hengel RS10 Quick start guide

INSTRUCTIONS NOTE

page 1 out of 37

Deep - Freezer and Storage Range

Reference SC-NI-EN-2008-4

Updated

Date

Nature of the evolution

1

16/12/08

Details on the assembly of shutter

2

22/04/10

Place of thermosensor probe

3

13/04/11

Adding of COMBITEMP and MULTITEMP

4

11/03/2014

New keyboard with digital display Bi Tronic 2

RS10 to RS110

MAJOR DUO 2 and MAJOR QUATTRO 2

CS10 to CS110

DUO 2 and QUATTRO 2

Basic and aditional module RCM20 to RCM3-20

Basic and aditional module RCN20 to RCN80

Basic and aditional module CCN20 to CCN80

Basic and aditional module RCP20 to RCP80

Basic and aditional module CCP20 to CCP80

Attached document

To preserve by the user

To preserve by the fitter

Electric diagrams+ technician parameters

X

Hengel, Performance at any degrees

ZA Les Berges du Rhins - 42120 PARIGNY - France

Tel: +33 4 77 23 40 00 - Fax: +33 4 77 23 40 09

website :www.hengel.com

Note to be preserved by the user

DEEP-FREEZER AND STORAGE RANGE

page 2 out of 37

The Hengel machines are particularly simple to go up. However, it is imperative of reading this instructions note

attentively.

Before the assembly, check the presence of the power supply cable of the machine. This cable must be with the

top of the machine. (either with a 2200 mm height of the ground)

1Presentation...........................................................................................................................................................................................................3

1.1 General presentation.......................................................................................................................................................................................3

1.2 Technical description .....................................................................................................................................................................................3

1.2.1 Principle of circulation of air.................................................................................................................................................................3

1.2.2 The Bi-tronic Control regulation (except MULTITEMP) .....................................................................................................................3

1.2.3 The thermo-sensor (range of deep-freezers) ..........................................................................................................................................4

1.3 Technical data for Deep-freezer range............................................................................................................................................................4

1.4 Technical data for storage range.....................................................................................................................................................................6

2Important notes......................................................................................................................................................................................................8

2.1 General instructions of installation and operation ..........................................................................................................................................8

2.2 Instructions of transport..................................................................................................................................................................................8

2.3 Instructions of demolition...............................................................................................................................................................................8

3Instructions of installation.....................................................................................................................................................................................9

3.1 Assembly of the case......................................................................................................................................................................................9

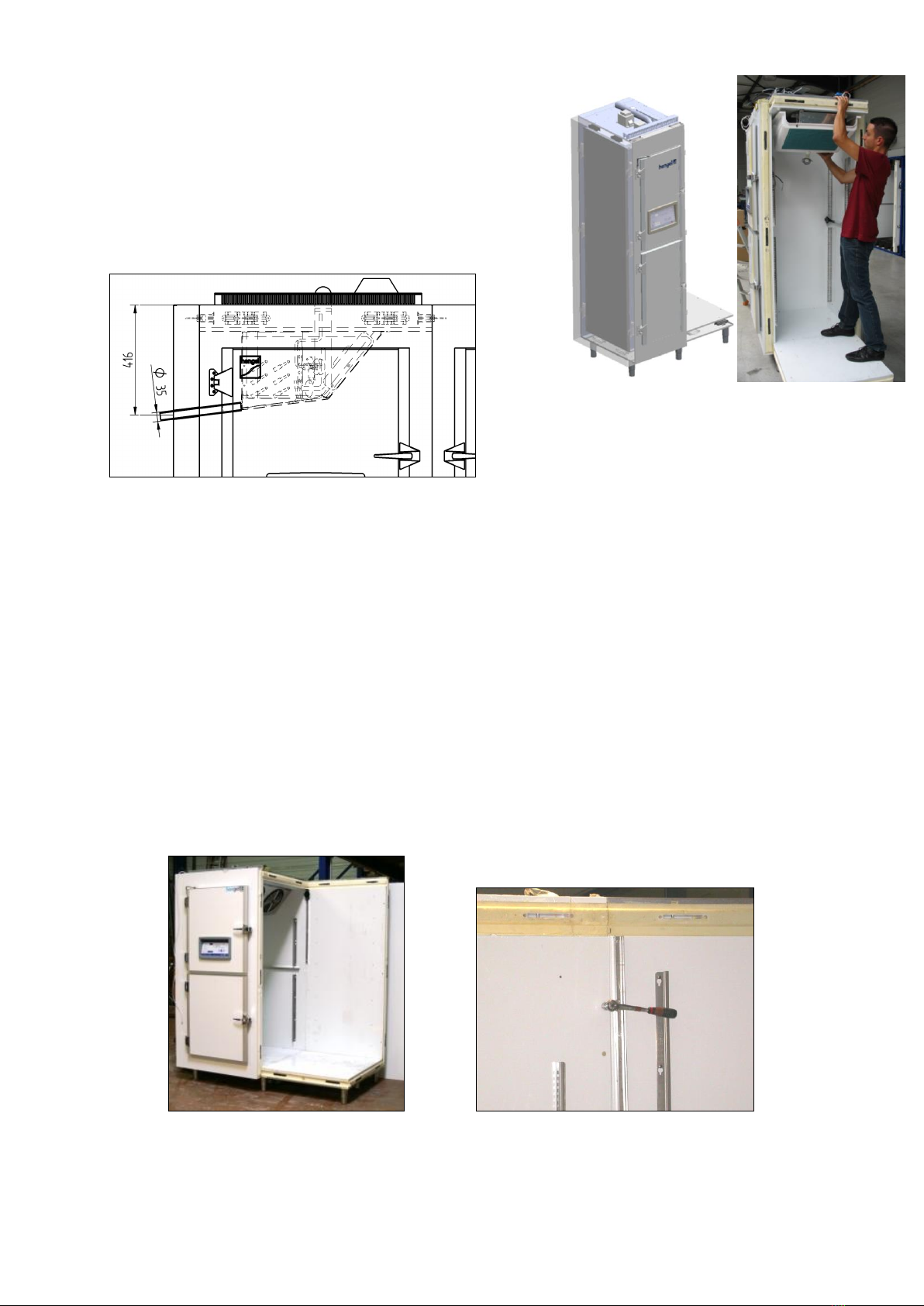

3.1.1 Burst sight of the machine (range of deep-freezers) ..............................................................................................................................9

3.1.2 Burst sight of the machine (range of conservatives)............................................................................................................................10

3.1.3 Burst sight of the machine (range of COMBITEMP AND MULTITEMP conservatives)..................................................................11

