HELIX CTI-CRYOGENICS CRYO-TORR 100 User guide

CTI-CRYOGENICS

HELIX TECHNOLOGY CORPORATION

CRYO-TORR® 100, 7, 8 and

8F

HIGH-VACUUM PUMPS

(USED WITH 8300™ OR SC (AIR) COMPRESSOR)

Installation, Operation

and Servicing Instructions

MB040240

Rev. A (9/91)

Revised

September

1991

Copyright © 1991, Helix Technology Corporation.

Printed

in

U.S.A.

3750

-------~--~.-"-_=~==~~.,__-___:c~~~=:~---==_=cc::_:

266 SECOND AVENUE POST OFFICE BOX

9171

WALTHAM, MA 02254-9171 (617) 622-5000

Manual

Contents

This

manual

provides installation, operation

and

servicing instructions

by

major

system component

(cryopump, compressor,

and

controller)

to

simplify

getting the world's finest high·vacuum

pump

into

operation quickly

and

efficiently,

meeting

its

designed

capabilities.

Technical Inquiries

en·CRYOGENICS

has

a

world

wide

system

of

customer supportcenters available

to

answer technical

questions, or

to

assist

you

with

installation, operation

and

maintenance ofyour

product.

All

customer support

centers

have

"rapid

response" capabilities providing

24·hour technical

support.

In

the

Continental

U.S.A.

and

Canada

you

may

call

toll

free

for

assistance 24

HOURSA DAY, 7DAYSA WEEK.

U,S.

AND

CANADA

DIAL

TOLL

FREE:

1·8oo·FOR·GUTS

367·4887

EasWm

en·CRYOGENICS

266

Second

Avenue

Waltham, Massachusetts 02254·9171, U.S.A.

Telephone

(617)

622·5000

Telecopier/Fax

(617)

622·5222

Western

en·CRYOGENICS

3350

Montgomery

Drive

Santa Clara, California

95054,

U.S.A.

Telephone

(408)

727·8077

Telecopier/Fax

(408)

988·6630

EUROPE

Germany

en·CRYOGENICS,

GmbH

Haasstrasse

15

D·61oo Darmstadt

Germany

Tel:

49·6151·86377

Fax:

49·6151·891635

ii

EI:lloo:

CTI·CRYOGENICS,

SA

4, rue Rene

Raze1

Saclay

F·

91892

ORSAY

CEDEX

France

Tel:

311·6985·3900

Fax:

311·6985·3725

England

en·CRYOGENICS,Ltd.

Unit 4,

Avenue

Two

Station Lane Industrial Estate

Witney,

Oxford

OX8

6YD

England

Tel:

44·993·776436

Fax:

44·993·772067

FAR EAST

llII2Wl

Daido

Sanso

K.K.

6·40 2·cho,

Chikko

Shinmachi

Sakai City

Osaka Pref.

592

JAPAN

Tel:

81·722-44·3011

Fax:

81·722·44·8135

K=I

Zeus

Company,

Ltd.

4th

Floor, Zeus Bldg.,

512·8, Dogok·Dong, Sucho·ku

Seoul,

Korea

Mailing

Address:

Youngdong

P.O.

Box

992

Seoul,

Korea

Tel:

82·2·577·3181/6

Fax:

82·2·576·3199

Your

high·

vacuum

equipment

is

designed

and

manufactured

to

ensure a

minimum

of

maintenance.

However, should your

unit

require service or if

you

need

technical assistance, contact

the

nearestcustomer

support center.

Have

the

following information

available

when

placing the call

so

we

may

assist

you

quickly.

• Equipment Type • Product Application

• Product Serial

No.

•

Hours

ofOperation

• Product Part

No.

• Specific

Problem

Area

eTl-CRYOGENICS

---

~-

---

----

HELIX TECHNOLOGY CORPORATION

-- ----

-------~-

- - - -

-----

--

-----,-"""-

SAFETY

CONSIDERATIONS

Your

Cryo·Torr"'

High

Vacuum

Pump

has

been

engineered

to

provide

extremety

safe

and

dependable

operalion

when

properly

used.

Certain

safely

considerations

need

to

be

observed

during

the

normal

use

of

your

vacuum

pump

equipmenl.

Warning

blocks

within

the

Manual

text

pinpoint

these

specific

safety

considerations.

Warnings

are

delined

as

hazards

or

unsafe

practices

which

could

result

in

severe

injury

or

loss

of

life.

