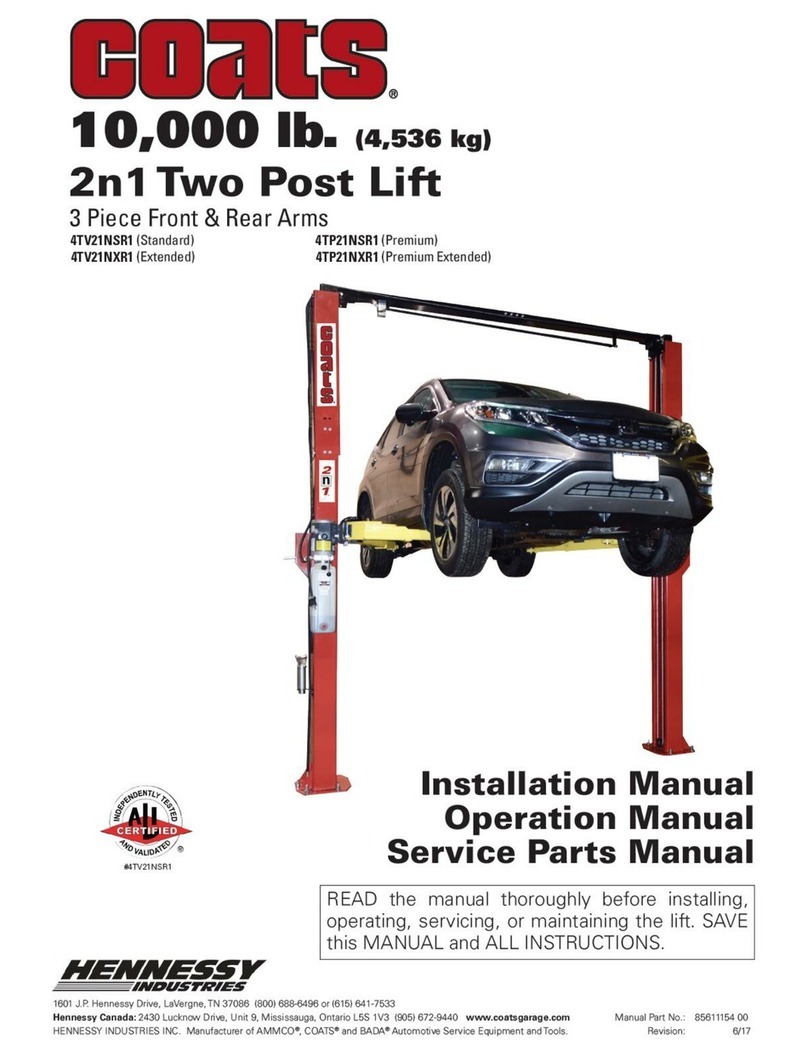

Henkel PLG-XH User manual

LG_XH_CNH_EFF_ALL_8520301_011.DOC

HENKE PARALLEL LIFT GROUP

HENKE MODEL: PLG-XH, AQC-XH, STB-XH

For CASE & NEW HOLLAND SERIES MOTOR GRADERS

PARTS BOOK AND INSTALLATION MANUAL

SERIAL NUMBER: __________________ VERSION 1.1, JULY 2012

HENKE MANUFACTURING CORPORATION

MANUFACTURERS OF SNOW REMOVAL EQUIPMENT FOR 95 YEARS

3070 WILSON AVE. LEAVENWORTH, KS 66048 PHONE(913)682-9000 FAX(913)682-0300

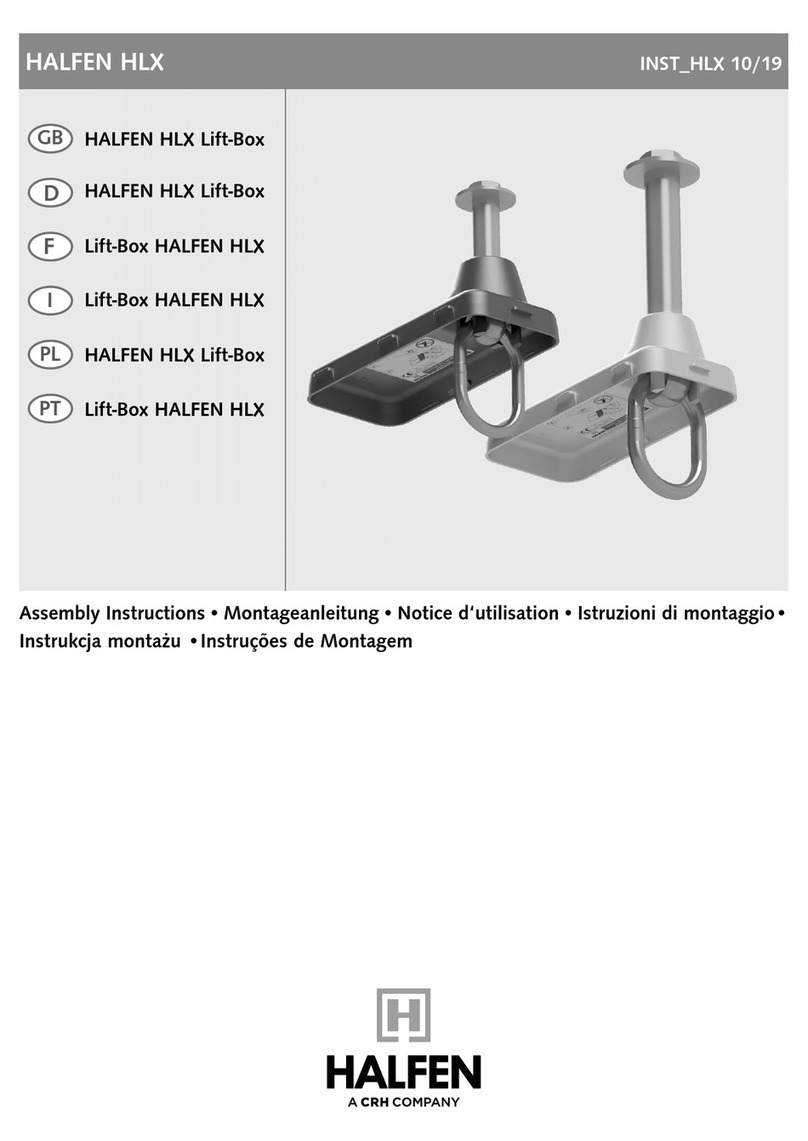

Parallel Lift Head

Scarifier Tool Bar

AQC Lift Head

LG_XH_CNH_EFF_ALL_8520301_011.DOC Page 2 of 21

Introduction

Thank you for your purchase of a Henke Lift Group. Your new Lift Group is designed

with heavy-duty features for years of reliable use.

In addition to their field-proven standard units, Henke designs and manufactures many

plows and hitches to meet specific customer requirements.

Call Henke at 913-682-9000 if you need any replacement parts, or if we can provide you

any other assistance.

LG_XH_CNH_EFF_ALL_8520301_011.DOC Page 3 of 21

TableofContents

Introduction ................................................................................................................................................................ 2

Safety ............................................................................................................................................................................ 4

Maintenance ............................................................................................................................................................... 5

Parts Lists for Reversible Lift Group ................................................................................................................ 7

Cutting Edges, Curb Guards, Wear Guards .................................................................................................. 17

Warranty Policy & Procedure ........................................................................................................................... 20

ListofFigures

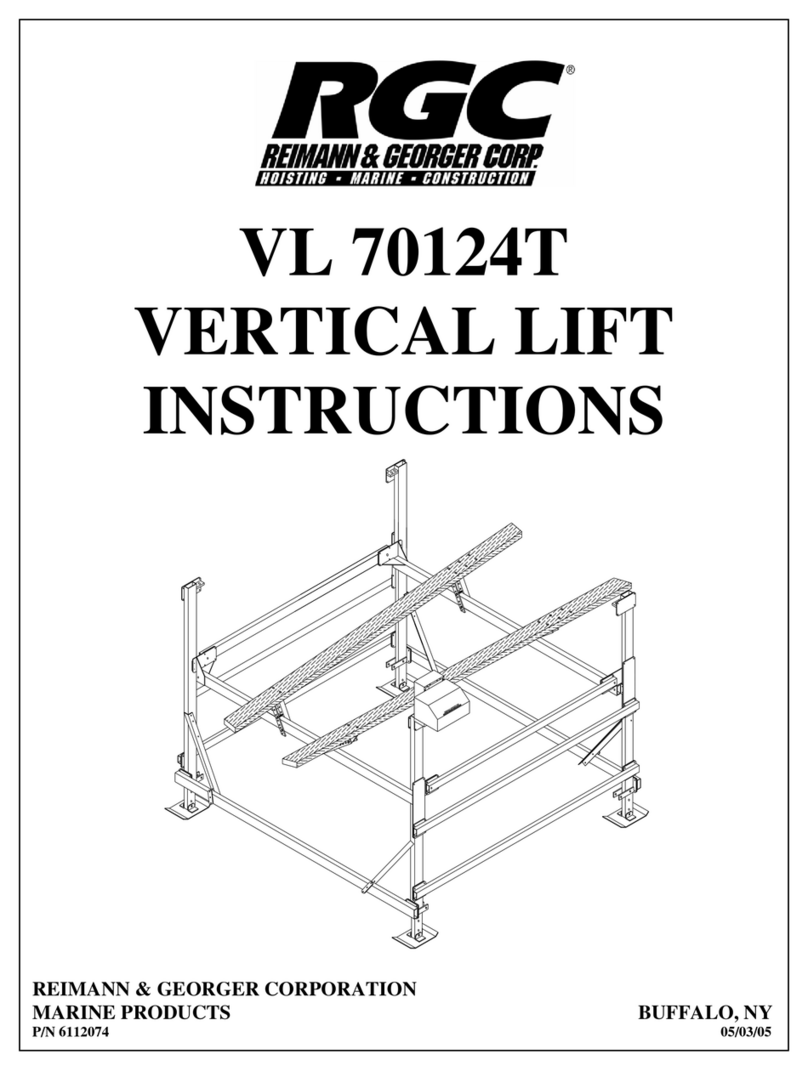