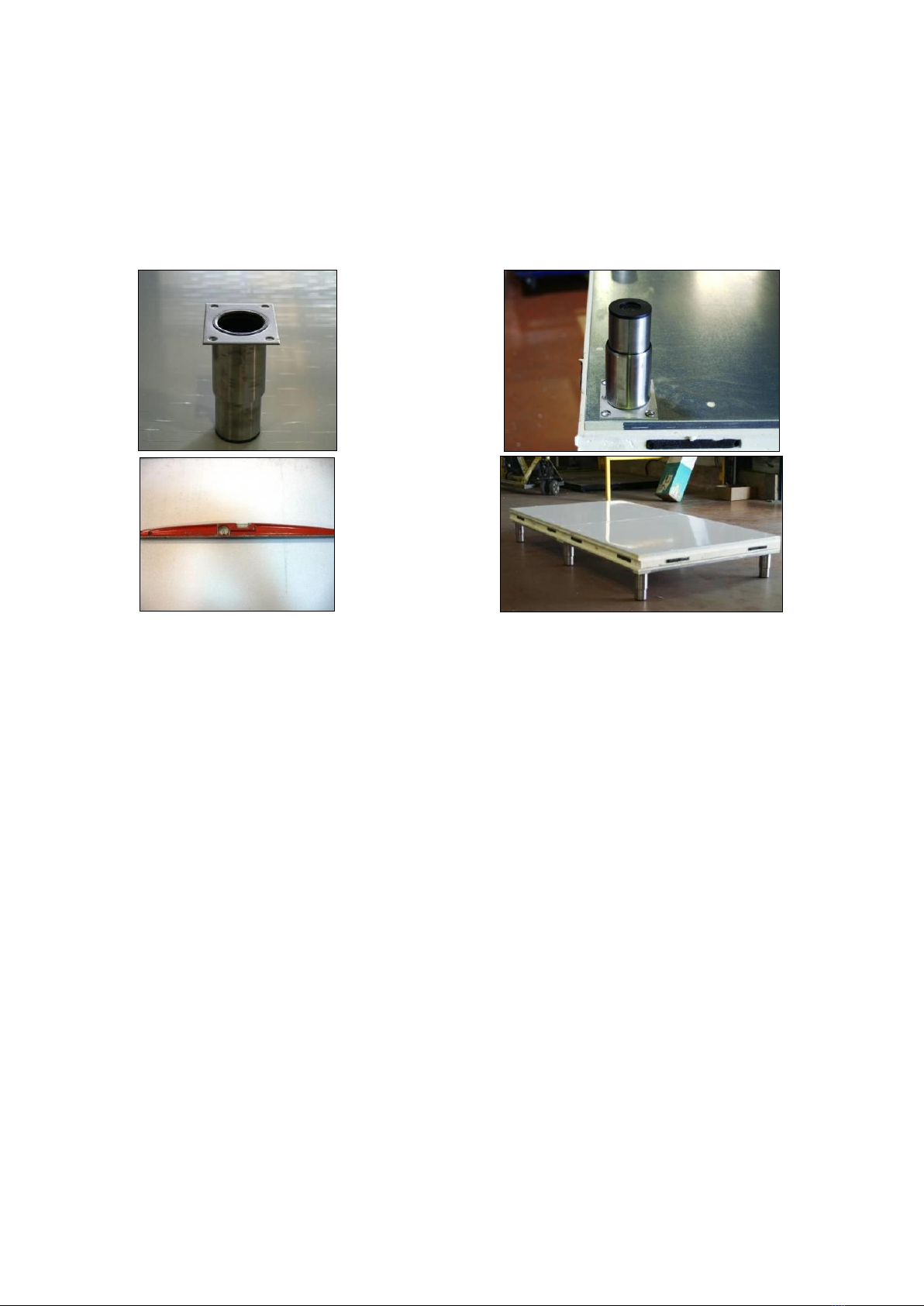

3.1.4 Assembly of the grounds.....................................................................................................................................................................13

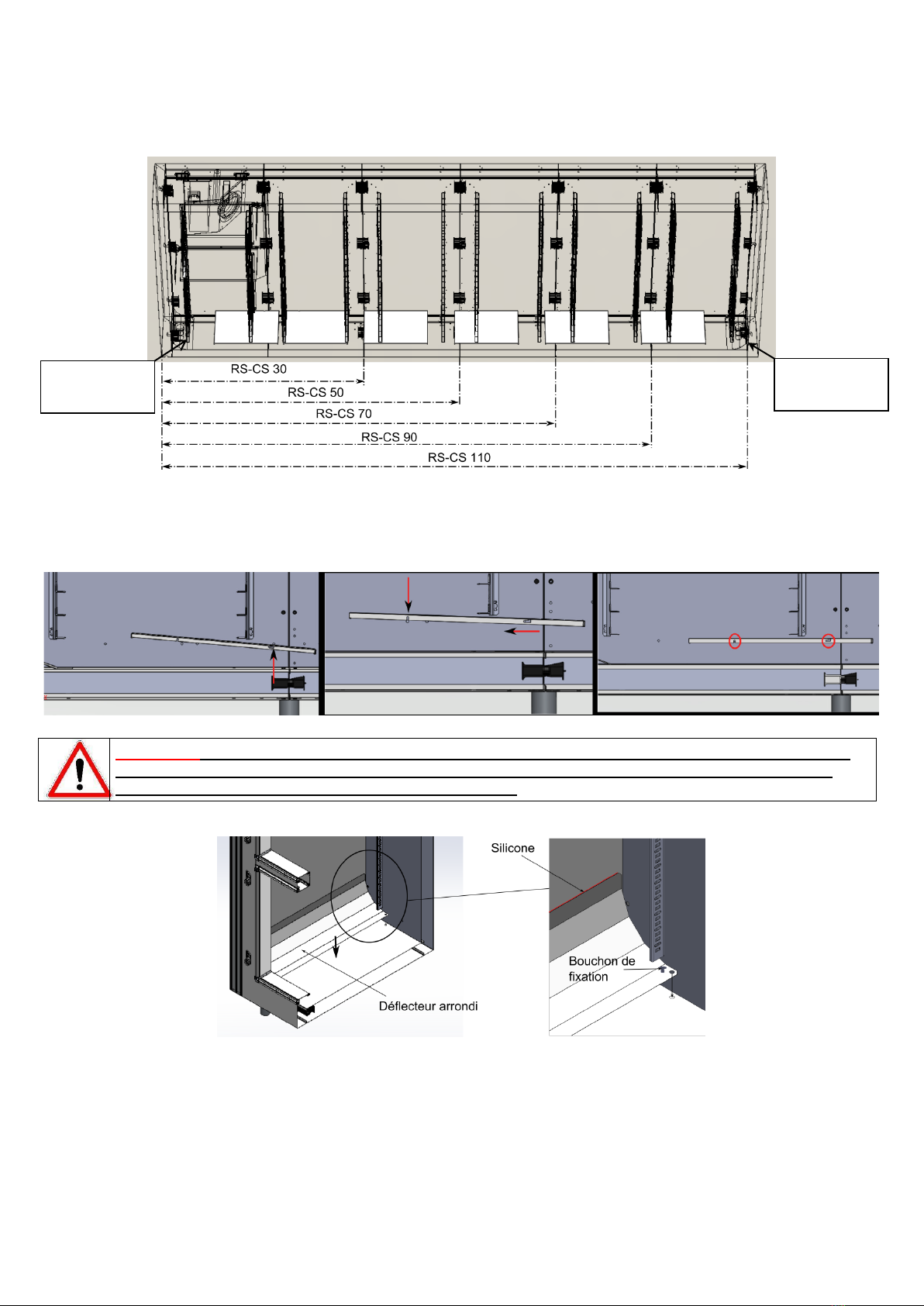

3.1.5 Assembly of the back panel.................................................................................................................................................................14

3.1.6 Frontage assembly...............................................................................................................................................................................14

3.1.7 Assembly of the first side (left side of the equipment)........................................................................................................................14

3.1.10 Assembly of the second side panel..................................................................................................................................................16

3.1.11 Position of shutters on deep-freezer................................................................................................................................................17

3.1.12 Assembly of evaporator sheets and plate of separation (range of deep freezers, except duo2 and quattro2) ..................................18

3.1.13 Assembly of air guide plates ...........................................................................................................................................................19

3.2 Electric connections .....................................................................................................................................................................................20

3.2.1 Installation of the electric box .............................................................................................................................................................20

