Helmer i.series User manual

Undercounter Freezer

Service Manual

i.Series™ and Horizon Series™

Plasma Models

• i.Series: iPF105 (Version B)

• Horizon Series: HPF105 (Version B)

Laboratory Models

• i.Series: iLF105 (Version B)

• Horizon Series: HLF105 (Version B)

Model

S/N

0086

ISO 13485:2003 CERTIFIED

HELMER, INC.

14395 Bergen Boulevard

Noblesville, IN 46060 USA

Phone +1 (317) 773-9073

USA and Canada (800) 743-5637

360142-1/E

i

360142-1/E

Section I: General Information......................................1

1 About this Manual ........................................................3

2 Safety ..................................................................4

2.1 Labels ..........................................................................4

2.2 Avoiding injury ....................................................................4

3 Conguration ............................................................5

3.1 Finding model and input power information..............................................5

3.2 Identifying the control system ........................................................5

3.3 Preparing the temperature probe......................................................6

3.4 Preparing the chart recorder .........................................................7

Section II: i.Series™ Models. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

4 ProductConguration....................................................11

4.1 Installing batteries for backup power ..................................................11

4.2 Freezersetpointconguration .......................................................12

4.3 Automaticdefrostcycleconguration .................................................13

4.4 External monitoring devices.........................................................14

4.5 Moving drawers, shelves, and baskets ................................................15

4.6 Leveling the freezer ...............................................................16

4.7 Door characteristics ...............................................................17

4.8 Optional adapter kits for medication dispensing locks.....................................17

4.9 Door hinge and handle reversal, all models.............................................17

4.10 Hinge reversal (glass door and solid door) .............................................22

4.11 Hinge spring assembly reversal......................................................24

4.11 Stacking undercounter units ........................................................24

5 Temperature Controller Programs ..........................................25

5.1 Temperature setpoint settings .......................................................26

5.2 Temperature calibration settings .....................................................27

6 Maintenance ............................................................29

6.1 Recharging refrigerant.............................................................29

6.2 Checking the monitoring system backup battery.........................................30

6.3 Cleaning the freezer...............................................................30

6.4 Defrosting the freezer .............................................................31

6.5 Removing and installing the unit cooler cover ...........................................32

6.6 Removing and replacing the Access Control cartridge ....................................34

6.7 Supplies........................................................................36

7 Troubleshooting.........................................................37

7.1 General operation problems ........................................................37

7.2 Chamber temperature problems .....................................................38

7.3 Alarm activation problems ..........................................................39

7.4 Testing problems .................................................................42

7.5 Condensation and icing problems ....................................................43

Contents

Contents

ii

360142-1/E

8 Parts ..................................................................44

8.1 Control and monitoring.............................................................44

8.2 Front...........................................................................46

8.3 Rear and under ..................................................................47

8.4 Side access panel ................................................................50

8.5 Interior .........................................................................50

8.6 Door and hinge parts ..............................................................53

9 Schematics.............................................................54

9.1 iPFandiLFmodels;105conguration ................................................54