FIGURE 1 – Extra Heavy Lift Groups .................................................................................................... COVER

FIGURE 2 – Extra Heavy Parallel Lift Goup with Parallel Lift Head .................................................... 7

FIGURE 3 – Extra Heavy Parallel Lift Goup with Scarrifier Tool Bar ................................................. 9

FIGURE 4 – Extra Heavy Parallel Lift Goup with AQC Lift Head ......................................................... 11

FIGURE 5 – Hydraulic Plumbing for Lift Group Cylinder ...................................................................... 13

FIGURE 6 – Hydraulic Plumbing Schematic ................................................................................................ 14

ListofTables

TABLE 1 – Extra Heavy Parallel Lift Goup with Parallel Lift Head, Parts List ................................ 8

TABLE 2 – Extra Heavy Parallel Lift Goup with Scarrifier Tool Bar, Parts List ........................... 10

TABLE 3 – Extra Heavy Parallel Lift Goup with AQC Lift Head, Parts List ..................................... 12

TABLE 4 – Hydraulic Valve Kit for 7080563 Holding Valve ................................................................ 14

TABLE 5 – Hydraulic Hose Kit .......................................................................................................................... 15

TABLE 6 – Hydraulic Hose Kit for Extra Heavy Lift Group ................................................................... 15

TABLE 7 – Cutting Edges ..................................................................................................................................... 17

TABLE 8 – Cutting Edge Hardware ................................................................................................................. 18

TABLE 9 – Henke Curb Guards & Wear Guards ........................................................................................ 19

LG_XH_CNH_EFF_ALL_8520301_011.DOC Page 4 of 21

<<THIS PAGE IS INTENTIONALLY LEFT BLANK>>

Safety Section 1-1

© 2009 Alamo Group Inc.

