HELIX 8200 Training manual

HELIX TECHNOLOGY CORPORATION

http://www.helixtechnology.com

C

HELIX TECHNOLOGY CORPORATION

-

TI CRYOGENICS

8200 Compressor

Installation, Operation and Service

Instructions

8040353

Rev. 101 (11/2001)

View our inventory

The information in this document is believed to be accurate and reliable. However,

Helix Technology Corporation, cannot accept any financial or other responsibilities that may

result from the use of this information. No warranties are granted or extended by this document.

Helix Technology Corporation reserves the right to change any or all

information contained herein without prior written notice. Revisions may be issued at the time of

such changes and/or deletions.

Any duplication of this manual or any of its parts without expressed written permission from

Helix Technology Corporation is strictly prohibited.

Any correspondence regarding this document should be forwarded to:

Helix Technology Corporation

Mansfield Corporate Center

Nine Hampshire Street

Mansfield, Massachusetts 02048-9171 U.S.A.

Telephone: (508) 337-5000

FAX: (508) 337-5464

The following Helix Technology Corporation trademarks and service marks may appear in this

document:

All other trademarks or registered trademarks are the property of their respective holders.

Copyright© 2001 Helix Technology Corporation Printed in U.S.A.

Conductron™ Convectron®Cryodyne®Cryogen®

Cryogenerator®Cryo-Torr®CTI-Cryogenics®FastRegen™

GOLDLink®Granville-Phillips™ GUTS®Helix Technology.. Your

Vacuum ConnectionSM

Helix®Micro-Ion®Mini-Ion™ On-Board®

RetroEase®RetroFast®Stabil-1®Stabil-Ion®

ThinLine™ TurboPlus®Vacuum AssuranceSM

8200 Compressor

P/N 8040353 iii

C

HELIX TECHNOLOGY CORPORATION

-

TI CRYOGENICS

Table of Contents

Section 1 - Introduction

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Installation, Operation and Servicing Instructions . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Section 2 - Inspection

Packaging of the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

The Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Section 3 - Installation

Compressor Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Preparing the Compressor Input-Power Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Cooling Water Requirements (Water-Cooled Compressors Only) . . . . . . . . . 3-3

Cooling Water: General Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Cooling Water: Flow and Pressure Requirements . . . . . . . . . . . . . . . . . . . . . . 3-4

Cooling Water: Temperature Rise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Final Preparation of Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Connecting the Compressor to the Cold Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Section 4 - Maintenance Procedures

Scheduled Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Removing the Compressor Adsorber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Installing the Compressor Adsorber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Unscheduled Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Suggested Unscheduled Maintenance Equipment . . . . . . . . . . . . . . . . . . . . . . . 4-3

Adding Helium Gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Helium Circuit Decontamination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Appendix A - Customer Support Information

Appendix B - Troubleshooting Procedures

Appendix C - Electrical Schematics for 8200 Compressor

Appendix D - Components in the Electrical Control Module of the 8200 Com-

pressor

8200 Compressor

iv P/N 8040353

C

HELIX TECHNOLOGY CORPORATION

-

TI CRYOGENICS

Table of Contents (continued)

