Heinz Walz KF-24/6B User manual

COLD TRAP

and

TEMPERATURE CONTROLLER

KF-24/6B

KF-18/2B

MGK-1B

TR-KF-24

TR-KF-18

3rd Edition: August 2011

Coldtrap new-3.doc

©Heinz Walz GmbH, 2011

Heinz Walz GmbH •Eichenring 6 •91090 Effeltrich •Germany

Phone +49-(0)9133/7765-0 •Fax +49-(0)9133/5395

CONTENT

I

CONTENT

1Safety Instructions......................................................................1

1.1 General Safety Instructions......................................................................... 1

1.2 Special Safety Instructions.......................................................................... 1

2General.........................................................................................2

2.1 Transport....................................................................................................... 2

3Cold Trap KF-24/6B .....................................................................3

3.1 Installation..................................................................................................... 3

3.2 System Description ...................................................................................... 5

3.2.1 Design......................................................................................................... 5

3.2.2 Function...................................................................................................... 7

4Cold Trap KF-18/2B .....................................................................9

4.1 Installation..................................................................................................... 9

4.2 System Description .................................................................................... 11

4.2.1 Design....................................................................................................... 11

4.2.2 Function.................................................................................................... 13

5Mesuring Gas Cooler MGK-1B .................................................15

5.1 Installation................................................................................................... 15

5.2 System description..................................................................................... 17

5.2.1 Design....................................................................................................... 17

5.2.2 Function.................................................................................................... 18

6Temperature Controller TR-KF-24............................................21

6.1 System description..................................................................................... 21

7Temperature Controller TR-KF-18............................................24

7.1 System description..................................................................................... 24

8Operation ...................................................................................26

8.1 General......................................................................................................... 26

8.2 Virtual Keyboard......................................................................................... 27

8.3 Main Window............................................................................................... 28

8.4 Protocol & Status........................................................................................29

CONTENT

II

8.5 Temperature Set Value............................................................................... 29

8.6 Control Start / Stop..................................................................................... 30

8.7 Chart Settings ............................................................................................. 30

8.7.1 Touch Pen Options: Chart 2 and Chart 3................................................. 31

8.7.2 Graph Magnification.................................................................................. 31

8.7.3 Scale: Chart 1........................................................................................... 32

8.7.4 Scale: Chart 2 and Chart 3....................................................................... 32

8.8 Settings........................................................................................................ 32

8.8.1 Screen Brightness .................................................................................... 33

8.8.2 Temperature Regulation........................................................................... 33

8.8.3 Extern Value............................................................................................. 33

8.8.4 Graph........................................................................................................ 33

8.8.5 Dew-Point Calibration............................................................................... 34

8.8.5.1 Offset................................................................................................. 34

8.8.5.2 Calibration......................................................................................... 34

8.8.5.3 Factory Value.................................................................................... 35

8.8.6 Start-up Sequence.................................................................................... 36

8.9 Menu............................................................................................................. 36

8.9.1 System Value............................................................................................ 36

8.9.2 Protocol..................................................................................................... 37

8.9.3 Settings..................................................................................................... 37

8.9.4 Service...................................................................................................... 37

8.9.5 About........................................................................................................ 37

8.9.5.1 Program Update................................................................................ 37

8.9.5.2 Load Factory Values......................................................................... 37

8.9.5.3 ST-Control Update............................................................................ 38

8.9.6 PC OFF .................................................................................................... 38

9Accessories...............................................................................39

