Helvest Flex KB800 User manual

Helvest FleX Layout module KB800 - User Manual

Operating instructions for the Helvest®FleX KB800 board

1. General product presentation

1.1 KB800 odule for push button interfacing

The KB800 board controls digital accessories (such as switches or signals) via

pushbuttons alongside digital control via the control unit or PC.

It is a La out module for the HP100 motherboard and works in conjunction with

another La out module that controls the accessories.

An example of use is shown in figure 1: the "La out 1" module can be an module

of the Helvest FleX s stem and controls 4 accessories (turnouts or signals). These

can be controlled either b DCC ( through the DCC100 card) or b buttons

connected to the KB800 module.

This can be useful to move turnouts or signals locall in the station (e.g. to perform

shunting), or to test accessories during programming or during installation.

The KB800 module must be inserted in a "la out" slot on the HP100 board and is

automaticall recognised b the board. The s stem recognises the KB800 module

and the other module that controls the accessories on the same board and

automaticall associates them. No matter which one is in position "1" and which one

is in position "2", the can also be swapped with respect to the example in fig. 1.

To insert the module, switch off the power to the HP100 board, ensure that the

connectors are aligned and appl gentle pressure until the module is full inserted

into the slot.

1.2 Mounting the PCB on the layout

The complete board must be mounted in such a wa that it DOES NOT touch

an thing during operation. In particular, it must not come into contact with an

metallic or flammable material.

For temporar installations, it can be placed on a non-flammable insulating surface

(plastic,glass, ceramic floor, etc...).

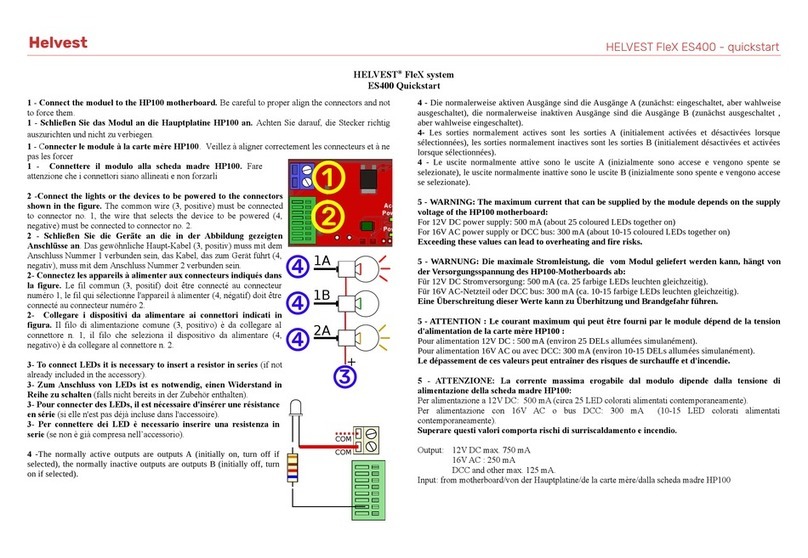

Fig. 1

Layout 1 - Module DCC100

KB800

COM

COM

1

1B

2

2B

3

3B

4

4B

1

1B

2

2B

Your DCC central

Ihre DCC Zentrale

P1

P2

P1

P2

Helvest FleX Layout module KB800 - User Manual

For fixed la outs, mount it on the structure b

screwing the HP-100 onto a wooden surface

with the screws and spacers provided. (figure

3). This operation must be done before inserting

the GAW400 module (if additional cards have

alread been inserted, the can be gentl

removed without an problems).

1.3 Connecting push buttons

All the following operations must be done with

power switched off.

Insert the module on the HP100 board, taking

care to align the connectors correctl and

inserting the board without forcing it.

An t pe of "normall open" button can be connected to the module (i.e. one that is

alwa s off except the instant it is held down, such as the doorbell button in houses).

A total of eight pushbuttons can be connected, corresponding to four accessories

(turnouts, signals, etc.), each of which has two positions (straigh or diverging track,

red or green, etc.).

The buttons must be connected to

connectors 1 and 2 (fig. 3). Figure 4

shows the connection in detail. One pin of

each button must be connected in

connector 2 to the specific output that has

to be controlled (black wires in the

figure), while the other terminal must be

connected to connector 1 together with all

the other buttons of the board (red wires in the figure). The two terminals of

connector 1 can be used indifferentl (the one with the solid line or the one with the

hatching in fig. 4).

PLEASE NOTE: Onl the buttons must be

connected to the KB800 board, and NOT the

accessories ou wish to control.

1.3 Connecting accessories and DCC

Accessories (switches, signals, etc.) are

connected to the other La out module. Buttons

in position 1A and 1B will be associated with

accessor 1 of the other module, those in

position 2A and 2B with accessor 2 and so on.

The DCC signal must be connected to the terminal block of the HP100 (figure 1).

2. DCC OPERATION

2.1 Switching on the decoder

Once all connections have been made, power up the decoder. The green LED in

position no. 4 "PWR" will light up, indicating that the board is powered. The row of

LEDs in position no. 3 lights up briefl , indicating that the s stem has recognised the

module and communication is active.