Appendix E - Flow Diagrams for 8200 Air-Cooled and Water-Cooled Compres-

sors Figures

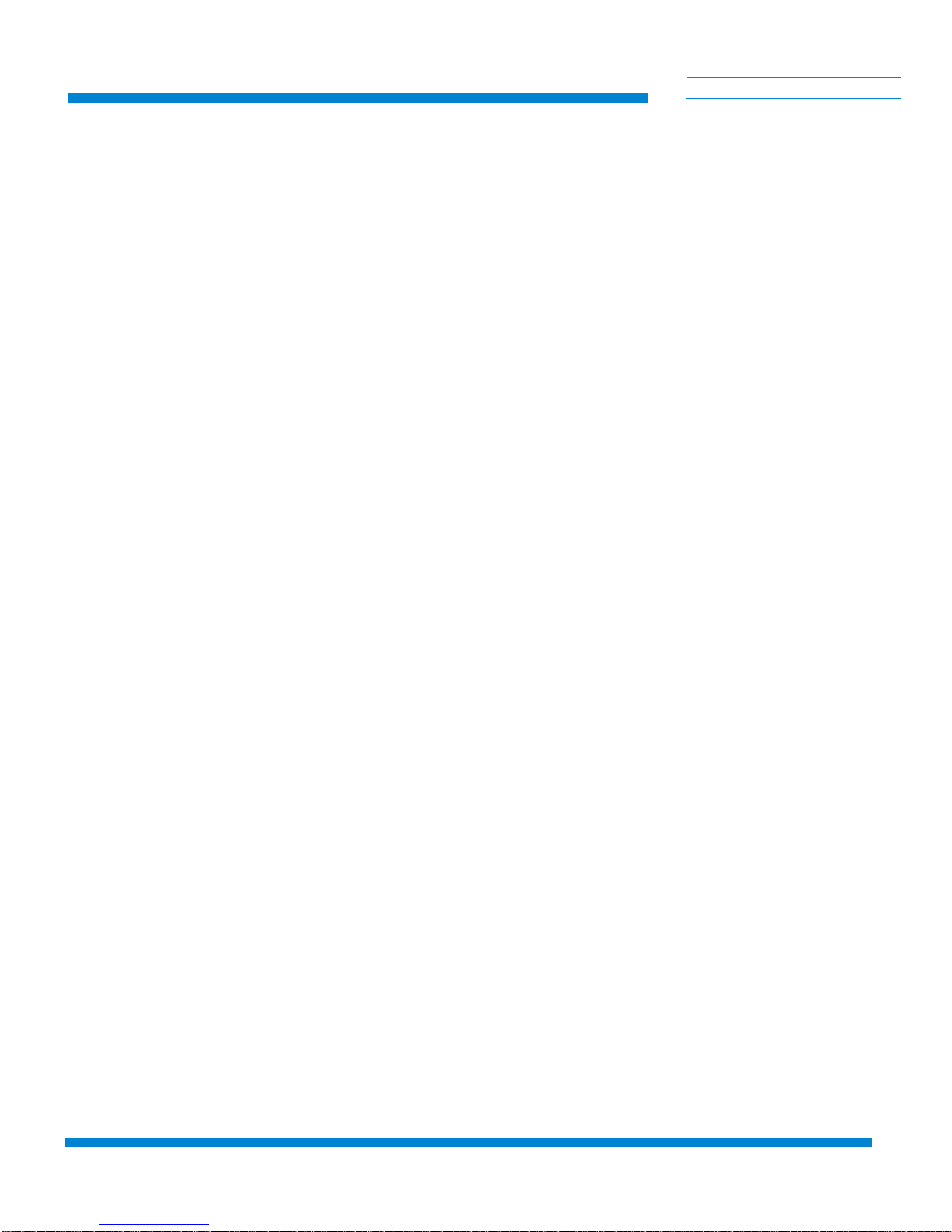

Figure 1-1: Air and Water Cooled 8200 Compressor Dimensions . . . . . . . . . . 1-2

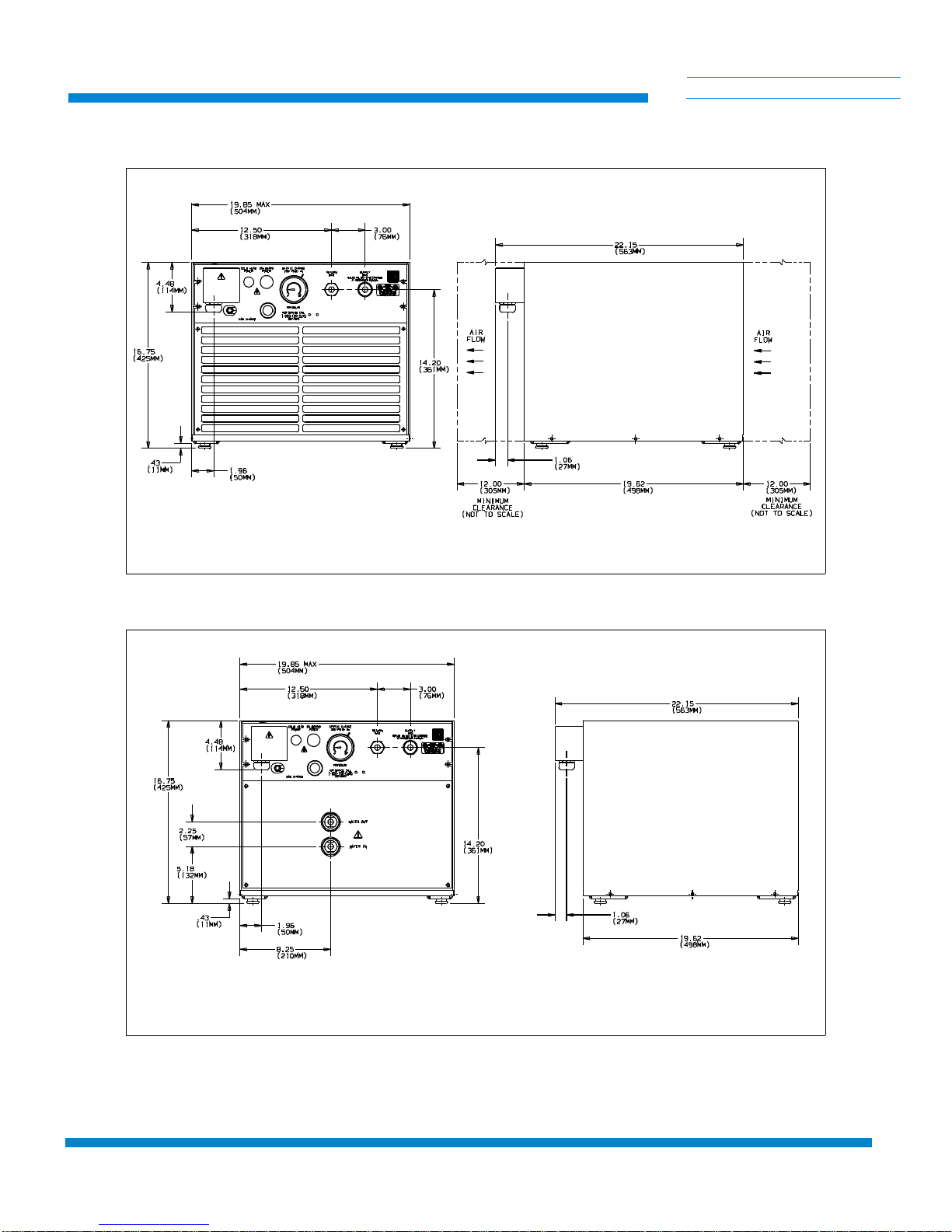

Figure 1-2: Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Figure 3-1: Electrical Terminal Enclosure with Cover in Place . . . . . . . . . . . . 3-2

Figure 3-2: Assembly of Conductors to Terminal Block . . . . . . . . . . . . . . . . . 3-3

Figure 3-3: 8200 Compressor Cooling Water Flow and Pressure Requirements 3-5

Figure 3-4: 8200 Compressor Water Discharge Temperature Increase (°F) . . . 3-6

Figure 3-5: Typical 8200 Compressor Installation . . . . . . . . . . . . . . . . . . . . . . 3-9

Figure 4-1: Disconnecting/Connecting the Adsorber Self-Sealing Coupling . . 4-2

Figure 4-2: Removing the Adsorber from the Compressor . . . . . . . . . . . . . . . . 4-2

