HELIX Compressor 9600 Manual

©2007 Helix Technology Corporation Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 iii

The information in this document is believed to be accurate and reliable. However,

Helix Technology Corporation, cannot accept any financial or other responsibilities that may

result from the use of this information. No warranties are granted or extended by this

document.

Helix Technology Corporation reserves the right to change any or all information contained

herein without prior written notice. Revisions may be issued at the time of such changes

and/or deletions.

Any duplication of this manual or any of its parts without expressed written permission from

Helix Technology Corporation is strictly prohibited.

Any correspondence regarding this document should be forwarded to:

Helix Technology Corporation

Mansfield Corporate Center

Nine Hampshire Street

Mansfield, Massachusetts 02048-9171 U.S.A.

Telephone: (508) 337-5000

FAX: (508) 337-5464

The following Helix Technology Corporation trademarks and service marks may appear in

this document:

All other trademarks or registered trademarks are the property of their respective holders.

Conductron®Convectron®Cryodyne®Cryogem®

Cryogenerator®Cryo-Torr®CTI-Cryogenics®FastRegen™

GOLDLink®Granville-Phillips®GUTS®Helix®

Helix Technology..

Your Vacuum ConnectionSM Micro-Ion®Mini-Convectron®Mini-Ion™

On-Board®RetroEase®RetroFast®Stabil-1®

Stabil-Ion®ThinLine™ TurboPlus®TrueBlueSM

Vacuum AssuranceSM

©2007 Helix Technology Corporation Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 v

Table of Contents

Table of Contents

Figures

Tables

Safety Conventions

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-1

Signal Word Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-1

Safety Shape Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-2

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-2

Section 1 - 9600 Compressor Description

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Compressor Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

System Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

CTI-CRYOGENICS Helium Refrigeration System . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Cooling Water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Component Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

System Circuit Breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Elapsed Time Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Control Circuit Breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Power ON Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Gas Charge Flared Fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Helium Pressure Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Power Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Return Gas Coupling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Cooling Water IN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Cooling Water OUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Cryopump Electrical Outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Compressor Remote Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Supply Gas Coupling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

vi Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 ©2007 Helix Technology Corporation

Multiple On-Board Cryopump Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Multiple Cryo-Torr Cryopump Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Section 2 - Unpacking and Inspection

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Shipping Carton Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Removal from Shipping Carton . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Compressor Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Helium "OFF" Condition Pressure Verification . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Shipping Carton Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Section 3 - Installation

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Supply and Return Water Line Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Hard Water Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Flexible Water Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Phase Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Connecting/Disconnecting Helium Flex Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Connecting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Disconnecting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Single On-Board Cryopump Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Multiple On-Board Cryopump Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Helium Line Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Power Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Multiple Cryo-Torr Cryopump Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Helium Line Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Power Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Section 4 - Operation

Adjusting System Helium Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

"OFF" Condition Helium System Pressure Verification . . . . . . . . . . . . . . . . . . . . . 4-1

Compressor Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Replacement of Helium Circuit Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Section 5 - Maintenance

Scheduled Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Suggested Maintenance Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Adsorber Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Adjusting System Helium Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

©2007 Helix Technology Corporation Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 vii

Reducing Helium Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Increasing Helium Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Adding Helium . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Appendix A - Customer Support Information

Customer Support Center Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Guaranteed Up-Time Support (GUTS®) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Product Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

E-mail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Appendix B - Flow Diagram

Appendix C - Troubleshooting Procedures

Troubleshooting the Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Technical Inquiries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Appendix D - Schematic

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Index

viii Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 ©2007 Helix Technology Corporation

©2007 Helix Technology Corporation Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 ix

Figures

Figure 1-1: 9600 Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Figure 1-2: 9600 Compressor Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Figure 1-3: Water Flow Rate versus Pressure Drop . . . . . . . . . . . . . . . . . . . . . 1-6

Figure 1-4: 9600 Compressor Rear View Component Locations. . . . . . . . . . . 1-8

Figure 1-5: 9600 Compressor Connected to Multiple On-Board Cryopumps 1-12

Figure 1-6: 9600 Compressor Connected to Multiple Cryo-Torr Cryopumps 1-13

Figure 3-1:9600 Compressor Installation Flowchart . . . . . . . . . . . . . . . . . . . . 3-2

Figure 3-2: 9600 Compressor Circuit Breaker Terminals (Cover Removed) . 3-5

Figure 3-3:Connecting/Disconnecting Helium Flex Line Couplings. . . . . . . . 3-8

Figure 3-4: Single On-Board Cryopump Connections . . . . . . . . . . . . . . . . . . . 3-9

