Heiniger Acutecc Euro Grinder User manual

719-301 (EURO)

719-302 (GB)

Euro Shearers

Grinder

Manufactured by

H E I N I G E R A U S T R A L I A

F0262 Acutecc Euro Grinder Manual

1

22/09/2006

Rev:01

Contents

1.

General information

1.1

Motor specification sticker

1.2

Intended use

1.3

Contact addresses

2.

Safety regulations

2.1

Essential operator skills

2.2

Proper use

2.3

Power supply connections

2.4 Further measures for avoiding accidents

2.5 Residual dangers

2.6 Information symbols

3. Technical data

Technical data

Thermal overload

Equipment Items

Component list

Spare parts list

Discs & Pendulum

4. Guarantee

Introduction

Guarantee period

Guarantee conditions

5. Accepting delivery

6. Transporting

7. Initial start-up

8. Assembly

Assembly

Euro guards

Fitting the discs onto the grinder

9.

Grinder operating instructions

9.1

Setting up or adjusting the grinder to grind combs

9.2

Setting the length of the pendulum for combs

9.3

Grinding combs on the disc

9.4

When is the comb sharp?

9.5 Setting up or adjusting the grinder to grind cutters

9.6 Setting the length of the pendulum for cutters

9.7 When is the cutter sharp?

10. Emery setting procedure for Heiniger discs and double sided clamp plate.

11. Maintenance

12. Trouble shooting

13. Material groups

14. Component illustration

15. Spare parts illustration

16. Warranty registration card

F0262 Acutecc Euro Grinder Manual

2

22/09/2006

Rev:01

1. General information

1.1 Motor specification sticker

1.2 Intended use

The Heiniger Acutecc Shearers Grinder is designed for sharpening combs and cutters

for use on mechanical shearing handpieces.

It is to be used in conjunction with other equipment designed for this sharpening process.

All other uses are expressly prohibited.

1.3 Contact addresses

Heiniger Ltd

Industrieweg 8

PO Box CH-3360

Herzogenbuchsee Switzerland

T: +41 (0)62 956 92 00

F: +41 (0)62 956 92 81

E: kontact@heiniger. com

W: www.heiniger.com

Heiniger Australia PTY LTD

5A Tayet Link

Bibra Lake WA 6163

T: +61 (0)8 9434 0000

F: +61 (0)8 9434 0011

E: mail@heiniger.com.au

W: www.heiniger.com.au

F0262 Acutecc Euro Grinder Manual

3

22/09/2006

Rev:01

2. Safety regulations

2.1 Essential operator skills

The owner/manager of the grinder has an obligation to ensure that the operator is

competent to use the grinder.

Operating the grinder safely only makes small demands of the operator. However, it is

essential that they are observed and carried out.

The operator must have read and understood the manual or have been instructed in

the operation of the grinder by a skilled person and have had the potential dangers

pointed out to him. The operator shall be able to demonstrate an understanding of the

grinder controls and the hazards associated with the grinder.

It is an offence to operate the grinder without the Euro guards fitted and in proper

working order.

2.2 Proper use

HEINIGER Australia has fitted this grinder with safety devices in accordance with

relevant regulations to protect the operator during use.

Should these safety devices become inoperable for any reason it is the responsibility

of the owner to ensure that it is repaired before further use.

The proper use of the grinder is described in 9. Grinder operating instructions

The proper set up of the grinder is described on the wall chart that is supplied with this

grinder and in this manual at 9. Grinder operating instructions.

The details in 3. Technical Data, count as mandatory operating limits and ratings.

2.3 Power supply connections

The voltage specified on the makers sticker and in this manual and that of the local

power supply must match. The grinder may only be connected to an AC power supply.

In the event that the grinder is operated from a generator, the supply voltage must not

exceed that specified on the motor specification sticker.

Never plug the grinder into damaged sockets.

Observe the relevant regulations applicable in your country.

Completely unroll the power cable before plugging in.

Maintenance and cleaning of the grinder should only be carried out when the grinder

is not plugged in. When this is not practicable, greater care needs to be taken with the

grinder.

2.4 Further measures for avoiding accidents

The operating instructions must be kept safely and accessible at all times.

The disc guards must remain in place at all times unless

performing maintenance, in which case

the grinder must be unplugged from the power source.

Never use the grinder on an unsafe or unstable stand, pedestal or bench.

Never use the grinder with loose fitting clothing.

Always ensure adequate working room around the grinder.

Unauthorized persons are not permitted to use the grinder.

Unauthorized persons are not permitted

in the vicinity of the grinder when it is being operated or

maintenance is being carried out.

