Heinzmann StG 2120 Series User manual

Heinzmann GmbH & Co. KG

Engine & Turbine Management

Am Haselbach 1

D-79677 Schönau (Schwarzwald)

Germany

Phone +49 7673 8208-0

Fax +49 7673 8208-188

www.heinzmann.com

V.A.T. No.: DE145551926

HEINZMANN

Electronic Speed Governors

Explosion Proof Actuators

StG 2120.xx

StG 30.90-xx

StG 40.90-xx

Copyright 2001 by Heinzmann GmbH & Co. KG. All rights reserved. This document may not be reproduced or handed on to third parties.

Manual T 02 001-e / 12-09

Read this entire manual and all other publications appertaining to the

work to be performed before installing, operating or servicing your

equipment.

Practice all plant and safety instructions and precautions.

Failure to follow instructions may result in personal injury and/or

damage to property.

HEINZMANN will refuse all liability for injury or damage which

results from not following instructions

Please note before commissioning the installation:

Before starting to install any equipment, the installation must have been

switched dead!

Be sure to use cable shieldings and power supply connections meeting

the requirements of the European Directive concerning EMI.

Check the functionality of the existing protection and monitoring

systems.

To prevent damages to the equipment and personal injuries, it is

imperative that the following monitoring and protection systems

have been installed:

Overspeed protection acting independently of the speed governor

Overtemperature protection

HEINZMANN will refuse all liability for damage which results from

missing or insufficiently working overspeed protection

Generator installation will in addition require:

Overcurrent protection

Protection against faulty synchronization due to excessive frequency,

voltage or phase differences

Reverse power protection

Overspeeding can be caused by:

Failure of the voltage supply

Failure of the actuator, the control unit or of any accessory device

Sluggish and blocking linkage

Warning

Danger

Danger

Danger!

High

Voltage

Danger

The examples, data and any other information in this manual are

intended exclusively as instruction aids and should not be used in any

particular application without independent testing and verification by

the person making the application.

Independent testing and verification are especially important in any

application in which malfunction might result in personal injury or

damage to property.

HEINZMANN make no warranties, express or implied, that the

examples, data, or other information in this volume are free of error,

that they are consistent with industry standards, or that they will meet

the requirements for any particular application.

HEINZMANN expressly disclaim the implied warranties of

merchantability and of fitness for any particular purpose, even if

HEINZMANN have been advised of a particular purpose and even if a

particular purpose is indicated in the manual.

HEINZMANN also disclaim all liability for direct, indirect, incidental

or consequential damages that result from any use of the examples,

data, or other information contained in this manual.

HEINZMANN make no warranties for the conception and engineering

of the technical installation as a whole. This is the responsibility of the

user and of his planning staff and specialists. It is also their

responsibility to verify whether the performance features of our devices

will meet the intended purposes. The user is also responsible for correct

commissioning of the total installation.

Warning

Danger

Contents

Explosion Proof Actuators StG 2120.xx, StG 30.90-xx, StG 40.90-xx

Contents

Page

1 Safety Instructions and Related Symbols ........................................................................... 1

1.1 Basic Safey Measures for Normal Operation.................................................................. 2

1.2 Basic Safety Measures for Servicing and Maintenance .................................................. 2

1.3 Before Putting an Installation into Service after Maintenance and Repair Works ......... 3

2 General ................................................................................................................................... 4

2.1 Scope of Delivery ............................................................................................................ 4

2.2 Description of Function................................................................................................... 5

3 Technical Informationen ...................................................................................................... 6

3.1 Technical Data................................................................................................................. 6

3.2 Measurements.................................................................................................................. 7

4 Mounting and Connection .................................................................................................. 10

4.1 Mounting ....................................................................................................................... 10

4.2 Electrical Connection .................................................................................................... 11

5 Operation ............................................................................................................................. 12

5.1 Commisioning ............................................................................................................... 12

5.2 Operation ....................................................................................................................... 12

6 Maintenance and Service.................................................................................................... 13

7 Download of Manuals ......................................................................................................... 14

1 Safety Instructions and Related Symbols

Explosion Proof Actuators StG 2120.xx, StG 30.90-xx, StG 40.90-xx 1

1Safety Instructions and Related Symbols

This publication offers wherever necessary practical safety instructions to indicate inevitable

residual risks when operating the engine. These residual risks imply dangers to

persons

product and engine

environment.