Figure C-1: 8200 Compressor Electrical Schematic P/N 8032563P001

Rev. 100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

Figure C-2: 8200 Compressor Electrical Schematic P/N 8032564P001 Rev. D C-3

Figure D-1: Components in the Electrical Control Chassis of the

8200 Compressor Three-Phase Scott-T Configuration . . . . . . . . . . D-1

Figure D-2: Components in the Electrical Control Chassis of the

8200 Compressor - Single-Phase RC Configuration . . . . . . . . . . . D-2

Figure E-1: Flow Diagram of the 8200 (Air-Cooled) Compressor . . . . . . . . . . E-2

Figure E-2: Flow Diagram of the 8200 (Water-Cooled) Compressor . . . . . . . . E-3

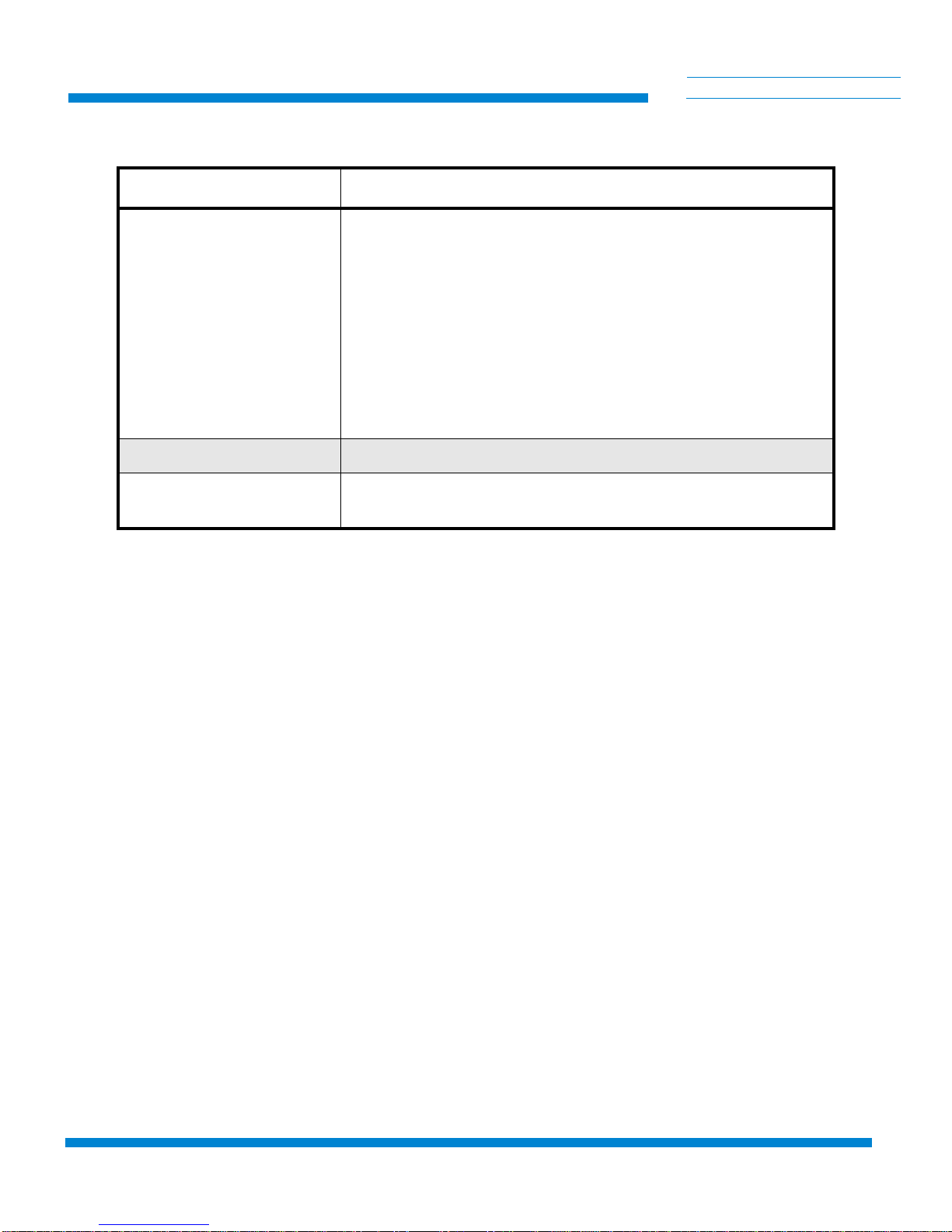

Tables

Table 1-1: Power Requirements (Steady-State Conditions) . . . . . . . . . . . . . . . 1-4

Table 1-2: General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Table 3-1: Voltage Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Table A-1: CTI-CRYOGENICS Product Customer Support Centers . . . . . . . . A-2

Table B-1: Compressor Troubleshooting Procedures . . . . . . . . . . . . . . . . . . . . B-1

8200 Compressor

P/N 8040353 1-1

C

HELIX TECHNOLOGY CORPORATION

-

TI CRYOGENICS

Section 1 - Introduction

General

The manual provides instructions for installing, operating and servicing the

8200 Compressor. This compressor is available in two versions: air-cooled,

P/N 8032549G001/G002 and water cooled, P/N803255G001/G002.

If you are installing or operating a Cryo-Torr or On-Board System you

should also have available the appropriate cryopump or refrigerator.

When you purchase a system, you will receive two manuals necessary for

system installation, plus a loose- leaf binder with index tab separators,

allowing you to compile a complete indexed system notebook.

Installation, Operation and Servicing Instructions

Installation, Operation and Servicing Instructions for your 8200

Compressor provide easily accessible information. All personnel with

installation, operation, and servicing responsibilities should become

familiar with the contents of these instructions to ensure high quality, safe,

reliable performance.