Never leave the grinder until it has completely stopped.

Ensure that the power cord is suspended to avoid accidents.

Never leave the grinder unsupervised when connected to the power

Avoid kinks and tight coils in the cable when storing, this can damage the cable.

Store the grinder in a dry undercover area when not in use.

Avoid getting electrical components of the grinder wet.

Never use a grinder or any part of a grinder, i.e. discs, pendulum when it is worn or damaged.

F0262 Acutecc Euro Grinder Manual

4

22/09/2006

Rev:01

Any damage or failure to the grinder which may constitute a risk to the health and safety

of any person shall be immediately reported by the operator to the owner/manager who

shall take appropriate action.

Examples of the type of damage, which would constitute such a risk include:

Frayed or damage insulation on electrical wiring.

Failure or wear of any control or component, i.e. switch, discs or pendulum.

Damaged or loose fasteners, nuts, bolts, etc.

Discs that are damaged in any way.

Incorrectly or badly set emeries.

Missing or damaged guards.

2.5 Residual dangers

Should dangers and hazards occur during operation of the grinder that are not directly

related to grinding, we request that you inform Heiniger of this. This also applies to a

technical failure that causes a hazard.

2.6 Information symbols

Warning

Indicates a potentially dangerous situation. If preventative action is not taken death or

very serious injury could result.

Warning

Indicates a potentially dangerous situation. Take preventative action.

Note

Note, non-compliance with which can lead to operating malfunctions or damage.

Warning

Eye protection must be worn.

Warning

Hearing protection must be worn.

Illustration

This symbol, together with its number, refers to the relevant illustration at the end of the

manual.

3.

Technical data

3.1

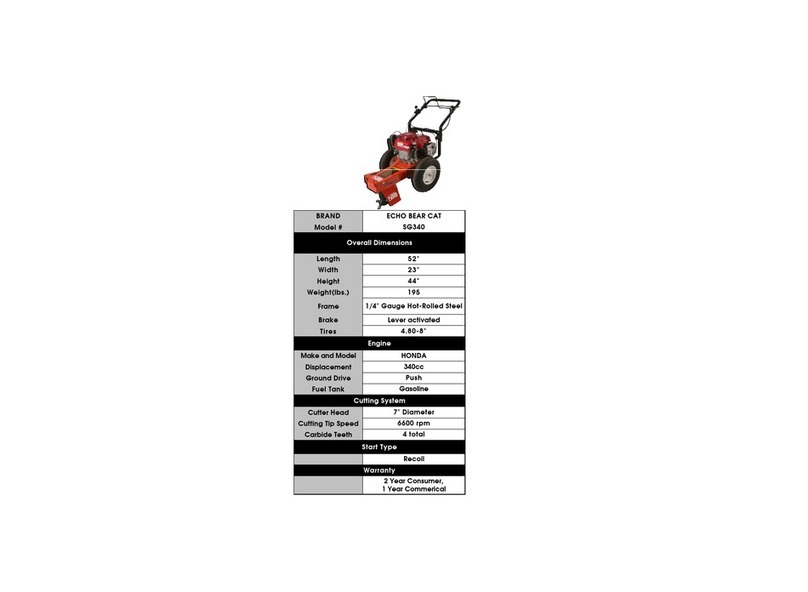

Technical data

Designation

Shearing Grinder

Model

Acutecc Euro Grinder

RPM

2800 r.p.m.

Volts

240V

kW

1.1 kW

Amps

7.5 A

Hz

50 Hz

Duty

S2

Dimensions (operational)

H 770mm L 400mm W 430mm

Dimensions (folded down)

H 480mm L 400mm W 430mm

Motor shaft

1” (BSW or UNC, RH & LH)

Weight (operational)

40 kg

Weight (shipping)

62 kg

3.2 Thermal overload

The grinder motor is fitted with an internal thermal overload; if the motor overheats this

will automatically shut the motor off.

If this happens the red indicator light in the switch will remain on.

Note: If the grinder motor stops due to overheating, turn the motor off at the switch,

failure to do so will result in an unexpected start when the thermal overload has cooled

sufficiently.

