface can carry the full weight of the unit (see TECHNICAL

SPECIFICATIONS Section 2.0, page 4)

4.2 Refer to FIG. 1, page 4 for details of the dimensions of the AQUATAP water heating unit

and the relative positions of the water and electrical connections.

4.3 The AQUATAP heater unit must be located beneath the dispensing tap. It must be

dispensing tap to the OUTLET and VENT connections on the AQUATAP unit. The pipes

must not be lengthened. The dispenser tap can be positioned so it discharges into a sink

or mounted on its own purposed designed drip tray (available as an accessory, Product

Code 95970138).

top rear edge of the unit, it must be ensured that these can be accessed in order to

facilitate removal of the front cover for maintenance and servicing.

cable. It is recommended that this is connected to a fused double pole isolating switch

electrician. Refer to Section 9.0, page 14 INSTALLATION – ELECTRICAL

REQUIREMENTS for full details of the electrical installation.

8

5.0 INSTALLATION - WATER SUPPLY

5.1 The INLET connection to the AQUATAP water heating unit is located on the top rear

to make a compression connection directly to the INLET connection.

facilitate servicing the heater.

5.5 The hot OUTLET connection from the AQUATAP water heating unit is located on the top

hot supply hose to the dispensing tap is attached. Refer to section 8.0 INSTALLATION –

DISPENSING TAP CONNECTION, page 12 for full details of how to mount and connect

the dispensing tap to the water heating unit.