SAFETY SECTION

SAFETY

Lift Groups Safety Section 1-2

© 2009 Alamo Group Inc.

SAFETY

GENERAL SAFETY INSTRUCTIONS AND PRACTICES

A careful operator is the best operator. Safety is of primary importance to the manufacturer and should be to

the owner/operator. Most accidents can be avoided by being aware of your equipment, your surroundings, and

observing certain precautions. The first section of this manual includes a list o f Safety Messages that, if

followed, will help protect the operator and bystanders from injury or death. Read and understand these Safety

Messages before assembling, operating or servicing this Implement. This equipment should only be operated

by those persons who have read the manual, who are responsible and trained, and who know how to do so

responsibly.

The Safety Alert Symbol combined with a Signal Word, as se en below, is use d throughout this

manual and on decals which are attached to the equipment. The Safety Aler t Symbol means:

“ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!” The Symbol and Signal Word

are intended to warn the owner/operator of impending hazards and the degree of possible injury

faced when operating this equipment.

Indicates an imminently hazardous situation that, if not avoided, WILL result in DEATH OR

VERY SERIOUS INJURY.

Indicates an imminently hazardous situation that, if no t avoided, COULD result in DE ATH

OR SERIOUS INJURY.

Indicates an imminently hazardous situation that, if not avoided, MAY result in MINOR

INJURY.

Identifies special instructions or procedures that, if no t strictly observed, could result in

damage to, or destruction of the machine, attachments or the environment.

NOTE: Identifies points of particular interest for more efficient and convenient operation or repair.(SG-1)

Practice all usual and customary safe working precautions and above all---remember safety is

up to YOU. Only YOU can prevent serious injury or death from unsafe practices.

READ, UNDERSTAND, and FOLLOW the following Safety Messages. Serious injury or

death may occur unless care is taken to follow the warnings and instructions stated in the

Safety Messages. Always use good common sense to avoid hazards. (SG-2)

SAFETY

Lift Groups Safety Section 1-3

© 2009 Alamo Group Inc.

SAFETY

Repeated or substantial breathing of hazardous dusts, including

crystalline silica, could cause fatal or serious respiratory disease including

silicosis. Concrete, masonry, many types of rock, and various other

materials contain silica sand. California lists respirable crystalline silica as

a substance known to ca use cancer. Operation of this equipment under

certain conditions may generate airborne dust particles that could contain

crystalline silica. In those conditio ns, personal protective equipment

including an appropriate respirator must be used. If excessive dust is

generated, a dust collection or suppression system should also be u sed

during operation. (SG-41)

Si no lee ingles, pida ayuda a alguien que si lo lea para que le traduzca las

medidas de seguridad. (SG-3)

Never operate the Sno w Plow until you have rea d and completely

understand this Manual , the Truck or Power units Operator’s

Manual, and each of the Safety Messages found in these Manuals

and those affixed to the Snow Plow, Truck, or Power units and its

components. Learn how to stop the power unit engine suddenly in

an emergency

.

Never allow inexperienced or untrained personnel

to operate the Truck or Pow er unit and Sno w Plow without

supervision. Make sure the operator has fully read and understood

the manuals prior to operation.

(SPNG-4)

In addition to the design and configuration of this Snow Plow, including Safety Signs and Safety Equipment,

hazard control and accident prevention are dependent upon the awareness, concern, prudence, and proper

training of personnel involved in the operation, transport, maintenance, and storage of the machine. Refer

also to Safety Messages and operation instruction in each of the appropriate sections of the Truck or Power

unit Manuals. Pay close attention to the Safety Signs affixed to the Snow Plow. (SNPG-5)

PARTS INFORMATION

HENKE Snow Plows use ba lanced and matched system components for plows, carriers, and other

components. These p arts are made and tested to HENKE specifications. Non-genuine or “will fit" parts do

not consistently meet these specifications. The use of non-genu ine or “will fit” parts may reduce Snow Plow

performance, void HENKE warranties, and present a safety hazard. Use genuine HENKE parts for economy

and safety. (SNPG-6)

SEE YOUR HENKE DEALER

Always maintain the safety signs in good readable condition. If the safety signs are missing,

damaged, or unreadable, obtain and install replacement safety signs immediately. (SG-5)

SAFETYL

Lift Groups Safety Section 1-4

© 2009 Alamo Group Inc.

SAFETY

OPERATOR SAFETY INSTRUCTIONS AND PRACTICES

All Safety Shields, Guards and other Protective Safety devices should be used and

maintained in goo d working condition. All safety devices should be inspected

carefully at least daily for missing or broken components.

NEVER REMOVE

PROTECTIVE SHIELDS AND GUARDS! NEVER MODIFY OR CUT PROTECTIVE SHIELDS OR

GUARDS!

When shields or guards are removed to access areas for maintenance, they must be

replaced and be in good condition before operating. M issing, broken, or worn shields,

guards, and other protective devices must be replaced at once and prior to operation

to reduce the possibility of injury.