9.1 WLAN-USB Adapter for Remote Control.................................................. 39

10 Maintenance...............................................................................40

11 Pin Assignment and Fuses.......................................................41

11.1 Connectors of KF-24/6B............................................................................. 41

11.2 Connectors of KF-18/2B............................................................................. 41

11.3 Connectors of MGK-1B.............................................................................. 42

CONTENT

III

11.4 Fuses and Connectors of TR-KF-24.......................................................... 43

11.5 Fuses and Connectors of TR-KF-18.......................................................... 44

12 Technical Data ...........................................................................45

12.1 Cold Trap KF-24/6B..................................................................................... 45

12.2 Cold Trap KF-18/2B..................................................................................... 46

12.3 Measuring Gas Cooler MGK-1B................................................................. 47

12.4 Temperature Controller TR-KF-24............................................................. 48

12.5 Temperature Controller TR-KF-18............................................................. 48

13 Warranty Conditions .................................................................49

SAFETY INSTRUCTIONS CHAPTER 1

1

1Safety Instructions

1.1 General Safety Instructions

1. Read the safety instructions and the operating instructions first.

2. Pay attention to all the safety warnings.

3. Keep the device away from water or high moisture areas.

4. Keep the device away from dust, sand and dirt.

5. Always ensure there is sufficient ventilation.

6. Do not put the device anywhere near sources of heat.

7. Connect the device only to the power source indicated in the

operating instructions or on the device.

8. Clean the device only according to the manufacturer’s recom-

mendations.

9. Ensure that no liquids or other foreign bodies can find their way

inside the device.

10. The device should only be repaired by qualified personnel.

1.2Special Safety Instructions

The Cold Traps and Temperature Controllers are research

instruments which should only be used for purposes specified in

this manual. Please follow the instructions of this manual in

order to avoid potential harm to the user and damage to instruments.

CHAPTER 2 GENERAL

2

2General

The Cold Traps KF-24/6B,KF-18/2B, and the Measuring Gas

Cooler MGK-1B are suitable for cooling gas to a predetermined

dew-point, so that excess humidity condenses. In this capacity the

devices can be used in the following applications:

-Input control in gas exchange measuring systems

-Humidity compensation (bypass humidity control) in gas ex-

change measuring chambers

-Calibration of measuring devices for humidity determination

(e.g. dew-point mirror or humidity sensors)

Unlike the cold traps, which have one gas conduit, the measuring gas

cooler has two equal gas conduits in parallel for pre-drying a refer-

ence and a sample gas in gas analysis.

The cold traps and the measuring gas cooler require a temperature

controller for operation.

2.1 Transport

Before transport, any condensate has to be drained from the conden-

sate hose; otherwise some of the liquid may run into the gas conduit

of the cold trap, and may be pushed out unintentionally with the gas

flow.

Note: If condensate has entered the gas conduit of the cold trap

or measuring gas cooler, the device must be dried by

flushing it with air for approximately 30 minutes.

COLD TRAP KF-24/6B CHAPTER 3

3

3Cold Trap KF-24/6B

3.1 Installation

The Temperature Controller TR-KF-24 is required for the operation

of the Cold Trap KF-24/6B.