F0262 Acutecc Euro Grinder Manual

5

22/09/2006

Rev:01

3.3 Equipment Items

Discs

Clamp plate

Pendulum

Bolt set

Safety Glasses

Grinding wall chart

Spanner

Acutecc Hollow Gauge

Ear plugs

Operators manual

Grinding radius gauge

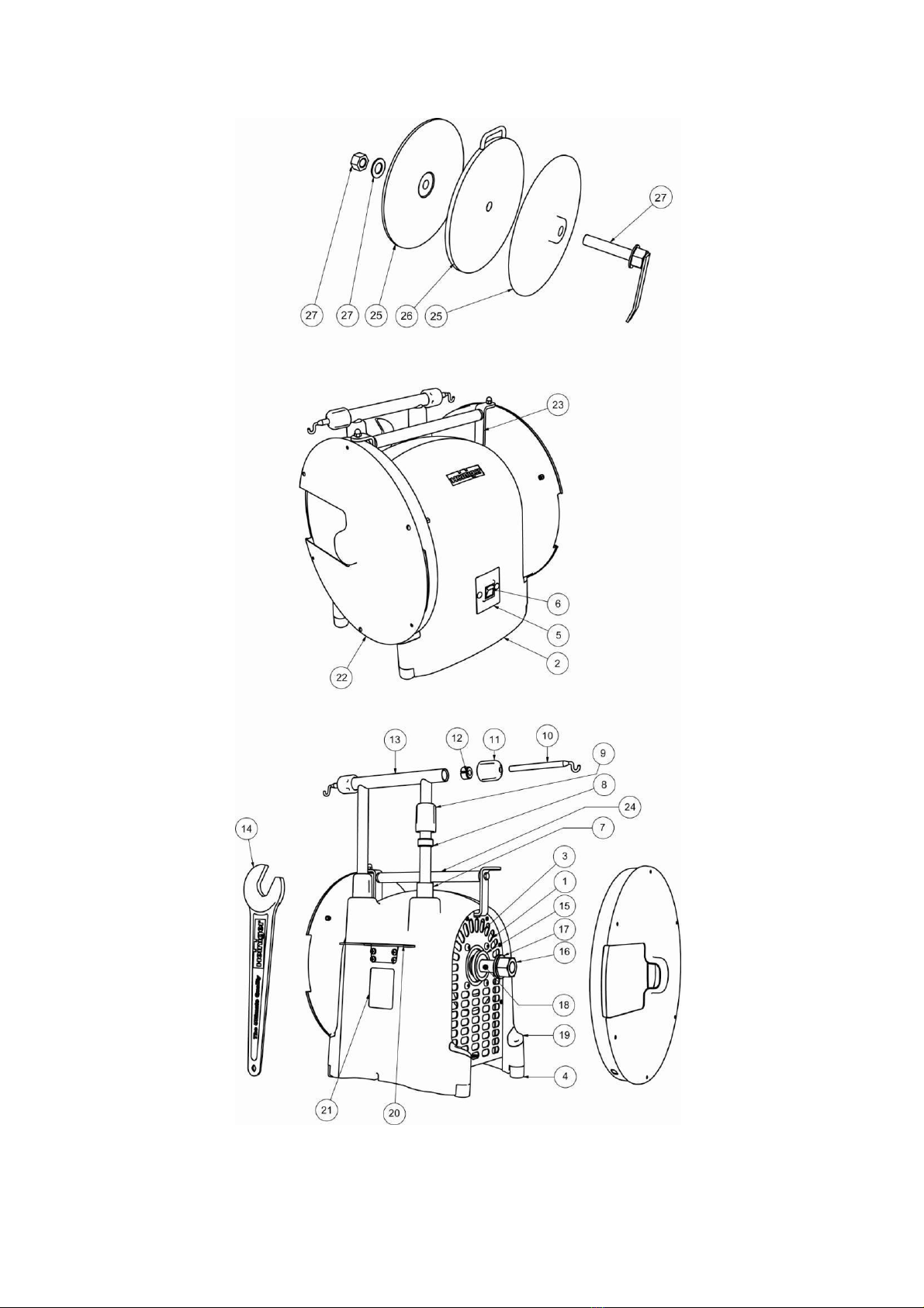

3.4

Component list

1.

Electric motor

15. Disc collar

2.

Motor cover

16. Disc nut

3.

Motor side cover

17. Disc washer

4.

Foot

18. Motor shaft

5.

Switch plate

19. Guard spacer

6.

Switch

20. Spanner bracket

7.

Telescopic tube

21. Motor specification sticker

8.

Cross arm collet

22. Euro guard

9.

Cross arm tube nut

23. Guard bracket

10.

Pendulum hook

24. Handle

11.

Pendulum hook tube nut

25. Disc

12.

Pendulum hook collet

26. Clamp plate

13.

Cross arm

27. Bolt set

14.

Spanner

Note: 12. Component illustration is at the end of the manual.