(SNPS-02)

The Snow Plow power unit should be equipped with a fire extinguisher, rated for all fires, in

an accessible and visible area. T he fire extinguisher should be inspected routinely by a

certified inspector for operational use and replaced as needed. Never obstruct access to

the fire extinguisher. (SNPS-6)

NEVER use drugs or alcohol immediately before or while driving or operating the Snow

Plow. Drugs and alcohol will affect an operator’s alertness and coordination and therefore

affect the operator’s ability to operate the Equipment safely. Before operating the

Equipment, an op erator on prescription or over-the-counter medication must

consult a medical professional regarding any side ef fects of the medication

that would hinder their ability to operate the Equipment safely. NEVER

knowingly allow anyone to op erate this Equipment when their alertness or

coordination is im paired. Serious injury or death to the operator or others

could result if the operator is under the influence of drugs or alcohol. (SNPD-3)

Always wear OSHA a pproved Personal Protective Equipment (PPE) while operating,

servicing, repairing, and/or cleaning the Equipment. PPE is designed to provide bodily

protection during such activities.

Personal Protective Equipment includes:

-Protective Eye Wear

-Steel Toed Safety Footwear

-Gloves

-Hearing Protection

-Close Fitted Clothing

-Hard Hat-When working around a raised hopper.

-Respirator-Depending on conditions and material being swept or cleaned.

Specialized protective equipment may be required if dangerous or hazardous material is being moved by the

plow. (SNPD-4)

SAFETY

Lift Groups Safety Section 1-5

© 2009 Alamo Group Inc.

SAFETY

Prolonged operation of the Snow Plow ma y cause operator boredom and/or fatigue

affecting the safe operation of the Snow Plow and Truck or Power unit. It is recommended

that the op erator take scheduled work breaks to help prevent these potentially impaired

operating conditions. If p ossible, completely shut down th e Equipment, exit the cab and

move around stretching your arms and legs. Never operate the Equipment in a fatigued or

bored mental state that impairs proper and safe Equipment operation. (SNPD-5)

PROLONGED EXPOSURE TO LOUD NOISE MAY CAUSE

PERMANENT HEARING LOSS!

Equipment operation can o ften

be noisy enough to cause permanent hearing loss. We

recommend that you always wear hearing protection if the noise in

the Operator’s position exceeds 80db. Noise over 85db over an

extended period of time wil l cause severe hearing loss. N oise

over 90db adjacent to the Operator over an e xtended period of

time will cause permanent or total hearing loss.

Note:

Hearing

loss from loud noise [from sweepers, chain saws, radios, and

other such sources close to the ear] is cumulative over a lifetime

without hope of natural recovery.

(SNPD-6)

Prolonged operation of the Equipment in col d weather may cau se operator hypothermia

affecting the safe operation of the Snow Plow and Truck or Power unit. It is recommended

that the operator wear appropriate clothing take scheduled work breaks to help prevent

these potentially impaired operating conditions. If pos sible, completely shut down the

Equipment, exit the cab and warm the body in a properly heated area. Never operate the

Equipment in a fa tigued or impaired mental state that effects the proper and safe

Equipment operation. (SNPD-8)

Use both hands for support when getting on and off the truck or power unit. Use handles

and steps on the equipment for support when boarding. Never use the Truck or Snow Plow

control levers for support when boarding the equipment. (SNPO-01)

Use available truck or power unit handles and steps to exit th e operator’s station. Make

sure you have solid footing before stepping down. Be car eful of your step and use extra

caution when mud, ice, snow, or other matter has accumulated on the steps or handrails.

Never rush to exit or jump off the truck or power unit. (SNPO-02)

Do not attempt to mount the Truck or Power Unit while the machine is moving.

Never attempt to mount a run away Snow Plow. Serious injury or death m ay

occur from being run over by a moving Truck, Power Unit, or Snow Plow.

(SNPO-03)

BEFORE leaving the operator’s seat, always engage the parking brake and/or set the

Truck’s or Power Unit’s transmission in the park position, stop the engine, remove the key,

and wait for all moving parts to stop. Never dismount a Truck or Power Unit that is moving

or while the engines are running. Op erate the equipment controls from the Op erator’s

seat only. (SNPO-04)

SAFETY

Lift Groups Safety Section 1-6

© 2009 Alamo Group Inc.

SAFETY

Always wear a seat belt while driving the equipment during operation and transport.

Serious injury or even death could result from falling from the operator’s station or from

being involved in a collision. (SNPO-05)

Start the engines only when seated and belted in th e operator’s seat. Operate the

equipment controls only while properly seated with th e seat belt secur ed around you.

Inadvertent movement of the power unit or attachment components may cause serious

injury or death to th e operator and passersby. Read the truck or Power Unit o perator’s

manuals for proper starting instructions. (SNPO-06)

Do not operate, or perform maintenance to, th e Equipment while wearing loose fitting

clothing. Entanglement of loose clothing with the rotating elements can result in serious

injury or death. Stay clear of all rotating elements at all times. (SNPD-7)

Operate only in conditions where you have clear visibility of the area in d aylight or with

adequate artificial lighting. Never operate in darkness of foggy conditions where you

cannot clearly see at least 50 feet in front and to the sides of the equipment. Make sure

that you can clearly see and identify passersby, steep slopes, ditches, drop-offs, overhead

obstructions, power lines, oversized debris and foreign objects. If yo u are unable to see

these types of items, discontinue operation until visibility improves. (SNPO-8)

When transporting the Snow Plow be tween locations, follow all local traffic laws and

regulations. (SNPO-10)

Operate at a speed that allows you to safely operate and control the Truck and Snow Plow.

Safe plowing speed depends on street condition and the type and amount of debris being

moved. Slow down for corners, curbs, parked cars, protruding signs and other obstacles.

Use slow traveling speeds when operating on or near steep slopes, ditches, dr op-offs,

overhead obstructions, power lines, or when debris and foreign objects are to be avoided.