10 Settings................................................................56

10.1 Navigating the Home screen ........................................................56

10.2 Viewing and changing settings.......................................................57

10.3 Testing alarms ...................................................................60

10.4 Upgradingthesystemrmware ......................................................63

10.5 Calibrating the touchscreen.........................................................63

10.6 Viewing manufacturer and product information ..........................................63

11 Warranty ...............................................................64

11.1 Rel.i™ Product Warranty USA and Canada.............................................64

11.2 Outside of USA and Canada ........................................................65

12 References and Compliance...............................................66

12.1 Alarm reference ..................................................................66

12.2 Energy conservation and regulatory compliance.........................................66

Section III: Horizon Series™ Models................................67

13ProductConguration....................................................69

13.1 Installing batteries for backup power ..................................................69

13.2 Freezersetpointconguration .......................................................70

13.3 Automaticdefrostcycleconguration .................................................71

13.4 External monitoring devices.........................................................74

13.5 Moving drawers, shelves, and baskets ................................................75

13.6 Leveling the freezer ...............................................................76

13.7 Door characteristics ...............................................................77

13.8 Optional adapter kits for medication dispensing locks.....................................77

13.9 Door hinge and handle reversal, all models.............................................77

13.10 Hinge reversal (solid door with Access Control option) ....................................82

13.11 Hinge reversal (solid door without Access Control option)..................................84

13.12 Hinge spring assembly reversal......................................................86

4.11 Stacking undercounter units ........................................................86

14 Temperature Controller Programs ..........................................87

14.1 Hysteresis ......................................................................87

14.2 High alarm setpoint ...............................................................87

14.3 Low alarm setpoint................................................................87

14.4 Controltemperatureosetvalue .....................................................87

14.5 Monitortemperatureosetvalue .....................................................87

Undercounter Freezer Service Manual

iii

360142-1/E

15 Maintenance ............................................................88

15.1 Recharging refrigerant.............................................................88

15.2 Checking the monitoring system backup battery.........................................89

15.3 Cleaning the freezer...............................................................89

15.4 Defrosting the freezer .............................................................90

15.5 Removing and installing the unit cooler cover ...........................................91

15.6 Removing and replacing the Access Control cartridge ....................................93

15.7 Supplies........................................................................95

16 Troubleshooting.........................................................96

16.1 General operation problems ........................................................96

16.2 Chamber temperature problems .....................................................97

16.3 Alarm activation problems ..........................................................98

16.4 Condensation and icing problems ...................................................101

17 Parts .................................................................102

17.1 Control and monitoring............................................................102

17.2 Front..........................................................................103

17.3 Rear and under .................................................................104

17.4 Side access panel ...............................................................107

17.5 Interior ........................................................................107

17.6 Door and hinge parts .............................................................110

18 Schematics............................................................111

18.1 HPFandHLFmodels;105conguration..............................................111

19 Settings...............................................................112

19.1 Touring the monitoring and control system ............................................112

19.2 Viewing current settings...........................................................113

19.3 Changing settings ...............................................................114

19.4 Testing alarms ..................................................................115

20 Warranty ..............................................................117

20.1 Rel.i™ Product Warranty USA and Canada............................................117

20.2 Outside of USA and Canada .......................................................118

21 References and Compliance..............................................119

21.1 Alarm reference .................................................................119

21.2 Energy conservation and regulatory compliance........................................119

Contents

iv

360142-1/E

Undercounter Freezer Service Manual

This page left blank intentionally.

1

360142-1/E

Section I: General Information

Section I: General Information

2

360142-1/E

Undercounter Freezer Service Manual

This page left blank intentionally.

3

360142-1/E

General Information: About this Manual

1 About this Manual

This chapter explains the symbols and conventions used in this manual, copyright information about this

document, and trademark information for products supplied by Helmer.

1.1 Intended audience

This manual is intended for use by authorized end users and qualied service technicians, and is to be used

in conjunction with the i.C³™User Guide, Freezer Operation Manual, Chart Recorder Operation Manual,

and the Horizon Access Control Keypad User Guide, available on the CD shipped with the freezer.

1.2 Symbols and conventions

1.2.1 Cautions

A Caution is used to call attention to a condition or possible situation that could damage or destroy the

equipment or the operator’s work.

!

CAUTION Temperature probes are fragile. Handle them with care.

1.2.2 Notes

Notes contain additional information about a topic. Notes are used to provide information about how a

topic relates to another topic, or background information about a design characteristic.

NOTE Spare parts are available for purchase through Helmer.

1.2.3 Model references

Generic references are used to group undercounter freezers that contain similar features. For example,

“i.Series” refers to iPF105 and iLF105 freezers, and “Horizon Series” refers to HPF105 and HLF105

freezers. This manual covers all undercounter freezers, which may be identied singly or by their respective

“Series.”