3.5 Spare parts list

Part

Part number

Spare part illus

Disc set

719-010

8

Electric motor

719-311

4

Spanner

719-318

7

Euro guard

719-061

6

Foot

719-323

1

Pendulum hook set 719-324

2

Cross arm set

719-325

3

Switch

719-328

5

Handle

719-062

9

Note: 13. Spare parts illustration is at the end of the manual.

F0262 Acutecc Euro Grinder Manual

6

22/09/2006

Rev:01

3.6 Discs & Pendulum

The special light weight aluminium alloy discs and pendulum are precision tools and

when used in conjunction with this manual give the best possible edge on your gear.

With care they will provide you with years of service.

To protect the pendulum, always store and transport it in the supplied case, use it only

as instructed in this manual.

It is essential that the discs are not subject to abuse or neglect. Damage may occur that

will render the discs unusable.

Note: The discs may be hazardous if used in a damaged condition.

If discs become damaged they must be replaced.

Use only genuine replacement discs.

The discs are fitted to the grinder when dispatched and are protected by the Euro guard.

This is the best way to protect the discs when transporting.

When not fitted to the grinder the discs should be bolted to the clamp plate and

protected from knocks or being dropped.

Do not drop the discs or lean them against a wall.

Do not subject discs to rapid and extreme changes in temperature.

Do not use levering or striking tools to remove discs from the grinder.

Do not use excessive force to remove the discs from the grinder.

Do not use excessive force or tools to remove emery and glue from the disc.

Do not over tighten the bolt when setting emeries to the discs.

Do not damage the mounting shoulder on the rear of the disc.

Assemble and run the grinder as per this manual when received to ensure you have

received it in good condition. See 5. Accepting delivery & 8.2 Fitting the discs onto the

grinder

7

4. Guarantee

4.1 Introduction

Your HEINIGER Acutecc Euro Grinder was made by one of Australia's best known

shearing equipment manufacturers.

The HEINIGER name has been synonymous with quality manufactured shearing

equipment for 60 years. That is your best guarantee.

Your HEINIGER Acutecc Euro Grinder was manufactured specifically to sharpen

sheep shearing combs and cutters.

With a minimal amount of care, your HEINIGER Acutecc Euro Grinder will provide you

with years of excellent service.

4.2 Guarantee period

A global warranty covers your HEINIGER Acutecc Euro Grinder against faulty materials

and workmanship for 1 year from the date of purchase. HEINIGER dealers in more than

36 countries will honour this warranty. Ensure that the warranty card at the back of this

manual is completed and returned to effect warranty period.

4.3 Guarantee conditions

Grinder discs and clamp plate are not covered under this warranty, neither are

damage due to improper treatmentor lack of due care, accidents, normal wear or

claims for subsequent damages.

Servicing by personnel

not specifically authorized by HEINIGER renders the warranty

null and void.

To be valid the warranty certificate

must be completed, signed by the HEINIGER dealer and

bear the date of purchase.

In case of a warranty claim, the original invoice must be presented along with the grinder.

Notify your HEINIGER dealer immediately you have a problem.

HEINIGER dealers are responsible for any additional warranty they may give.

This warranty is subject to the regulations in force in the countries concerned.

5. Accepting delivery

All units are transported at the owner's risk.

Before accepting delivery, thoroughly inspect the Grinder for damage.

If any has occurred you should note the nature and extent of the damage in view of any

insurance claim you may wish to make.

Whilst all care is taken during manufacture and by our agents to ensure your grinder

arrives in perfect working order and condition, damage occurring during transit or

faulty operation resulting from damage occurring during transit will not be covered by

our warranty.

The following areas should be checked carefully:

The Euro guards; they should be located securely in place.

Electrical components, Discs and clamp plate, Pendulum.

6. Transporting

The grinder is supplied in a case; it is advisable to transport the grinder in this case

whenever practicable.

When moving the grinder in the case use only two adults or a suitable trolley.

When lifting the case use the case handles.

It is essential that the discs are protected in transit. If the discs are fitted to the grinder

whilst in transit they are protected by the Euro guards.

Lower the cross arm during transit.

If the grinder is to be transported not in the case, ensure that it cannot tip or slide.

8

7. Initial start-up

Note: Do not attempt to start the grinder unless this manual has been fully read and

understood.

Before starting the grinder ensure that the disc nuts are tight.

The on/off switch for the grinder is located on the front of the motor housing.

Ensure that the switch is in the off (up) position before connecting the grinder to a power

source.

Do not start the grinder unless the Euro guards are fitted and you are wearing safety

glasses.

Do not attempt to grind until the grinder is at full speed.

8. Assembly

8.1 Assembly

The Euro grinder is dispatched fully assembled, however it must be set up before being

used for grinding, for full setup instructions refer to 9. Grinder operating instructions

Note: The voltage specified on the grinder and that of the local power supply must match.