(SNPO-13)

Do not o perate the Equipment if excessive vibration or noise exist s. Shut

down the equipment an d the T ruck or Powe r Unit engine. Inspect th e

Equipment to determine the source of the vibration or noise. If parts are

loose, damaged, or missing, replace them immediately. Do not operate th e

Equipment until all necessary rep airs have been p erformed. To reduce the

possibility of property damage, serious injury, or even death, never operate

the Equipment with missing or damaged components. (SNPO-16)

Never attempt to plow debris that is too large for the Snow Plow (oversized objects such as

broken limbs and discarded tires). Such objects may damage the snow plow components

and cause serious mechanical damage to the equipment. If possible, carefully place such

objects out of the Snow Plow a nd traffic path until properly removed by another means.

(SNPO-17)

SAFETY

Lift Groups Safety Section 1-7

© 2009 Alamo Group Inc.

SAFETY

Unplowed snow, piled ice and debris, and snow drifts left behind the equipment might pose

a driving hazard to vehicle traffic colliding with the debris or losing traction on the material.

It is r ecommended to post warning signs alerting driver’s of th e equipment operation

presence and the need to reduce vehicle speed. If such hazards are left behind following

the Snow Plows passage, the area should be plowed a second time and any remaining

hazards removed by an alternative method. (SNPO-19)

Do not allow the Snow Plow to come in co ntact with potentially dangerous and/or

hazardous material. Such h azards may includ e, but are not exclusively limited to, the

following:

• Fire Hazards- Fuel spills, burning material,

• Chemical Hazards- Chemical spills, discarded chemical containers, batteries,

• Biological Hazards- Decaying Carcasses, BioMedical Waste,

• Radioactive Hazards-Radioactive Waste, Radioactive Material,

• Carcinogenic Materials-Asbestos,

• Corrosive Materials-Batteries, Acids and Bases.

In most areas, these types of material require special handling requirements for safe and proper disposal and

should not be plowed by the Snow Plow, nor can they be disposed of in a general landfill site like most swept

waste. Contact the appropriate authority for the collection and disposal requirements of such dangerous and/

or hazardous material. (SNPO-25)

Always wear required OSHA approved Personal Protective Equipment (PPE) when coming

in contact with and removing potentially dangerous and hazardous material that ha s

collected on the Snow Plow equipment or which is obstructing one or more components.

Pay close attention to dangerous and hazardous material including, but not exclu sively

limited to, chemicals, decaying carcasses and sharp objects. (SNPO-26)

Verbal communication near a T ruck or Power Unit and Snow Plow is d ifficult and

dangerous. Operating instructions and directions should be made prior to starting the

equipment. Unclea r and misunderstood communication may lead to o perator and

bystander injury or death and equipment damage. If com munication by the operator is

necessary, completely shutdown and exit the equipment. Never allow anyone to approach

the equipment while in operation. (SNPO-28)

Never allow children to play on, under, or around the Truck or Power Unit nor allow children

to operate equipment controls. Children can slip or fall off the equipment and be injured or

killed. Children can caus e the equipment components to shift or fall crushing themselves

or others. (SNPO-29)

Allow passengers only in si tuations where their presence is involved in th e operation

(operator training, supervision, maintenance inspection). Never carry passengers whose

presence distracts from the safe op eration or transport of the equipment. Pa ssengers

must be seated securely and belted in the cab’s passenger seat. Never allow any person

to ride on any other location of the Truck, Power Unit or Snow Plow during operation or

transport. (SNPO-30)

SAFETY

Lift Groups Safety Section 1-8

© 2009 Alamo Group Inc.

SAFETY

Extreme caution should be used by th e operator when operating near passersby. Stop

snow plowing if a passerby comes within 25 feet of the plow to prevent possible passerby

injury or death from being struck by the equipment or from a thrown object. (SNPO-31)

Make sure that no byst ander, animal or obstruction such as a vehicle, building, or

street sign are within the width of the Snow Plow. The design of the Snow Plow may

impair the operator vision when operating. Use extreme caution to ensure that the

Snow Plow is not driven into the path of pedestrian or vehicle traffic. Serious injury

or death and property damage could result from running into, being crushed by, or

run over by a Snow Plow.

(SNPO-33)

Make sure no bystanders or animals are within 25 feet of the e quipment

basket when dump ing contents from or clea ning the Snow Basket. Bucket

contents, which may exceed several thousand pounds, could fall and crush a

bystander or an animal resulting in possible injury or death. (SNPO-34)

Use extreme caution when operating the Equipment in traffic. To alert motorist of the

Equipment’s presence, use all equipped warning signals to alert motorist and pedestrians

of the equipment’s presence and relatively slow speed. Ser ious injury or death and

property damage may occur if a vehicle collides with this Equipment. (SNPS-3)

Before starting a sn ow plowing operation, make sur e all the warning signal lights are

connected, visible and working. Routinely inspect the equipment’s headlights, brake lights,

backup lights, and turn signal lights for operational condition. Immediately repair non-

functioning lighting. Always follow all local traf fic regulations while o perating the Snow

Plow. (SNPS-4)

Always turn on all safety lights and flashers when you operate the Snow Plow. (SNPS-5)

Be particularly careful in transport. The Implement has raised and moved the center of

gravity to the front of the Po wer Unit increasing the poss ibility of overturn and ti pping

forward. Turn curves or go up slopes only at low speed and using a gradual turning angle.

Go up slopes with the Implement located uphill. Slow down on rough or uneven surfaces.

(SPU-2)

SAFETY

Lift Groups Safety Section 1-9

© 2009 Alamo Group Inc.