The symbols used in this publication are in the first place intended to direct your attention to

the safety instructions!

This symbol is to indicate that there may exist dangers to the engine, to

the material and to the environment.

This symbol is to indicate that there may exist dangers to persons.

(Danger to life, personal injury)

This symbol is to indicate that there exist particular dangers due to

electrical high tension. (Mortal danger).

This symbol does not refer to any safety instructions but offers important notes for

better understanding the functions that are being discussed. They should by all

means be observed and practised. The respective text is printed in italics.

The primary issue of these safety instructions is to prevent personal injuries!

Whenever some safety instruction is preceded by a warning triangle labelled “Danger” this is

to indicate that it is not possible to definitely exclude the presence of danger to persons,

engine, material and/or environment.

If, however, some safety instruction is preceded by the warning triangle labelled “Caution”

this will indicate that danger of life or personal injury is not involved.

Note

Warning

Dan

g

er

Danger!

High

V

olta

g

e

1 Safety Instructions and Related Symbols

2 Explosion Proof Actuators StG 2120.xx, StG 30.90-xx, StG 40.90-xx

The symbols used in the text do not supersede the safety instructions. So please do not

skip the respective texts but read them thoroughly!

In this publication the Table of Contents is preceded by diverse instructions that

among other things serve to ensure safety of operation. It is absolutely imperative

that these hints be read and understood before commissioning or servicing the

installation.v

1.1 Basic Safey Measures for Normal Operation

The installation may be operated only by authorized persons who have been duly

trained and who are fully acquainted with the operating instructions so that they are

capable of working in accordance with them.

Before turning the installation on please verify and make sure that

- only authorized persons are present within the working range of the engine;

- nobody will be in danger of suffering injuries by starting the engine.

Before starting the engine always check the installation for visible damages and make

sure it is not put into operation unless it is in perfect condition. On detecting any faults

please inform your superior immediately!

Before starting the engine remove any unnecessary material and/or objects from the

working range of the installation/engine.

Before starting the engine check and make sure that all safety devices are working

properly!

1.2 Basic Safety Measures for Servicing and Maintenance

Before performing any maintenance or repair work make sure the working area of the

engine has been closed to unauthorized persons. Put on a sign warning that maintenance

or repair work is being done.

Before performing any maintenance or repair work switch off the master switch of the

power supply and secure it by a padlock! The key must be kept by the person

performing the maintenance and repair works.

Before performing any maintenance and repair work make sure that all parts of engine

to be touched have cooled down to ambient temperature and are dead!

Refasten loose connections!

Replace any damaged lines and/or cables without delay!

1 Safety Instructions and Related Symbols

Explosion Proof Actuators StG 2120.xx, StG 30.90-xx, StG 40.90-xx 3

Keep the cabinet always closed. Access should be permitted only to authorized perssons

having a key or tools.

Never use a water hose to clean cabinets or other casings of electric equipment!

1.3 Before Putting an Installation into Service after Maintenance and Repair

Works

Check on all slackened screw connections to have been tightened again.

Make sure the control linkage has been reattached and all cables have been reconnected.

Make sure all safety devices of the installation are in perfect order and are working

properly!

2 General

4 Explosion Proof Actuators StG 2120.xx, StG 30.90-xx, StG 40.90-xx

2General

2.1 Scope of Delivery

Actuator StG 2120.xx or Actuator StG xx.90-xx

Optionally: Coupling

Optionally: 1" control valve or 1.5" control valve for metering gaseous fuel for gas

turbines

Optionally: Control lever

The following cable glants M 20x1,5 can be used:

Manufacturer: AGRO AG

Type: 1820.11.26

Test certificat: PTB 00 ATEX 1059

Manufacturer: Hawke

Type: 501/453 RAC

Test certificat: BAS 01 ATEX 2072X.

Manufacturer: Hawke

Type: CSB 656

Test certificat: BAS 01 ATEX 2079X

2 General

Explosion Proof Actuators StG 2120.xx, StG 30.90-xx, StG 40.90-xx 5

2.2 Description of Function

The explosion-proof actuator types StG 2120.xx and StG xx90-xx, type of protection

flameproof enclosure “d”, are used for actuating gas valves in gas turbine control

applications.