Introduction

1-2 P/N 8040353

C

HELIX TECHNOLOGY CORPORATION

-

TI CRYOGENICS

Figure 1-1: Air and Water Cooled 8200 Compressor Dimensions

Air Cooled

Water Cooled

8200 Compressor

P/N 8040353 1-3

C

HELIX TECHNOLOGY CORPORATION

-

TI CRYOGENICS

Figure 1-2: Component Locations

16

15

14

13

17

18

10

11

123456 7

8

9

Rear View - Water Cooled

Rear View - Air Cooled

Front View - Air and Water Cooled

1. Compressor Input Power Block

2. Cold Head Power Receptacle

3. On-Board Power Receptacle

4. Helium Gas Fitting and Charge Valve

5. Helium Supply Pressure Gauge

6. Helium Gas Return Connector

7. Helium Gas Supply Connector

8. Rear Panel

9. Rear Grill

12

10. Cooling Water Output

11. Cooling Water Input

12. Rear Plate

13. 50/60 Hz Frequency Selector Switch

14. 208/220 Voltage Range Selector

Switch

15. Resettable Circuit Breakers

16. Compressor ON/OFF Switch

17. Front Panel

18. Front Grill

LEGEND

Introduction

1-4 P/N 8040353

C

HELIX TECHNOLOGY CORPORATION

-

TI CRYOGENICS

Table 1-1: Power Requirements (Steady-State Conditions)

Part Number Cooling Phase Hz Operating Voltage

Range

Nominal

Operating

Current

8032549G001 Air

Air 3

350

60 180-220

198-250 10A

10A

8032549G002 Air

Air 1

150

60 180-220

198-250 10A

10A

8032550G001 Water

Water 3

350

60 180-220

198-250 8.5A

8.5A

8032550G002 Water

Water 1

150

60 180-220

198-250 8.5A

8.5A

Table 1-2: General Specifications

Specification Description

Weight 140 lbs (63.5 kg) approximate

Weight

(shipping) 145 lbs (70.5 kg) approximate

Power

consumption 2.0 kw, nominal operating(water), 2.1 kw nominal operating

(air)

Compressor input-power

cable

(customer-supplied)

Recommended type SO-4 conductor, 600V, neoprene jacket

and 14-gauge wire.

Install per Figure C-1, Electrical Schematic diagram, ensuring

compliance with all national, state and local standards.

Helium pressure Static: 245-255 psig (1688-1757 kPa) at 70 to 80°F (21 to

27°C)

Supply: nominal operation: 270-290 psig (1860-2000 kPa) at

operating temperature.

Ambient operating

temperature range 50 to 100°F (10 to 38°C)

8200 Compressor

P/N 8040353 1-5

C

HELIX TECHNOLOGY CORPORATION

-

TI CRYOGENICS

Interface Cold head power receptacle: Mates with plug on cold head

power cable.

On-Board power receptacle: Mates with plug on cold-head

power cable.

Compressor input-power terminal block enclosure: Mates with

input power cable, fabricated by customer or available from

CTI-CRYOGENICS.

Gas-supply connector: 1/2-inch self-sealing coupling

Gas-return connector: 1/2-inch self-sealing coupling

Adsorber service schedule Replace every 12 months.

Cooling water require-

ments (water cooled only) 100°F (38°C) maximum discharge temperature

Refer to Figures 3-5 and 3-6 for parameters.

Table 1-2: General Specifications

Specification Description

8200 Compressor

P/N 8040353 2-1

C

HELIX TECHNOLOGY CORPORATION

-

TI CRYOGENICS

Section 2 - Inspection

Packaging of the System

A High-Vacuum Pump or Refrigerator System is packaged in separate

cartons for each major component. An Installation, Operation, and

Servicing Manual is included in the carton for the component packaged in

that carton.

The Compressor

On receipt, remove the 8200 Compressor from its shipping carton and

inspect the compressor for evidence of damage as described in this Section.

1. Unpack and remove the compressor from its shipping carton.

2. Check the carton contents. It should contain:

a. 8200 Compressor (air cooled or water cooled).

b. Compressor Manual P/N 8040353.

3. After unpacking, inspect the compressor for evidence of damage as

follows:

a. Inspect the compressor overall exterior for damage.

b. Report damage to the shipper at once.

c. Retain shipping cartons for storage or return shipment.

When installing your system, CTI recommends that as you unpack a

component, you perform an inspection and the necessary tasks for system

installation for the component according to the manual included with the

component. Final system installation and operation will be performed

following procedures in the high-vacuum pump or refrigerator manual.

4. Check the helium pressure gauge. The gauge should indicate 250 psig

(1725 kPa) minimum at 70°F. If additional gas pressure is required,

follow the instructions in Adding Helium Gas.

8200 Compressor

P/N 8040353 3-1

C

HELIX TECHNOLOGY CORPORATION

-

TI CRYOGENICS

Section 3 - Installation

Compressor Installation

Installation of your compressor requires no special tools other than those

supplied in the Installation and Scheduled Maintenance Tool Kit.

Preparing the Compressor Input-Power Cable

To supply input power to the 8200 compressor requires the fabrication of a

600-volt power cable that has an SO-4 conductor, 600-volt rating neoprene

jacket and 14-gauge or 2.3 mm2wire. Proceed as follows:

WARNING

Do not connect the compressor to the power source at this time. All of

the preparation must be completed and all panels reinstalled before elec-

trically connecting the compressor.

Unit must be wired by an authorized electrician in accordance with the

national Electrical Code, ANSI/NFPA 70-1987, as well as the local

codes. This shall include installation of a readily accessible disconnect

device into the fixed wiring supplying power.

An insulated earthing conductor that is identical in size, insulation mate-

rial and thickness to the earth and unearth branch circuit supply conduc-

tors, except that it is green with or without one or more yellow stripes is

to be installed as part of the branch circuit which supplies the unit or sys-

tem. The earthing conductor described is to be connected to the earth at

the service equipment, or supplied by a separately derived system at the

supply transformer or generator.