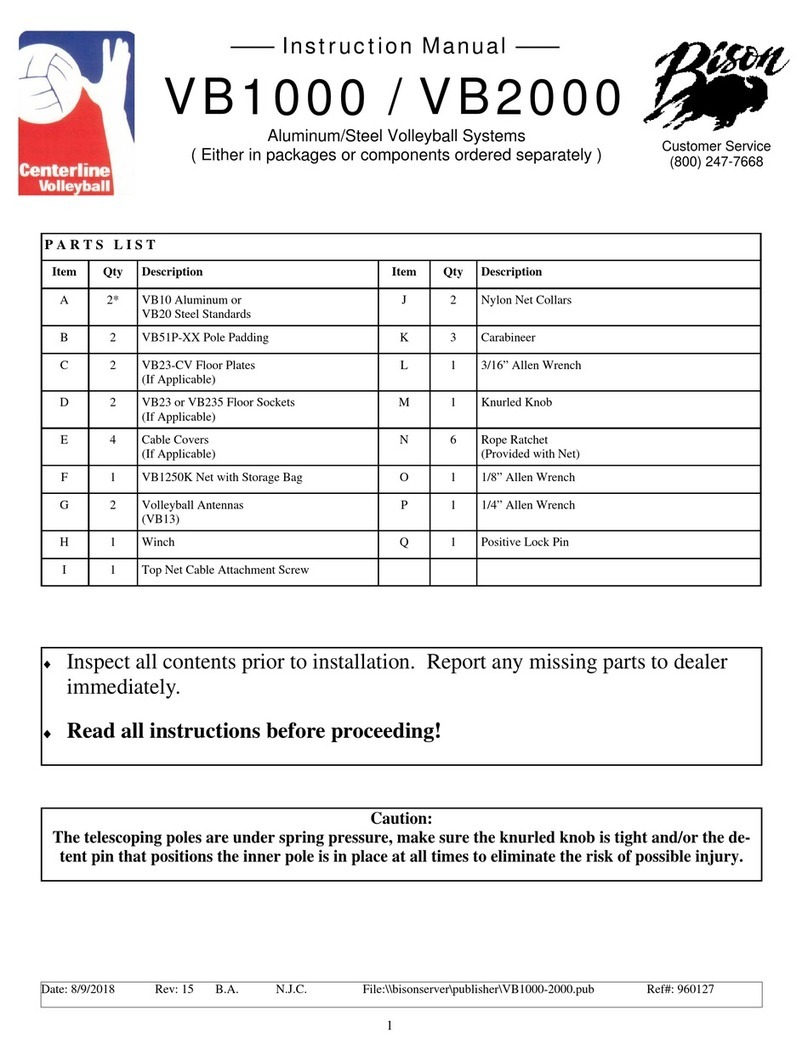

Fig. 1: Cold Trap KF-24/6B; left: Front side; right: Back side

1) Condensate hose with drain cock at the end

2) Gas IN and OUT

3) Connectors for cooling water

4) Connector for Temperature Controller TR-KF-24

5) Pt 100

The Cold Trap KF-24/6B may be operated indoors as well as in the

field. In the field, the user has to ensure that the device is sheltered

from the effects of the weather.

1

2

3

2

45

CHAPTER 3 COLD TRAP KF-24/6B

4

The cold trap must stand upright to enable the condensate to drain off

freely into the hose connected as condensate collector.

Note: The hose must hang free or be arranged so that it can be

filled with condensate, without forming air bubbles.

The collected condensate must be emptied before the hose is

completely filled up via the water drain cock attached to the end of

the hose. If there is some negative pressure in the cold trap,

which is the case if the gas is sucked through it by a gas pump, this

pump must be switched off before the cock is opened for draining;

otherwise, condensate might be sucked into the gas conduit of the

cold trap and enter the downstream measuring system. If the cold

trap is under slight overpressure there is no such risk.

The cold trap must be positioned so that its fan can freely ventilate

the external heat exchangers. Do not cover the fan inlets and outlets.

In order to avoid over-humidification of the downstream

measuring system, the gas flow should only be turned on after

the set dew-point has been reached.

Each cold trap should only be operated with its own matching tem-

perature controller, because calibration values are stored in the tem-

perature controller.

COLD TRAP KF-24/6B CHAPTER 3

5

3.2 System Description

3.2.1 Design

Fig. 2: Cross-section through the Cold Trap KF-24/6B

1) Perspex inserts

2) Platinum temperature sensor Pt 100

3) Peltier elements

4) Heat exchanger for liquid cooling

5) Air heat exchanger

6) Condensate drain

7) Interior part

8) PU-foam

9) Fan

CHAPTER 3 COLD TRAP KF-24/6B

6

The interior part (7) of the cold trap KF-24/6B is thermostated by the

Peltier elements (3). It has two boreholes for the gas conduit. At the

lowest point of this gas conduit there is a condensate drain (6). The

condensate collects here and runs into the condensate hose.

The interior part consists of aluminium, which is anodized for surface

protection. If corrosive gases shall be applied, the inner part can be

manufactured of stainless steel on request. Two Perspex inserts reach

into the inner part. They serve as gas feeders. The Perspex inserts

have inside threads G 1/4", which accommodate hose fittings.

The Peltier elements are in contact with two heat exchangers for

liquid cooling (4) and two heat exchangers for air cooling (5). In

normal operation, the heat generated at the Peltier elements is dissi-

pated by air cooling. For an extended refrigerating capacity, the heat

exchanger (4) can be cooled with water or other cooling liquids.