Figure 3-5: Single Cryo-Torr Cryopump Installation. . . . . . . . . . . . . . . . . . . 3-10

Figure 3-6: Recommended Multiple On-Board Cryopump or Waterpump Installation

(Splitter Box located at Process Tool) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Figure 3-7: Alternative Multiple On-Board Cryopump or Waterpump Installation

(Splitter Box located at Compressor) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Figure 3-8: Multiple Cryo-Torr Cryopump Installation . . . . . . . . . . . . . . . . . 3-15

Figure 3-9: Multiple Cryo-Torr Cryopump Installation . . . . . . . . . . . . . . . . . 3-16

Figure 5-1: Disconnecting Self Sealing Couplings. . . . . . . . . . . . . . . . . . . . . . 5-2

Figure 5-2: Adsorber Location in 9600 Compressor (Rear Panel Removed). . 5-4

Figure 5-3: Helium Pressure Control Components. . . . . . . . . . . . . . . . . . . . . . 5-5

Figure B-1: 9600 Compressor Flow Diagram P/N 8135001 Rev. A . . . . . . . . B-2

Figure D-1: 9600 High Voltage Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . D-4

x Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 ©2007 Helix Technology Corporation

©2007 Helix Technology Corporation Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 xi

Tables

Table 1-1:Compressor Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Table 1-2:Electrical Input Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Table 1-3:Cooling Water Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Table 1-4:General Compressor Operating Specifications . . . . . . . . . . . . . 1-7

Table 1-5:Cryopump Electrical Outlet Pin Assignments . . . . . . . . . . . . . 1-11

Table 1-6:Compressor Remote Connector Pin Assignments . . . . . . . . . . 1-11

Table 4-1:9600 Compressor Helium ("OFF" Condition) Charge. . . . . . . . 4-1

Table 5-1:Suggested Maintenance Equipment . . . . . . . . . . . . . . . . . . . . . . 5-1

Table C-1:Compressor Troubleshooting Procedures . . . . . . . . . . . . . . . . . C-2

Table D-1:Basic Control Assembly Legend. . . . . . . . . . . . . . . . . . . . . . . . D-1

Table D-2:On-Board/Cryo Electrical Module P/N 8135127G002 Legend D-2

Table D-3:On-Board Output Module P/N 8135148G001 Legend . . . . . . . D-3

xii Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 ©2007 Helix Technology Corporation

©2007 Helix Technology Corporation Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 S-1

Safety Conventions

Introduction

Follow all safety precautions during installation, normal operation, and when

servicing CTI-Cryogenics products.

This chapter explains the safety conventions used throughout this manual.

CTI-Cryogenics uses a specific format for cautions and warnings, which includes

standard signal words and safety shapes.

See also the Customer Support appendix or call your local Customer Support

Center for assistance.

Signal Word Descriptions

All cautions and warnings contain signal words, which call attention to safety

messages and designate the degree of hazard seriousness. The following table

shows the signal words and their meanings that may be used in this document.

Term Example Definition

CAUTION

A signal word accompanied by a safety shape

that indicates a potentially hazardous situation

or unsafe practice.

If not avoided, the action may result in minor

or moderate personal injury or equipment

damage. A CAUTION is highlighted in

yellow.

CAUTION

A signal word that indicates a situation or

unsafe practice, which if not avoided may

result in equipment damage. A CAUTION is

highlighted in yellow.

WARNING

A signal word accompanied by a safety shape

that indicates indicates a potentially hazardous

situation.

If not avoided, the action may result in serious

injury or death. A WARNING is highlighted

in orange.

Safety Shape Descriptions

S-2 Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 ©2007 Helix Technology Corporation

Safety Shape Descriptions

All cautions and warnings contain safety shapes, which have specific safety

meanings. The following table shows some of the safety shapes used in this

document and their meanings.

References

For more information about safety standards, see the following documents:

• ISO 7010: 2003(E), Graphic symbols - Safety colours and safety

signs - Safety signs used in workplaces and public areas

• ISO 3864-1: 2002(E), Graphic symbols - Safety colours and safety

signs - Part 1: Design principles for safety signs in workplaces and

public areas

Example Term Shape Definition

General Warning Indicates a general hazard. Details about this

hazard appear in the safety notice explanation.

High Voltage Indicates a high voltage hazard.

Hot Surface Indicates a surface is hot enough to cause

discomfort or a burn.

©2007 Helix Technology Corporation Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 1-1

Section 1 - 9600 Compressor Description

General

This manual provides the information required to install, operate, and

maintain the CTI-CRYOGENICS 9600 Compressor.