These actuators are distinguished by following features:

Fast response and high torque in either direction

Low consumption of electric energy

Operation within a wide range of supply voltage

To be mounted in any position

Test certificate for use in hazardous environments

The actuator represents the actuation unit within a closed control loop of gas, steam and

water turbines. By means of this unit, an electric signal from the control unit is converted

into mechanical movement for actuating valves of diverse design.

The rotating movement of the integrated actuator control output shaft of the StG2120

series is generated by a rotary magnet system. This design does not require any gearing.

For the StG xx.90-xx series DC disk motors are used as drives. Torque is transmitted to the

output shaft by a twin-stage gear.

Non-contacting sensing is used to scan the feedback cam on the control output shaft. The

electric signal is a function of the wave position.

3 Technical Informationen

6 Explosion Proof Actuators StG 2120.xx, StG 30.90-xx, StG 40.90-xx

3Technical Informationen

3.1 Technical Data

Description StG 2120 StG 30.90-xx StG 40.90-xx

Rotation angle 68° 90° 90°

Max. torque 12 Nm 22 Nm 44 Nm

Torque in steady state

condition 4 Nm 7.5 Nm 14.5 Nm

Current consumption of

whole governor

Max. current 7 A approx. 5 A approx. 7 A

Safe current in steady

state condition approx. 2.3 A approx. 1.7 A approx. 2.3 A

Resistance of coil system ca. 2,1 Ohm ca. 2 Ohm ca. 1 Ohm

Number of cable bushings 2 x M 20x1,5 2 x M 20x1,5 2 x M 20x1,5

Ambiente temperature

during operation * -20°C up to +60°C -20°C up to +60°C -20°C up to +60°C

Type of protection „e“ II 2 G EEx d IIB

T5

II 2 G EEx d IIB

T5

II 2 G EEx d IIB T5

Protection grade IP 55 IP 55 IP 55

Weigth 31 kg 24.5 kg 24.5 kg

*Operating ambient temperature for StG 30.90-06: -20°C to +40°C

3 Technical Informationen

Explosion Proof Actuators StG 2120.xx, StG 30.90-xx, StG 40.90-xx 7

3.2 Measurements

Figure 1: StG xx.90-xx

F¤ll ung Fuel Combust i ble

50

0

100

125+/-0,1

150

M8 90 20

162

62

22

19

17

108

178

12

70+/-0,1

104

82,5

M10

88

50

3,5

19,5

1770+/-0,1

130,5

M20x1,5

M20x1,5

100

F¤llung Fuel Combustible

0

50

100+/-0,1

274

295

35

90°

SAE-Serration

1/2"-36

166

214

21

21

86

3 Technical Informationen

8 Explosion Proof Actuators StG 2120.xx, StG 30.90-xx, StG 40.90-xx

70

100+/-0,1

134

86

227+/-2

B

Screwing cable gland 20x1,5

Screwing cable gland 20x1,5

3 Technical Informationen

Explosion Proof Actuators StG 2120.xx, StG 30.90-xx, StG 40.90-xx 9

A

B

168+/-0,1

225+/-0,1

253+/-0,1

Figure 2: StG 2120.xx

A

125+/-0,1

224

290

18

4xM10-20 tief

SAE-Serration

1/2"-36

SAE-Serration

1/2"-36

18

33

33

4 Mounting and Connection

10 Explosion Proof Actuators StG 2120.xx, StG 30.90-xx, StG 40.90-xx

4Mounting and Connection

4.1 Mounting

Any works on the actuators may be performed only by properly trained

specialists and in compliance with applicable standards.

For metering gaseous fuels for gas turbines, both actuators are available as a complete set

with a 1" or 1.5" control valve.

The mounting location must be chosen in such a way as to avoid vibrations and shocks as

far as possible.

Furthermore, the mounting location of the actuator must be chosen in accordance with the

protection grade.

In principle, any mounting position is admissible. One should, however, avoid mounting

the actuators in such a way that the screwed cable glands are pointing upward.

Warning

4 Mounting and Connection

Explosion Proof Actuators StG 2120.xx, StG 30.90-xx, StG 40.90-xx 11

4.2 Electrical Connection

Any works on the actuators may be performed only by properly trained

specialists and in compliance with applicable standards.

Be sure to follow the connection diagram of the plant manufacturer when installing the

electric connection. All cable sizes must be chosen in accordance with the specification.