IAWARNINGI

TOXtC,

CORROSIVE

OR

OANGEROUS

GASES

present

in

a

cryopump

could

cause

severe

injury

upon

contacl.

1.

Always

vent

such

gases

to

a

safe

location,

using

an

inert

purge

gas.

2.

Clearly

identify

such

gases

on

containers

used

to

store

or

ship

equipment

after

such

exposure.

FLAMMABLE

OR

EXPLOSIVE

GASES

present

in

a

cryopump

could

cause

severe

injury

if

igniled.

1.

Always

venl

such

gases

to

a

safe

location,

using

an

inert

purge

gas.

2.

Do

nol

install

a

hot·filament

Iype

vacuum

gauge

on

the

cryopump

side

of

the

roughing

valve;

it

could

be

an

ignition

source

of

flammable

gases

in

the

pump.

3.

Cryopumping

oxygen/ozone

requires

special

precautions

and

frequent

regeneration.

Ozone

may

be

present

as

a

by·product

of

oxygen

processes.

HIGH

VOLTAGE

is

present

within

the

system

and

can

cause

severe

injury

from

electric

shock.

1.

Disconnect

the

system

from

all

power

sources

before

making

electrical

connections

be·

tween

system

components

and

also

belore

pertorming

Troubleshooting

and

Maintenance

procedures.

HIGH

GAS

PRESSURE

is

present

within

the

system

and

can

cause

severe

injury

from

propelled

particles

or

parts.

1.

Do

not

modify

or

remove

the

pressure

relief

valves,

either

on

the

cryopump

or

within

the

helium

compressor.

2.

Always

depressurize

the

adsorber

to

atmospheric

pressure

before

disposing

of

il.

3.

Always

bleed

the

helium

charge

down

to

atmospheric

pressure

before

servicing

or

disassembling

the

self·sealing

gas

half·couplings.

BEFORE

INSTALLING,

OPERATING

OR

SERVICING

EQUIPMENT,

READ

THIS

MANUAL

WHICH

CONTAINS

IMPORTANT

SAFETY

INFORMATION.

r r

iii

7

CRYOPUMP

OXYGEN

PROCEDURES

_I

AWARNING

COMBUSTION

SUPPORTED

BY

OXYGEN

IN

THE

PUMP

COULO

CAUSE

SEVERE

INJURY.

WHEN

OXYGEN

IS

USED

AS

A

PROCESS

GAS,

SPECIAL

PRECAUTIONS

DESCRIBED

IN

THE

TEXT

BELOW

SHOULD

BE

TAKEN.

When

oxygen

is

used

as

a

process

gas,

the

following

precautions

should

be

taken.

1.

Follow

all

cryopump

operaling

instructions

including:

en-CRYOGENICS

•

Insure

that

there

are

no

sources

of

ignition

(e.g.,

hot

filament

vacuum

gauges)

on

the

cryopump

side

of

the

high

vac

valve

operating

during

the

warming

or

venling

of

the

pump.

•

Perform

inert

gas

purge

regenerations

at

flow

rates

recommended

for

cryopumps.

2.

Regenerate

as

frequently

as

praclical

to

minimize

the

amount

of

oxidizer

present

in

the

cryopump.

3.

It

is

standard

practice

in

the

vacuum

industry

that

any

system

exposed

to

richer·than·air

oxygen

levels

should

be

prepared

for

oxygen

servICe

per

the

manufacturer's

recommendations,

including

use

of

oxygen

service

lubricating

oils

in

roughing

pumps.

~I

AWARNING

EXPLOSION

OCCURING

FROM

OZONE

IN

THE

PUMP

COULD

CAUSE

SEVERE

INJURY.

OZONE

CAN

BE

PRESENT

AS

A

BY·PRODUCT

OF

I

OXYGEN

PROCESSES.

IF

OZONE

IS

PRESENT,

SPECIAL

PRECAUTIONS

DESCRIBED

IN

THE

TEXT

BELOW

MUST

BE

TAKEN.

Ozone

may

be

unknowingly

produced

in

an

ionizing

process

(e.g.,

sputtering,

etching,

glow

discharge).

Explosive

conditions

may

exist

if

ozone

is

present,

especially

during

warming

of

the

cryopump.

Signs

of

ozone's

presence

are:

1.

Crackling/popping

sounds

(as

in

electrical

arcing)

occurring

within

the

first

few

minutes

of

regeneration,

2.

Gas

venting

from

the

cryopump

during

regeneration

may

have

a

pungent

smell,

similar

to

that

present

in

an

arc

welding

opera·

tion

or

after

an

electrical

storm.