NOTE: All personnel with installation, operation, and maintenance

responsibilities should become familiar with the contents of both the 9600

Compressor Installation, Operation, Maintenance, and appropriate

cryopump manuals to ensure safe, high quality, and reliable system

performance.

Compressor Configurations

The 9600 Compressor supports either On-Board or Cryo-Torr Cryopumps.

For multiple cryopump installations, an On-Board Splitter Box or Cryo-

Torr Interface can be used for cold head power distribution that reduces

total cable requirements as shown in Figure 1-5 and Figure 1-6.

System Documentation

The manuals for a system cover two basic components: the cryopump and

the Compressor. A manual is shipped with each system component to

provide information for installation and operation of that component. A

loose-leaf binder with index tab separators is also provided so you can

compile a complete set of tabulated manuals.

CTI-CRYOGENICS Helium Refrigeration System

The operation of CTI-CRYOGENICS’ cryopumps is based upon a closed

loop helium expansion cycle. The system is made up of two major

CAUTION

Refer to “Appendix A - Customer Support Information” to contact the

local Customer Support Center for information on connecting 9600

Compressors to a manifold with other CTI-CRYOGENICS

compressors.

CTI-CRYOGENICS Helium Refrigeration System

1-2 Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 ©2007 Helix Technology Corporation

components: the cryopump, which contains the cold head, and the helium

Compressor which compresses the helium gas.

Refrigeration is produced in the cryopump cold head through periodic

expansion of high pressure helium in a regenerative process. The high

pressure helium is provided by the Compressor. Low pressure helium

returning from the cold head is compressed into the necessary high

pressure to be returned to the cold head. The energy required to compress

the helium is rejected as heat through the cooling water.

High pressure room temperature helium is transferred to the cold head

through the supply lines. After expansion, low pressure helium is returned

to the Compressor (at or near room temperature) to repeat the cycle in a

closed loop fashion. Large separation distances can be accommodated

between the Compressor and the cryopump.

In the Compressor, helium is compressed using a highly reliable oil

lubricated commercial Compressor. Helium purification takes place via

several stages of oil removal. The final stage of purification is performed

with a replaceable adsorber cartridge. In order to maintain peak efficiency,

the adsorber must be replaced every three years. The 9600 Compressor is

shown in Figure 1-1.

©2007 Helix Technology Corporation Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 1-3

Figure 1-1: 9600 Compressor

9600

COMPRESSOR

COMPRESSOR

9600

Specifications

1-4 Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 ©2007 Helix Technology Corporation

Specifications

Dimensions

The dimensions of the Compressor are shown in Figure 1-2.

Figure 1-2: 9600 Compressor Dimensions

19.52 in.

(496 mm) 21.50 in.

(546 mm) 1.28

(32mm)

23.36 in.

(593 mm)

3.18 in.

(81 mm)

14.4 in.

(366 mm)

CAUTION

Do not place a weight greater than 75 lbs. (34Kg) on top of the

Compressor.

©2007 Helix Technology Corporation Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 1-5

Weight

The weight of the Compressor is listed in Table 1-1.

Electrical

The electrical specifications of the Compressor are listed in Table 1-2.

Cooling Water

The water used to cool the Compressor must meet the specifications shown

in Table 1-3 for proper system operation.

Table 1-1: Compressor Weight

Weight lbs./kg

267/121kg

Table 1-2: Electrical Input Specifications

Parameter Value

Operating Voltage Range/Frequency 342-457V/50 Hz

342-506V/60 Hz

Phase 3

Nominal Input Power 5.5 KW/60 Hz

5KW/50 Hz

Nominal Power Factor 0.85

Rated FL/LR* Current 8/40

Minimum Electrical Service 15 Amps

*FL/LR = Full Load/Locked Rotor

Table 1-3: Cooling Water Specifications

Parameter Value

Maximum Inlet Temperature 90°F (32°C)

Minimum Inlet Temperature 50°F (10°C)

Flow Rate 2.75 ±1.25 gpm (10.4 ± 4.7 lpm)

NOTE: Water conditioning may be required for applications not meeting these requirements.

Specifications

1-6 Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 ©2007 Helix Technology Corporation

Figure 1-3: Water Flow Rate versus Pressure Drop

General

The information in Table 1-4 provides general Compressor operating

specifications.