SAFETY

CONNECTING OR DISCONNECTING IMPLEMENT SAFETY

INSTRUCTIONS AND PRACTICES

MAINTENANCE AND SERVICE SAFETY INSTRUCTIONS AND

PRACTICES

Do not stand or allow bystander or coworkers between the attachment

and the truck or powe r unit while ins talling or disconnecting the

attachment. Ke ep hands and body clear of th e attachment and the

attachment mounts. Serious injury or death can result from a person

being crushed between the attachment and truck or power unit. (SNPC-01)

Reset the tripped snow p low edge by r aising the snow plow off the ground. DO NOT

attempt to reset the trip edge by hand. T he trip edge is spring loaded and sudden and

unexpected movement can occur resulting in serious injuries. Keep and hands and feet

away from the trip edge. If the trip edge does not reset, stop plowing and have the snow

plow repaired before resuming snow plowing. (SNPO-12)

Make sure the implement is pr operly attached to the Power Unit and the r etaining pins

securely lock th e Implement into position. Im proper mounting of the Imp lement onto the

Power Unit can result in the Implement falling causing serious injury. (SNPC-02)

The operator of the equipment must be tr ained in the operation and safe use of this

machine. The operator must read and completely understand the operator’s manuals of

the Snow Plow, Truck or Power unit manufacturers. New operators should be trained in an

open area clear of obstructions before operating on public roadways. If operation of the

entire Snow Plow unit (Truck or Power unit) is not completely understood, consult your

authorized sales representative for a de tailed explanation. Never allow an untrained or

unqualified driver to operate the Snow Plow. (SNPD-1)

The Snow Plow driver must meet the requirements and possess a Motor Vehicle License

as determined by the state in which the Snow Plow is operated if used on public roadways.

Contact your local State Department of Public Safety of fice for special licensing

requirements to operate the Snow Plow in your area. (SNPD-2)

Perform service, repairs and lubrication according to the maintenance section. Ensure the

unit is properly lubricated as specified in the lubrication schedule and all bolts and nuts are

properly torqued. Failure to properly service, repair and maintain this Implement in good

operating condition could cause component failure and possible serious injury or even

death. (SG-35)

SAFETY

Lift Groups Safety Section 1-10

© 2009 Alamo Group Inc.

SAFETY

Periodically inspect all moving p arts for we ar and replace

when necessary with authorized service parts. Look for loose

fasteners, worn or broken parts, and leaky or loose fittings.

Make sure all pins are properly secured. Serious injury may

occur from not ma intaining this equipment in good working

order. (SNPM-01)

Inspect the entire Snow Plow before each use. Accidents may occur or damage to the

equipment may result if the Snow Plow is not maintained in g ood mechanical working

order.

• Check for loose bolts, worn or broken parts, pinched hydraulic hoses, and leaky or loose fittings.

• Make sure all pins are secure and safety pin equipped.

• Make sure replacement parts are the correct size and properly installed.

• Make sure all fluid levels are full and replenish as necessary.

• Make sure fuel, oil, and coolant caps are replaced and tightened.

• Check tire condition for tread wear and tire pressure at the rated PSI.

• Make sure that all safety shields and guards are attached and in good condition.

• Make sure all scheduled maintenance is up to date. (SNPM-02)

Do not modify or alter this Sn ow Plow. Do not permit anyone to modify or

alter this equ ipment, any of its components or any Snow Plow function.

Modification can result in equipment fa ilure and cause serious injuries to the

operator, coworkers, or bystanders. (SNPM-03)

Use extreme care when climbing onto the equipment to perform repairs, maintenance,

and cleaning. Use proper stands and ladders to access areas that cannot be reached from

ground level. Slipping and falling off the equipment can cause ser ious injury or death.

(SNPM-04)

Never attempt to repair, lubricate, adjust, clean, remove obstructions or perform any other

type of service to any component while the Snow Plow is in motion or while the engine is

running. Completely shut down the engine and wait for all motion to come to a complete

stop before servicing the Snow Plow. (SNPM-05)

Never leave the Snow Plow unattended while the plow is in the raised position. Accidental

operation of the lifting lever or a hydraulic failure may cause a sudden drop of the unit

which could result in injury or death by crushing. If the plow must be raised for inspection

or service securely block up and support the Plow to prevent it falling. (SNPM-06)

Never crawl under the Snow Plow or any raised component unless it is properly blocked

up and support to prevent it from falling. Accidental operation of a lifting lever or hydraulic

failure may cause a sudden drop of the unit with injury or death by crushing. (SNPM-07)

SAFETY

Lift Groups Safety Section 1-11

© 2009 Alamo Group Inc.

SAFETY

Use proper protective equipment including gloves, safety eye wear , arm protection when

handling plow blades and components during replacement, adjustment, and maintenance.

Plow edges and components can become sharp and have burrs that could inflict puncture

and cuts to the hands, arms, and/or eyes if proper protective equipment is not worn.

(SNPM-08)

Replace bent, cracked, or broken plow blade with a new blade. Ne ver attempt to

straighten or weld on plow blades because this will likely crack or otherwise damage the

blade with subsequent failure and possible serious injury from broken blade being ejected

from plow. (SNPM-10)

Escaping pressurized hydraulic oil generated by hydr aulic pumps has the potential to

inflict serious injury and possible death. Never attempt to repair a pump or hose or tighten

a connection while the system is pre ssurized. Always shu t down the engine and relieve

hydraulic oil pressure before performing any repairs to the hydraulic system. (SNPM-11)

Hydraulic pressure must be relieved from the hydraulic circuit prior to d oing any

maintenance or repair work and when the Snow Plow is parked at the end of the day.

