RULES

FOR

SAFE OPERA TION

Readinstructionsbeforeusinggrinder

-FOR BENCHGRINDERS-

1.

EXAMINE GRINDING WHEELSFORCRACKSor5.DONOTFORCEWORKagainstthe grindingwheel!

otherdamagebefore operating.Excessivepressuremaycausedamageorbreakageof

REPLACECRACKEDWHEELIMMEDIATELY.the grinding

wheel,

resultingin injurytothe operator

or bystander.

2.

DONOTOVER-TIGHTENWHEELNUTS.

3. USEONLY WHEEL FLANGES FURNISHEDWITH

GRINDER.Useof otherflangesmaycausedamageor

breakagetothegrinding wheelandresultin injuryto

theoperator.

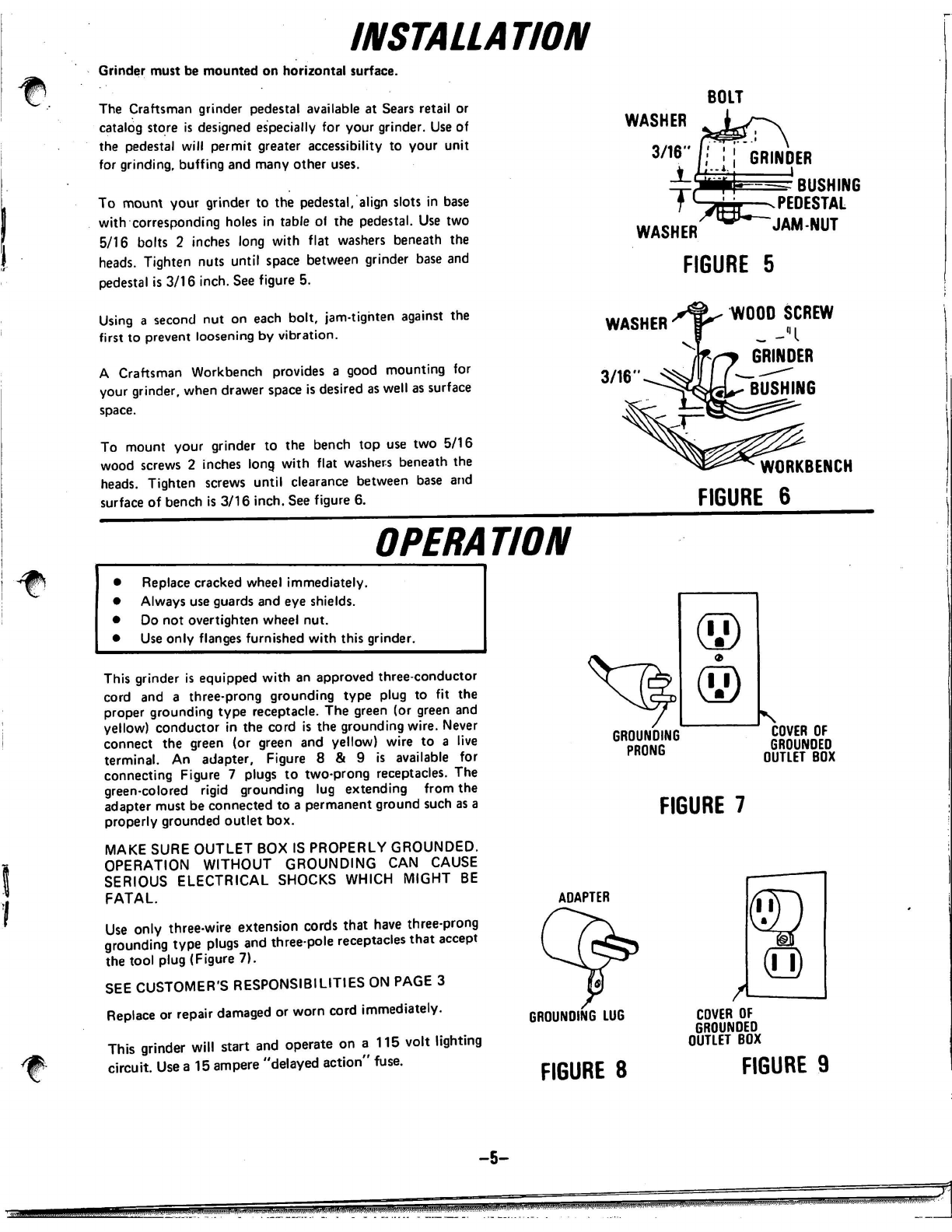

4. MOUNTTHE GRINDER SECURELYtoprevent

damage.See"INSTALLATION"page.

6. STOP GRINDER

ADJUSTMENTS.

BEFORE MAKING

7. ALWAYSUSE

GUARDS

AND EYESHIELDS.

8. ADJUSTDISTANCE BETWEENWHEELANDWORK

RESTto maintain1/16inchorlessseparationasthe

diameterofthewheeldecreaseswithuse.

-FORALLTOOLS-

1.

KEEPGUARDS

IN

PLACEandinworkingorder.

2.

REMOVE ADJUSTINGKEYSAND WRENCHES.

Form habitof checkingtoseethatkeysandadjusting

wrenchesareremovedfromtool beforeturningiton.

3. KEEPWORKAREA CLEAN.

benchesinviteaccidents.

Clutteredareasand

4. AVOID DANGEROUS ENVIRONMENT. Don'tuse

power toolsindamporwet locationsorexposethem

to

rain.

Keepworkareawell lighted.

12.

DON'T OVERREACH.Keepproper footingand

balanceatalltimes.

13.

MAINTAIN TOOLSWITH CARE.Keep toolssharp

andcleanforbestandsafest performance. Follow

instructionsfor lubricatingandchangingaccessories.

14.

DISCONNECT TOOLS before servicing;when

changingaccessoriessuchasblades,bits,cutters,etc.

15.

AVOID UNINTENTIONAL STARTING.Makesure