Up to 10 m 2,5 mm2

More than 10 – 20 m 4,0 mm2

More than 20 – 40 m 6,0 mm2

The actuator is driven by a HEINZMANN control unit. In special

cases, the actuator may be connected to some other control as provided

by the plant manufacturer. This will, however, require that

HEINZMANN have explicitly agreed and that the specifications

provided by HEINZMANN be strictly observed

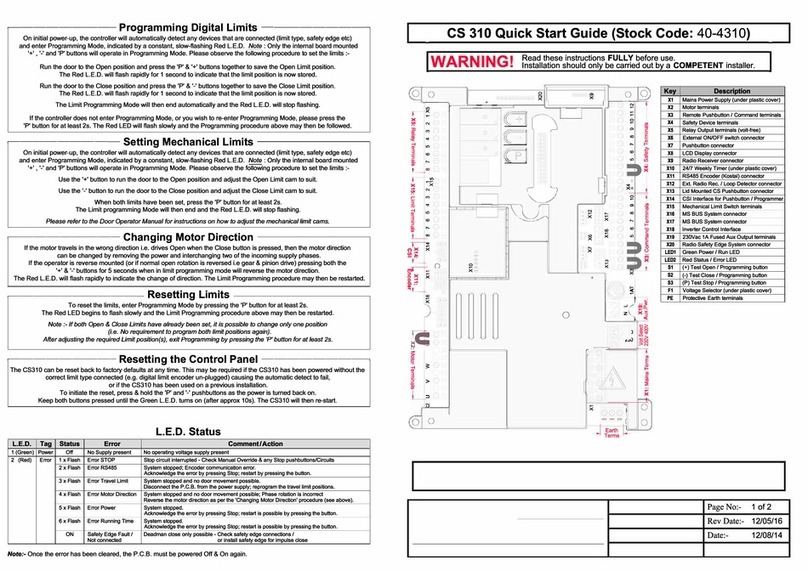

2

1

3

4

5

l

StG

1212

11

48

49

DC XX.2-01

JHMNG

KG 30 / KG 40

Figure 3: Electrical Connection

Good earthing according to standards must be ensured. The actuator type StG 2120.xx has

a separate earthing screw which must be secured properly.

Warning

Warning

Fehler! Verweisquelle konnte nicht gefunden werden. Operation

Explosion Proof Actuators StG 2120.xx, StG 30.90-xx, StG 40.90-xx

12

5Operation

5.1 Commisioning

Any works on the actuators may be performed only by properly trained

specialists and in compliance with applicable standards.

The user is responsible for correct and proper commissioning of the installation as a whole.

Please note before commissioning the installation:

Before starting to install any equipment, the installation must have been switched

dead!

Check the functionability of the existing protection and monitoring systems.

Commissioning may be conducted only with the cover of the terminal box mounted.

5.2 Operation

The actuator must be operated in such manner as to safely exclude any damages.

With particular regard to electric and technical operating, the device may be used only in

conformance with the specifications.

Warning

5 Maintenance and Service

Explosion Proof Actuators StG 2120.xx, StG 30.90-xx, StG 40.90-xx

13

6Maintenance and Service

Any repair work may be executed only and exclusively at the factory of the

manufacturer.

Before cleaning the device, make absolutely sure that it has been switched

dead!

The device must be regularly checked for damages.

The exterior of the device must be kept in orderly condition. The surface may not be damaged

mechanically or by chemical substances.

For cleaning the device, only methods conforming with the protection grade may be applied.

The actuator must always be kept in clean condition. In order to prevent accumulation of heat,

any soiling of the exterior should be avoided.

The device may not be opened under any circumstances by the user.

Warning

Warning

7 Download of Manuals

Explosion Proof Actuators StG 2120.xx, StG 30.90-xx, StG 40.90-xx

14

7Download of Manuals

Technical manuals can be downloaded in pdf-format from our homepage:

www.heinzmann.com

If the desired manual should not be available there, send an e-mail to:

or write to:

HEINZMANN GmbH & Co. KG

Technische Redaktion

Am Haselbach 1

D-79677 Schönau/Germany

Please include the following information:

your name

name and address of your company

e-mail or address where you want the manuals to be sent to (if different from above)

item code (as on front page, bottom right) and title of the desired manual

or alternatively the technical data of your HEINZMANN equipment

We would be pleased to receive your comments about the contents and presentation of our

publications. Send your comments to the e-mail or address shown above please.

This manual suits for next models

2

Table of contents

Other Heinzmann Controllers manuals