NOTE:

A

change

in

process

may

increase

the

amount

of

ozone

present.

If

ozone

is

present,

the

following

precautions

must

be

taken.

1.

All

of

the

above

oxygen

precautions

must

be

followed.

The

required

regeneration

frequency

is

dependent

upon

flow

and

process

conditions.

Daily

regeneration

may

be

required.

Call

CTf.CRYOGENICS

for

assistance.

2.

Reduce

the

oxygen

mixture

to

the

lowest

level

the

process

will

allow.

iv

v/vi

eTi-CRYOGENICS

--

---------------~----------

..

Hiux

TECHf-!C?!P~~£~~_~ORATI<2_~

Contents

Section

1.

Introduction

2.

Inspection

3.

Quick Installation and

Startup

4.

Installation

5.

Operation

6.

Regeneration

7.

Maintenance Procedures

Appendices

A.

Troubleshooting Procedures

B.

Illustrated Parts Breakdown

C.

Accessories List for Cryo-Torr

High-Vacuum Pumps

D.

Conversion

of

Hydrogen-

Vapor-Pressure Gauge

Readings to Temperature

a

)

Illustrations

1.1

Typical

Cryo-

Torr®

High-Vacuum

Pumping

System

(Cryo-

Torr 8

Cryopump

and

8300™

Compressor

shown)

...........

viii

1.2

Cutaway

views

of

Cryo-Torr Cryopumps. . . • . . . . . . . . . .

1-2

3.1

Block

diagram

for

system installation. . . . . . . . . . • • . . . . 3-2

3.2

Cryopump

interconnection

...•..•....

3-3

4.1

Multiplecryopump installation

with

8300™

Compressorpowered

by

8002'"Controller. . . . . . . • . .

.....

4-4

B.1

Exploded

view

of

Cryo-

Torr

100

Cryopump

.••.......•......•..

B-3

B.2 Explodedview ofCryo-Torr 7

Cryopump. • . . . • . . . . . . . . . . . . . .

B-5

B.3

Explodedview ofCryo-Torr 8

Cryopump. . . . • . . . . . . . . . . • . . . .

B-7

B.4

Exploded

view

ofCryo-Torr

8F

Cryopump. . . . . . . . . . . . . . . . . .

.•

B-9

vii

CTI-CRY()(jENICS

Tables

1.1

Cryopump

Specifications. . . . . . . • . .

..

1-2

3.1

Summary

ofProcedures

for

Quick Installation

and

Startup. . . . . . .

..

3-1

5.1

Typical Pressure Variations

During

Cooldown

and

Normal

Operation. . . . .

..

5-2

A.l Troubleshooting

the

Cryopump

. . . . . .

.•

A-3

LfoTf--

&

~g-

3'7J

I

f;roa

k-,

OX

-.

3'"C;;?

~

Y6?j'l)

(

®

HELIUM

INSTALLATION

CRYO-TORR

8

FILTRATION

TOOL

KIT

CRYOPUMP

CARTRIDGE

INSTALLATION,

OPERATION

CON

NECTING

PIPI

NG

8001

CONTROLLER}

COLD

HEAD

POWER

CABLE

AND

SERVICING

INSTRUCTIONS

CONTROLLER/COMPRESSOR

POWER

CABLE

QI-c:B-YOGENICS

~_~_~-'-~_J~c_~~_Q~9,~y

___

c_q~_~Q~_~T~9~

8300

COMPRESSOR

COMPRESSOR

LOW

VOLTAGE

CONTROL

CABLE

Figure

1.1

Typical

Cryo-Torr<ll>

High-Vacuum

Pumping

System

(Cryo-Torr

8

Cryopump

and

8300™

Compressor

shown)

viii

ai-CRYOGENICS

HELIX TECHNOLOGY CORPORATION

Section 1:

Introduction

1.1

General

...........................

1·1

1.2

Installation,

Operation

and

Servicing

Instructions

. . . . . . . . . . . . . . . . . . . . . . . .

1·1

1.1

General

This

manual

provides instructions for installing,

operating

and

servicing

the

Cryo-

Torr®

100,

7,

8

and

8F

Cryopumps. If

you

are installing or operating a

high-

vacuum

system

you

should also have available the

Model

SC Compressoror

8300

T>I Compressor

and

the

manuals listed

below

that

apply

to

your particular

system.