The grinder may only be connected to an AC power supply.

In the event that the grinder is operated from a generator, the power supply must not

exceed that specified on the grinder.

Note: When removing the grinder from the case use two adults and lift the grinder

as illustrated.

Loosen the two Cross arm tube nuts (9.) and lift the Cross arm (13.) to its full height. Re-

tighten the tube nuts while holding the Cross arm at its full height.

8.2 Euro guards

The Euro grinder is fitted with guards enclosing the discs to protect the user during

use. See 2.2 Proper use & 2.4 Further measures for avoiding accidents.

The Euro guards must remain in place at all times unless performing maintenance. It is

necessary to remove the outer part of the Euro guard to remove and refit the discs. The

outer part of the Euro guard is secured with three screws & nuts. When refitting the Euro

guards always use all three screws & nuts, tightened securely.

8.3 Fitting the discs onto the grinder

Note: Unplug the grinder from power before proceeding. The outer Euro guard on

either side must be removed to remove or fit a disc. The thread on the left-hand shaft is

left-handed. Always use the washer.

8.3.1 Slide the disc onto the shaft of the grinder, ensuring the collar on the shaft and the disc are

free from dirt, dust or any other foreign matter, tighten the disc nut.

8.3.2 Once both discs are fitted and tightened, check by placing a flat hand onto each disc and

try to move the discs in opposite directions. If either disc moves on the shaft the nuts are

not tight. Re-tighten and check again. Always refit the Euro guards.

Note: The discs fitted to the grinder have been individually checked for balance. It must be

noted that it is possible for the glue and/or the emery to throw the balance off, see 11.

Troubleshooting

9

9. Grinder operating instructions

Includes: Grinder setup, Grinding technique & using the Heiniger variable handle

adjustable pendulum

Warning:

Always ensure that the Euro guards are securely fitted before setting up and using the

grinder.

Ensure the emeries are stuck to the disc and have no air bubbles between the emery

and disc.

Ensure you have cut the excess emery from the disc leaving the edge smooth.

Always wear protective goggles and ear protection.

Ensure the disc nuts are tight.

The on/off switch for the grinder is located on the front of the motor housing.

Ensure that the switch is in the off (up) position before connecting the grinder to a power

source.

When the grinder is running do not allow anything to come into contact with any part of

the discs.

Do not attempt to grind until the grinder is at full speed.

Note: Before setting up the grinder, ensure that the cross arm has been lifted to its full

height and the tube nuts are locked.

9.1 Setting up or adjusting the grinder

to grind combs

With grinder turned off and the

pendulum with a comb in place

hanging from the pendulum hook,

push the pendulum towards the

grinding disc. Adjust the pendulum

hook in or out so the heel of the

comb hits the grinding disc first.

As the heel of the comb touches the

grinding disc, adjust the pendulum

hook in or out to make the tip or ball

of the comb to be 1.5mm (or a match

thickness) away from the grinding

disc. The grinder is now set (see fig

’A’).

10

9.2 Setting the length of the pendulum

for combs

Remove the comb from the

pendulum. With the grinder turned off,

hang the pendulum on the pendulum

hook. Place the Heiniger grinding

gauge on the pendulum comb pins

making sure that the smallest end of

the grinding gauge is nearest the

grinder shaft (see fig ‘B’). Then put

your comb on the comb pins.

Place the comb on the disc where

you will finish your grind, we suggest

towards the outside of the disc with

no teeth being off the disc (see fig

‘B’), then adjust the length of the

pendulum up or down until the long

red line on the gauge runs through

the centre of the motor shaft (see fig

‘B’). Then tighten the pendulum tube

nut. Remove the comb and the

grinding gauge from the pendulum.

The pendulum length is now set.

9.3 Grinding combs on the disc

Holding your pendulum with the knuckle of your index finger directly under your thumb,

(see fig ‘C’) land your comb onto the disc. Using very firm pressure grind from side to

side taking the outside three teeth of the comb past the edge of the disc, then grind as

far to the very centre of the disc as possible, (see fig ‘D’). On a Heiniger grinder, grind

towards the grinder shaft until your comb touches the washer.

Move the comb side to side from three teeth off the disc to the centre with very firm even

pressure until the comb is sharp. Then on the last stroke move from the inside of the disc

to the outside, where you set the length of the pendulum (see fig ‘B’), and remove the

comb from the disc.

Note:

Always hold the pendulum on the pendulum hook with your spare hand (see fig ‘A’).

Use all the paper

(see fig ‘D’).