switchisin"Off" position beforepluggingin.

5. KEEPCHILDREN AWAY.All visitors shouldbekept

asafedistancefromworkarea.

6.

MAKE

WORKSHOP KID-PROOFwithpadlocks,

masterswitchesorby removingstarterkeys.

7. DON'TFORCE TOOL.Itwilldothejob betterand

saferattherateforwhichitwasdesigned.

8. USE RIGHT TOOL. Don't forcetoolor attachmentto

do a j o bitwasnotdesignedfor.

9.

WEARPROPER APPAREL.Noloose clothingor

jewelrytogetcaughtin moving parts.Non-slip

footwearis recommended.Wear protectivehair

coveringto containlonghair.

10.

USE SAFETYGOGGLES which complywithANSI

Z87.1-1968.

Alsousefaceordustmaskif cutting

operationisdusty.

11.

SECUREWORK.Useclampsora visetoholdwork

when practical.It'ssaferthanusingyourhandandit

freesbothhandstooperate

tool.

16.

USE RECOMMENDEDACCESSORIES.Consultthe

owner'smanualforrecommendedaccessories.Theuse

of improperaccessoriesmaycausehazards.

17.

NEVERSTANDONTOOL.Seriousinjury couldoccur

if

thetoolis tippedorifthe cuttingtoolis

unintentionally contacted.

18.

CHECK DAMAGED PARTS.Beforefurtheruseofthe

tool,

a guardor otherpartthatisdamaged shouldbe

carefullycheckedtoassurethatitwilloperate properly

and performits intended function—checkfor

alignmentof moving parts, bindingof moving parts,

breakingof parts, mounting,andany other conditions

thatmay affectits operation.A guardor otherpart

thatisdamaged shouldbe properlyrepairedor

replaced.

19.

GROUNDTHE OUTLETBOXto preventpossible

fatalshocks.See"OPERATION"page.

20.

NEVER LEAVETOOL RUNNING UNATTENDED.

JW\

powertoolinstitute,inc.

-2-