Place the Snow Plow(s) on the ground or securely blocked up. Turn off the Truck engine

then engage the hydraulic remote cylinders several times to relieve hydraulic pressure

prior to performing any maintenance or repair work. (SNPM-12)

Never remove debris from or unclog jams in the plow or lifting components until the engine

have been completely shutdown and all components have come to a comp lete stop and

are lowered to g round level and hydraulic pressure relieved. Always wear PPE when

removing collected material and debris from the equipment. Serious injury or death may

occur if any of these precautions are not followed when removing plugged or entangled

debris. (SNPM-15)

Engine Exhaust, some of its constituents, and certain vehicle components contain or emit

chemicals known to the state of California to cause cancer and birth defects or other

reproductive harm. (SNPM-20)

Do not operate this equipment with hydraulic oil or fu el

leaking. Oil and fuel are expensive and their presence

could present a hazard. Do not check for leaks with your

hand! High-pressure oil streams from breaks in the line

could penetrate the skin and cause tissue damage including

gangrene. To check for a hose leak, SHUT the ENGINE OFF and

remove all hydraulic pressure. Wear oil impenetrable gloves, safety

glasses and use Cardboard to check for evidence of oil leaks. If you

suspect a leak, REMOVE the HOSE and have it tested at a Dealer.

If oil does penetrate the skin, have the injury treated

immediately by a physician knowledgeable and skilled in

this procedure. (SNPM-21)

Always read carefully and fully comply with the manufacturers instructions when handling

fuels, oils, solvents, cleansers, and any other chemical agent. (SNPM-22)

SAFETY

Lift Groups Safety Section 1-12

© 2009 Alamo Group Inc.

SAFETY

TRANSPORTING SAFETY INSTRUCTIONS AND PRACTICES

Battery posts, terminals and related accessories contain lead and lead compounds,

chemicals known to the state of California to cause cancer and birth defects or other

reproductive harm. Wash Hands after handling. (SNPM-23)

Avoid contact with hot surfaces on the bottom of the skid shoes or plow cutting

edges. Use gloves and eye protection when servicing hot components. Contact

with a hot surface can cause serious injury from burns or scalding. (SNPM-24)

Remove the negative battery cable from the battery before performing any maintenance on

the electrical system to p revent an accidental circuit shorting and sparks. Sparks can

result in wiring damaged, fire or personal injury. (SNPM-25)

Before conducting maintenance on the Snow Plow stop the truck or Power Unit, place the

transmission in the park position and set the parking brake. Turn the engine off and

remove the key to prevent inadvertent or accidental starting of the engine. Unexpected

engine start up or vehicle movement can result in serious bodily injuries or death. (SNPM-27)

Transport the Truck, Power Unit, and Snow Plow only at safe speeds. Serious accidents

and injuries can result from driving this equipment at unsafe speeds. Become familiar with

the driving characteristics of the equipment and how it han dles before operating or

transporting on streets and highways. Make sure the Truck’s or Power Unit’s steering,

brakes, and wheels are in good condition and operate properly)

Before transporting the Equipment determine the safe transport speeds for you and the machine.

Make sure you abide by the following rules:

• Test the Truck or power unit and Snow Plow at a slow speed and increase the speed slowly. Apply the

brakes smoothly to determine the stopping characteristics of the Truck equipped with the Snow Plow. As

you increase the speed of the Truck, the stopping distance increases. Determine the maximum safe

transport speed for you and the equipment. When driving down a hill or on wet or icy roads, the braking

distance increases: use extreme care and reduce your speed. Do not operate the equipment with weak

or faulty brakes.

• Obey all traffic laws and regulations. Never exceed the posted speed limit.

• The Snow Plow has moved the center of gravity of the equipment forward. Use extreme caution when

transporting at highway speeds. Slow down for sharp corners or on slopes to avoid loss of steering con-

trol.

• Only transport the equipment at the speeds determined as safe and which allow for proper control of the

machine while driving and stopping during an emergency.

• When operating in traffic, use the Truck’s or Power Units directional indicator or signal lights to indicate

your movement. Always use the flashing warning lights and other equipped warning features to alert

motorist of your presence and slow moving speed when operating in traffic. Be Aware of Traffic Around

You and Watch Out for the Other Guy. (SNPO-09)

SAFETY

Lift Groups Safety Section 1-13

© 2009 Alamo Group Inc.

SAFETY

Federal Laws and Regulations

This section is inten ded to explain in broad terms the concept and effect of federal laws and regulations concerning

employer and employee equipment operators. This section is not intended as a legal interpretation of the law and

should not be considered as such.

Employer-Employee Operator Regulations

U.S. Public Law 91-596 (The Williams-Steiger Occupational and Health Act of 1970) OSHA

This Act Seeks:

“...to assure so far as po ssible every wo rking man and woman in the nation safe an d healthful working

conditions and to preserve our human resources...”

DUTIES

Sec. 5 (a) Each employer-

(1) sh all furnish to ea ch of his employees employment and a place of employment which are free from

recognized hazards that are causing or are likely to cause death or serious physical harm to his employees;

(2) shall comply with occupational safety and health standards promulgated under this Act.

(b) Each employee shall comply with occupational safety and health standards and all rules, regulations and

orders issued pursuant to this Act which are applicable to his own actions and conduct.

OSHA Regulations

OSHA regulations state in part: “At the time of initial assignment and at least annually thereafter, the employer

shall instruct every employee in the safe operation and servicing of all equipment with which the employee is,

or will be involved.”

Employer Responsibilities:

To ensure employee safety during plow and truck or other power unit operation, it is the employer’s responsibility to:

1. Train the employee in the proper and safe operation of the plow and truck or other power unit.

2. Require that the employee read and fully understand the plow and truck or other power unit Operator’s manual.

3. Permit only qualified and properly trained employees to operate the plow and truck or other power unit.

4. Maintain the plow and truck or other power unit in a safe operational condition and maintain all shields and guards

on the equipment.

5. Ensure the truck or other power unit is equipped with a functional ROPS and seat belt and require that the

employee operator securely fasten the safety belt and operate with the ROPS in the raised position at all times.