Take three teeth of the disc

(see fig ‘D’).

Use very firm even pressure.

On the last stroke, grind from the centreto the outside edge, where you set the length of the pendulum (see fig ‘B’), and not off

the disc.

9.4 When is the comb sharp?

The whole surface of the comb must be ground, especially where the cutter has been

cutting on the teeth. With good light, look carefully at the cutting edges of the teeth

and make sure there are no shiny or silver lines on the cutting edges of the tooth

once you have ground because these are blunt edges (see fig ‘G’).

11

The light will shine on a rounded/blunt edge but will not shine on a sharp edge.

Note: You must grind your combs until the blunt edge is sharp (see fig ‘f’). If in doubt,

grind it again.

12

9.5 Setting up or adjusting the grinder

to grind cutters

With the grinder turned off, hang the

pendulum from the pendulum hook.

Fit the cutter to the cutter pins and

lightly slide the cutter over the disc

a couple of times using the grinding

action (see fig ‘H’).

If the pendulum hook is too far in the

cutter will be rubbing on the tip (see

fig ‘I’), if the pendulum hook is too

far out, the cutter will rub on the heel

(see fig ‘J’). Adjust the pendulum

hook until the cutter rubs on both the

tip and heel (see fig ‘K’).

13

9.6 Setting the length of the pendulum

for cutters

Remove the cutter from the

pendulum. With the grinder turned off,

hang the pendulum on the grinder

pendulum hook. Place the Heiniger

grinding gauge on the cutter pins

making sure the smallest end of the

Heiniger grinding gauge is near the

grinder shaft (see fig ‘M’). Place the

cutter on the cutter pins on top of the

grinding gauge. Place the cutter on

the disc where you will finish your

grind, we suggest 25mm in from the

outside of the disc (see fig ‘M’), then

adjust the length of the pendulum up

or down until the long red line on the

gauge runs through the centre of the

motor shaft (see fig ‘M’). Then

tighten the pendulum tube nut.

Remove the cutter and the grinding

gauge from the pendulum. The

pendulum length is now set.

Grinding cutters on the disc

Holding the pendulum with the

knuckle of your index finger directly

under your thumb, (see fig ‘C’), land

your cutter on the disc. Using an even

moderate pressure, grind from side to

9.7 When is the cutter sharp?

Check that you have a slight burr on the

four tips of your cutter that move up or

down when you touch them (see fig ‘N’),

check that the whole surface of the cutter

is ground and there are no dull patches.

If in doubt, grind it again.

14

side, making sure you use all the

paper, by going from as far to the

outside as possible to as far to the

inside as possible.

Grind from side to side until the cutter

is sharp. Keeping the same pressure

on the cutter, on the last stroke move

from the centre to where you set the

length of the pendulum (see fig ‘M’),

then remove the cutter from the disc.

10. Emery setting procedure for Heiniger discs and double sided clamp plate.

10.1 Undo clamp plate bolt and nut using the grinder spanner.

10.2 Separate clamp, discs, bolt, nut and 2 washers.

10.3 Ensure discs and clamp plate are dry and completely free from any foreign matter. If

necessary clean discs and clamp plate only with warm soapy water and a scrubbing

brush, allow to dry.

Note: Do not use any form of petroleum based solvents when cleaning discs.

10.4 Place one of the washers on the clamp plate bolt. Place one disc over the clamp plate

bolt grinding side up.

10.5 On a table or bench place both discs grinding side up, place a towel or cloth underneath the

discs so as not to damage the boss or underside of the discs.

Note: Damaging the boss of the disc will create vibration when grinding.

10.6 Shake glue bottle vigorously. Apply glue to both discs around the middle of the face or

grinding side, use approximately 20 ml, and spread evenly using either a brush or the

palm of your hand coating the entire grinding side surface of both discs. In warm weather

we advise to work quickly or the glue may set prematurely.

Note: Do not use excess glue, using excess glue will cause the emery to lift or

bubble between the emery and the disc face.

10.7 While the glue is still wet place either a coarse (40 grit) or fine (80 grit) emery, smooth side

down over the protruding clamp plate bolt and let the smooth side of the emery rest on the

glue.

Note: Do not spin or twist emery on the glue this will cause bubbles or lifting.

10.8 Place the clamp plate over the protruding clamp plate bolt and let it rest on the emery.

Note: Do not place any other material between emery and clamp plate eg: rubber or

newspaper.

10.9 Place another emery either coarse (40 grit) or Fine (80 grit) over the protruding clamp plate

bolt, rough or grinding side down and let it rest on the clamp plate.