Model Group i.Series Horizon Series

Plasma iPF105 HPF105

Laboratory iLF105 HLF105

1.3 Copyright and trademark information

Helmer®, i.Series®, i.C³™, Horizon Series™, and Rel.i™ are registered trademarks or trademarks of

Helmer, Inc. in the United States of America. Copyright © 2012 Helmer, Inc. All other trademarks and

registered trademarks are the property of their respective owners.

4

360142-1/E

Undercounter Freezer Service Manual

2 Safety

This chapter describes general safety information for servicing the freezer. The Freezer Operation Manual

includes additional safety information for operating the freezer. Your organization may provide additional

safety information.

2.1 Labels

Caution, risk of danger Caution, shock hazard

Caution, unlock all casters Earth ground terminal Protective earth ground terminal

2.2 Avoiding injury

► Review safety instructions before installing, using, or maintaining the equipment.

► Before performing procedures, review any specic safety instructions.

► Do not open multiple, loaded drawers at the same time.

► Before moving unit, ensure casters are free of debris.

► Avoid removing electrical service panels and access panels unless so instructed.

► Use supplied power cords only.

► Notify appropriate safety personnel when handling or disposing of materials that are infectious, toxic,

pathological, radioactive, or otherwise biologically or environmentally harmful.

!

CAUTION Decontaminate parts prior to sending for service or repair. Items not

decontaminated appropriately will not be accepted. Documentation stating

contents are not contaminated and are safe to handle must accompany returns.

Contact Helmer or your distributor for decontamination instructions and a

Return Authorization Number.