In the middle of the interior part, two temperature sensors (Pt 100)

(2) are located. One of them acts as actual value sensor for the tem-

perature controller. It is connected to a measuring transducer, which

is mounted under a cylindrical cap at the side of the housing. The

measuring transducer supplies a voltage between 0 and 4.095V,

which is proportional to the measured dew-point in the range of

-50 to 70°C. The other Pt 100 is installed for control measurements.

It is connected to the two screw terminals located at the back side of

the housing.

The cavities between the housing, Peltier elements,and the interior

part are filled with polyurethane foam (8) to provide thermal insula-

tion.

COLD TRAP KF-24/6B CHAPTER 3

7

3.2.2 Function

The Temperature Controller TR-KF-24 is used to set the desired

dew-point temperature of the Cold Trap KF-24/6B. It supplies the

power to the Peltier elements in such a way that the temperature of

the interior part is adjusted to the set dew-point temperature.

Depending on the ambient temperature, the cold trap reaches the set

dew-point after a few minutes. Humid gas is passed through the inte-

rior part of the cold trap, where it cools to the set dew-point tempera-

ture. Condensate falls, collects in the bottom of the cold trap and runs

into the condensate hose.

If a dew-point is desired that is higher than the dew-point of the in-

coming gas, more humidity must be generated by using a gas wash-

ing bottle.

If a dew-point is desired that is close to or higher than the ambient

temperature, the outgoing hose must be heated. By heating the hose,

condensation cannot form inside. Unheated hoses should not be laid

on the ground, which is usually markedly colder than the ambient

environment, especially outside in the field.

If the cold trap operates continuously at dew-point temperatures be-

low 0 °C, the conduits will freeze depending on the flow rate and

humidity of the gas. To defrost the unit, switch off the controller.

Alternatively, the dew-point may be set to 10°C above ambient

temperature. The gas flow should be switched off during

defrosting.