MANUAL

REQUIRED

SYSTEM

8300

MODELSC

COMPONENT COMPRESSOR COMPRESSOR

Cryo-Torr 100,7,

M8040240

M8040240

8

and

8F

High-

Vacuum

Pump

83OO

T>I

M8040242

------

Compressor

ModelSC

-----.

M8040243

Compressor

8001

"'/8002'"

M8040241

------

Controller

The

manuals

cover

two

basic

components:

The

cryopump, compressor,

and

the

controller where

applicable.

Each

manual

presents infonnation

for

installation, operation

and

servicing of that

component.

Amanual

is

shipped

with

each

system

component

(cryopump, compressor,

and

controller).

I-I

When

you

purchase a

system,

you

will

receive the three

manuals necessary for

system

installation, plus a

loose-

leafbinder

with

index

tab

separators allowing

you

to

compile acomplete indexed

system

notebook.

The

Cryo-TorrHigh-Vacuum

Pump

System,

shown

in

Figure

1.1,

provides

fast,

clean pumping ofall gases

in

the

10-

3

to

10-

10

torr

range.

It operates

on

the principle

that

gases

can

be

condensed

and

held at extremely

low

vapor pressure, achieving

high

speeds

and

throughputs at

the

cryogenic temperatures of

the

operating cryopump.

The

cryopump

is

a reliable

rugged

unit that requires a

minimum

of

servicing.

The

cryopump

exposes

no

moving

parts, operating fluids, or

backing

pumps

to

the

working

vacuum;

the

possibility ofcontamination

is

eliminated.

Figure

1.2

shows

cutaway

views

of

the

cryopumps.

The

CT-8F cryopump

is

virtually identical

in

operation to

the

CT-8

and

is

ofa flat

pump

design

that offers a

dimen-

sional alternative

when

vertical space is limited. The

CT-SF

cryopump

is

available

with

gas

and

electrical

connectors facing

in

either a left or right direction to

match

your

piping

and

electrical interface.

1.2

Installation,

Operation

and

Servicing

Instructions

Installation, Operation

and

Servicing Instructions

for

your Cryo-Torr

vacuum

pump

provide complete

and

easily accessible

information.

All

personnel

with

installation, operation,

and

servicing responsibilities

should

become

familiar

with

the

contents of

these

instructions

to

ensure safe, reliable,

and

efficient

cryopump performance.

Ui

15K

CONOHISING

ARRAY

VACUUM

VESSEL

15K

CRYO-

AOSOR81NG

ARRAY

80K

RADIATION

SHIELO

COlO~HEAO

CYLINDER

PRESSURE

RELIEF

VALliE

(HIOOEN)

STANOPIPE

FILTER

GAS

flOW

FROM

USER'S

VACUUM

SYSTEM

INTO

INLET

OF

CRYOPUMP

I I I j j

CT·100

GAS

FLOW

FROM

USER'S

VACUU'"

SYSTEM

INTO

INLET

Of

CRYOPUMP

IHIHIH

CT-8

80K

CONDENSING

ARRAY

MOUNTlNG

flANGE

PURGE

FITTING

ACCESSORY

PORT

CONNECTION

TEMPERATURE

SENSOR

CONNECTOR

PRESSURE

RELIEF

VALVE

~

MO'",""

FLANGE

15K

ARRAY

80K

RADIATION

SHIELO

~-"':UU'VESSEL

REGENERATION

PURGE

fiTTING

COLO-HEAD

CYLiNOER

ORIVE-UNIT

ACCESSORY

PORT

CONNECTION

15K

CONOENSING

ANO

CRYO-

ADSORBING

ARRAY

1

CfI-CRYCXJENICS

HELIX TECHNOLOGY CORPORATION

GAS

fLOW

FROM

USER'S

VACUUM

SYSTEM

INTO

INLET

OF

CRYOPUMP

MQUNTING

flANGE

CONDENSING

ARRAY

L_--

VACUUM

VESSEL

'1.,-+---80K

RADIATION

SHiElD

COLO-HEAD

CYLINDER

~~.