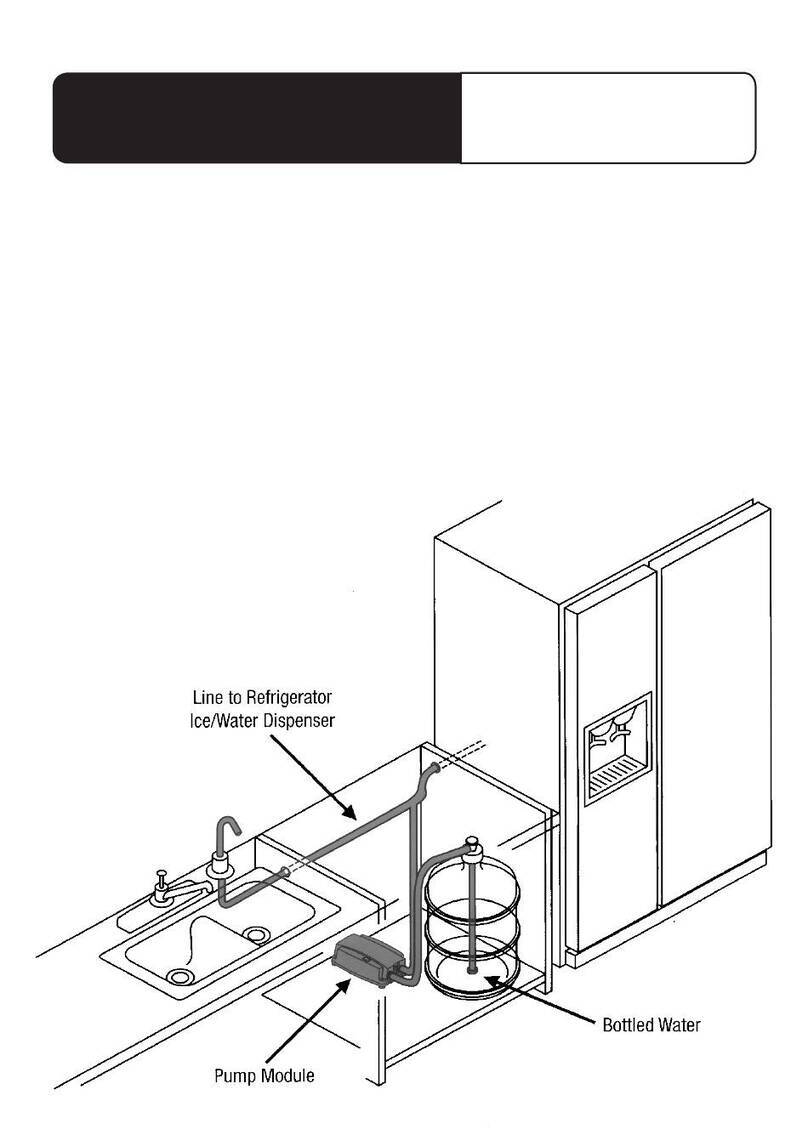

FIGURE 4: PLUMBING DIAGRAM

9

ISOLATING

VALVE

CLAMP

HOT TAP

OUTLET

HOSE

FLEXIBLE

HOSE

MAINS

WATER

SUPPLY

CLAMP

TAP

VENT

HOSE

6.0 INSTALLATION – VENT PIPE

6.1 The VENT connection from the AQUATAP water heating unit is located on the top rear

hose OF the dispensing tap is attached. Refer to section 7.0 INSTALLATION –

DISPENSING TAP MOUNTING below for full details of how to mount and connect the

dispensing tap to the water heating unit.

6.2 The VENT will ensure that any excess steam or pressure is safely vented to

atmosphere in the event of a fault with the unit. IT MUST NOT BE BLOCKED,

OBSTRUCTED, DISCONNECTED OR REMOVED.

7.0 INSTALLATION – DISPENSING TAP MOUNTING

7.1 The dispensing tap supplied is suitable for mounting onto a worktop or counter

surface. It should be positioned such that it discharges into a sink or drip tray (FIG. 6,

page 11 for tap dimensions). A purpose designed drip tray is available as an

accessory (order Product Code 95970138). If this is used, then the instructions

supplied with the drip tray accessory should be followed.

7.2 Cut a 35mm diameter hole in the position selected through the worktop or counter

surface or use the template provided if using the drip tray. NOTE: Do not mount the

dispenser directly onto a stainless steel sink.

hoses to the dispenser tap with the clips provided.

7.4 Ensure the sealing washer provided is correctly located on the base of the tap. A light

application of clear silicon sealant on the base of the tap and the sealing washer will

the top and position the tap base onto the worktop.

If necessary adjust the position of the dispenser tap and then tighten the securing nut.

7.8 Make sure all pipe work is bonded and the earthing clamps conform to BS 951 and

REMOVE”.

10

11

WORK TOP

35mm HOLE35mm HOLE “C” CLAMP

SECURING NUT

SEALING WASHER

FIGURE 5 : TAP MOUNTING

HOT PIPE VENT PIPE

309

235

181

60.0

FIGURE 6 : DISPENSER DIMENSIONS

61.0

55 MAX

12

8.0 INSTALLATION – DISPENSING TAP CONNECTION

8.1 The hot supply hose should be connected to the OUTLET hose spigot of the AQUATAP

water heating unit. The hose should rise continuously from the heater to the tap without

kinks or twists. If necessary it can be cut to a shorter length, but it should never be

lengthened. The hose should be secured in place on the spigot using the clips provided.

Warning, only use the hose supplied with the unit or a temperature rated WRAS

approved hose. Spare hose and clips can be ordered, part number 95 607 364.

8.2 The VENT hose should be connected to the VENT hose spigot of the AQUATAP water

heating unit. The hose should rise continuously from the heater to the tap without kinks

or twists. If necessary it can be cut to a shorter length, but it should never be lengthened.

The hose should be secured in place on the spigot using the clips provided.