CHAPTER 3 COLD TRAP KF-24/6B

8

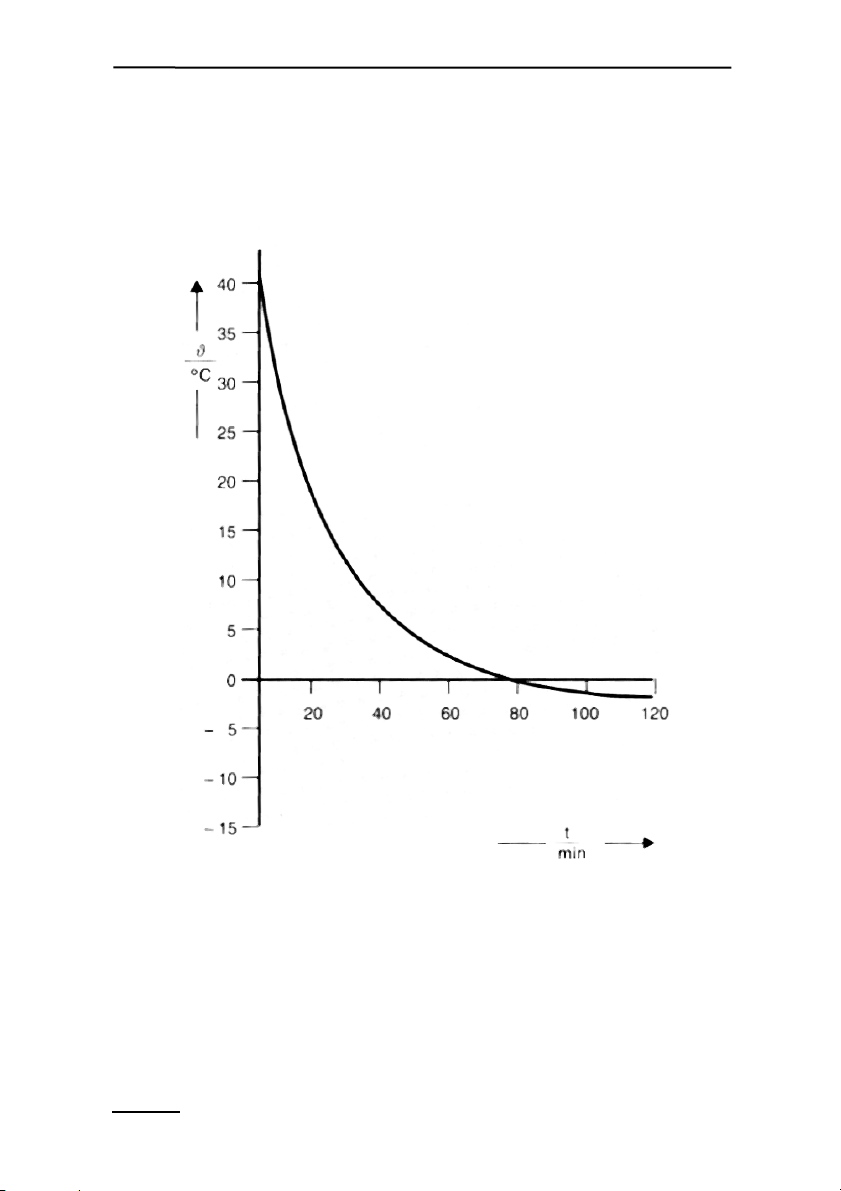

The diagram below (Fig. 3) shows the cooling time at ambient tem-

perature +40 °C down to -1 °C.

Fig. 3: Cooling time from +40 °C to -1 °C for a gas flow of 20 l/min

at 40°C ambient temperature

COLD TRAP KF-18/2B CHAPTER 4

9

4Cold Trap KF-18/2B

4.1 Installation

The Temperature Controller TR-KF-18 and the external AC Power

Supply 3020-N are required for the operation of the Cold Trap KF-

18/2B.

The Cold Trap KF-18/2B can be operated indoors as well as in the

field. In the latter case the user has to ensure that the device is shel-

tered from the effects of the weather.

1) Condensate hose with drain cock at the end

2) Gas IN

3) Gas OUT

2

1

3

Fig. 4: Cold Trap KF-18/2B

CHAPTER 4 COLD TRAP KF-18/2B

10

At the front side of the cold trap is a condensate hose with drain cock

connected. Also at the front side is the gas outlet (OUT). The gas

inlet is located on the top of the cold trap (Fig. 4).

A9-pin jack for the connection of the temperature controller is lo-

cated at the back of the housing beneath the fan.

The cold trap must stand upright to enable the condensate to drain off

freely through the condensate drain into hose connected as conden-

sate collector. For this purpose the rear feet are slightly higher

than the front ones to enable the condensate to flow forwards

into the direction of the condensate hose.

Note: The hose must hang freely or be arranged so that it can be

filled with condensate without forming air bubbles.

The collected condensate must be emptied before the hose is

completely filled via the water drain cock attached to the end of the

hose. If there is some negative pressure in the cold trap, which is

the case if the gas is sucked through it by a gas pump, this pump

must be switched off before the cock is opened for draining;

otherwise, condensate might be sucked into the gas conduit of the

cold trap and enter the downstream measuring system. If the

cold trap is under slight overpressure there is no such risk.

In addition, the cold trap must be positioned such that the fan can

ventilate the external heat exchanger. Do not cover the fan.

In order to avoid over-humidification of the downstream measuring

system, the gas flow should only be turned on after the set dew-point

has been reached.

Each cold trap should only be operated with its own matching tem-

perature controller, because calibration values are stored in the tem-

perature controller.

COLD TRAP KF-18/2B CHAPTER 4

11

4.2 System Description

4.2.1 Design

Fig. 5: Cross-section through Cold Trap KF-18/2B

1) Perspex gas connection

2) Gas outlet

3) PU-foam

4) Gas conduit

5) Condensate drain

6) Housing

7) Interior part

8) Peltier elements

9) Heat exchanger

10) Round jack

11) Fan

12) Temperature sensor Pt 100

13) Temperature sensor Pt 100

CHAPTER 4 COLD TRAP KF-18/2B

12

The interior part (7) of the cold trap KF-18/2 is thermostated by the

Peltier elements (8). It has two boreholes for the gas conduit (4). At

the lowest point of this gas conduit there is a condensate drain (5).