-~-

ORIIIE

UNIT

ACCESSORY

HELIUM-

iPO'::R::T'~-CTIOH

,/a~~~~~~~~

~~~~~fh~t~t--

US

SUPPLY

C,

CONNECTOR

•,

FI

LTER

CT·7

G~S

HOl

FRail

uSE~'S

\~(UW

SlSI[~

I~TO

I~~ET

Of

CH10Pl!~?

CRi~E-u~lr

OISPl~CER

A$SEIIBLl

CT-8F

HELlUM-

GAS

RETURN

CONNECTOR

RELIEF

VALVE

&OK

'O\CHSI~~

MRlY

&OK

Pll'lAT!C~

SHIELD

~ACUUU

,ESSEL

T[~P£~~IUP£

S[~SO'!

{0~NE:Cl0R

~CCESSQRl

POR'

CO~~ECTlO~

PRESsu.q[ RWEF

~Al~E

HrUUI!-GAS

SU;>;>lY

CO!.HtlOR

HE~IUY-GAS

HTUR~

{O~~ECIOR

UI'

/.\

r

Figure 1.2 Cutaway views

of

Cryo·Torr Cryopumps

l\

V'

1-2

eTi-CRYOGENICS

HELIX

-TEC'H'NOLOGY

CORPORATION

-----

----------,-,----------------

----,-,,-------

) Table

1.1

Cryopump Specifications

WEIGHT

(APPROXIMATE)

SHIPPING

WEIGHT

CRYOPUMP LBS KG LBS

KG

CT-IOO

22

10

30

11

CT-7

25

11

32

14.5

CT-S

45

20

50

23

CT-SF

42

20

47

21

PUMPING SPEEDS (LITER/SECOND)

CRYOPUMP WATER

AIR

HYDROGEN ARGON

CT-IOO

1,000

350

4S0

285

CT-7

3,600

1,000 1,000

S50

CT-S

4,000

1,500

2,500

1,200

)

CT-SF

4,000

1,500

2,200

1,200

CROSSOVER (MAXIMUM GAS BURST)

CRYOPUMP TORR-LITERS

CT-IOO

40

CT-7

50

CT-S

150

CT-SF

150

CONDENSABLE GASES CAPACITY

(ARGON, NITROGEN, OXYGEN, ETC,)

CRYOPUMP STANDARD LITERS TORR-LITERS

CT-IOO

90

6S,400

CT-7

350 266,000

CT-S

1,000

760,000

CT-SF

1,000

760,000

1-3

J

CTI-CRYCXJENICS

-,,----

------~--

- -

-,,-

---

-

------

Table

1.1

Cryopump Specifications (Cont.)

Capacity: HYDROGEN GAS CAPACITY

HYDROGEN PARTIAL STANDARD

TORR·

CRYOPUMP PRESSURE (TORR) LITERS LITERS

CT-IOO

5 x

10-

8 1

7ffJ

CT-IOO

5 x

10-6

2

1,520

CT-7

5 x

10-

8 2

1,520

CT-7

5 x

10-6

4

3,040

CT-8

5 x

10,8

6 4,560

CT-8

5 x

10-6

12

9,120

CT-8F 5 x

10,8

4 3,040

CT-8F 5 x

10-6

8 6,080

ARGON THROUGHPUT (MAXIMUM)

TORR·LITERS!

CRYOPUMP SCCIMINUTE SECOND

CT-IOO

75

0,95

CT-7

75

0.95

CT-8

700

8.9

Interface connections CT-8F 700

8.9

Helium supply

and

reJum

piping

10

ft.

(3

m)

each

with

1/2-inch

self-sealing couplings.

(Longer

lengths,

elbows

and

tees

available.)

Cold-headpower cable

10

ft.

(3

m).

(Longer

lengths

available.)

Temperature sensor

(a)

Hydrogen-vapor-pressuregauge

(b) Diode temperature sensor connector

mates

with

Amphenol

PIN

48-J6R-1O-55/48-23-4

I

Accessory port connection

(Roughing)

Supplied

by

CTI

NW-25

ISO-KFflange

(with

clamp

and

blank

flange)

Regeneration purge fitting

Supplied

by

CTI

Parker

CPI

ULTRASEAL

SIZE

6

(with plug

and

nut)

Mok:

The

cryopump

may

be

operated

in

any

position.

1-4

en-CRYOGENICS

Ii

HELIX TECHNOLOGY CORPORATION

-----~-----------------~~

---

- -

--,-----

Table

1.1

Cryopump

Specifications (Cant.)

Interface

dimensions:

Note:

The

dimensions

present

below

are

basic

interfacing

dimensions