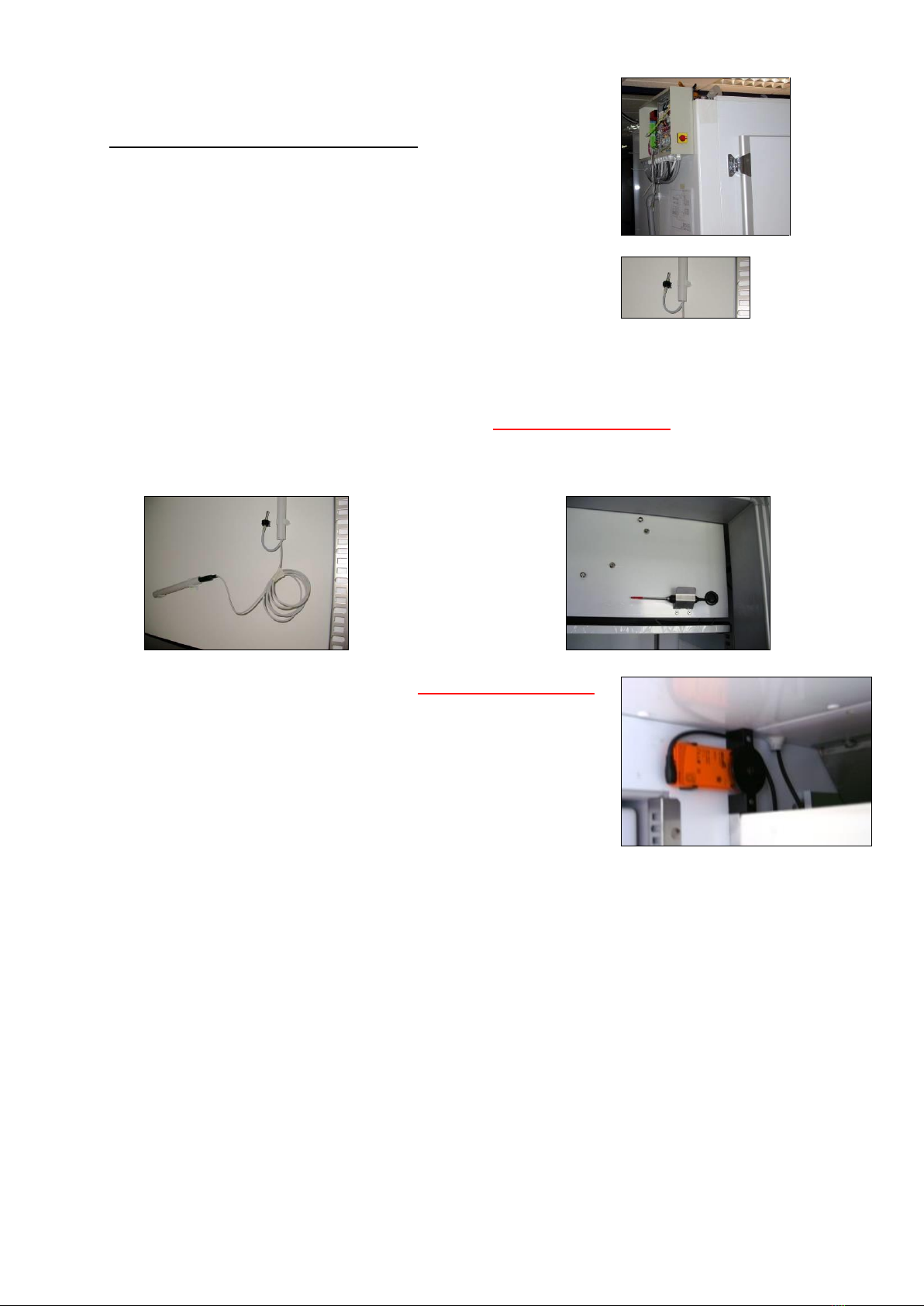

3.2.2 Installation of the environment probe..................................................................................................................................................20

3.2.3 Installation of the thermosensor probe (range of deep-freezers)..........................................................................................................20

3.2.4 Connection of the servo-motor (range of deep-freezers) .....................................................................................................................20

3.2.5 Installation of the BUS cable connecting the electric box and keyboard.............................................................................................20

3.2.6 Connection of the door-contact............................................................................................................................................................20

3.2.7 Connection of the door contacts ..........................................................................................................................................................20

3.2.8 Connection of the electric box.............................................................................................................................................................21

3.3 Refrigerating connections.............................................................................................................................................................................21

3.4 Drainage of condensates...............................................................................................................................................................................21

3.5 Finishings.....................................................................................................................................................................................................22

3.5.1 Interior of the equipment .....................................................................................................................................................................22

3.5.2 Adjustement of the doors (wickets).....................................................................................................................................................22

3.6 Step of first startup.......................................................................................................................................................................................22

3.6.1 Instructions for the first use.................................................................................................................................................................22

3.6.2 Introduction of the Bi-tronic Control interface....................................................................................................................................23

3.6.3 Technician Parameters Bi-tronic Control regulation ...........................................................................................................................23

4Use of the Machine..............................................................................................................................................................................................24

4.1 Use of Bi-tronic Control regulation..............................................................................................................................................................24

4.1.1 Starting up (storage mode)...................................................................................................................................................................24

4.1.2 Deep-freezing cycle with time control (range of deep-freezers)..........................................................................................................24

4.1.3 Deep freezing cycle with the Thermo sensor probe (range of deep-freezers)......................................................................................25

4.1.4 Defrosting............................................................................................................................................................................................26

4.1.5 Clock set up.........................................................................................................................................................................................26

4.1.6 Alarms.................................................................................................................................................................................................26

4.1.7 Stop of the interface of regulation .......................................................................................................................................................27

4.2 Utilisation council ........................................................................................................................................................................................28

4.2.1 Information over times of deep freezing, storage and defrosting of the products................................................................................28

5Maintenance of the equipment ............................................................................................................................................................................29

5.1 Cleaning of the machine (Twice a year).......................................................................................................................................................29

5.2 Maintenance of the equipment (2 to 3 times per year)..................................................................................................................................29

5.3 Malfunctions / Maintenance assistance ........................................................................................................................................................30

6Access to the various spare parts.........................................................................................................................................................................32

6.1 Shutter elements (range of deep-freezers) ....................................................................................................................................................32

6.2 Evaporator elements .....................................................................................................................................................................................33

6.3 Frontage elements.........................................................................................................................................................................................34

6.4 Door’s element .............................................................................................................................................................................................35

7Additional information........................................................................................................................................................................................36

7.1 Declaration CE of conformity ......................................................................................................................................................................36

7.2 Contacts of your installer..............................................................................................................................................................................37

