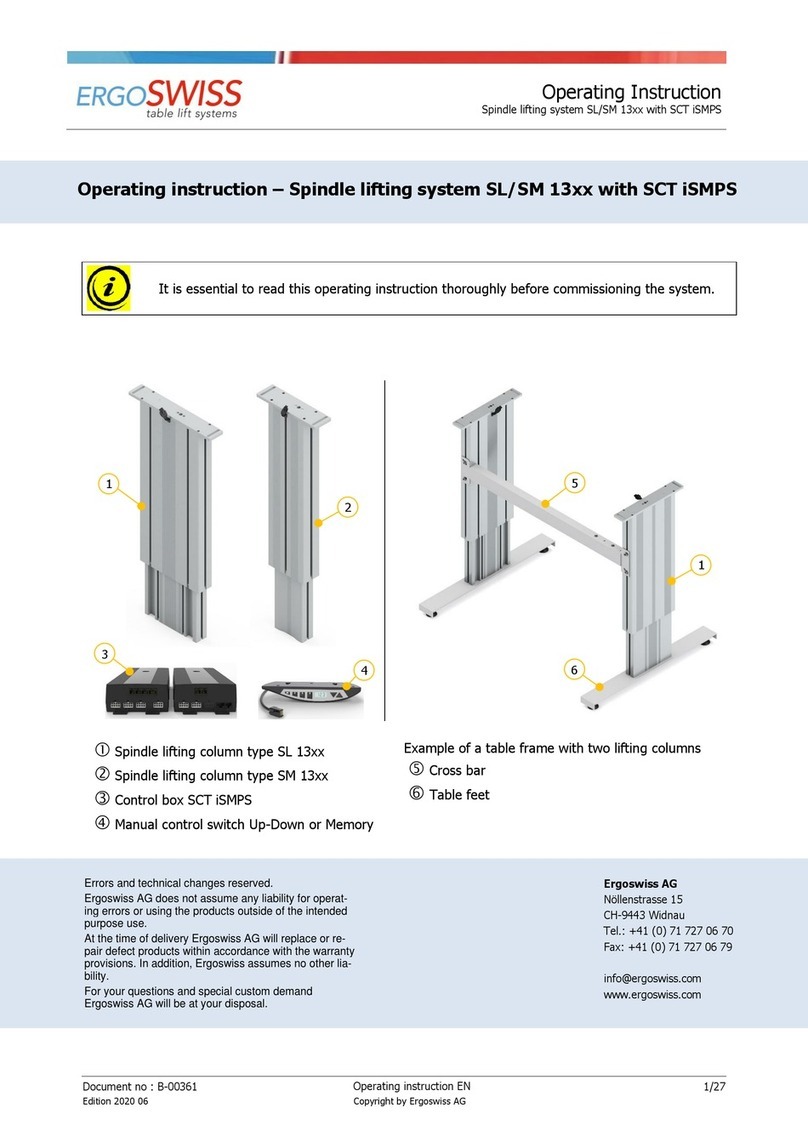

Operating Instruction

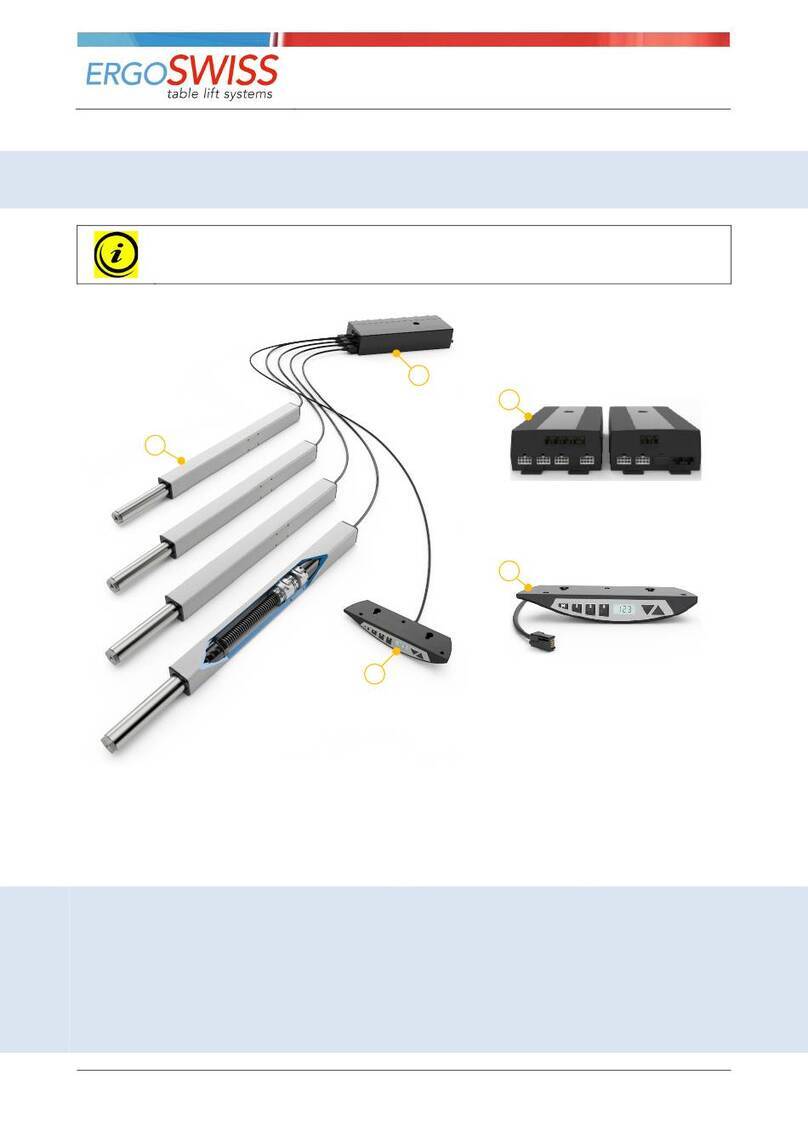

Spindle lifting system SLA/SLG VD

ument no.: B-00081

Operating instruction EN

Copyright by Ergoswiss AG

3/20

Table of content

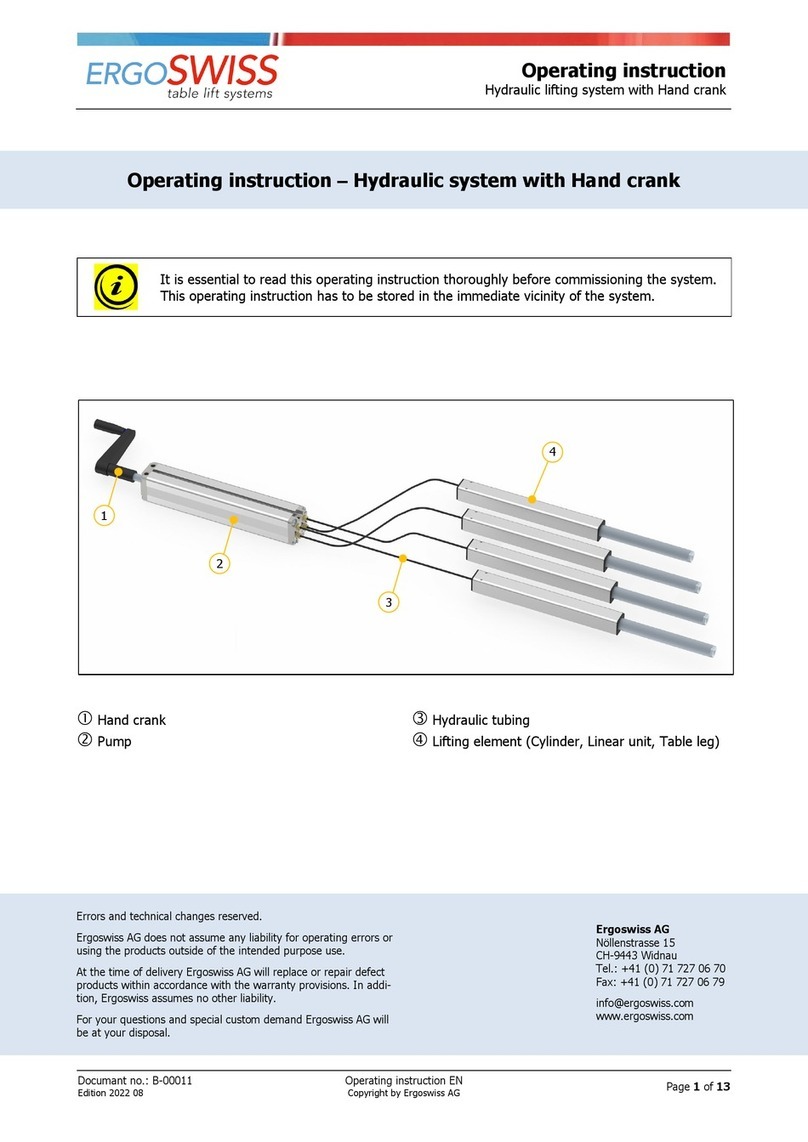