2.2 Switching accessories.

The accessories can be controlled via the digital control unit, or b pressing one of

the buttons connected to the KB100 board. In this case, LED n. 3 in fig.3

corresponding to the activated accessor turns on at the same time.

There is no priorit between DCC and pushbuttons: the accessor is positioned

according to the last command received, regardless of whether this came from the

pushbutton or the DCC.

2.3 Progra ing

Programming the KB800 module is not necessar . Of course, the addresses of the

other installed module must be programmed for operation via the control unit.

Fig. 4

Fig. 3

1

2

3

4

1

2

COM

COM

1B

1A

2A

2B

Fig. 2

Helvest FleX Layout module KB800 - User Manual

3. EXAMPLES OF USE

3.1 Station or freight yard control panel

The KB800 module can be used to directl control turnouts and station signals, via a

self-built or commercial control panel.

One of the greatest potentialities is the simplification of shunting: if ou control a

shunting locomotive with a handheld device, intervening directl on the vehicles to

hook and unhook, it is much more comfortable to have buttons at hand.

In complex la outs with automated s stems, it is also possible to carr out shunting

on secondar tracks while the trains run on the tracks managed b the control unit,

software or another operator.

3.2 Accessory testing and setting

Another possibilit of use is to

test accessories during their

installation or while

programming them. Let's

suppose ou have installed a

decoder with two modules (8

accessories), and ou want to

test the accessories and control

their movement directl without

going back and forth to the

control unit. To do this, ou onl

need to temporaril plug in a

KB800 module connected to a

push-button panel and perform

these operations:

1. Disconnect the decoder power suppl ;

2. Remove the module that ou do not want to test, and insert a KB800 module in

its place: in fig. 5 it is assumed that ou want to test the accessories connected to the

"La out 1" module. In this case, the module in the "la out 2" slot is removed and the

KB800 module is inserted in its place.

3. Switch on the power suppl

4. Using the control panel, activate the accessories and make an mechanical

adjustments or similar.

5. When finished, switch off the power suppl , remove the KB800 and restore the

removed module.

4 . Troubleshooting

To troubleshoot power supply/connection issues etc., see HP100 board

troubleshooting.

Problem Possible causes

The module is

inserted but not

responding, and the

power LEDs do not

light up.

If the HP100 board is powered (green LED on the HP100 is on),

the module is not properl plugged in. Check for proper

insertion.

The board is in contact with metal parts.

The module is

plugged in, the power

LEDs are on, but the

accessories do not

move and the ellow

LEDs (no.3 fig. 3)

are off.

Check if the card is correctl plugged into the HP100.

Turn the power off and on again.

Check that the pushbuttons are correctl connected.

The module is

plugged in, the power

LEDs are lit, the

ellow LEDs light up

when the button is

pressed, but the

accessories do not

react.

The other La out module might not be inserted properl or the

accessories might be connected imperfectl .

If the above measures do not work, please contact us via the form on helvest.ch.

Layout 1 - Module DCC100

Layout 2 - Module

KB800

Programming ouput

Programmierausgang

Your DCC central

Ihre DCC Zentrale

Fig. 5

Helvest FleX Layout module KB800 - User Manual

4 . TECHNICAL SPECIFICATIONS

Board t pe: module for accessor control via push

buttons, for HP100 motherboard.

Input power for logic circuit: 5V DC, from motherboard.

Operating temperature:: 0 °C - 40 °C

Dimensions 80 x 35 mm

Firmware HP100 >1.2

Instruction manual rev. 1.0 (2021).

All rights reserved. Cop ing, even partial, of the contents of this manual is onl

permitted with the express written permission of the manufacturer.

"Helvest" is a registered trademark of Helvest S stems GmbH, Fribourg (CH).