The condensate collects here and runs into the condensate hose.

The interior part consists of aluminium, which is anodized for

surface protection. If corrosive gases shall be applied, the inner

part can be manufactured of stainless steel upon request. A

Perspex insert (1) reaches into the inner part serving as gas

feeder. It has an inside thread G 1/8" accommodating hose

connectors. The gas outlet (2) is located at the front side of the cold

trap.

The air cooling system consists of a heat exchanger (9)

equipped with a fan (11). It dissipates the heat generated at the

Peltier elements.

In the middle of the interior part, two temperature sensors (Pt

100) (12 and 13) are located. One of them (12) acts as actual value

sensor for the temperature controller. It is connected to a

measuring transducer, which is mounted under the cylindrical

protective cap at the side of the housing. The measuring

transducer supplies a voltage between 0 and 4.095V, which is

proportional to the measured dew-point in the range of -50 to

+70°C. The other Pt 100 (13) is installed for control measurements.

It can be accessed via sockets also located beneath the cylindrical

protective cap.

The cavities between the housing, Peltier elements and the interior

part are filled with polyurethane foam (8) to provide thermal insula-

tion.

COLD TRAP KF-18/2B CHAPTER 4

13

4.2.2 Function

The Temperature Controller TR-KF-18 is used to set the desired

dew-point temperature of the Cold Trap KF-18/2B. It controls the

supplied power in such a way that the Peltier elements cool the inte-

rior part to the set dew-point temperature. Depending on the ambient

temperature, the cold trap reaches the set dew-point after a few min-

utes. For further information, see function of Cold Trap KF-24/2B

(chapter 3.2.2).