DEEP-FREEZER AND STORAGE RANGE

page 3 out of 37

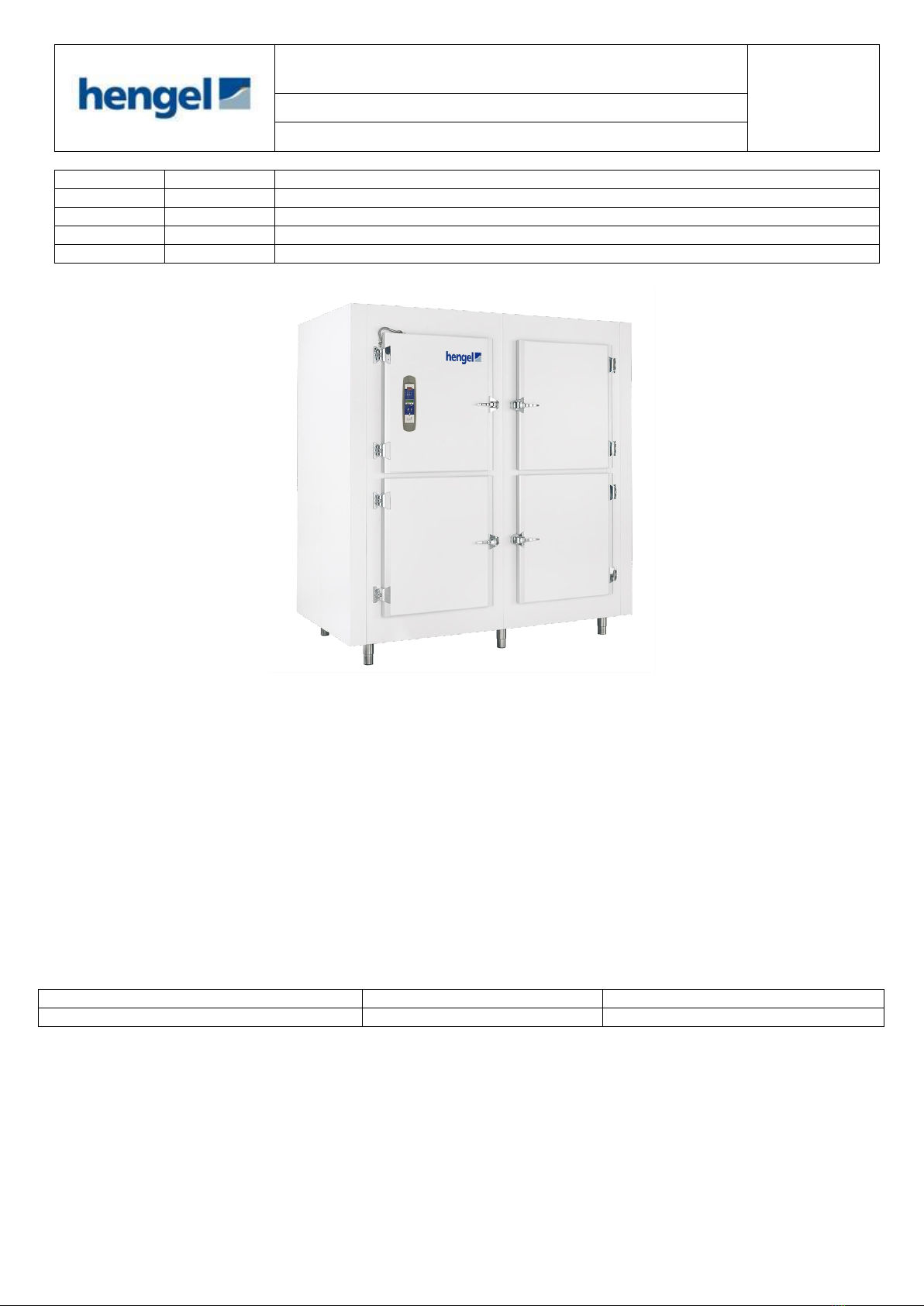

1 Presentation

1.1 General presentation

The company HENGEL thanks you for your trust.

The HENGEL equipment are the result of a long experience in the deep-freezing, storage and retarder proving field for

bakery and pastry products.

Thanks to its expertise, HENGEL is able to meet all the professionals’ specificities and to offer several machines ensuring

a great deep freezing-storage quality, a great proving control, but also an irreproachable material quality, perfectly

adapted to the constraints of the profession.

This note of instructions will enable you to understand, to install and to use the equipment you have just acquired under

the best possible conditions.

1.2 Technical description

The deep freezer Hengel are equipped with a refrigerating unit and an evaporator leaving the possibility of extending the

machine later on to eleven compartments of storage.

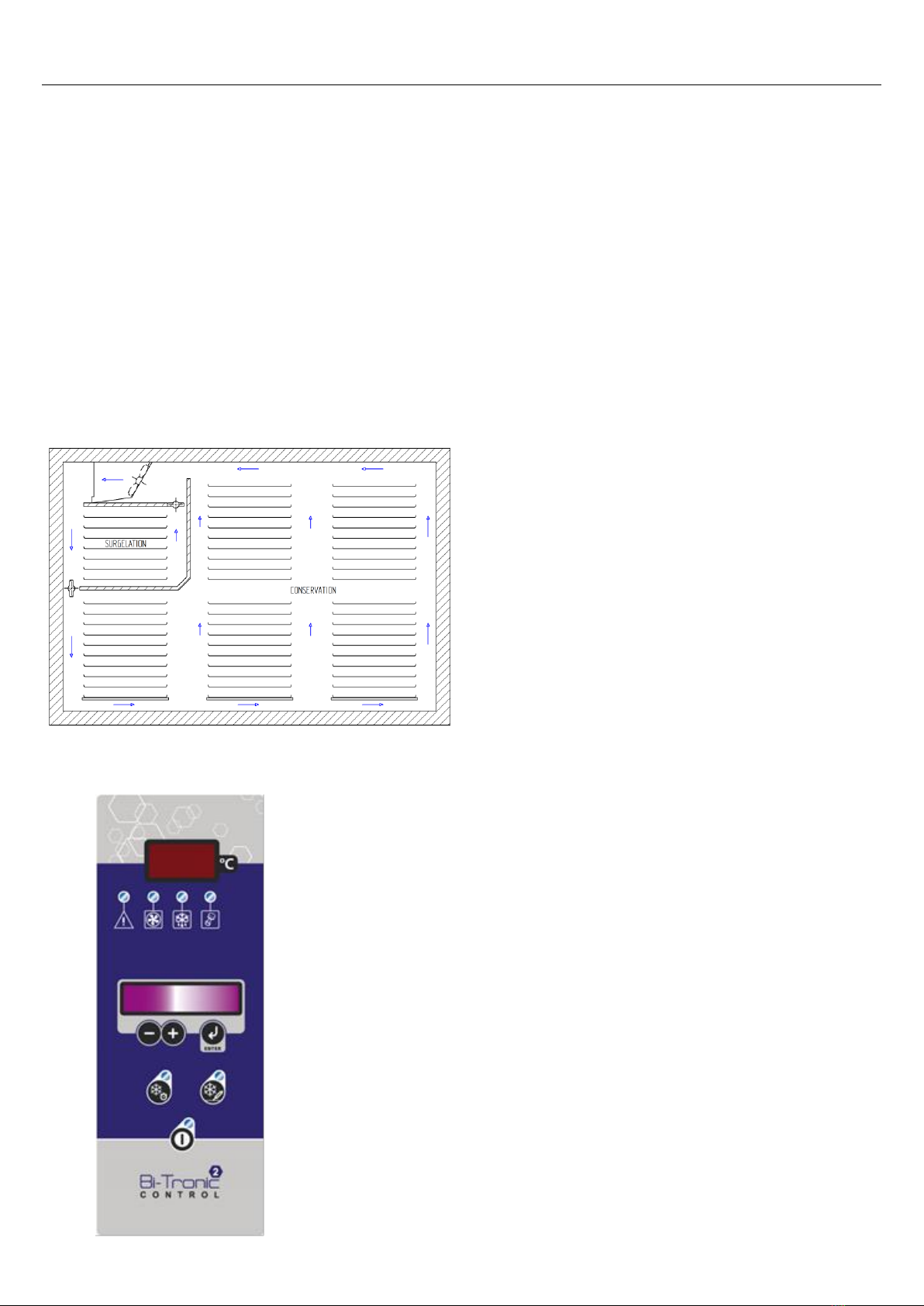

1.2.1 Principle of circulation of air

Placed between the compartment of deep freezing and the

storage one, the separation panel opens and closes

shutters for the passage of air and thus manages the

distribution of the cold, thanks to its servo-motor. The logic

of air circulation created by Hengel ensures a

homogeneous temperature in the whole equipment.