1. Prepare the input power cable by terminating each of the four

conductors with a #10 ring terminal. Follow the terminal

manufacturer’s instructions to insure proper crimping.

2. Disassemble the electrical terminal enclosure cover, mounted on

the compressor rear panel, as shown in Figure 3-1. Remove the two

screws securing the cover and lift it off.

3. If necessary, back off strain relief screws.

Installation

3-2 P/N 8040353

C

HELIX TECHNOLOGY CORPORATION

-

TI CRYOGENICS

4. Thread input power cable end up through the strain relief into the

enclosure.

5. Attach the power conductors onto the appropriate terminals of the

terminal block.

a. For three-phase hookups, attach the three power leads to ter-

minals X, Y and Z.

b. For single-phase hookups, attach the two power leads to ter-

minals X and Y. DO NOT USE TERMINAL Z.

6. Tighten all terminals to 18-22 in.-lbs. torque.

7. Tighten down screws on strain relief.

CAUTION

Ensure that strain relief is tightened down on the outer insulation of the

input power cable and that the cable does not slide.

8. Remount the terminal enclosure cover and secure with two screws.

9. Refer to Final Preparation of Compressor for correct phasing

checkout procedure.

WARNING

Insure that the ground wire is returned to a suitable ground in a non-

interrupting manner.

Figure 3-1: Electrical Terminal Enclosure with Cover in Place

Cover Screws

8200 Compressor

P/N 8040353 3-3

C

HELIX TECHNOLOGY CORPORATION

-

TI CRYOGENICS

Figure 3-2: Assembly of Conductors to Terminal Block

Cooling Water Requirements (Water-Cooled Compressors Only)

If flexible water hose connections are used, install the barbed fittings

supplied with the compressor on the input and output connections:

1. Apply a light coating of standard plumbing thread sealant on

the barbed fitting threads.

2. Tighten fittings on 1/2-inch FPT input and 1/2-inch FPT output con-

nections. DO NOT OVERTIGHTEN.

3. Connect flexible hoses to the fittings and secure with hose clamps.

If hard piping is desired, install the water lines directly onto the compressor

1/2-inch FPT input and output connections. DO NOT OVERTIGHTEN.

CAUTION

Check water connections for leaks.

Power Cable

Ground Screw

X

Y

Z(not used for single phase)

Installation

3-4 P/N 8040353

C

HELIX TECHNOLOGY CORPORATION

-

TI CRYOGENICS

Cooling Water: General Considerations

NOTE: Adjust your water flow to maintain an optimum discharge water

temperature of 85°F with a minimum input pressure of 2 psig. For detailed

water requirements, see below.

1. Cooling water must meet flow and pressure requirements as

indicated in the following subsections.

2. Cooling water having a pH value of 6.0 to 8.0 and a calcium-car-

bonate concentration of less than 75 ppm, the quality of typical

municipal drinking water, is acceptable. If the cooling water has a

pH value lower than 6.0 or a calcium- carbonate concentration

higher than 75 ppm, water conditioning may be required.

3. To conserve water, the cooling water should be shut off when the

compressor is not running.

CAUTION

If cooling water below 45°F (7°C) is allowed to run through the

compressor while the compressor is not operating, the compressor oil

will change viscosity and thicken, causing the compressor to overheat

and shut off at startup. In this event, repeatedly restart the compressor

and allow it to run until it has shut off several times. The oil

temperature will rise and thereby allow continuous compressor

operation.

4. Drain and purge water from the compressor before shipping it back

to the factory or subjecting it to freezing conditions. Purge water

from the compressor by blowing compressed air, regulated to 30 to

40 psig (200 to 275 kPa) into the compressor output connection and

allowing water to exit from the water input connection.