10.10 Place the other disc over the protruding bolt glue side or grinding side down and let it rest

on the emery.

10.11 Place the other washer over the protruding clamp plate bolt followed by the clamp plate nut;

tighten with the grinding spanner.

Note: Do not tighten the nut by hitting the grinding spanner tight with another object, tighten

the grinding spanner only with your hands.

10.12 If emeries are square and not pre-cut round, trim excess emery around the clamp plate.

10.13 Allow to set for a minimum of 1 hour.

10.14 Separate discs and clamp plate carefully and leave to completely dry before use a minimum

of 1 hour.

Note: Heiniger double-sided clamp plates must have 2 discs to clamp effectively even if

only one emery is being set at a time.

15

11. Maintenance

Use only genuine or equivalent specification replacement parts.

All parts are available through Heiniger dealers.

Use only qualified personnel for electrical repairs.

Always contact an authorized service centre if you are unsure how to rectify a problem or in

the event of malfunctions not contained in this manual.

Only perform maintenance when the grinder is disconnected from the power.

Electric motor

Periodically remove an outer Euro guard and disc and use dry compressed air to blow any

dust build up from inside the plastic electric motor cover and on the motor. Failure to keep

the motor dust free may reduce the cooling ability of the motor and cause it to cut out due to

overheating. See 3.2 Thermal overload

Do not disturb the collars fitted to the motor shaft, if they are moved they must be

refitted and trued to the shaft by qualified personnel. Failure to do so may cause

vibration. Keep the motor shaft, collars, disc nuts & washers clean and dry at all times, if

required clean with a little kerosene and dry thoroughly.

If the grinder is to be stored use anti rust on the shaft and collar, ensure this is cleaned off

before using.

Periodically check the condition of the power cord, replace if worn or damaged.

Foot

Ensure that feet are fitted and secure; failure to do so may lead to the grinder becoming

dangerously unstable.

Switch

Ensure the silicone boot covering the switch remains intact and in place. Failure to do so will

shorten the life of the switch. Replace damaged switches immediately.

Pendulum hook

If the pendulum hooks are damaged replace them before the grinder is used.

Cross arm

Periodically remove the Cross arm assembly and clean any dust or grease from inside the

tube nuts and collets and the thread on the telescopic tube.

Euro guard

The grinder is fitted with Euro guards that enclose the disc; these guards are integral to the

safe use of the grinder. At all times maintain the guards in correct working order, they must

fit the grinder correctly and securely. In the event of damage they must be repaired or

replaced before the grinder is used. When fitting the outer Euro guard to the grinder ensure

a new comb will fit between disc and guard without touching both disc and guard.

Discs

Keep the steel boss in the centre of the disc dry and free of dirt and grease.

If the discs are to be stored use anti rust on the boss. Ensure this is cleaned off before

using. Ensure that no anti rust gets on the face of the disc.

It is essential that the discs are not subject to abuse or neglect. Damage may occur

that will render the discs unusable.

Note: The discs may be hazardous if used in a damaged condition.

If discs become damaged they must be replaced. Use only genuine Heiniger replacement

discs.

The discs are fitted to the grinder when dispatched and are protected by the Euro

guard. This is the best way to protect the discs when transporting.

When not fitted to the grinder the discs should be bolted to the clamp plate and

protected from knocks or being dropped.

Clamp plate

The clamp plate must be protected from damage as the discs are.

Pendulum

Refer to the pendulum manual for maintenance instructions.

16

12.