1System description .....................................................................................................................................4

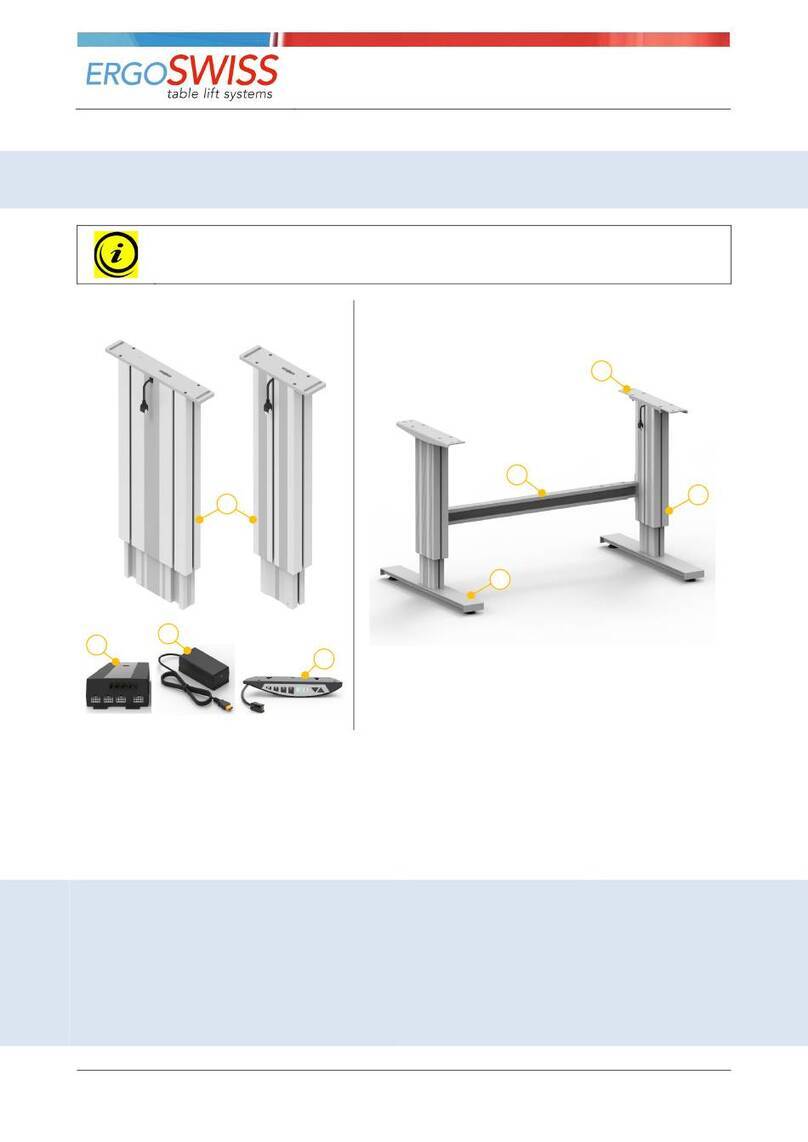

1.1 General................................................................................................................................................4

1.2 Intended purpose use ...........................................................................................................................4

1.3 Target group and prior knowledge .........................................................................................................4