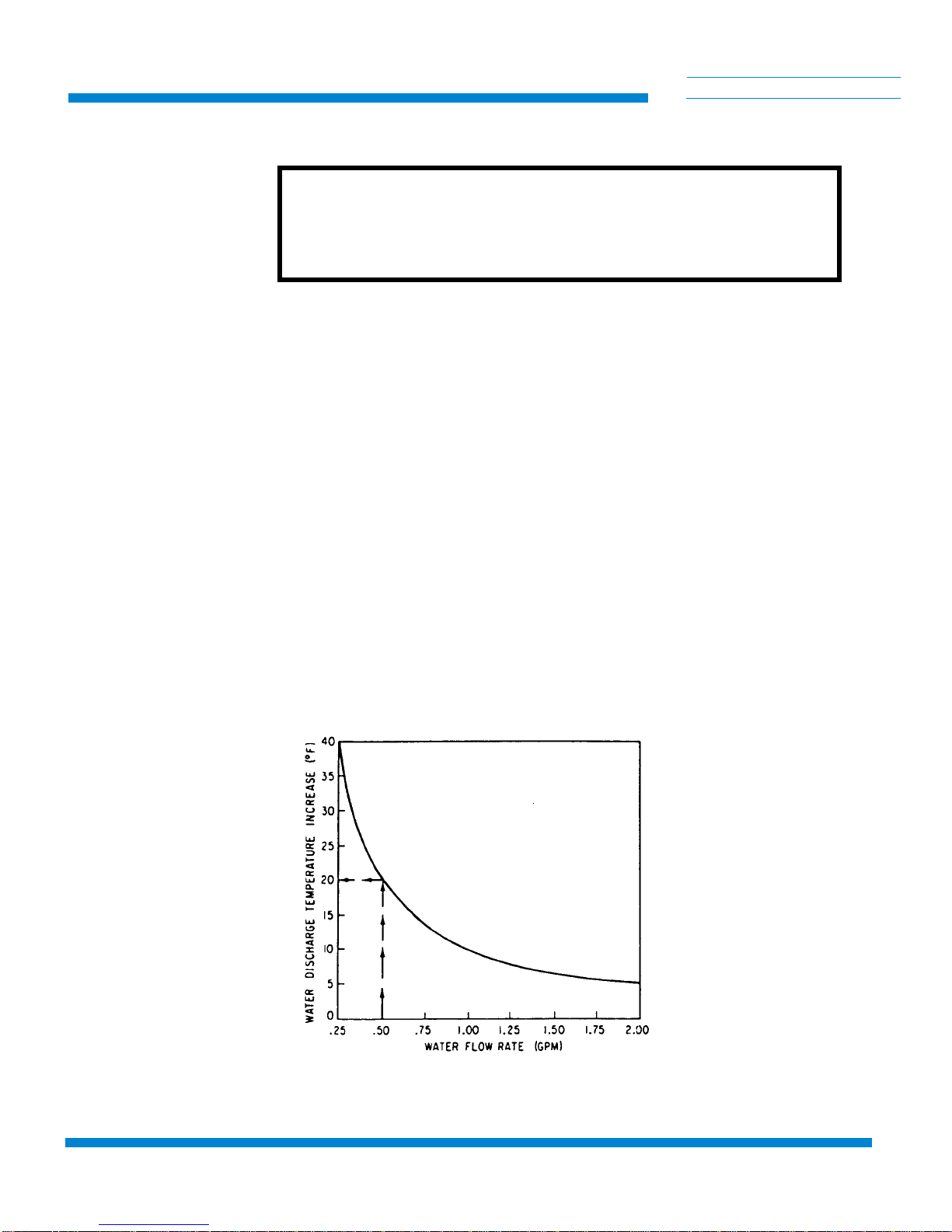

Cooling Water: Flow and Pressure Requirements

CAUTION

If your water supply pressure falls below 2 psig due to back pressure,

the compressor will overheat and shut down.

Use the two graphs in Figure 3-3, to determine the minimum acceptable

cooling water supply pressure at different flow rates and temperatures.

8200 Compressor

P/N 8040353 3-5

C

HELIX TECHNOLOGY CORPORATION

-

TI CRYOGENICS

Find the minimum pressure:

1. Determine the temperature variation of the cooling water.

Allow a ±10°F to the present water temperature if a variation

cannot be ascertained. Plot the high and low temperatures on

the vertical axis of the lower graph.

The example describes cooling water that varies between 40°F and70°F.

2. Determine the optimum water flow rate by drawing a horizontal

line from the upper temperature variation figure on the lower graph

to the upper curve of the allowable operating range indicated by

cross-hatching. Draw a line from this intersecting point straight

down to the horizontal axis to find the optimal flow rate.

The example shows a solid arrow extending from 70°F and intersecting the

allowable operating range. Dashed arrows pointing downward indicate a

water flow rate of 0.5 gallons per minute.

3. Determine the cooling water supply pressure drop by drawing a line

straight up from the flow rate in the lower graph to the upper graph.

At the point at which this line intersects the upper graph, draw a

line leftward to the vertical axis and find the water supply pressure

drop.

The example shows dashed arrows extending from the lower to the upper

graph. On the upper graph the dashed arrows intersect the graph curve at

approximately 2.5 psig.