Moreover, it allows toavoid the products dryness because of

the air blowing done along the walls of the machine, making

it possible to diffuse naturally in the center of the

compartments.

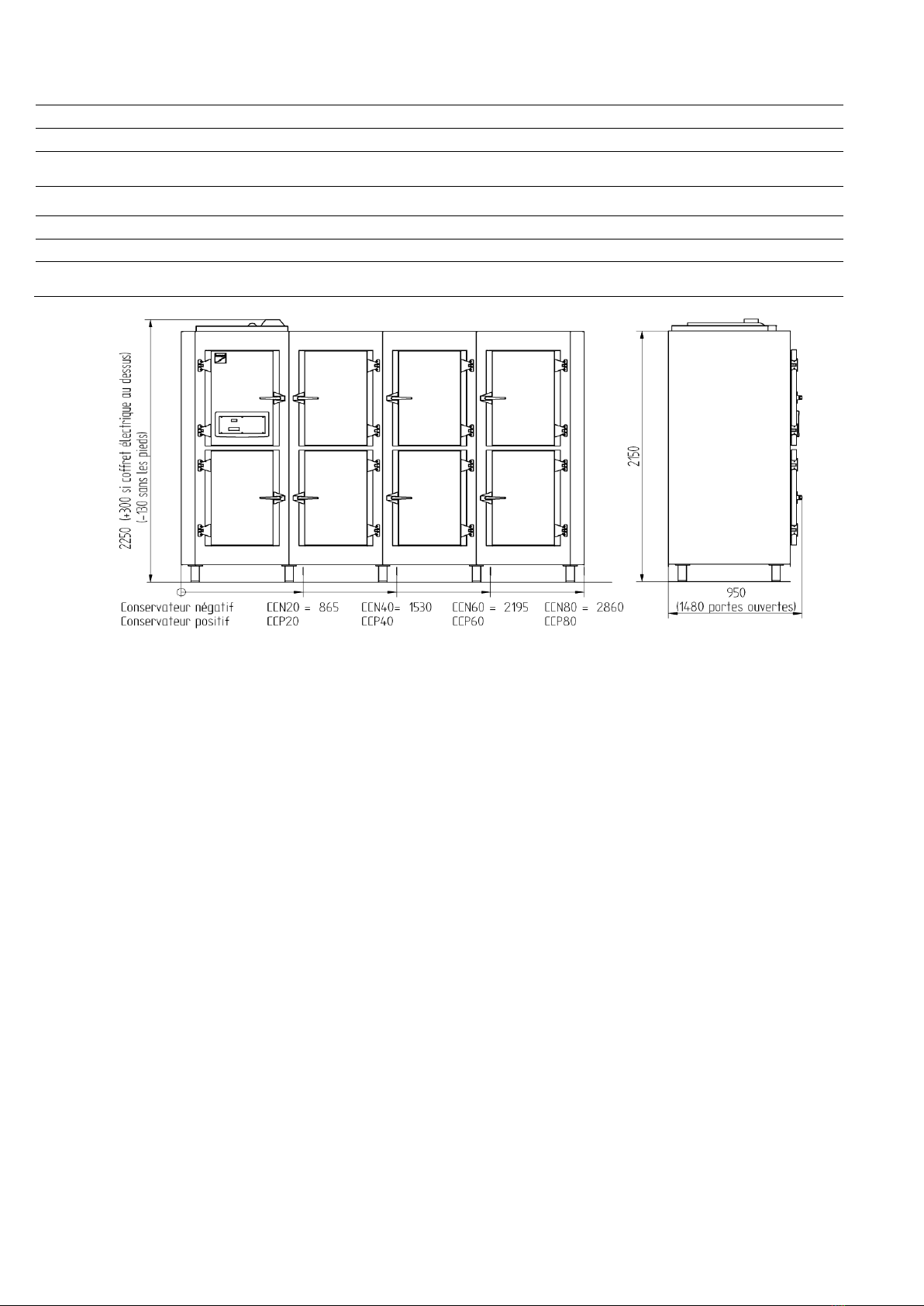

1.2.2 The Bi-tronic Control regulation (except MULTITEMP)

This regulator offers many reliable functions that were designed to

facilitate your daily tasks.

ERGONOMICS

keyboard of control at the eyes’ level

clear messages

easy cleaning

SIMPLICITY

simple and intuitive use

permanent display :

cycle in progress

instructions in progress internal temperature

FUNCTIONALITY

deep freezing with timer

deep freezing with thermo-sensor probe

standard

linear (control of the descent in temperature)

- various possible defrost launchings

- indication in light of the incidents and audible alarm

- stop of ventilation to the opening of the doors

- anti short-cycle on compressor to increase its lifespan

DEEP-FREEZER AND STORAGE RANGE

page 4 out of 37

1.2.3 The thermo-sensor (range of deep-freezers)

An exclusive system of Hengel makes it possible to determine the exact deep-freezing time

for your products.

An electronic probe pricked in the heart of the product to freeze stops the deep-freezing

process automatically as soon as the ideal temperature is reached. This self-management

guarantees appreciable energy savings and an exact and final knowledge of the precise

deep-freezing time for all the products.

1.3 Technical data for Deep-freezer range

RS 600x800 Modular

RS10

RS30

RS50

RS70

RS90

RS110

Appliance widht (mm)

1100

2000

2900

3800

4700

5600

Standard capacity in plates with

spacing of 75mm (2 plates by

levels)

Deep freezing

14

14

14

14

14

14

Storage

20

60

100

140

180

220

Compressor power (R404)(HP)

3 HP

Scroll

3 HP

Scroll

3 HP

Scroll

3 HP

Scroll

3 HP

Scroll

3 HP

Scroll

600x800 Non-modular

MAJOR DUO 2

MAJOR QUATTRO 2

Appliance widht (mm)

1100

2000

Standard capacity in plates with

spacing of 75mm (2 plates by

levels)

Deep freezing

14

14

Storage

20

60

Compressor power (R404)(HP)

2 HP - Hermetic

2 HP - Hermetic

DEEP-FREEZER AND STORAGE RANGE

page 5 out of 37

RS 400x600 Modular

CS10

CS30

CS50

CS70

CS90

CS110

Appliance widht (mm)

865

1530

2195

2860

3525

4190

Standard capacity in plates with

spacing of 75mm

Deep freezing

7

7

7

7

7

7

Storage

10

30

50

70

90

110

Compressor power (R404)(HP)

2 HP

2 HP

2 HP

2 HP

2 HP

2 HP

400x600 Non-modular

DUO 2

QUATTRO 2

Appliance widht (mm)

865

1530

Standard capacity in plates with

spacing of 75mm

Deep freezing

7

7

Storage

10

30

Compressor power (R404)(HP)