Helvest FleX Layout module KB800 - User Manual

Table of contents

Other Helvest Flex Control Unit manuals

Popular Control Unit manuals by other brands

ESBE

ESBE VFA200 Series quick start guide

Flomatic

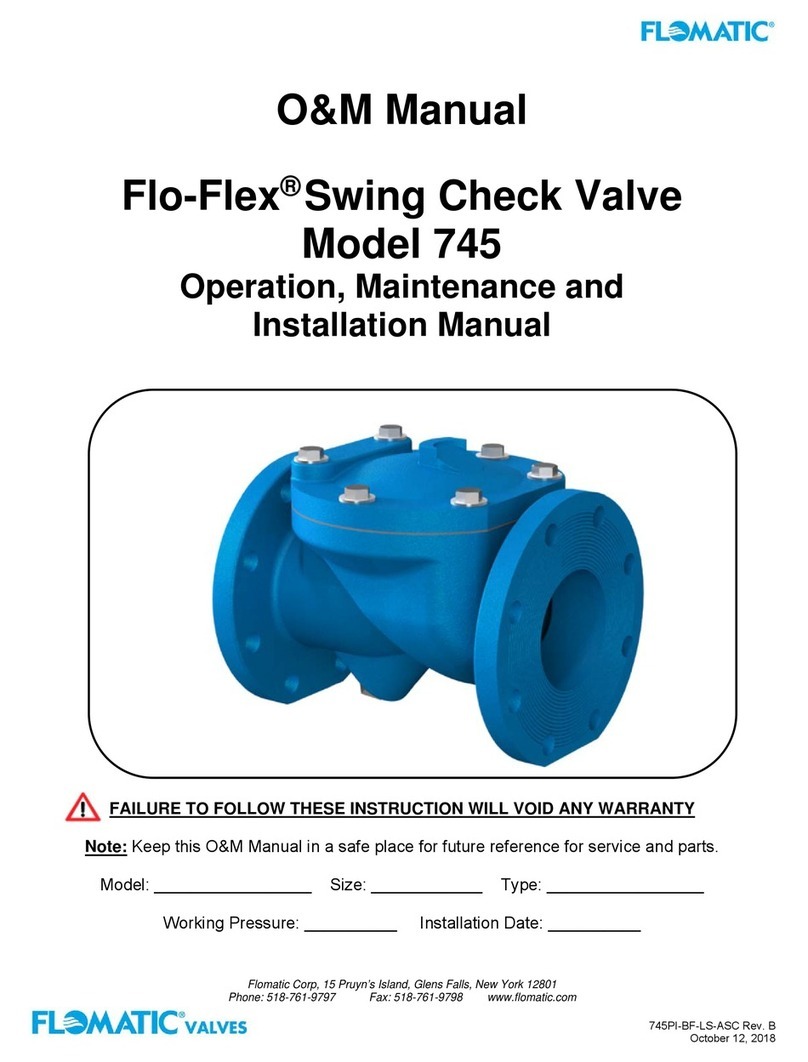

Flomatic Flo-Flex 745 manual

Agilent Technologies

Agilent Technologies G7050A Installation and setup guide

Vega

Vega VEGABAR 80 Series operating instructions

Eaton

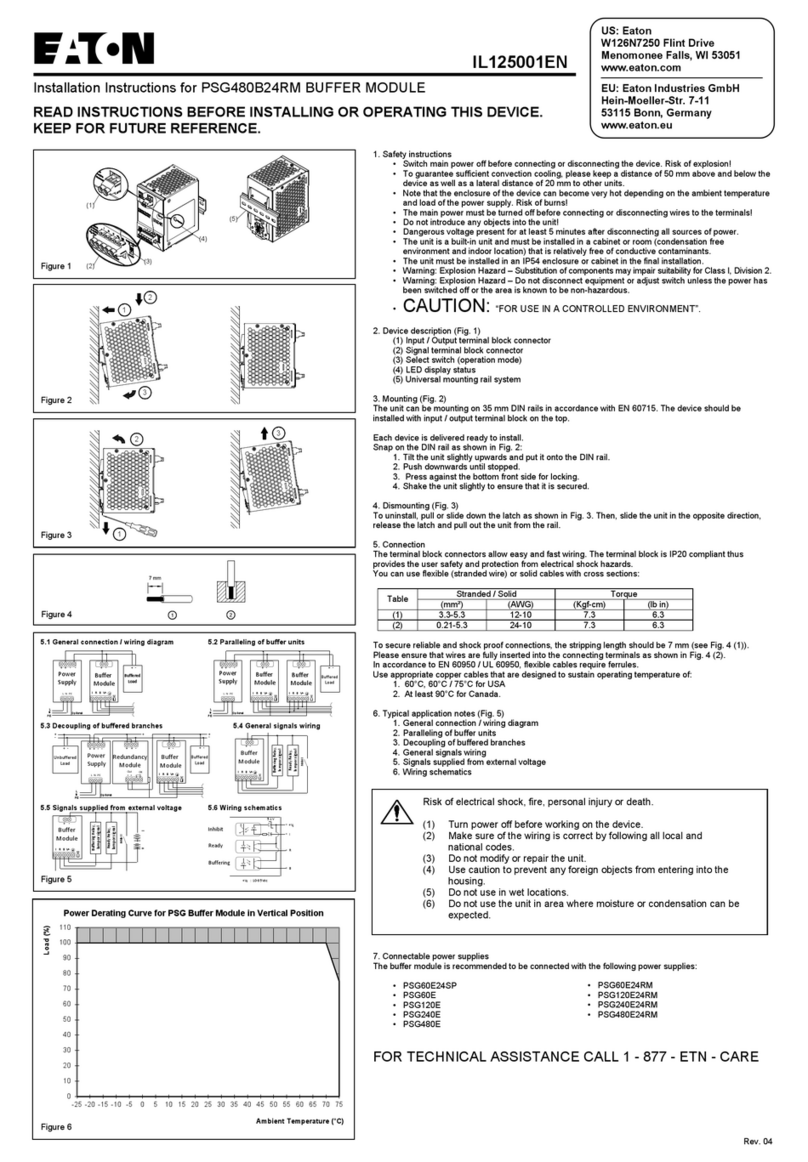

Eaton PSG480B24RM installation instructions

Grundfos

Grundfos CIM 200 Functional profile and user manual