5

360142-1/E

3 Conguration

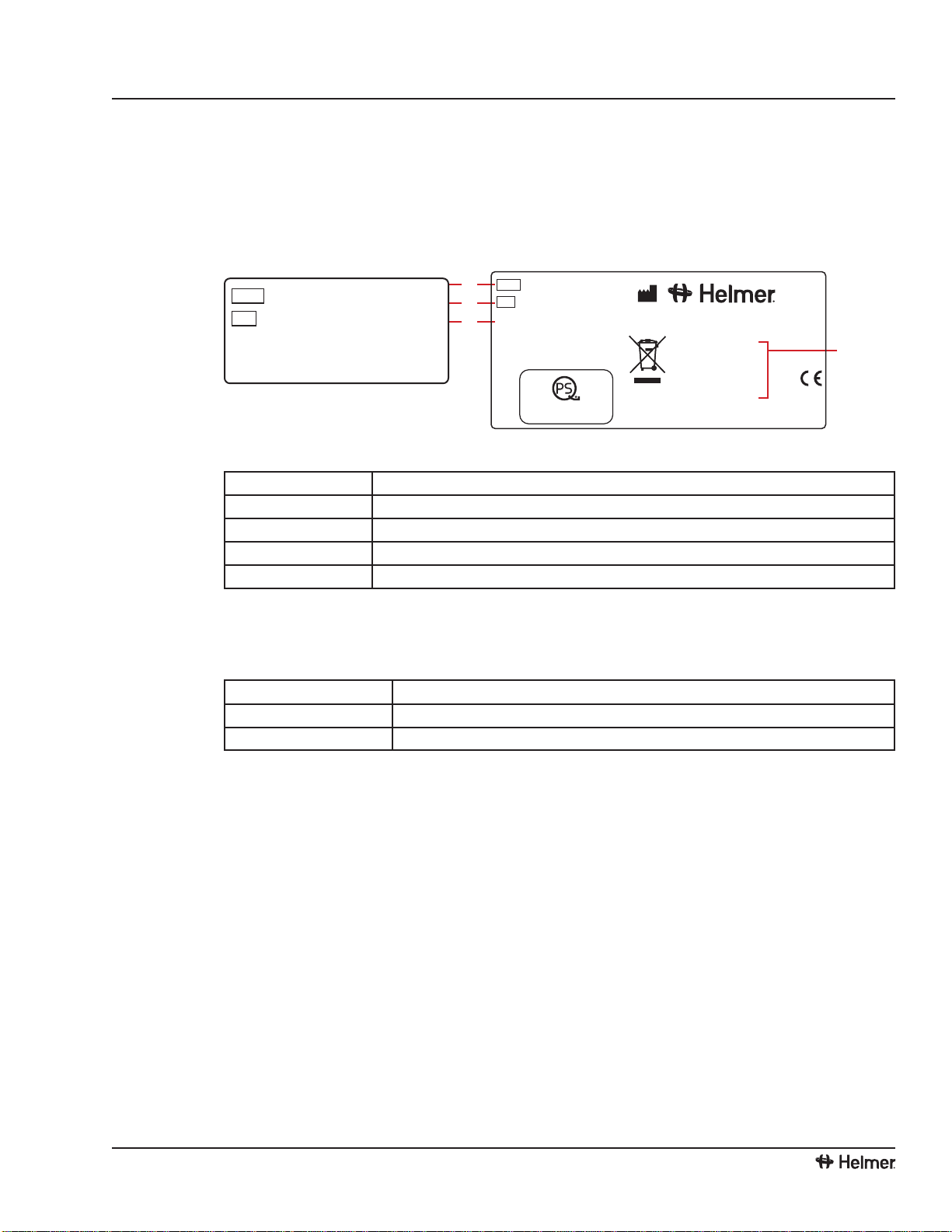

3.1 Finding model and input power information

Service information varies depending on the model and input power requirements. This information

appears on the Product Specication label, located on the rear of the freezer. The model also appears on a

label located in the chamber on the upper side of the right wall.

D

A

B

C

REF

SN ILF105

000000

Voltage 115 V

HZ 60

Amps 5.75 A

Version A

Laboratory Freezer

Weight 197 lb / 89 kg

www.helmerinc.com

Noblesville, IN USA

2011

0086

UL 61010-1/CSA 61010-1

Certified

CUS

REF

SN ILF105

000000

Version A

www.helmerinc.com

Left:Chamberlabel.Right:ProductSpecicationlabel(locatedontherearatlowerleft).

Label Description

A Model (REF)

B Serial number (SN)

C Version

D Power requirements

3.2 Identifying the control system

Service information varies depending on the control system. Helmer freezers have one of two control

systems installed. The type of control system varies by model.

Model group Control system

iB105 and iLR105 i.C³ monitoring and control system

HB105 and HLR105 Horizon Series monitoring and control system

3.2.1 i.C³ control system

i.Series freezers are equipped with the i.C³ monitoring and control system. The i.C³ system combines

temperature control and monitoring into a single interface, displaying multiple information logs with

historical information in full color. The touchscreen monitor, located on the freezer door, displays

operational information. The chamber temperature controller is integrated into the i.C³ system.

i.C³ monitoring and control system display.

GeneralInformation:Conguration

6

360142-1/E

3.2.2 Horizon Series control system

Horizon. Horizon Series freezers feature the Horizon combined monitor and temperature controller. The

Horizon Series system controls chamber temperature and monitors and displays operational information.

The user interface for this system is located on the freezer door.

Horizon Series monitoring and control system display.

3.3 Preparing the temperature probe

The temperature probe monitors chamber temperature.

In addition to using standard probes installed by Helmer, external probes may be introduced through the

existing rear port and immersed in the existing probe bottle.

For each probe bottle, obtain:

► Approximately 4 oz (120 ml) of product simulation solution. Solution is a 1:1 ratio of water to

propylene glycol (or equivalent low-temperature uid).

Left: Probe bottle with temperature probe. Right: Access port on rear of freezer.

To install an additional external probe through the rear

1 Peel back the putty to expose the port and insert probe through the port into chamber.

2 Insert probe into the bottle.

3 Replace putty, ensuring a tight seal.

Tollatemperatureprobebottle

!

CAUTION ► Clean bottle rst, as required.

► Temperature probes are fragile; handle with care.

1 Remove all probes from bottle.

2 Remove bottle from bracket and ll with approximately 4 oz (120 ml) of product simulation solution.

3 Cap tightly to minimize evaporation.

4 Place bottle in bracket and replace probes, immersing at least 2 inches (50 mm) in solution.

Undercounter Freezer Service Manual

7

360142-1/E

3.4 Preparing the chart recorder

If installed, see the Temperature Chart Recorder Operation and Service Manual on CD.