Pressure Drop (inlet-to-outlet) See Figure 1-3

Maximum Inlet Pressure 100 psi (6.9 bars)

Alkalinity 6.0 - 8.0 pH

Calcium Carbonate < 75 ppm

Table 1-3: Cooling Water Specifications (Continued)

Parameter Value

NOTE: Water conditioning may be required for applications not meeting these requirements.

4.00

3.50

3.00

2.50

2.00

1.50

1.00

0.50

1357911

WATER FLOW RATE (GPM)

WATER PRESSURE DROP (PSID)

ACCEPTABLE

OPERATING

LINE

.07 .49

.21 .35 .63 .7715.2

13.3

11.40

9.50

7.60

5.70

3.80

1.90

WATER FLOW RATE (LPM)

WATER PRESSURE DROP (Bars)

NOTE: Figure 1-3 defines the water flow rate through the Compressor as a function of the pressure drop from

water inlet to water outlet. You must provide the correct pressure drop in your water supply system to ensure that

the water flow condition meets the requirements specified in Table 1

-

3.

Other manuals for Compressor 9600

2

Table of contents

Other HELIX Air Compressor manuals

Popular Air Compressor manuals by other brands

Scheppach

Scheppach HM100TC Translation of original instruction manual

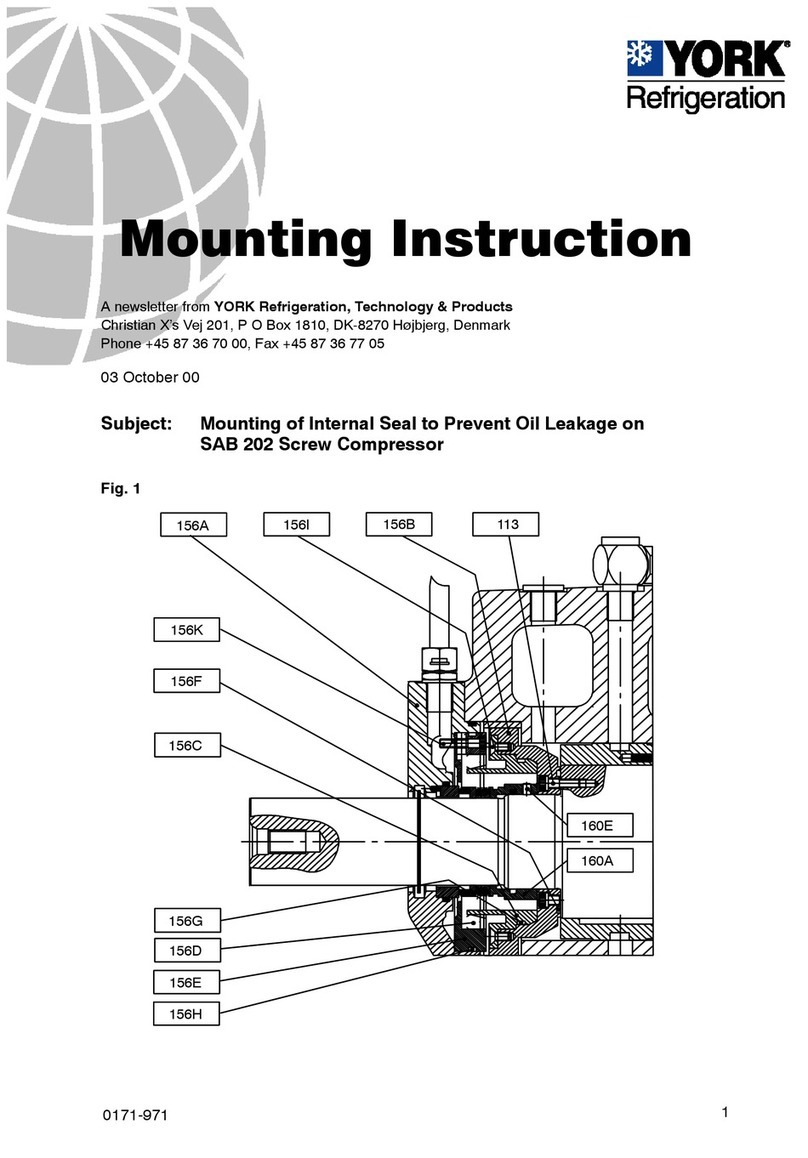

York

York SAB 202 Mounting instruction

Invacare

Invacare IOH200AW Operator's manual

Machine Mart

Machine Mart airmaster TIGER 9/24 Operation & maintenance instructions

Chicago Pneumatic

Chicago Pneumatic CPF Series instruction manual

King Industrial

King Industrial KC-1620A instruction manual