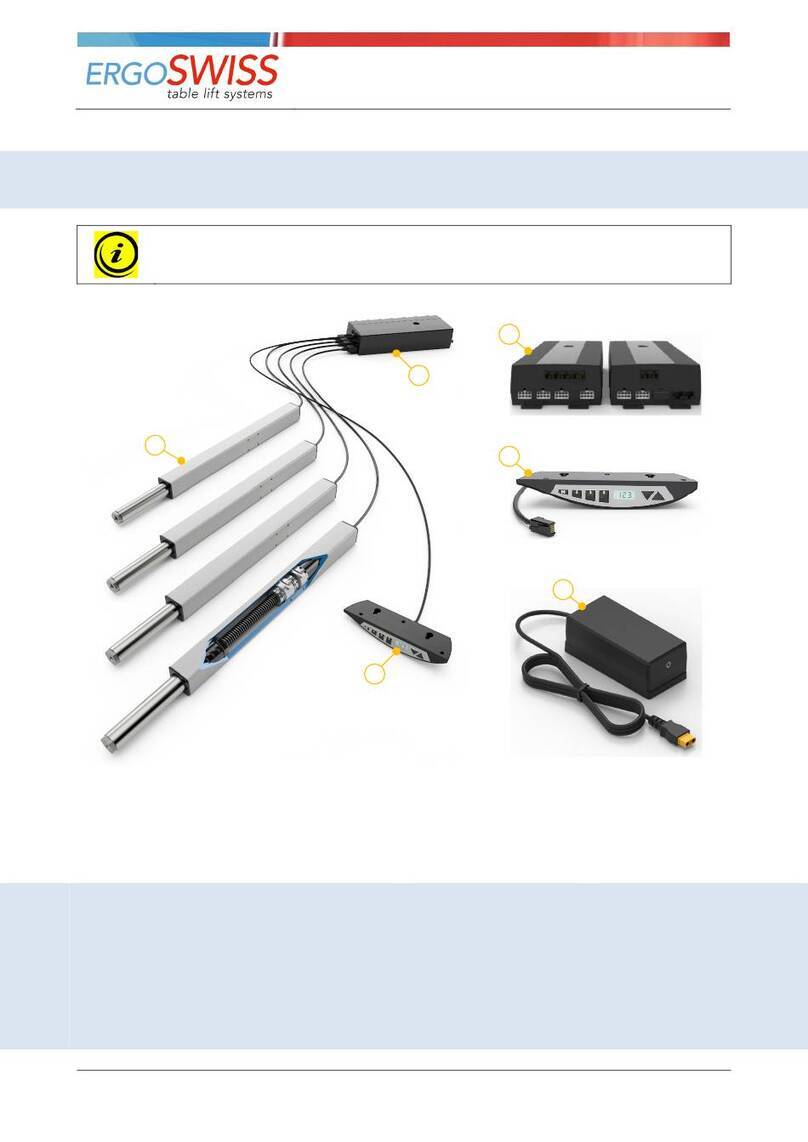

1.4 Performance characteristics ...................................................................................................................5

1.4.1 Linear unit SLA 13xx.........................................................................................................................5

1.4.2 Linear unit SLG 13xx.........................................................................................................................5

1.4.3 Motor SX D30 24 V...........................................................................................................................5