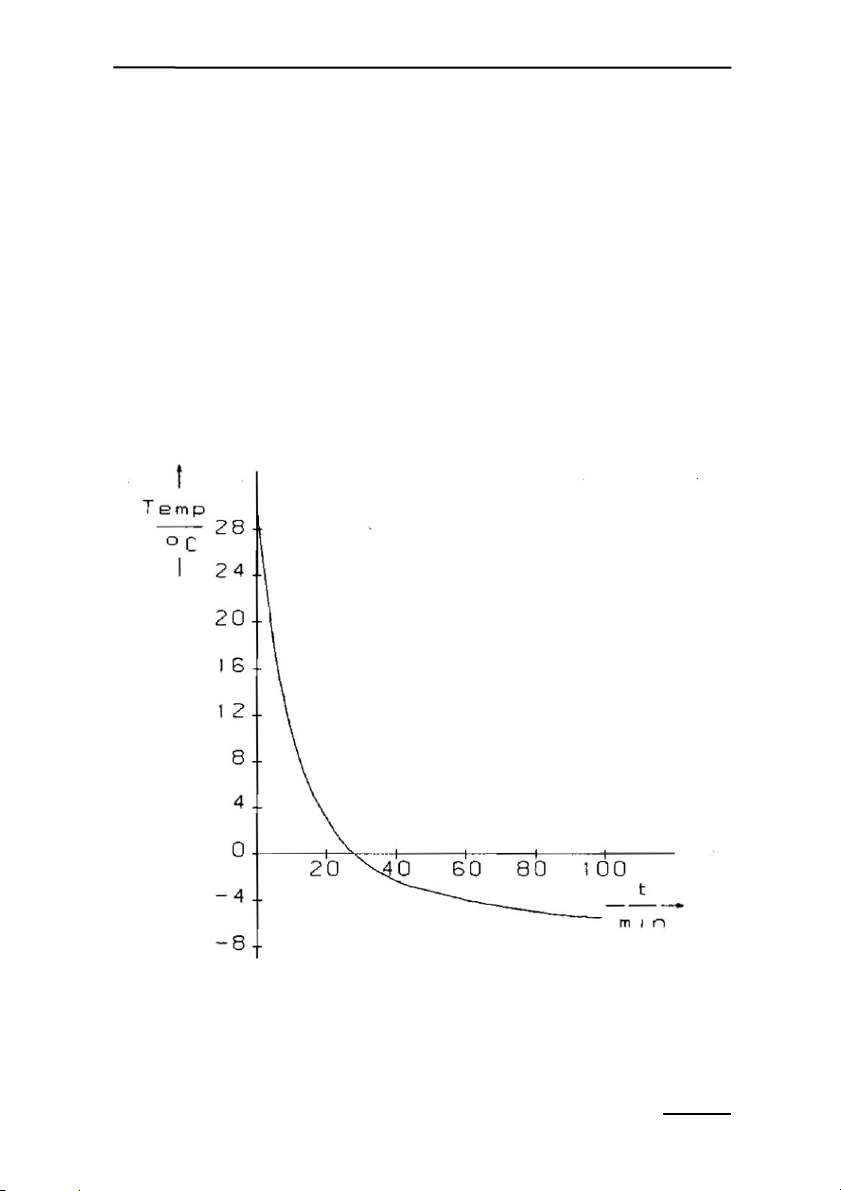

The diagram below (Fig. 6) shows the cooling time for +30 °C down

to -5.5 °C.

Fig. 6: Cooling time for +30 °C down to -5.5 °C for a gas flow of

4 l/min

CHAPTER 4 COLD TRAP KF-18/2B

14

If the measuring gas cooler operates continuously at dew-point tem-

peratures below 0 °C, the conduits may freeze,depending on

the quantity and humidity of the gas. To defrost the unit, switch

off the controller. Alternatively, the dew-point may be set to 10°C

above ambient temperature. The gas flow should be switched off

during defrosting.

Defrosting can be accelerated by removing the Perspex insert from

the interior part. This can be done by loosening the two knurled nuts

at the gas inlet and taking the aluminium plate off. With slight

turning movements the Perspex unit can be withdrawn.