ISOLATING

VALVE

CLAMP

HOT TAP

OUTLET

HOSE

FLEXIBLE

HOSE MAINS

WATER

SUPPLY

TAP

VENT

HOSE

FIGURE 7 : TAP MOUNTING (BOIL ONLY)

CLAMP

DISPENSER CABLE

FUSED SPUR

1.5mm 3 CORE HOFR

SHEATHED CABLE

(NOTE: DRIP TRAY/SINK NOT SHOWN FOR CLARITY)

13

FIGURE 8: WIRING DIAGRAM

PUMP

TRANSFORMER

SOLENOID VALVE

LEVEL

SENSOR

(TOP)

LEVEL

SENSOR

(BOTTOM)

LEVEL

SENSOR

(EARTH)

TERMINAL BLOCK

CONTROL PCB

P2

P3

J13 J5 P1

J

10 6 4 3 12 9 2 1

J5 - PIN 1

J5 - PIN 2

09V

THERMAL CUT-OUT

L

N

230V

10 9 8 7 6 5 4 3 2 1

- LEVEL SENSOR (TOP)

- LEVEL SENSOR (BTM)

- SPARE

- SPARE

- THERMISTOR (TOP)

- THERMISTOR (BTM)

- ANTI-SCALE LOOP

- THERMISTOR (TOP)

- THERMISTOR (BTM)

}

10 9 8 7 6 5 4 3 2 1

- LEVEL SENSOR (TOP)

- LEVEL SENSOR (BTM)

- SPARE

- SPARE

- THERMISTOR (TOP)

- THERMISTOR (BTM)

- ANTI-SCALE LOOP

- THERMISTOR (TOP)

- THERMISTOR (BTM)

}

J5

8

7

6

5

4

3

2

1

TOP

P2

65

43

21

TOP

LINK BETWEEN PINS 1 & 6

J13

4

3

2

1

TOP - POWER LED ORANGE

- POWER LED BLACK

- READY LED BLACK

- READY LED BLUE

P3

ELEMENT

NOTE: SOME INTERNAL EARTH LINKS

NOT SHOWN FOR CLARITY. ALL EARTH

LINKS MUST BE SECURELY FASTENED

TO AN EARTHING POINT

230 - 240V~

P1 - TRANSFORMER 9v CONNECTION

P2 - TAP DISPENSER CONNECTIONS

P3 - LED WIRING CONNECTOR

J5 - TEMPERATURE & LEVEL CONTROL

CONNECTOR

J13 - LINK CONNECTOR

PCB PLUG FUNCTIONS

- RED

- PURPLE

- BLACK

- BROWN

- WHITE

- YELLOW

- BLUE

- GREEN

14

9.0 INSTALLATION – ELECTRICAL REQUIREMENTS

9.1 Warning: This appliance must be earthed. It is suitable for 230/240V~ supply only.

9.2 Installation must be carried out by a competent electrician in accordance with the latest

edition of BS 7671 (the IEE Wiring Regulations).

electrician using 3 core cable with a minimum conductor cross sectional area of 1.5 mm².

The electrical supply cable must be connected to the electrical supply via a double pole

isolating switch with a contact separation of at least 3mm in both poles. The electrical

supply should be fused 13 amp.

9.4 The AQUATAP dispensing tap must be connected to the water heating unit by means of

the black sheathed control cable. The cables from each unit are terminated in a mating

9.5 A schematic wiring diagram of the AQUATAP installation is shown in FIG. 8, page 13.

be reduced by switching the unit off. It is recommended that this is done automatically by

incorporating a suitable time switch in the electrical supply to the unit. A suitable time

switch is available as an accessory (order Product Code 95970124) which can be

set to switch the unit on for a suitable period of time to allow it to reheat before it is next

used. NOTE: If selecting an alternative time switch it must be capable of switching

a 13 amp resistive load.

10.0 COMMISSIONING

10.1 The AQUATAP heater incorporates an electronic controls system which has a self

commissioning and calibration function. No installer or user adjustment is necessary

before use.

10.2 Check that all electrical, water and vent pipe connections have been correctly made and

are secure.