required

for

cryopump

installation.

If

additional

dimensions

are

required,

contact

your

sales

representative

or

the

Order

Processing

Department

to

obtain

an

interface

drawing

for

your

particular

cryopump.

DIMENSIONS

A B C D E

CRYOPUMP

(lnJmm) (lnJmm) (lnJmm) (lnJmm) (inJmm)

cr-100

(MET.SEAL) 12.9 (328) 9.4 (240) 6 (152) 3.9 (99)

10(256)

(ISO) 12.8 (323) 9.3 (235) 5.12 (130) 3.9 (99) 10 (256)

cr-7

(ISO) 13.25 (337) 9 (229) 9.5 (130) 7.9 (200) 11.8 (300)

(ANSI) 13.25 (337) 9 (229)

11

(279) 7.9 (200) 12.6(320)

(UHV) 13.25 (337) 9 (229) 10 (254)

7.9(200)

12(307)

cr-8

(ANSI) 20.7 (526) 13.8 (351)

11

(279) 8 (203) 14.5 (370)

(MET.SEAL) 20.7 (526) 13.8 (351) 10 (254) 8 (203) 14.5 (370)

(UHV) 20.7 (526) 13.8 (351) 10 (254) 8 (203) 14.5 (370)

(ISO) 20.7 (526)

13.8

(351)

9.5 (240) 8 (203) 14.5 (370)

cr-SF

(ANSI) 22.6 (574) 15.8 (402)

11

(279) 8 (203) 14.5 (370)

(ISO) 21.8 (555) 15 (381) 9.5 (240) 8 (203) 14.5 (370)

+Nore:

CT·8F

depth

dimensions

is

7.1

in.

(179.6

mm)

approximate

CT-7

I:

®

®

'I

TIT

®©@

li

-rea;

CT·8F CT-8

1-5/1-6

)

ai-CRYOGENICS

HELIX TECHNOLOGY CORPORATION

---

--

-------

--

- -

----~~----

Section

2:

Inspection

2.1

Packaging of the System.

2.2 The Cryopump. . . . . . .

2.1

Packaging of the System

A Cryo-Torr High-Vacuum

Pump

System is packaged

in

three orfour separate cartons, depending

upon

whether

an

8300

or Model

SC

Compressor is

used.

Listed below

are

the

contents ofeach carton,

as

they

relate

to

these

two

compressor applications.

Note

that

an

Installation, Operation,

and

Servicing Manual

is

included

in

cartons

for

the

high-vacuum pump,

compressor and controller; each

manual

covers

the

componentpackaged

in

that carton.

When installing a

Cryo-

Torr High-Vacuum Pump

System,

CTI

recommends that

as

you

unpack

a

component;

you

then

perform

an

inspection and

the

necessary

tasks

for

system

installation

for

the

component

according

to

the

manual

(included

with

the

component).

Final system installation

and

operation

will

beperformed

following procedures

in

the

cryopump

manual

(M8040240).

2.2 The Cryopump

2-1

2-1

On

receipt, remove

the

cryopump

from

its shipping

carton and inspect

the

cryopump

for

evidcnce of

damage.

Report

any

damage

to

the

shipper at once.

Also,

retain

the

shipping cartons

for

use

in

storage or

return shipment.

Inspect

the

cryopump

for

damage

by

examining

the

following:

1.

Overall exterior.

2.

Mounting flange

and

its sealing surfaces after

removing the protective cover.

3.

Louver assembly of

the

80K

condensing array.

Replace

the

protective cover.

For Your Information--

If

you

are already familiar

with

the

details ofcryo-

pump

installation, proceed directly

to