This manual suits for next models

4

Table of contents

Other Heinz Walz Accessories manuals

Popular Accessories manuals by other brands

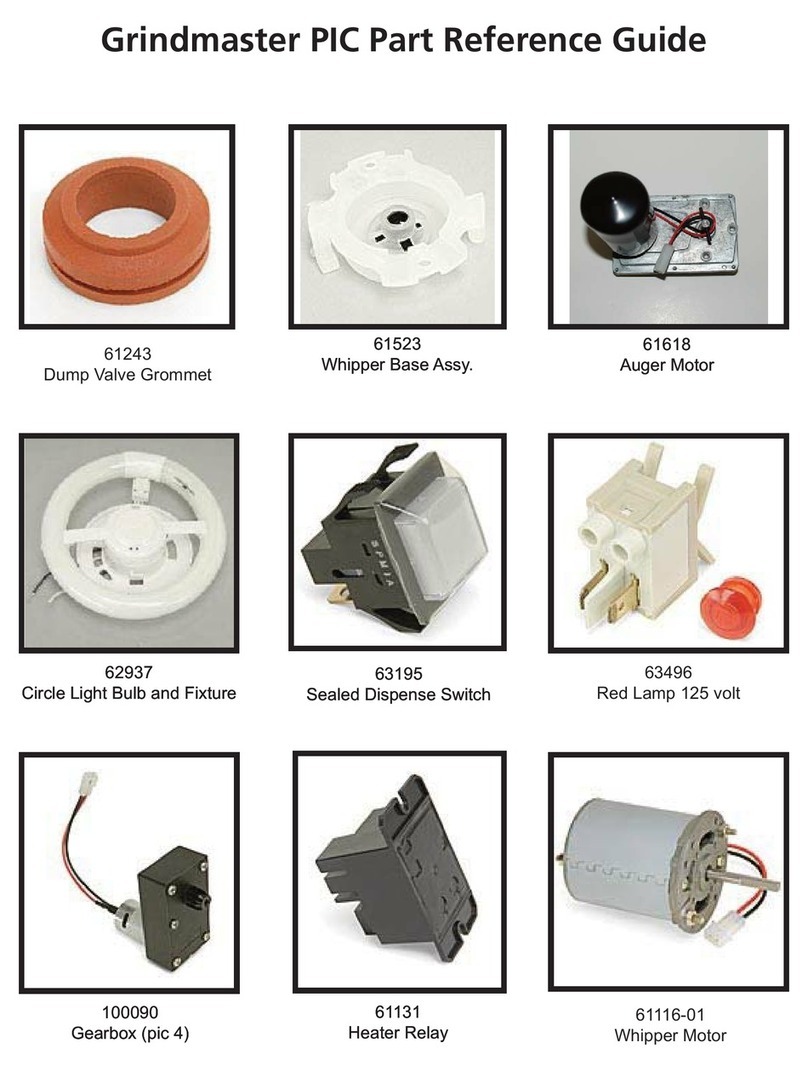

Grindmaster

Grindmaster PIC-4 Series Parts reference guide

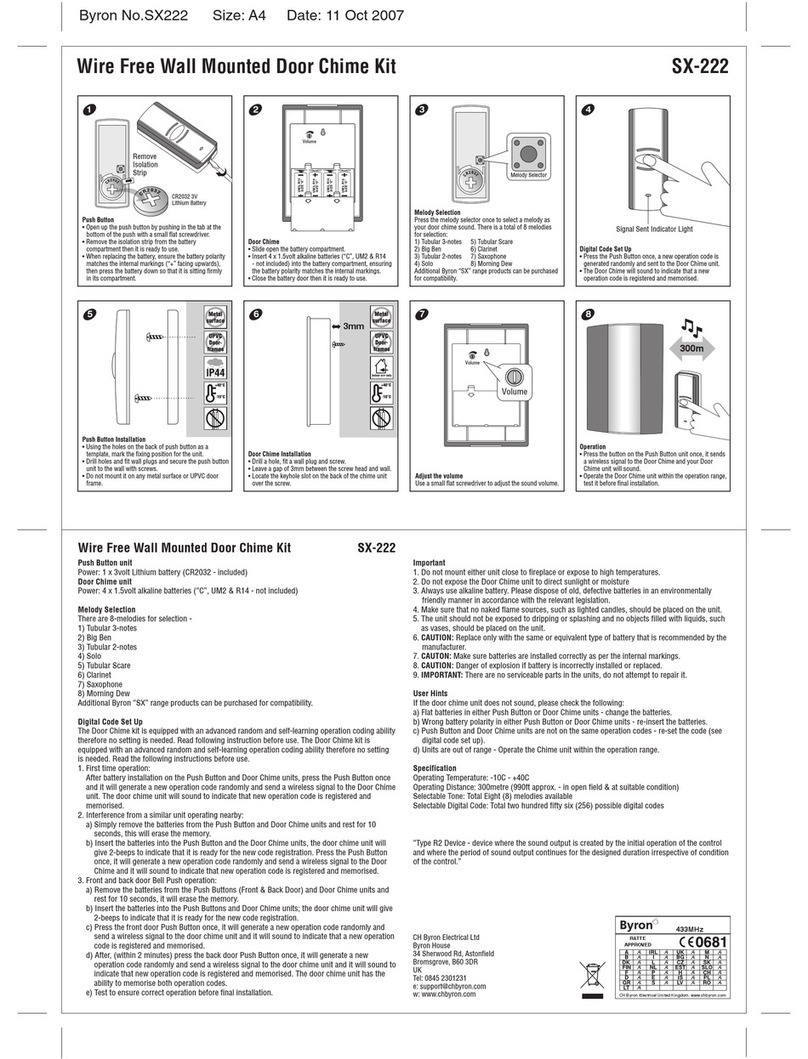

Bison

Bison VB1000 instruction manual

IFM Electronic

IFM Electronic PN50 Series operating instructions

Byron

Byron SX-222 Installation and operation instruction

IMI SENSORS

IMI SENSORS 640B02 Installation and operating manual

ADEMCO

ADEMCO 2700ECM Installation and maintenance instructions