Complete these tasks to prepare recorder for use:

► Installing the backup battery.

► Adding paper.

► Calibrating the chart recorder to match the chamber temperature.

3.4.1 Accessing the chart recorder

► Pull the door open.

Opening the chart recorder door.

3.4.2 Changing chart paper

One piece of chart paper records temperatures continuously for seven days. For additional information on

changing the chart paper, see the Temperature Chart Recorder Operation and Service Manual on CD.

GeneralInformation:Conguration

8

360142-1/E

This page left blank intentionally.

Undercounter Freezer Service Manual

9

360142-1/E

Section II: i.Series™ Models

Section II: i.Series™ Models

10

360142-1/E

Undercounter Freezer Service Manual

This page left blank intentionally.

11

360142-1/E

i.Series™Models:ProductConguration

4 ProductConguration

4.1 Installing batteries for backup power

The monitoring systems and chart recorder each have a battery backup system, enabling a period of

continuous operation if power is lost.

NOTE The monitoring systems will start on battery power alone. If the freezer was

previously not connected to AC power and the backup battery is connected or

switched on, the monitoring system will begin running on battery power.

Battery life varies by manufacturer as well as voltage level remaining. Providing full power is available,

and no battery-related alarms are active, backup power is available for up to 20 hours (the Low Battery

alarm will activate after approximately 18 hours of battery use).

NOTE If AC power is lost, the monitoring system will automatically disable some

features to prolong backup battery power. Data collection functions will

continue until backup battery power is depleted.

!

CAUTION ► Before installing or replacing batteries, disconnect power to the freezer.

► When installing a replacement battery for the monitoring system, use only a

battery which meets the specications outlined in chapter 6.7 (Supplies).

The the battery is located below the chamber, behind the front cover. A cover plate must be removed to

access the backup battery.

Monitoring system backup battery (access panel removed).

Models Monitoring system Battery requirements

iPF105 and iLF105 Combined alarm monitoring and

control system One rechargeable 12 V lead acid

sealed battery

The rechargeable backup battery that is switched o for shipping. Switch the battery ON to provide the

monitoring system with backup power in the event of a main power failure.

12

360142-1/E

Undercounter Freezer Service Manual

4.2 Freezersetpointconguration

The temperature controller adjusts chamber temperature around the freezer setpoint. The controller

activates the compressor when the chamber probe registers temperature above the setpoint.

The controller also senses unit cooler temperature through a probe in the cooler. The temperature in the unit

cooler typically varies from the temperature in the chamber, so an oset value is used in the control system.

The unit cooler temperature combined with the oset value establishes the freezer setpoint.

NOTE The probe in the bottle is connected to the monitoring system and senses

chamber temperature. This probe does not impact the freezer setpoint.

4.2.1 Determining current freezer setpoint

First, conrm:

► Freezer has run for at least 24 hours to stabilize chamber temperature.

► Chamber temperature is not uctuating because of excessive door openings and closings.

► Freezer has been placed per location requirements. See operation manual.

► Preventive maintenance has been completed. See operation manual.

► Troubleshooting items associated with chamber temperature have been reviewed.

Obtain:

► An independent thermometer, calibrated and traceable per national standards.

► Tape. This is used to secure the probe to the thermometer.

1 Remove all probes from the probe bottle.

2 Unscrew the cap from the bottle.

3 Tape the independent thermometer to the temperature probe, and replace them in the bottle so their

ends are immersed at least 2 inches (50 mm).

4 On the independent thermometer, monitor temperature for about 10 minutes to determine an

approximate range.

5 From the range, calculate an approximate average temperature. This is the current setpoint.

6 Remove thermometer and probe from the bottle and remove tape.

7 Replace bottle cap, ensuring a tight t.

8 Place probes in bottle, immersing at least 2 inches (50 mm).

13

360142-1/E

i.Series™Models:ProductConguration

4.2.2 Changing freezer setpoint

The default setpoint is either -20.0 °C or -30.0 °C, depending on use.