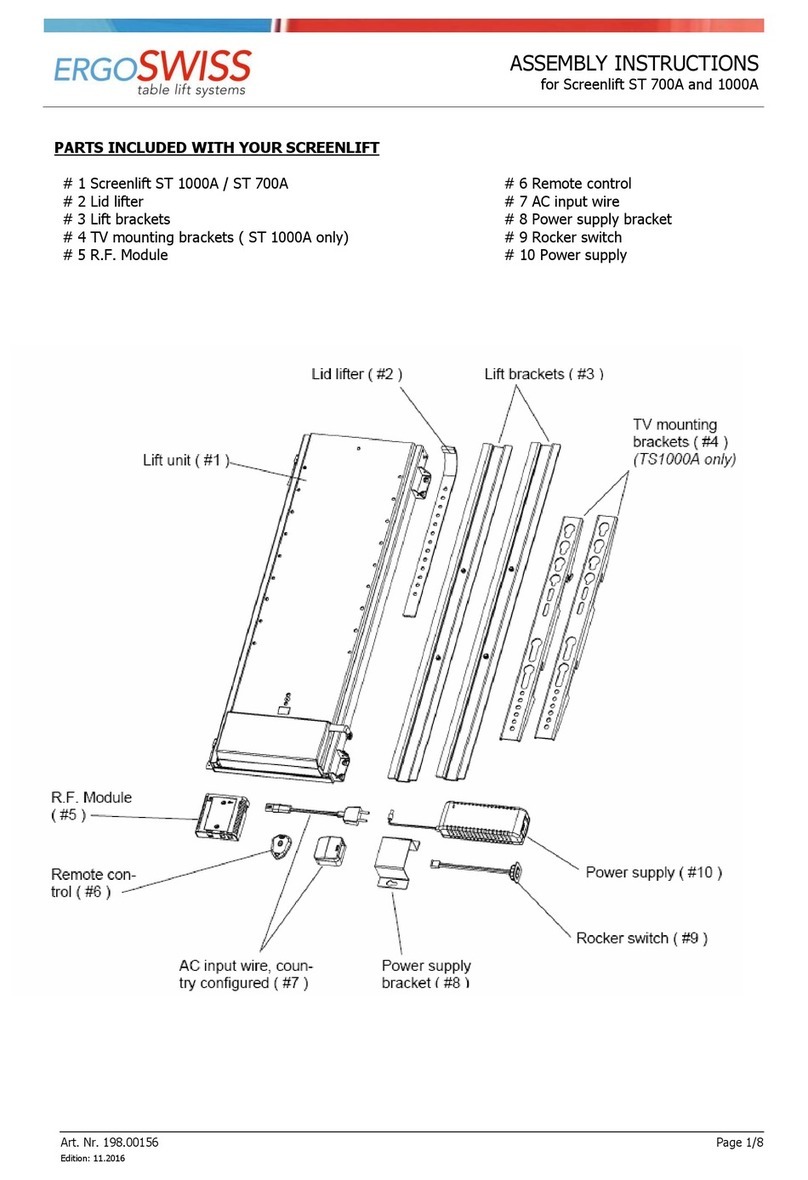

1.4.4 Control box VD SCT2 and SCT4 .........................................................................................................5

1.4.5Manual control switch VD Up / Down and memory ..............................................................................5

2Safety requirements ...................................................................................................................................6

2.1 Explanations of the symbols and notes ...................................................................................................6

2.2 Basic safety instructions ........................................................................................................................7