Section 3

so

your cryopump can be

made

operational

quickly.

If

not,

proceed

to

Section 4

for

detailed installation

procedures.

COMPRESSOR

USED

CARTON

MANUAL

LABEL

8300

MODEL

SC (AIR) NO.

CRYO-TORR@

Cryopump Cryopump

M8040240

Compressor

8300 Compressor

~

..

-M8040241

----- SC (Air) Compressor M8040243

Accessories

MaintenanceTool Kit

Maintenance

Tool

Kit

and

Accessories,

and

Accessories

..

_-

PIN 80320400013 PIN 80320400004

Controller

8001

or

8002

.~

..

-M8040241

Controller

2-1/2-2

Section

3:

Quick Installation

and Startup

crl-CRYoc.ENICS

HELIX TECHNOLOGY CORPORATION

Many Users are already familiar with the details

of

cryopump, controller, and compressor installation, and

basic operation. This section presents the installation

and startup steps

in

summary form

so

that the cryopump

can

be

made operational quickly. Table 3.1, and Figure

3.1, presentsummary procedures for quick installation

and startup. Each step in the table is followed by a

reference to the location in the Manual where detailed

information is given.

This Section

is

merely designed to get your system

"running". No attempt is made here to present detailed

procedures for installing and operating your system.

Detailed information is covered in Section 4 and

Section

5.

Table

3.1

Summary

of

Procedures

for

Quick Installation

and

Startup

REFER

TO

REFERENCE

STEP

PROCEDURE

(See

Figures

3.1

and

3.2)

FOR

DETAILS

ACAUTION

1.

DO

NOT

connect

the

controller

or

cryopump

to

its

power

source

until

all

connections

have

been

made

between

the

components

of

the

high-vacuum

system.

2.

The

switch(es)

on

the

front

of

the

controller

or

compressor

must

be

in

the

OFF

position

before

making

any

and

all

electrical

connections.

1.

Mount

the

cryopump

to

the

vacuum

system.

Section

4.1,

page

4··1

2.

Connect

roughing

system,

purge

gas

system

and

vent

pipe

to

Section

4.2,

thru

4.4

cryopump.

pages

4-1

and

4-2

3.

Connect

the

helium-gas

supply

and

return

lines

between

the

Section

4.5,

page

4-2

cryopump

and

the

compressor.

4.

Electrically

connect

the

compressor

and

controller.

(ModeI8300

Section

4.6,

page

4-3

Compressor)

a.

Connect

compressor

control

cable

between

controller

and

compressor.

b.

Connect

controller

to

compressor

power

cable.

5.

Connect

cold-head

power

cable

from

the

cryopump

to

the

Section

4.6,

page

4-3

controller

or

compressor.

6.

Connect

the

controller

or

compressor

main

power

cable

to

the

Section

4.6,

page

4-3

power

source.

YOUR

SYSTEM

IS

NOW

READY

FOR

OPERATION.

7.

Start

the

system

by

using

the

system

power

ON/OFF

switch.

Section

5.3,

page

5-2

(On

SC

Compressor

also

turn

on

the

cold