10.3 To remove the main cover, unscrew the fascia securing screw and remove the fascia,

remove two top cover securing screws and four cover securing screws. The cover

can now be pulled back from the heater assembly. Caution should be taken here as the

wires, make sure the LED with the orange wire is at the top and the LED with the

blue wire is at the bottom.

10.4 If the cover has been removed, this should be replaced and secured with the supplied

AQUATAP heater.

10.5 Once commissioned it is advisable to insulate both hot and cold hoses.

15

unit is in the self commissioning mode. Whilst in this mode the water will not be hot

enough for use. DO NOT DRAW ANY WATER OFF DURING THE SELF-

COMMISSIONING MODE.

BOILING WATER

LED

READY LED

FIGURE 10 : LED POSITIONS (DISPENSER)

SAFETY BUTTON

HOT WATER

BUTTON

FIGURE 9 : FRONT COVER REMOVAL

FASCIA

SECURING

SCREW

COVER

SECURING SCREWS

HOOK TOP EDGE

OF FASCIA INTO

COVER

APERTURE

TOP COVER

SECURING

SCREWS

MAIN COVER

16

after a short delay but may result in the calibration temperature being too low. Should this

occur the electrical supply should be switched off for several seconds. When switched on

DO NOT DRAW

ANY WATER OFF DURING THE SELF COMMISSIONING MODE.

residues and pasteurise the surfaces in contact with the water.

by the hot water button. The hot water dispensing button must remain

If released it will be necessary to press

water can be dispensed.

power is switched off and the AQUATAP casing

removed to check for any internal leaks.

ALWAYS DISCONNECT THE ELECTRICAL

SUPPLY BEFORE REMOVING THE COVER.

If there are no leaks evident, replace and secure

the front casing. Switch on the electrical supply.

AQUATAP unit will be ready for use.

10.11 Following commissioning, the following should be explained to the user:

malfunction of the unit or dispenser tap any maintenance or servicing must only be

carried out by a competent installer.

the correct use of the system.

10.12 The commisioning record should be completed (see Section 15.0, page 28).

10.13 These instructions should be left with the user for future reference.

SAFETY BUTTON

HOT WATER

DISPENSING BUTTON

FIGURE 11 : OPERATING BUTTONS

17

11.0 USER INSTRUCTIONS

completely automatic.The indicator lights on the dispensing tap will indicate the status

self-calibrating, the AQUATAP will enter this mode after any period the electrical supply

dispense boiling water.

11.2 Hot water drawn from the dispensing tap will at all times

be close to boiling point so due caution must be taken

when using the product, especially if it is likely to be

11.3 Hot water cannot be dispensed unless the safety

should be pressed before the hot water dispensing

button. The dispensing button must be held in the

pressed position to continue dispensing. If it is

again before more hot water can be dispensed.

11.4 In the unlikely event that the full store of hot water is completely drawn off from the

prevent air being drawn through the pump and it possibly air locking, it does not indicate

BOILING WATER

LED

READY LED

FIGURE 12 : LED POSITIONS

SAFETY BUTTON

HOT WATER

DISPENSING BUTTON

18

12.0 MAINTENANCE

NOTE: Any maintenance on the AQUATAP water heater and dispensing tap must be carried out

with this type of appliance.

ALWAYS DISCONNECT THE ELECTRICAL SUPPLY BEFORE REMOVING THE COVER

ANY WATER CONTAINED IN THE WATER HEATER MAY BE VERY HOT, EXERCISE

CAUTION WHEN REMOVING

WARNING: THE ELECTRONICS CONTROL BY SWITCHING THE NEUTRAL (N), IN SOME

INSTANCES NEUTRAL TERMINATIONS WILL BE AT 230 - 240V WITH RESPECT TO EARTH

rate of scale deposition in hard water areas. However, some deposits may still occur in

the storage tank; these should be periodically removed.

regular inspection of the tank every 6 to 12 months will provide longer life of the product

and maintain optimum performance (removal of steam plate assembly will give access to

the storage tank).