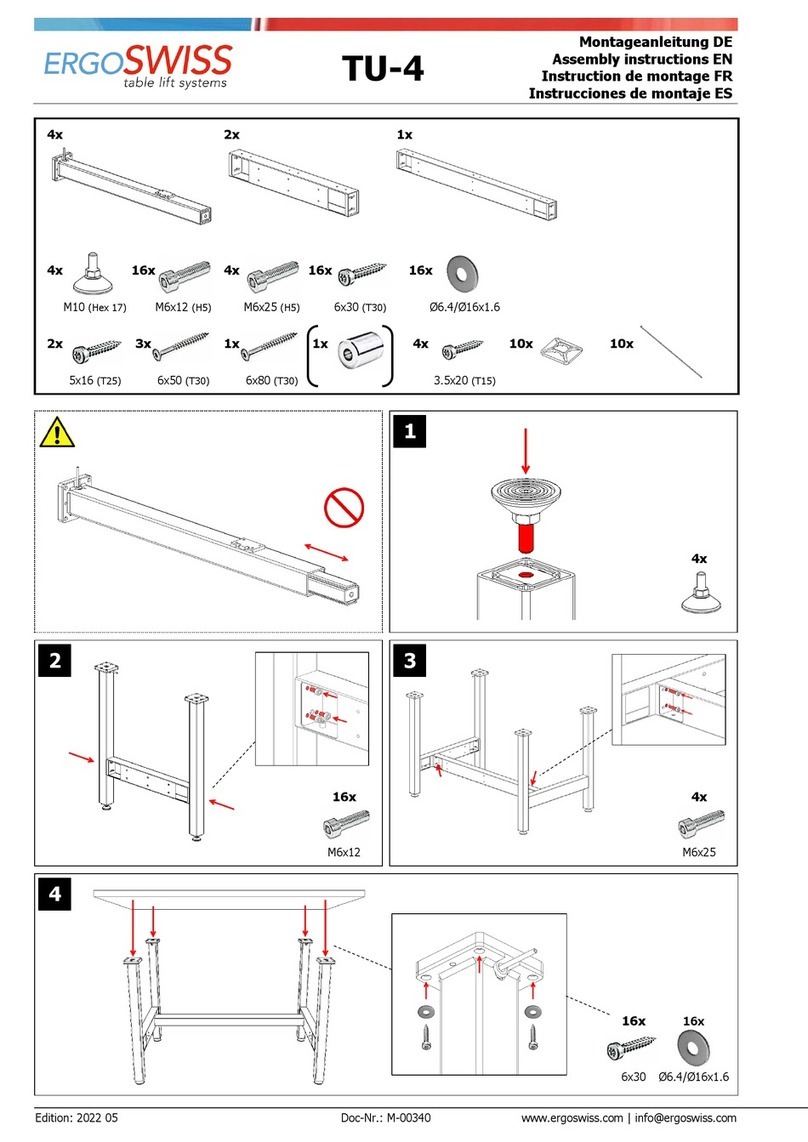

3Preperation for first initial operation .........................................................................................................8