head

switch.)

3-1

ai-CRYOGENICS

UNPACK

AND

UNPACK

AND

UNPACK

AND

UNPACK

AND

INSPECT

INSPECT

INSPECT

INSPECT

CRYOPUMP

COMPRESSOR

TOOLKIT

CONTROLLER

AND

CARTON

A CARTONB

ACCESSORIES

CARTOND

CARTONC

INSTALLCRYOPUMP

TO

VACUUM

SYSTEM:

-CONNECTVENTPIPE

-CONNECTROUGHPUMP

-

CONNECT

PURGE

GAS

CONNECTCRYOPUMPTO

COMPRESSOR:

-

CONNECT

HELIUM-GAS

RETURN

AND

SUPPLY LINES

-

CHECK

HELIUM

PRESSURE

1

8300 COMPRESSOR SC COMPRESSOR

ELECTRICAL

CONNECTION

OF

ELECTRICAL

CONNECTION

OF

COMPRESSOR,

CONTROLLER

AND

COMPRESSOR

AND

CRYOPUMP:

CRYOPUMP:

-CONNECT

COLD

HEAD

CABLE

-

CONNECT

COMPRESSOR

POWER

FROM

COMPRESSOR

TO

COLD

CABLE

TO

CONTROLLER

AND

HEAD

COMPRESSOR

-

CONNECT

COMPRESSOR

INPUT

-

CONNECT

COMPRESSOR

CON-

POWER

CABLE

TO

MAIN

POWER

TROL

CABLE

TO

CONTROLLER

SOURCE

AND

COMPRESSOR

-

CONNECT

COLD

HEAD

POWER

CABLE

FROM

CONTROLLER

TO

COLD

HEAD

-

CONNECT

CONTROLLER

INPUT

POWER

CABLE

TO

MAIN

POWER

SOURCE

I 1

START

SYSTEM

Figure

3.1

Block diagram for system installation

3-2

)

)

TO

COLO

HEAD

.v==_

POWER

CONNECTOR

TO

INPUT

POWER

OUTLET

SC

COM

PRESSOR

8001/8002

CONTROLLER

_

HELIUM-GAS

RETURN

LINE

(FROM

COLO

HEAD)

_

HELIUM-GAS

SUPPLY

LINE

(TO

COLO

HEAD)

TO

INPUT

POWER

OUTLET

___

~rt~35~~~~~r=~

REMOTE

I

_

TO

COLO

HEAD

POWER

CONNECTOR

CABLE

I

CONNECTOR

<:)

I

~~gCLE~O~llLY)

gg~f~6[SOR

COMPRESSOR

_f--,i::J\\\:-"/~:::C~~IBLE

POWER

CABLE

CARTRIDGE

(MAY

BE

REMOTELY

LOCATED)

CONTROLLER

--'---'-SIDE

MOUNTED

(OPTIONAL)

ROUGHING

VALVE

PURGE

VALVE

-CRYOGENICS

HELIX TECHNOLOGY CORPORATION

USER'S

VACUUM

CHAMBER

CRYOPUMP

HELIUM-GAS

====~~~=d~~i-~2:

_

RETURN

LINE

_

(FROM

COLO

HEAD)

COIINECT(lR

IJ

IN

OUT

WATER

8300

COMPRESSOR

HELIUM

-

GAS

_

SUPPLY

LINE

_

====::::r

(TO

COLO

HEAD)

ELECTRICAL

POWER

FROM

CONTROLLER

/

COMPRESSOR

Figure

3.2

Cryopump

interconnection

3-3/3-4

This manual suits for next models

3

Table of contents

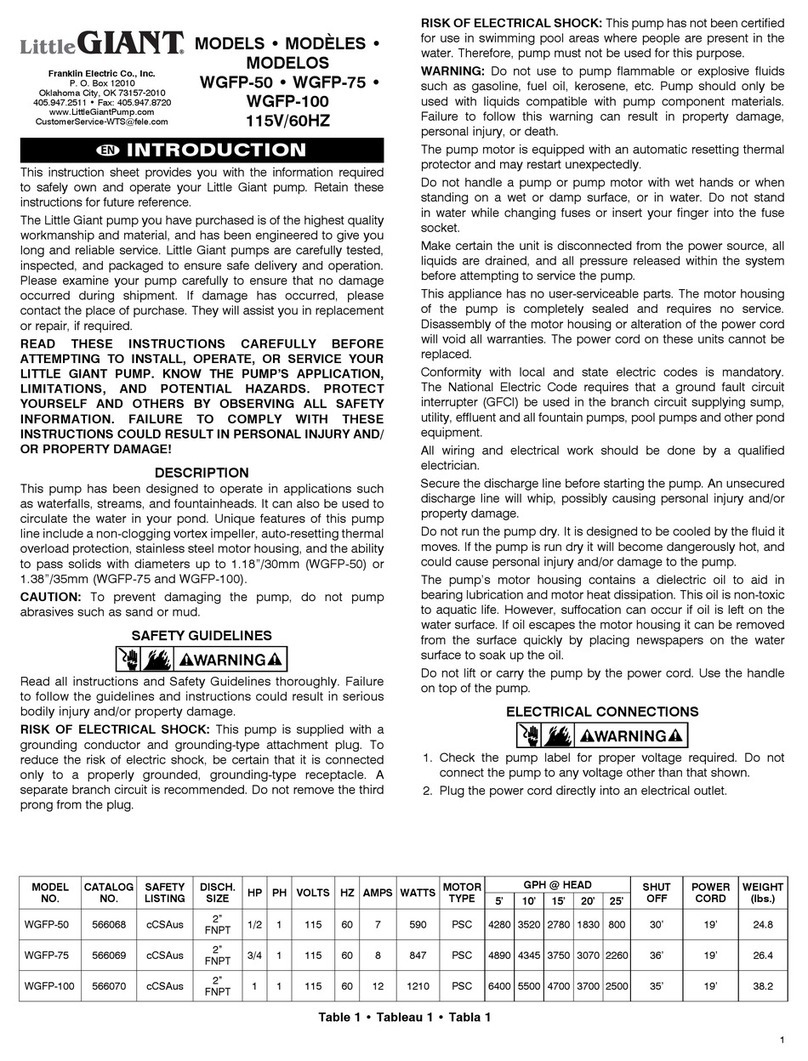

Popular Water Pump manuals by other brands

Little Giant

Little Giant UPSP-5 quick start guide

Bijur Delimon

Bijur Delimon FZ-A Operation manual

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS T2C60SC-B Installation, operation and maintenance manual

Strend Pro

Strend Pro SWP-110 instruction manual

White Knight

White Knight PSA140SS owner's manual

Giant

Giant P205 Repair and Operating instructions/ repair and service manual

DIVERSITECH

DIVERSITECH CP-22 Installation and safety instructions

Franklin Electric

Franklin Electric Little Giant WGFP-50 manual

Resol

Resol FlowSol D Installation, Operation, Commissioning, Maintenance

SKC

SKC 224-PCXR4 operating instructions

Graco

Graco 15H886 instructions

Walrus

Walrus TPH50T5KF instruction manual