Change the setpoint if:

► Your organization requires a chamber temperature dierent from the default setting.

► The normal chamber temperature is too high or low, even after completing preventive maintenance and

applicable troubleshooting tasks.

Before changing setpoint, conrm:

► Freezer has been placed per location requirements. See operation manual.

► Preventive maintenance has been completed. See operation manual.

► Troubleshooting items associated with chamber temperature have been reviewed.

The temperature controller is integrated into the monitoring and control system. The temperature

setpoint is congured through the i.C³ screen.

!

CAUTION Do not change setpoint to a value outside the temperature control range.

1 Determine the new setpoint temperature.

2 Determine the change in value to reach the desired setpoint. The adjustment should be about half

the dierence between the current setpoint and the new setpoint. For example, if the desired normal

temperature is -30.0 °C, but the current setpoint is -29.0 °C, then the dierence is 1.0 °C, and the

setpoint adjustment value would be 0.5 °C.

3 On the i.C³ screen, touch i.C³ APPS, i.C³ Settings. Enter the Settings password then touch

Temperature Setpoints.

NOTE The Settings screen may be password protected. A valid four-digit password

must be entered to view settings. If viewing settings for the rst time, enter the

factory default password of “1234”.

4 Touch plus (+) or minus (-) on the Temperature Setpoint spin box until the correct value appears. The

button increments are ±0.1 °C.

5 The setpoint is changed. Touch Home to return to the home screen.

4.3 Automaticdefrostcycleconguration

The freezer features an automatic defrost system. This system periodically runs to melt accumulated ice on

the evaporator, which can obstruct air ow and degrade the freezer’s capability to reach the temperature

setpoint.

The number of programmed defrost events is dependent on environmental conditions and the frequency

of usage. The recommended number of daily defrost cycles is three to four, programmed at even intervals.

Defrost events should take place when the freezer door is opened infrequently. Opening the door can raise

the chamber temperature above the normal defrost cycle temperature, typically 4 °C to 10 °C above the

freezer setpoint.

NOTE Depending on the high temperature alarm setpoint and the actual temperature

increase during the defrost cycle, frequent door openings may trigger repeated

high temperature alarms.

The defrost settings are integrated into the temperature monitoring and control system. The i.C³ can

perform a maximum of four defrost cycles per day. Specify the number of defrost cycles per day and

the time at which each of the defrost cycles is to occur. The timing for the defrost cycles is based on the

14

360142-1/E

Undercounter Freezer Service Manual

internal time settings of the monitoring and control system. For information in setting the system time, refer

to the i.C³ User Guide.