6. Forbid the employee operator to carry additional riders on the Tractor or Implement.

7. Provide the required tools to maintain the plow and truck or other power unit in a good safe working condition and

provide the necessary support devices to secure the equipment safely while performing repairs and service.

8. Require that the employee operator stop operating equipment if bystanders or passersby come within 25 feet.

Child Labor Under 16 Years of Age

Some regulations specify that no one under the age of 16 may operate power machinery. It is yo ur responsibility to

know what these regulations are in your own area or situation. (Refer to U.S. Dep t. of Labor, Employment Standard

Administration, Wage & Home Division, Child Labor Bulletin #102.)

Version 1.0, 03/29/2010

DECALS - PLG Lift Groups.doc

PLG – Parallel Lift Group

Kit Revision Notes:

DECALS

TRUCK HITCH – TILT & FD Safety Section 1-14

PLG – Parallel Lift Group

Henke

Part No. Qty. Description

7331003 1 Use genuine Henke replacement parts

7331004 1 Secure body with blocks

7331005 1 Stop Engine Stay clear of moving parts

7331006 1 Do not use hands to check for oil leaks

High Pressure oil leak-injection

7331007 1 Read and understand operator's manual

If you cannot read English get assistance

7331010 1 Keep Clear, Pinch Point

7330012 1 Serial Number Tag

7300047 1 Product Manual Canister

7300048 1 Plug - Product Manual Canister

Other Attachments and Decals

Use the following decals from sheet 7332006-010.

NOTE: Use all decals listed above from sheet 7332006-010

and discard remaining decals

Instructions:

Follow these instructions to position the above items to your Henke product for safety and

professional appearance. Apply on clean surfaces only. They should be properly applied

and kept in good condition. If a decal is worn out, torn, or otherwise defaced, call us for an

immediate replacement at 1-913-682-9000, or 1-888-682-9010.

DECALS

TRUCK HITCH – TILT & FD Safety Section 1-15

1. Position 7331007, 7331010, 7331005, & 7330012 as shown on Driver’s Side.

2. Position Canister 73300047 as shown below Serial Number Plate in preferred

location or positioned in alternate location on lower arm centered to prevent

interference when Lift Group is raised or lowered.

CANISTER 7300047

Alternate Location

This manual suits for next models

2

Table of contents

Popular Lifting System manuals by other brands

Grainger

Grainger 12R538 instruction manual

REID LIFTING

REID LIFTING PORTADAVIT QUANTUM Assembly & Operation guide

HENNESSY INDUSTRIES

HENNESSY INDUSTRIES coats 4TV21NSR1 manual

Glomstad Motor

Glomstad Motor GM - U95 PRO Use and maintenance manual

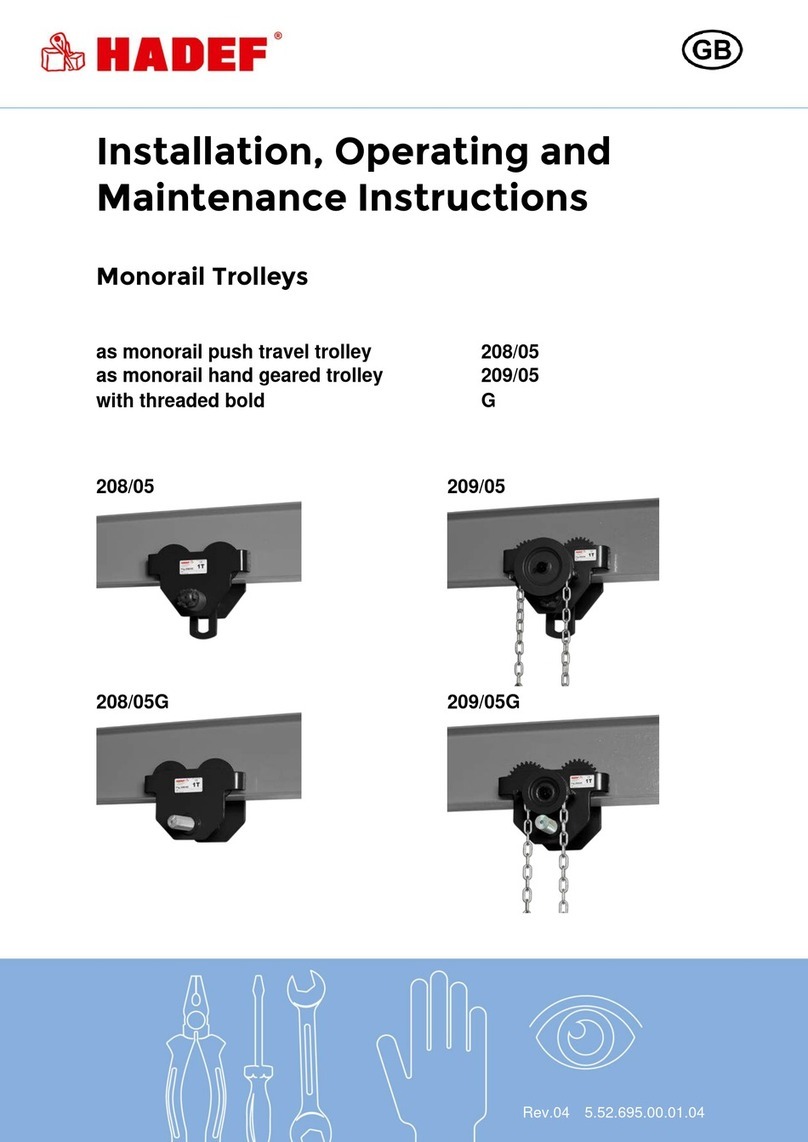

HADEF

HADEF 208/05 Installation, Operating and Maintenance Instruction

AUTOLIFT

AUTOLIFT I-Swim2 instruction manual