Figure 3-3: 8200 Compressor Cooling Water Flow and Pressure Requirements

Installation

3-6 P/N 8040353

C

HELIX TECHNOLOGY CORPORATION

-

TI CRYOGENICS

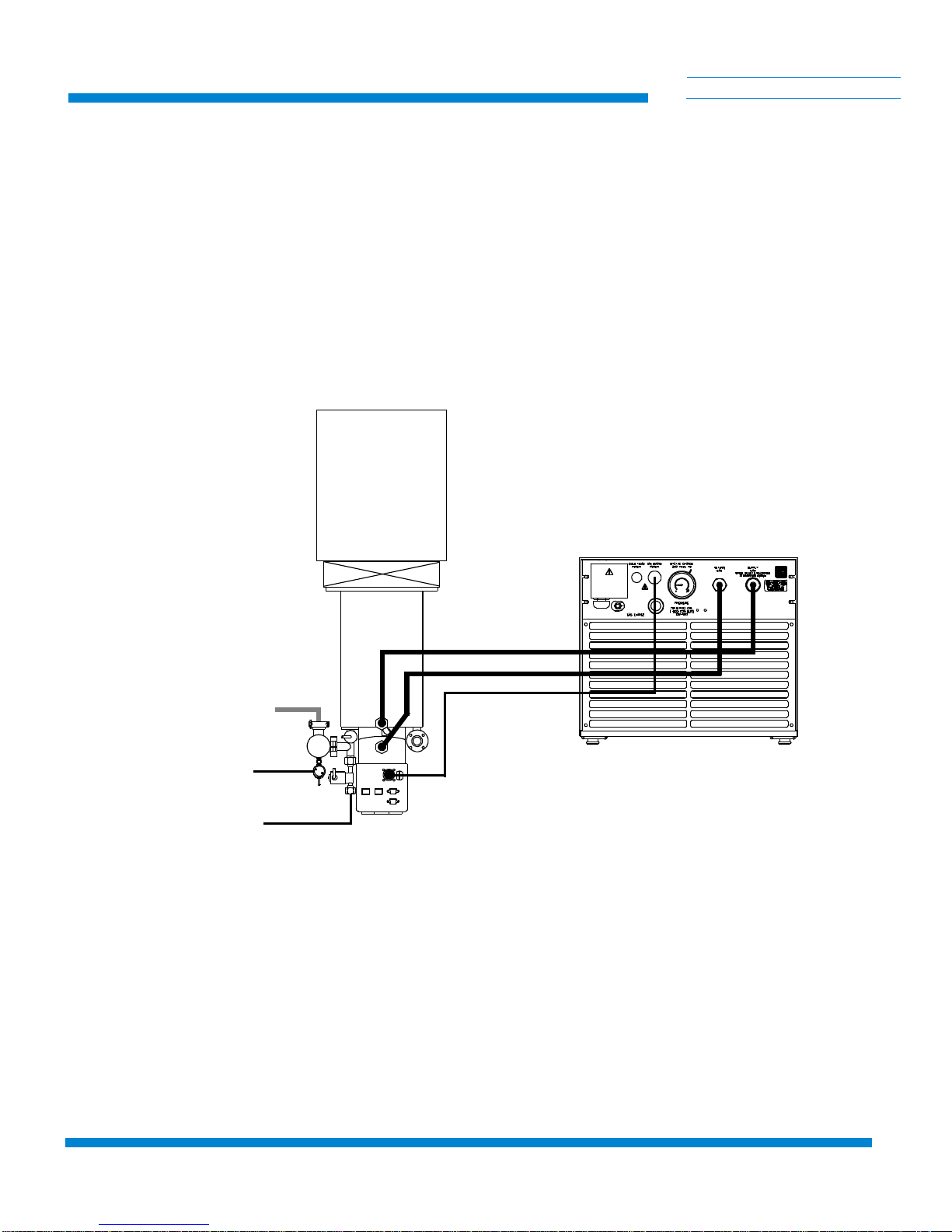

Cooling Water: Temperature Rise

CAUTION

The temperature of the cooling water as it leaves the compressor should

not exceed 100°F.

Use the graph in Figure 3-4 to determine the rise in cooling water

temperature as it passes through the compressor. This information is

provided for plant engineering personnel to determine cooling water

requirements.

Find the temperature rise:

1. Draw a vertical line upward from the horizontal axis of the

graph at the water flow rate determined from the previous

section, until it hits the graph curve.

The example shows dashed arrows pointing upward to the graph curve

from 0.50 gpm on the water flow rate axis.

2. At the point which the dashed arrows intersect the graph curve,

draw a straight line to the left to obtain the increase in output water

temperature.

The example shows a temperature increase of 20°F.

Figure 3-4: 8200 Compressor Water Discharge Temperature Increase (°F)

8200 Compressor

P/N 8040353 3-7

C

HELIX TECHNOLOGY CORPORATION

-

TI CRYOGENICS

Final Preparation of Compressor

1. Using a voltmeter, measure the phase-to-phase voltage from the

power source. Compare this voltage to the following table and

position the voltage range selector switch to the “208V” or

“220V” position as required. Also, set the frequency selector

switch to the 50 Hz or 60 Hz position, as appropriate. See

Figure 1-2 for location of selector switches.

2. Ensure that water is turned on for the water-cooled compressor.

3. Set the compressor ON/OFF switch (3) to OFF. Connect the input-

power cable to the power source Refer to Table 1-1, for electrical

power requirements.

4. Turn the compressor switch to the ON position and allow the com-

pressor to run for 15 minutes to stabilize the oil circuit. Make sure

that the compressor fan operates freely in the air-cooled compres-

sor.

5. Switch off the compressor and disconnect the input-power cable.

6. Install the compressor in its permanent location on a level surface.

Air cooled units must have a minimum clearance of 12 inches at the

front and back for adequate airflow.