2 HP - Hermetic

2 HP - Hermetic

DEEP-FREEZER AND STORAGE RANGE

page 6 out of 37

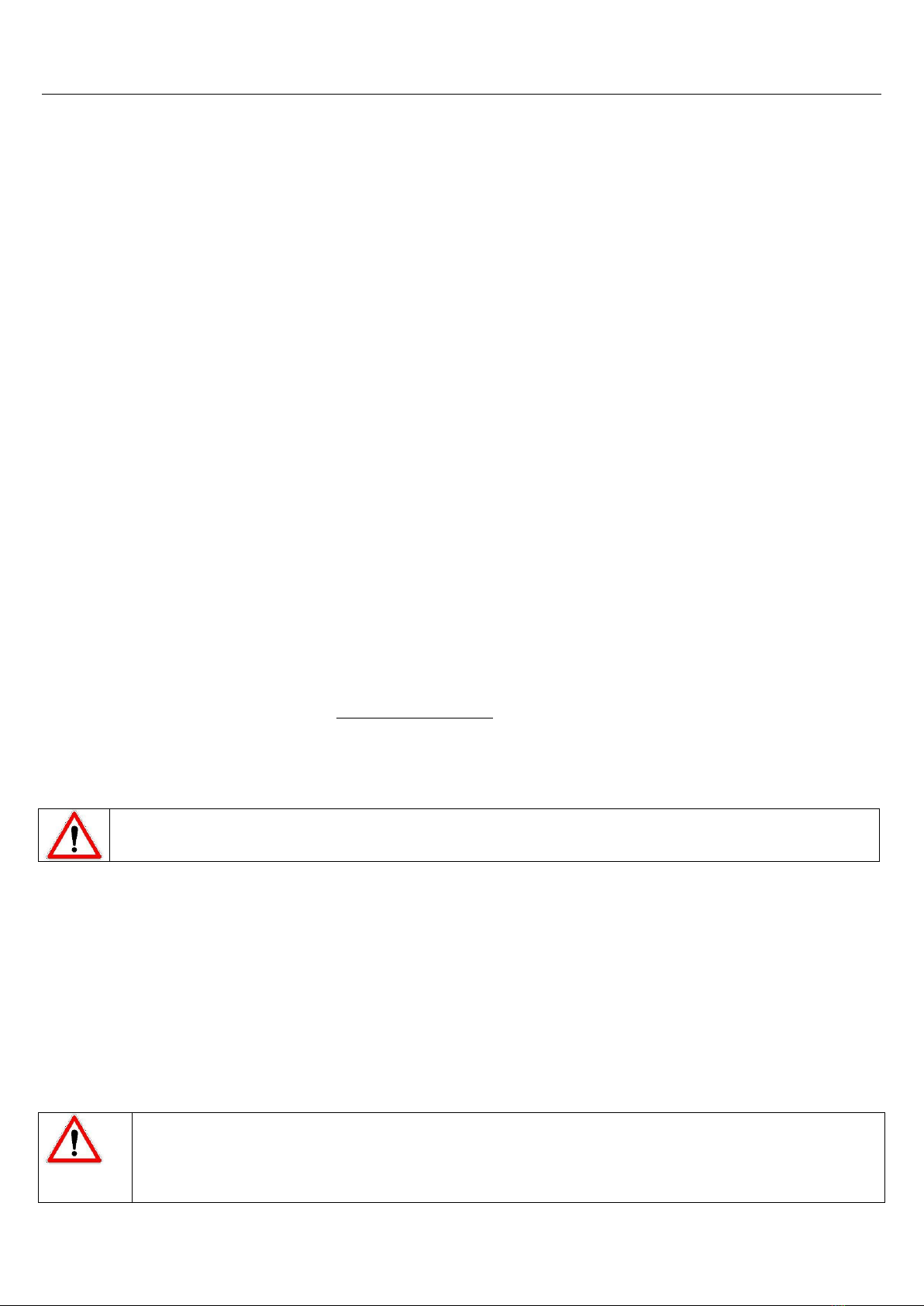

1.4 Technical data for storage range

Gamme 600x800 negative

RCN20

RCN40

RCN60

RCN80

Appliance widht (mm)

1100

2000

2900

3800

Standard capacity in plates with spacing of 75mm (2 plates

by levels)

36

72

112

154

Compressor power (R404)(HP)

3/4

2

2

2 1/2

Gamme 600x800 positive

RCP20

RCP40

RCP60

RCP80

Appliance widht (mm)

1100

2000

2900

3800

Standard capacity in plates with spacing of 75mm (2 plates

by levels)

36

72

114

156

Compressor power (R404)(HP)

1/2

5/8

5/8

3/4

DEEP-FREEZER AND STORAGE RANGE

page 7 out of 37

400x600 negative

CCN20

CCN40

CCN60

CCN80

Appliance widht (mm)

865

1530

2195

2860

Standard capacity in plates with spacing of 75mm

20

38

58

77

Compressor power (R404)(HP)

1/2

3/4

1 1/2

2

400x600 positive

CCP20

CCP40

CCP60

CCP80

Appliance widht (mm)

865

1530

2195

2860

Standard capacity in plates with spacing of 75mm

20

40

60

80

Compressor power (R404)(HP)

1/2

1/2

5/8

5/8

DEEP-FREEZER AND STORAGE RANGE

page 8 out of 37

2 Important notes

2.1 General instructions of installation and operation

Although the equipment of HENGEL are particularly simple to assemble and use, it is mandatory to attentively read the

instructions in order to ensure operation’s quality and the longevity of the machine.

The HENGEL machines are designed to function under specific temperature, hygrometry and use conditions that are

advisable to be respected for an optimum performance.

The cabinets are designed to function in a nominal environment of 32°C and 70% of hygrometry. Above that, the

performances of the machine might be affected.

The refrigerating unit is designed to function at a maximum ambient temperature of 43°C. Above this temperature, the

breakage risks of the compressor are very significant.

Moreover, more the ambient temperature is low::

- more electric consumption is low

- more the refrigerating power is significant

- more the lifespan of the compressor is long

- better are the performances

Anyway, it is appropriate that the refrigerating unit is installed in a very ventilated place, far from heat sources and

protected from of the sun and the rain.

In case of remote refrigerating units, the length of refrigerating pipings should not exceed 15m. For greater lengths,

please contact HENGEL.

Optimal limits of operation: - Deep freezing: -35°C

- Storage: -20°C/-25°C

Regulate your temperature of storage to –25°C does not improve the storage but generates a higher consumption.

To ensure a correct operation of the machine, do not store in any case your products directly on the ground because it

prevents the air circulation and thus the temperature homogeneity inside the cabinet.

The machine will have to be installed on a flat ground and of level.

The electric feeding and connections will have to be in conformity with the local standards.

It is necessary to envisage the spaces for the door opening and the maintenance

In the context of new standards concerning the cold storage, the leak detection must be performed

annually by qualified professionals.

2.2 Instructions of transport

All the machine’s elements are protected by packings.

These packings should not be exposed to bad weather. Avoid exposing them to significant temperature changes.

The loading and unloading of the transport vehicle can be made through a forklift.

The payload of the truck must suit the weight of the packaging.

During transport and handling, take all the essential precautions to not damage the various elements of the equipment

contained in the packing.

2.3 Instructions of demolition

For the machines’ demolition, it is essential to addressed to a company specialized in waste disposal.

They will perform the disassembly of the equipment separating its elements and will be in charge of recycling or storing

the discharge.

Any instructions not respected could cause a malfunction of the machine.

The installation, cleaning and maintenance operations must imperatively be carried out by qualified

professionals following the instructions provided in this note.

DEEP-FREEZER AND STORAGE RANGE

page 9 out of 37

3 Instructions of installation

Our machines are simple and fast to assembly. It is however necessary to follow the instructions of assembly attentively.

In case of negligence, difficulties may arise for the ceiling and shutter assembly, which would require the disassembly of

the machine.