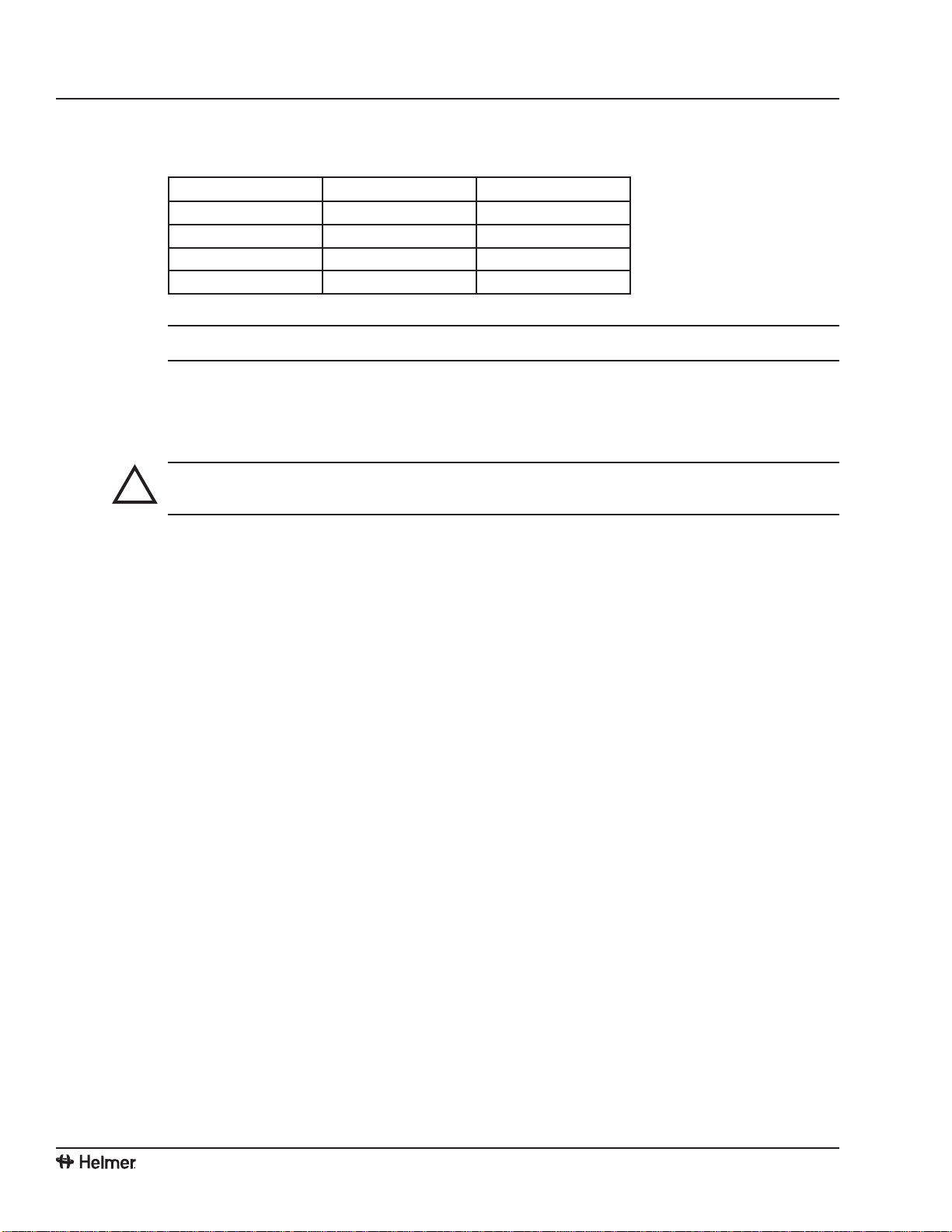

The default defrost cycle times and on/o status are:

Defrost event On/o Default time

1 On 12:00 AM

2 On 8:00 AM

3 On 4:00 PM

4O 6:00 PM

NOTE There must be a minimum of four hours between defrost cycles.

For additional information in enabling or disabling each defrost cycle and setting the system time each

defrost cycle occurs, refer to the i.C³ User Guide

4.4 External monitoring devices

!

CAUTION Do not connect any monitoring device that exceeds the maximum load capacity

for your model.

The freezer provides a remote alarm interface to send information to external devices, such as the Helmer

Remote Alarm Monitoring System. For more information and availability, contact Helmer or your local

distributor.

The remote alarm interface is a relay switch with three terminals: Common (COM), Normally Open (NO),

and Normally Closed (NC). These terminals are dry contacts and do not supply voltage. The interface

circuit is either normally open or normally closed depending on which terminals are used.

The requirements for your alarm system determine which wires must connect to which terminals.

To connect to the remote alarm interface

1 Switch the AC ON/OFF switch OFF.

2 Switch the battery backup switch OFF.

3 On the back of the freezer, locate the remote alarm interface.

4 Connect the remote alarm wires to the appropriate terminals according to the requirements for your

alarm system.

5 Using a cable tie, secure the wires together for stability (as needed).

6 Switch the battery backup switch ON.

7 Switch the AC ON/OFF switch ON.

Other manuals for i.series

10

This manual suits for next models

5

Table of contents

Other Helmer Freezer manuals