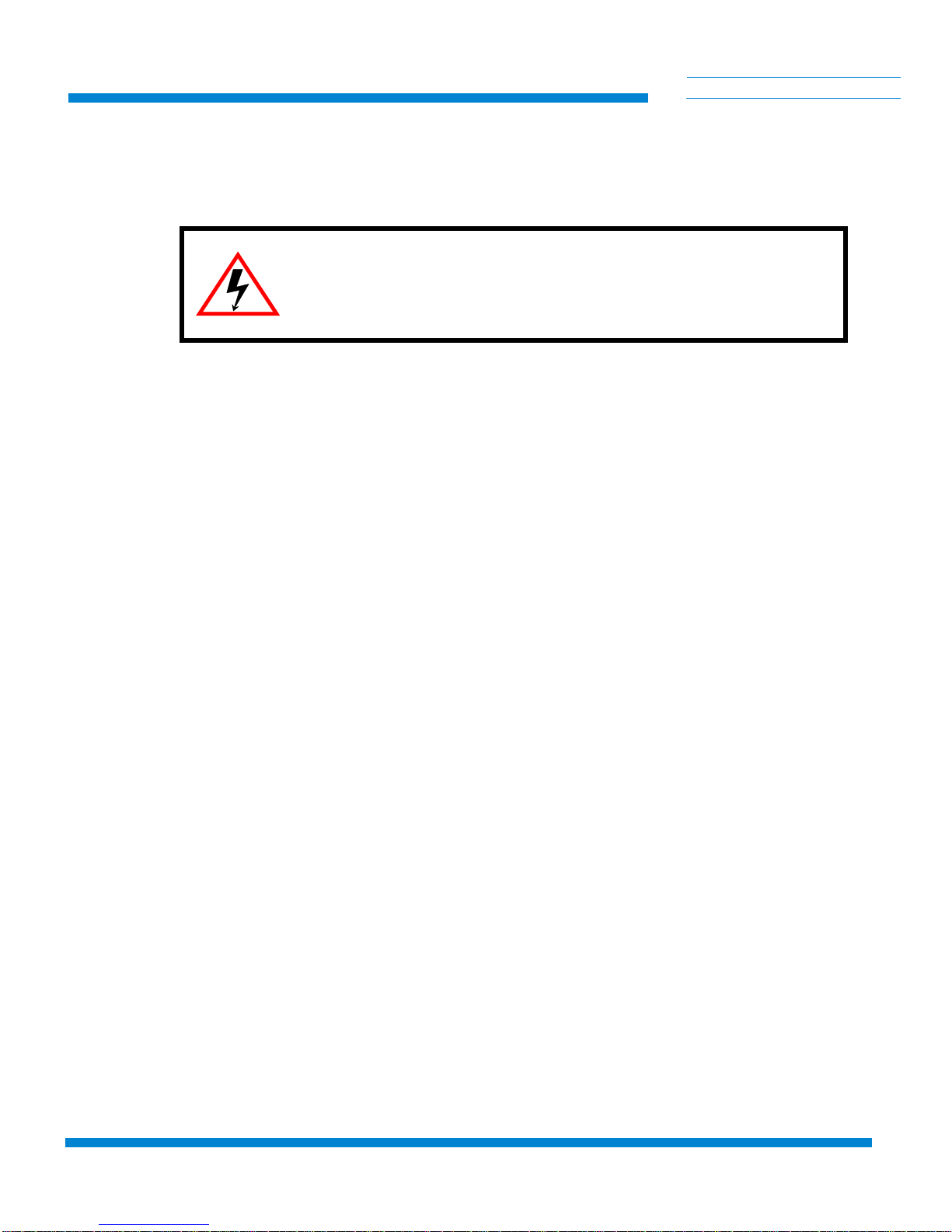

Connecting the Compressor to the Cold Head

Make the connections between the cryopump and compressor. See Figure

3-5.

1. Remove dust plugs and caps from the supply fittings and return

lines, compressor, and cold head. Check all fittings.

2. Connect the helium-gas return line from the gas-return connector

on the rear of the compressor to the gas-return connector on the

cold head.

Table 3-1: Voltage Specifications

Operating Voltage Range

60 Hz 50 Hz

Voltage

AdjustmentSwitch

S1 Position

198-212 180-212 208V

213-250 213-220 220V

Installation

3-8 P/N 8040353

C

HELIX TECHNOLOGY CORPORATION

-

TI CRYOGENICS

3. Connect the helium-gas supply line from the gas-supply connector

on the rear of the compressor to the gas-supply connector on the

cold head.

4. Attach the supply and return line identification decals (CTI-sup-

plied) to their respective connecting piping ends.

5. Verify proper helium supply static pressure by confirming that the

helium pressure gauge reads 245-250 psig (1690-1725 kPa), in an

ambient temperature range of 60 to 100°F (16 to 38°C).

WARNING

Do not operate the 8200 Compressor unless a Cryopump or Waterpump

is connected to the system.

If the indicated pressure is higher than 250 psig (1725 kPa), reduce the

pressure as follows:

a. Remove the flare cap from the gas charge fitting located on

the rear of the compressor.

b. Open the gas charge valve very slowly. Allow a slight

amount of helium gas to escape until the helium pressure

gauge reads 250 psig (1725 kPa).

c. Close the gas charge valve and reinstall the flare cap.

If the indicated pressure is lower than 245 psig (1690 kPa), add helium gas

as described in Adding Helium Gas.

6. Make the following electrical connections.

WARNING

The compressor ON/OFF power switch on the front of the compressor

must be in the OFF position before making any and all electrical connec-

tions.

a. Connect the cold head power cable to the rear panel of the

compressor and the other end to the electrical power con-

nector on the high-vacuum pump cold head.

b. Connect the compressor input power cable to the power

source.

c. Turn on compressor.

d. Your system is now ready for operation.

!

8200 Compressor

P/N 8040353 3-9

C

HELIX TECHNOLOGY CORPORATION

-

TI CRYOGENICS

Figure 3-5: Typical 8200 Compressor Installation

User’s

Vacuum

Chamber

On-Board Power Cable

Helium Return Line

Helium Supply Line

On-Board

Cryopump

Air Pressure (60-80 psi)

Nitrogen (40-80 psi)

Roughing Pump

8200 Compressor

P/N 8040353 4-1

C

HELIX TECHNOLOGY CORPORATION

-

TI CRYOGENICS

Section 4 - Maintenance Procedures

WARNING

Always disconnect the compressor from all sources of electrical power

before performing any maintenance procedures.

Scheduled Maintenance

The only scheduled maintenance required on the 8200 Compressor is

replacement of the compressor adsorber (P/N 8080255K001) every 12

months.

Removing the Compressor Adsorber

1. Shut down the compressor.

2. Disconnect the compressor input power cable from its electrical

power source.

3. Disconnect the flex lines from the gas-return and gas-supply con-

nectors at the rear of the compressor.

4. Remove the screws holding the compressor rear grille, rear panel,

front panel and cover (Figure 1-2). Front and rear panels remain in

place.

5. Use the two wrenches (supplied) to avoid loosening the body of the

coupling from its adapter.

6. Unscrew the two self-sealing coupling halves quickly to minimize

gas leakage as shown in Figure 4-1.

7. Disconnect the adsorber-inlet self-sealing coupling as shown in

Figure 4-1.

8. Remove the bolts, nuts, and washers that secure the adsorber to the

base of the compressor. Save all nuts, bolts, and washers for install-

ing the replacement adsorber.

9. Carefully lift the adsorber inward until the outlet self-sealing cou-

pling clears the rear panel and remove the adsorber as shown in

Figure 4-2.

10. Remove the adsorber from the compressor as shown in Figure 4-2.

Table of contents

Other HELIX Air Compressor manuals

Popular Air Compressor manuals by other brands

tresnar

tresnar GP-FL24 Translation of the original instructions

Campbell Hausfeld

Campbell Hausfeld FP202801 Operating instructions and parts manual

Campbell Hausfeld

Campbell Hausfeld DC01001 Operating instructions and parts manual

CompAir

CompAir D50H RS Operating and service manual

Becker

Becker X 4.25 DV operating instructions

AirMan

AirMan PDS375S-6A1 instruction manual