Trouble shooting

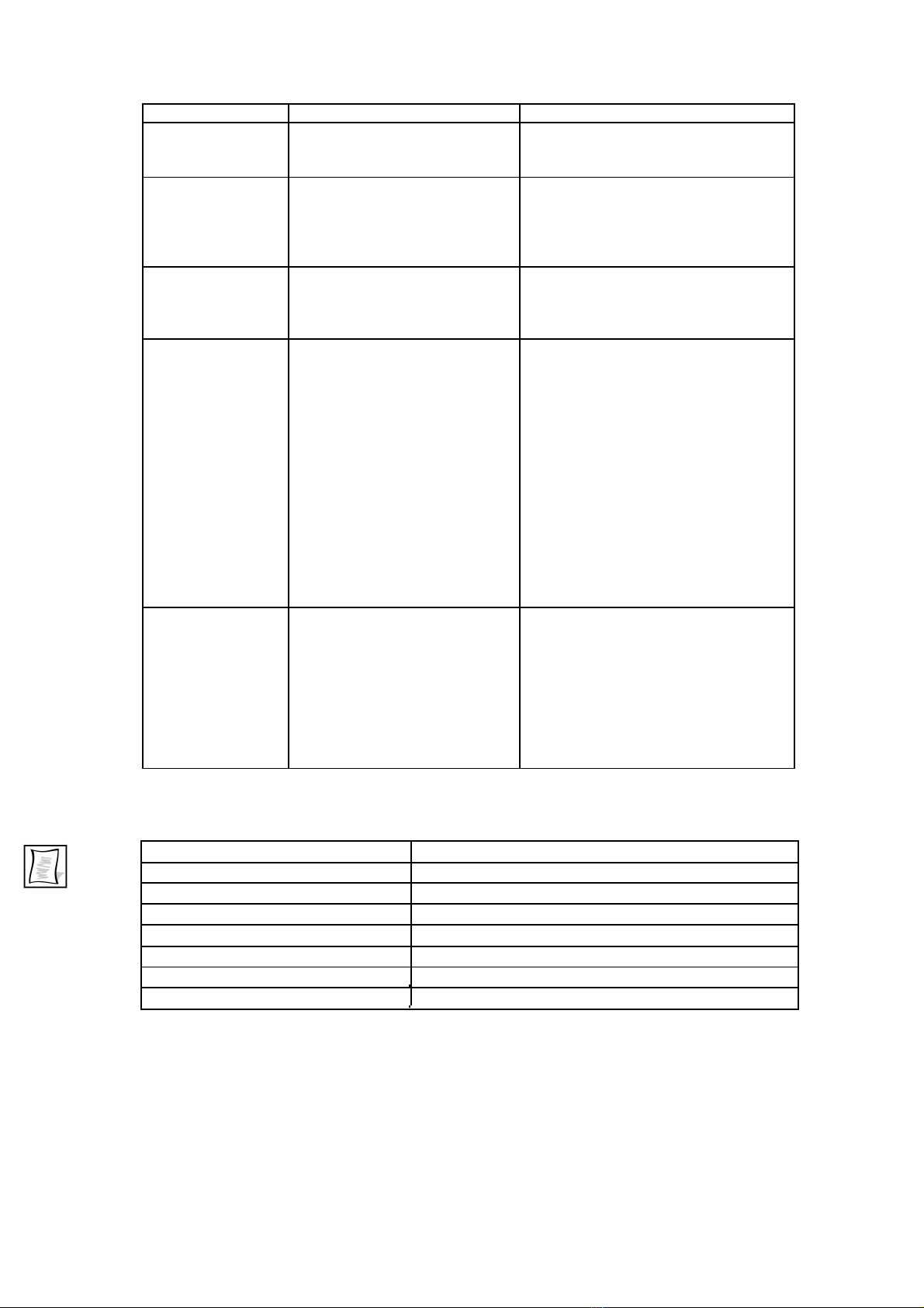

Problem

Cause

Solution

For all electrical faults qualified

persons only may undertake fault

finding and repairs.

Motor doesn’t

No power.

Check the plug is correctly connected

start, switch light

to the socket.

is off.

Check that power is available at the

socket.

Call an electrician.

Motor stops,

The motor has overheated and

Allow the motor to cool. Note: When

switch light is on.

the internal thermal overload

the motor has cooled sufficiently if

has cut out.

the switch is still turned on it will

restart without warning.

Grinder vibrates.

Discs out of balance.

1) Emeries not in centre of

1) Reset with emeries in the centre.

disc.

2) Clean discs in soapy water.

2) Discs have glue on the

back.

3) Reset emeries with even glue

3) Uneven glue spread under

spread.

emeries.

4) Remove discs clean collar and

4) Foreign matter between disc

disc and replace.

and collar on shaft.

5) Replace disc.

5) Discs buckled.

Emeries won’t

1) Wrong glue used.

1) Use Heiniger shearer’s glue.

stick to discs

2) Old glue used.

2) Use new Heiniger shearers glue.

3) Wash in hot soapy water.

3) Discs have film of foreign

matter on them (oil, dirt,

grease, old glue etc).

4) Buy new disc or clamp plate.

4) Disc or clamp plate buckled.

13. Material groups

Please be aware of the relevant regulations applicable in your country when disposing

of discarded parts. Refer to 14. Component illustration

Material

Contained in position

Iron/steel

1, 3, 14, 15, 16, 17, 20, 22, 23, 24, 27

Aluminium

1, 7, 25, 26

Copper

1

Stainless steel

10, 13

Polyethylene

2

ABS

8, 9, 11, 12, 19

Rubber

4

17

14. Component illustration

18

15. Spare parts illustration

19

Table of contents

Other Heiniger Grinder manuals