19

FIGURE 13: EXPLODED VIEW FOR STEAM TRAP REMOVAL AND DESCALING

Other manuals for Aquatap

2

Table of contents

Other Heatrae Sadia Water Dispenser manuals

Popular Water Dispenser manuals by other brands

Kool Tek

Kool Tek FCCW2 user manual

Delta Water Engineering

Delta Water Engineering Escalda installation guide

Pentair

Pentair FOLEO 5800 XTR user guide

Aquion

Aquion Micro Chrono Installation & operating instructions

KYOWA

KYOWA KW-1503 instruction manual

Clean Water Systems

Clean Water Systems 5900S Installation & start?up guide

Pelican Water Technologies

Pelican Water Technologies PSE1800 owner's manual

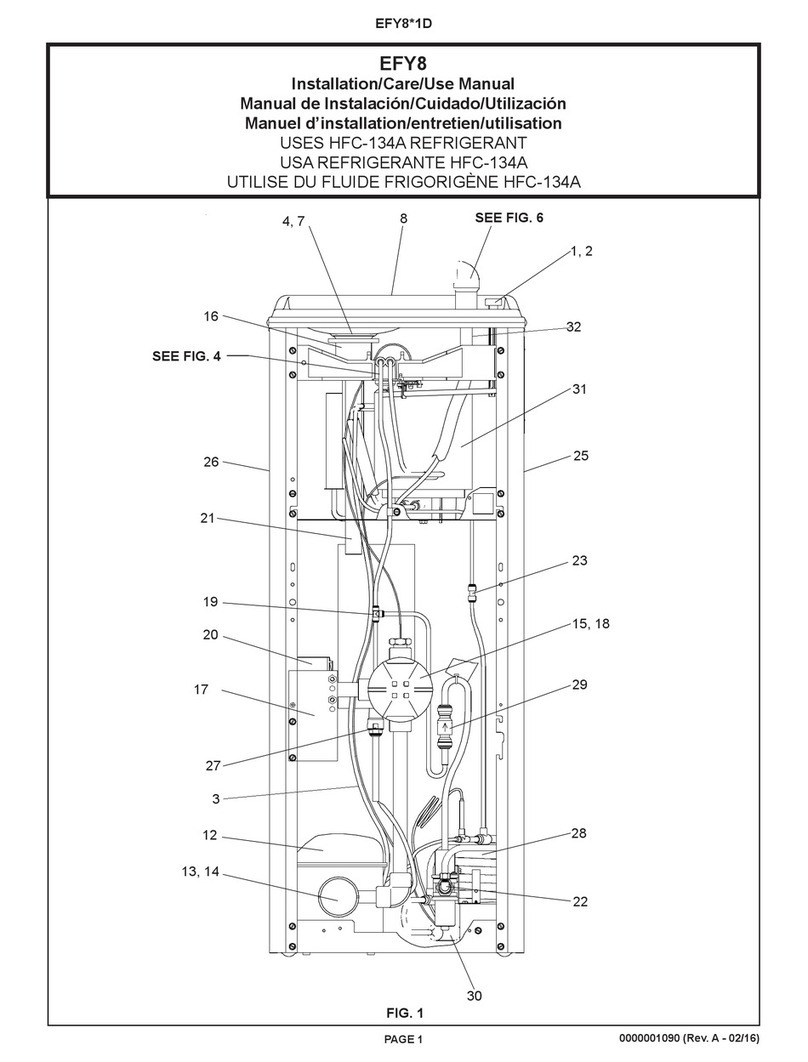

Elkay

Elkay EFY8 Series Installation, care & use manual

VEVOR

VEVOR 10707 Installation & maintenance instructions

Elkay

Elkay EBFATL8 1C Series Installation, care & use manual

BRIO

BRIO CL500CV Setup manual

GE

GE GXSS17Z01 Installation and owner's manual