3.1 Assembly of the case

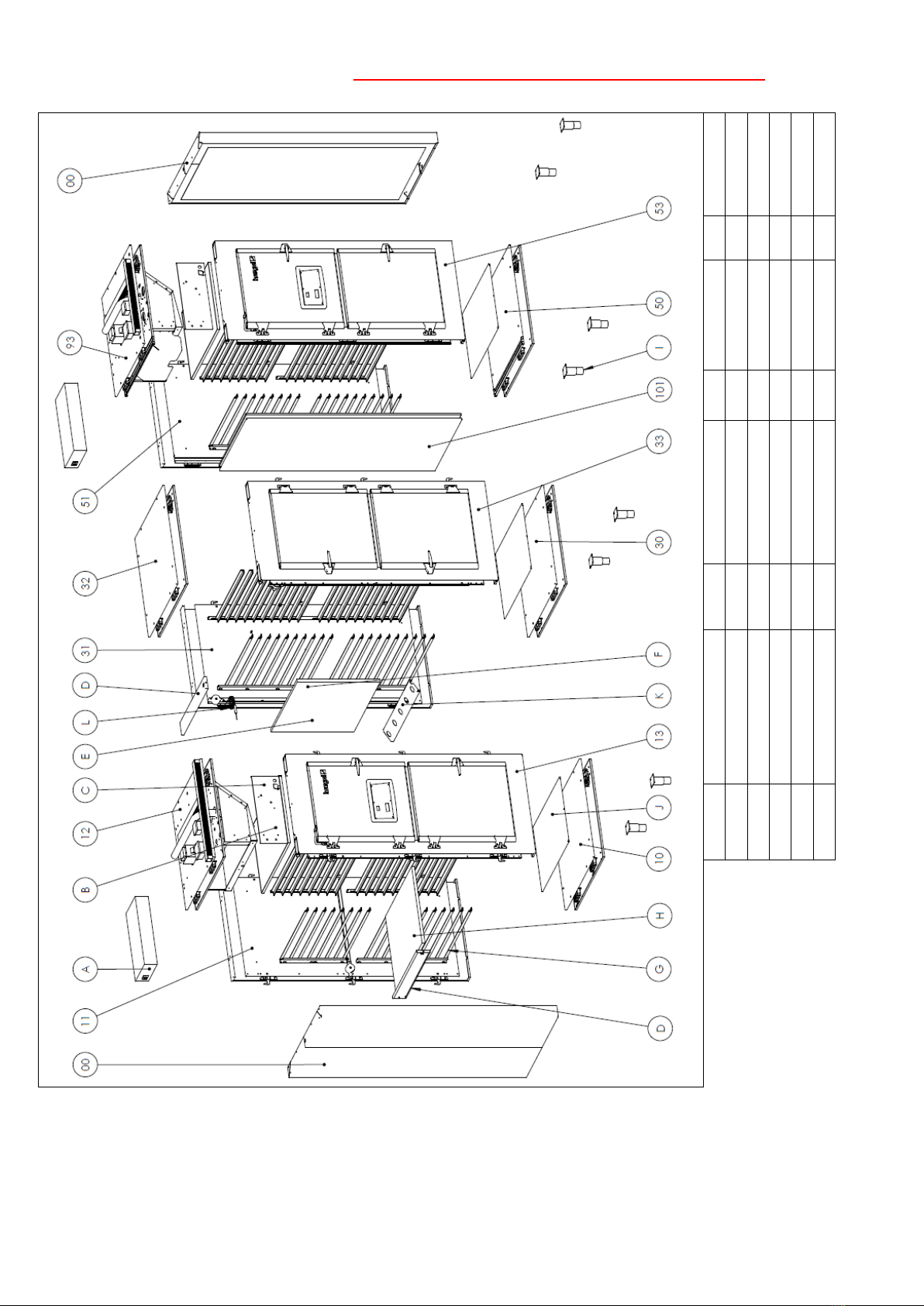

3.1.1 Burst sight of the machine (range of deep-freezers)

The machines in its generic form is presented in the following way:

Caution: For the QUATTRO 2 range, the evaporator platform is placed with the electric frame in front of

the machine.

Designation

Ground M-F

Fund M-F

Ceiling M-F

Frontage M-F

Ref

.

50

51

52

53

Designation

Ground M-F

Fund M-F

Ceiling M-F

Frontage M-F

Ref

.

30

31

32

33

Designation

Cheek

ground Male-Male

Fund M-M

Platform

évaporateur

Frontage M-Female

Ref.

00

10

11

12

13

Designation

Slide

Separation

Foot

Channel on ground

Deflector

Prick probe

R

e

f.

G

H

I

J

K

L

Designation

Electric box

Plate under evaporator

Hide evaporator

Shutter

Separation

Environment probe

Ref

.

A

B

C

D

E

F

DEEP-FREEZER AND STORAGE RANGE

page 10 out of 37

3.1.2 Burst sight of the machine (range of conservatives)

The machine in its generic form is presented in the following way :

Designation

Ground M-F

Fund M-F

Ceiling M-F

Frontage M-F

Ref

.

50

51

52

53

Designation

Ground M-F

Fund M-F

Ceiling M-F

Frontage M-F

Ref.

30

31

32

33

Designation

Cheek

ground Male-Male

Fund M-M

Platform

évaporateur

Frontage M-Female

Ref.

00

10

11

12

13

Désignatio

Electric box

Slide

Foot

Réf.

A

G

I

DEEP-FREEZER AND STORAGE RANGE

page 11 out of 37

3.1.3 Burst sight of the machine (range of COMBITEMP AND MULTITEMP conservatives)

Designation

Ground M-F

Fund M-F

Ceiling M-F

Frontage M-F

Divider panel

Ref

.

50

51

52

53

101

Designation

Ground M-F

Fund M-F

Ceiling M-F

Frontage M-F

Ref.

30

31

32

33

Designation

Cheek

ground Male-Male

Fund M-M

Platform

évaporateur

Frontage M-Female

Ref.

00

10

11

12

13

Désignatio

Electric box

Slide

Foot

Réf.

A

G

I

DEEP-FREEZER AND STORAGE RANGE

page 12 out of 37

- Positioning of the machine

Using dimensions of the table of the Technical Data and following diagram, mark the contour of the machine on

the ground. Leave a space of 5cm around the machine to avoid corrosion. Never press it against the wall.

Envisage the place for the tube passage and the drain of condensate siphon.

- Verifying the panels

The machines are labeled with a number in a sticker placed with evidence on the panels. It is advisable to check

the presence of all the panels on the pallets thanks to the burst sight view of the equipment.

TYPE

CHEEK

GROUND

FUNDS

CEILING

FRONTAGE

RS10 –MAJOR DUO

2

CS10 –DUO 2

RCN20 –RCP20

CCN20 –CCP20

00-00

10

11

12

13

RS30–MAJOR

QUATTRO2

CS30 –QUATTRO 2

00-00

10-30

11-31

12-32

13-33

RS50

CS50

RCN60 –RCP60

CCN60 –CCP60

00-00

10-30-50

11-31-51

12-32-52

13-33-53

RS70

CS70

RCN80 –RCP80

CCN80 –CCP80

00-00

10-30-50-70

11-31-51-71

12-32-52-72

13-33-53-73

RS90

CS90

00-00

10-30-50-70-90

11-31-51-71-91

12-32-52-72-92

13-33-53-73-93

RS110

CS110

00-00

10-30-50-70-90-110

11-31-51-71-91-111

12-32-52-72-92-112

13-33-53-73-93-113

During the assembly of the panels, make sure that they are not shifted between each other, and

check the anchoring hook in the female part.

Before the panels’ installation, remove film of protection found on the metal sheet of the panels

(except the ground panel). The assembly of the panels is done by the inside..

1.1 Panneau de sol

posé à l’envers

Refrigerating

connection

and Power

suply

DEEP-FREEZER AND STORAGE RANGE

page 13 out of 37

3.1.4 Assembly of the grounds

Screw the feet on the envisaged location.

The ground must be controlled with a spirit level, which will allow a possible adjustment of the feet.

One foot must necessarily be in each joint between two bottom panels

Once all the ground is assembled, check again the level and the good support of all the panels on the feet.

Protect the soil using a cardboard to prevent scratches

Remove film all around the bottom.

DEEP-FREEZER AND STORAGE RANGE

page 14 out of 37

3.1.5 Assembly of the back panel

Remove film of protection of the back panel

Attach the back panels (11) to the bottom (10) to get started

Attach, lock and verify the good alignment of the panels with the

ground (Fig.A)

Fig.A : Vérifier l’alignement

3.1.6 Frontage assembly

Remove the protection film from the frontage panels.

Implementthe frontage panel (13) ensuring that it is positioned in the

basement on the ground

Attach, lock and verify the alignment of the frontage with the ground

3.1.7 Assembly of the first side (left side of the equipment)

Please follow these steps carefully to get a good

alignment during assembly of the panel:

Remove the protective film from the panel

Place a bead of silicone moldings on the frontage, the ground and

the bottom

Lock the hooks (13-1) and (13-2) of the frontage, verifying the

alignment of the panel and the front part

Lock the hooks (11-1) and (11-2) of the back, verifying the alignment

of the panel and the front part

Lock both hooks of the ground with the side panel

The two hooks left (13-3) and (11-3) must be locked after the

assembly of the platform.

Fig B : Face d’alignement

11

10

DEEP-FREEZER AND STORAGE RANGE

page 15 out of 37

3.1.8 Assembly of the platform

Pose the platform on the bottom and make it slip to connect it on the

side panel.

Lock the plaform hooks from above

Finally lock the hooks on the high panels / frontage and back

Drill a hole enabling the PVC tube passage connected to the

evaporator tank.

Sizing for the case of avacuation in the center of the panel

Drilling for possible evacuation through the floor according to

your needs. In this case, please follow the same sizings

Clean the inside of the equipment after drilling

Vue 3D et photo correspondante au montage de la

plateforme

3.1.9 Assembly of the back and intermediate frontages as well as the separation panels

The following steps do not apply to the models RS10, CS10, Major Duo 2 and Duo 2

Remove the protection film from the second panel of separation

Engage this panel of separation in the U of the back

Position the frontage with hinges at right making sure that the panel is in position in its U

Verify the good alignement of the panels

Lock the frontage hooks.

Position and attach the other back panels (does not apply to the models RS10, CS10, Major Duo 2 and Duo 2)

Lock the back and the bottom once once all the panels are perfectly aligned (3 hooks on the top, 2 hooks on the

bottom)

DEEP-FREEZER AND STORAGE RANGE

page 16 out of 37

3.1.10 Assembly of the second side panel

Remove the protection film of the panel

Pose a silicone cord on the molding of the panel

Position the side panel while taking care of the good alignment of the

panels.

Lock the hooks starting with the ground.

DEEP-FREEZER AND STORAGE RANGE

page 17 out of 37

3.1.11 Position of shutters on deep-freezer

Connection of the servo-motor

Both servo-motors ensure the operation of the

deep freezing –storage of the equipment. The

opening and closing of each servo-motor

determines the operation’s mode.

In order to an optimal operation, we ahve modified

the position of the servo-motor positioned beside

the evaporator (see picture 2).

Picture 2

DEEP-FREEZER AND STORAGE RANGE

page 18 out of 37

3.1.12 Assembly of evaporator sheets and plate of separation (range of deep freezers, except duo2

and quattro2)

The sub-evaporator sheet is shorter than the two plates of separation of the deep-freezing compartment. For an easy

assembly please follow the three next steps by referring to the diagram below.

Place the plate on the evaporator in an inclined manner in order to insert it. Move it to the right to be able to bring it to

the horizontal.

Brin git to the left side. Afterwards align it against the valve of the right servomotor to be able to block it.

Block it using the bracket provided for this purpose

Position the steel plate between the isolating plate and the evaporator; and put it in abutment against the tube of

flow on the left.

Install the air shutter by pulling the key valve to compress the spring, and then switch on the servo-motor.

Afterwards, drag the plate’ separations in the slides ways and fix the air deflector.

In abutment against the flow

DEEP-FREEZER AND STORAGE RANGE

page 19 out of 37

3.1.13 Assembly of air guide plates

The last step in the assembly of the apparatus is the assembly of the air guide plates. You have a number of metal sheets

equivalent to the number of modules of the equipment. They have identical dimensions. For each module, a specific

location has been provided as shown in the following diagram.

This new placement has no impact on the modularity of our deep freezers and storage cabinets. Position the metal

sheet’s holes of the channel in front of those projected on the frontage and back panels of each module.

Warning: sheets of air-guiding channel are not centered compared to the racks, please follow the steps about their

assembly shown in the next diagram.

CAUTION : It is forbidden to put anything on and between the metal sheets of the floor channel, and

the bottom panel of the unit. This would prevent the air circulation and create a large temperature

difference between the different modules of the device

Assembly and fixation of the rounded deflector

Position the deflector in a way that the holes coincide with the floor panel’s hook holes.

Fix the deflector using two gray stoppers delivered with all the stoppers of the equipment.

Finish by placing a bead of silicone between the upper end of the deflector and the side to ensure the sealing.

Round

deflector

Round

deflector

DEEP-FREEZER AND STORAGE RANGE

page 20 out of 37

3.2 Electric connections

3.2.1 Installation of the electric box

Fix the electric box either on the ceiling, or on the top of the side panel, or on a

wall. (The length of the cable is limited to 1m50)

3.2.2 Installation of the environment probe

Pass the probe through the hole of the platform located close to the

separation.

Pass the probe in the vertical tube as shown in the picture.

Fix the probe using the fastener collar.

The environment probe must be placed with the exit of wire downwards

3.2.3 Installation of the thermosensor probe (range of deep-freezers)

Pass the thermosensor probe by this same hole

Also pass the probe in the vertical tube

Fix the probe in the tilted tube (Quattro) or fix the probe on the sheet close to the evaporator

Quattro

Other deep-freezer

3.2.4 Connection of the servo-motor (range of deep-freezers)

Make the cable goes over the servo-motor using the adhesive base plates

and collars.

Pass the cable in the hole located on the top of separation.

Pass the servo-motor’s cable in the hole of the environment probe and the

thermosensor.

Stop this hole with silicone to avoid any passage of air (formation of

frost, then of ice).

3.2.5 Installation of the BUS cable connecting the electric box and keyboard

Pass the BUS cable in the spring located in top of the first door and connected it to the electronic chart in the electric

box.

Stop up this hole with silicone.

3.2.6 Connection of the door-contact

Put in series all the door-contact interrupters (wire blue and chestnut) outgoing the top of the frontages.

Bring back a cable to the electric box and connect it at the boundaries P according to the electric diagram on the

platform.

3.2.7 Connection of the door contacts

Put in derivation resistances of entourage of the doors (purple wire) outgoing top of the frontages according to the

plan inserted with the transformer on the platform.

Connect wire 18V and 24V coming from the transformer following the plan on the platform

Bring back cable 230V to the electric box and connect it to the electronic chart.(see diagram in box)

This manual suits for next models

31

Table of contents