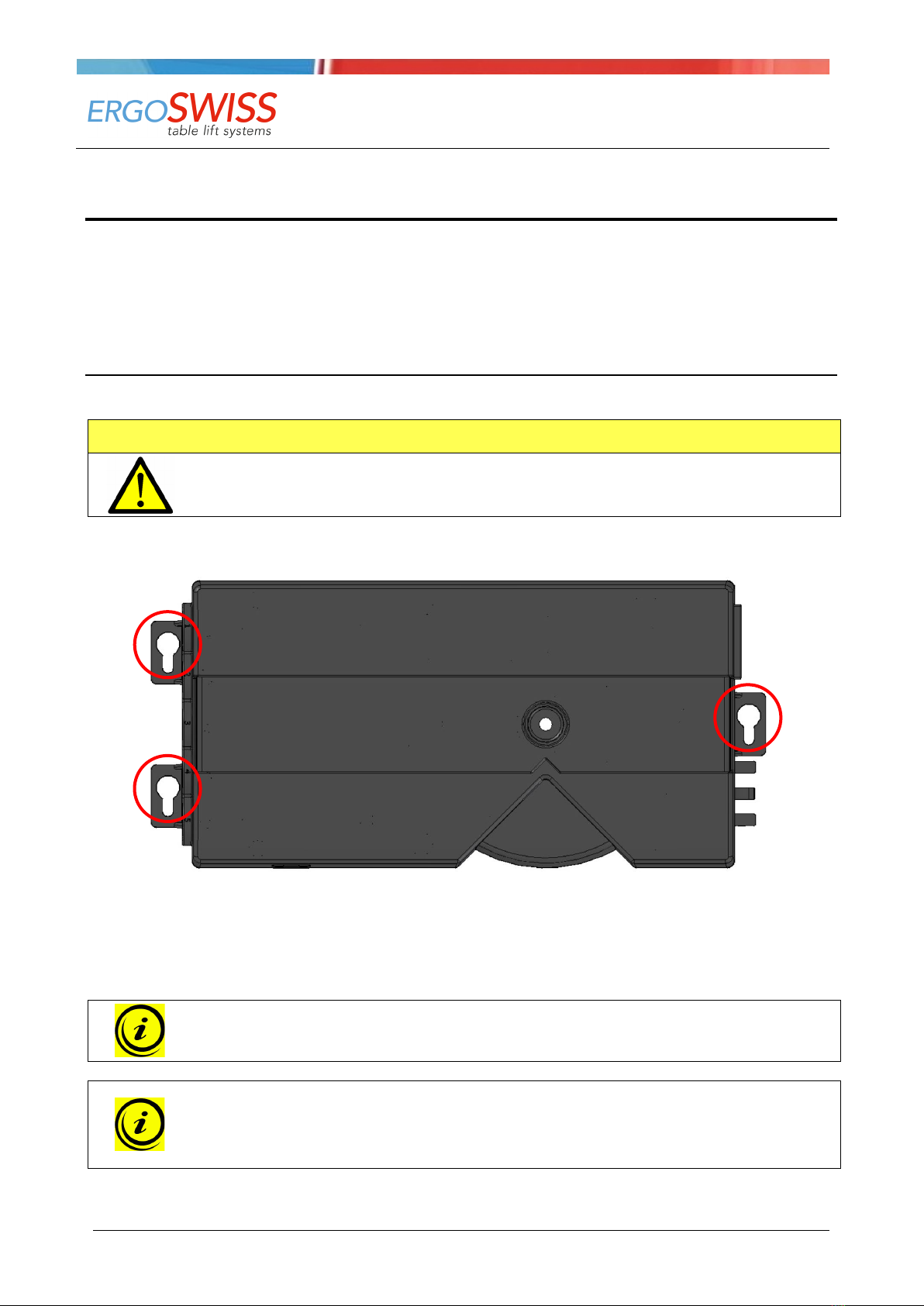

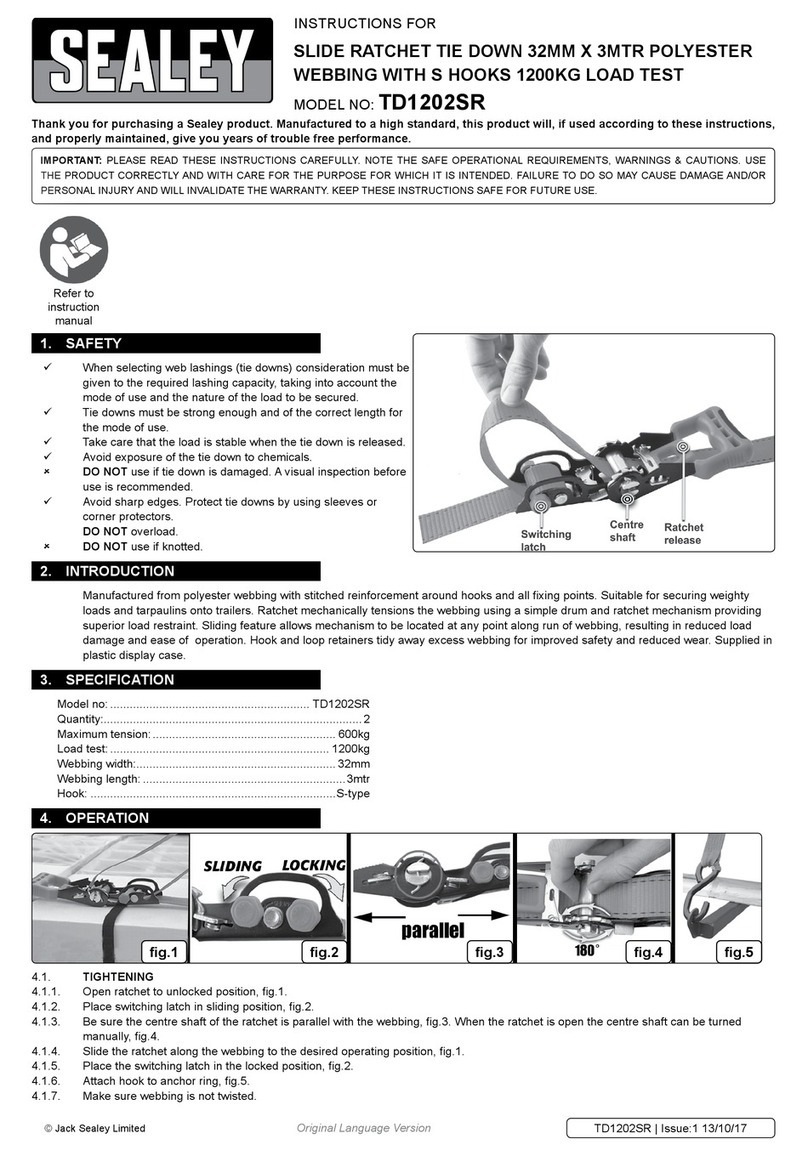

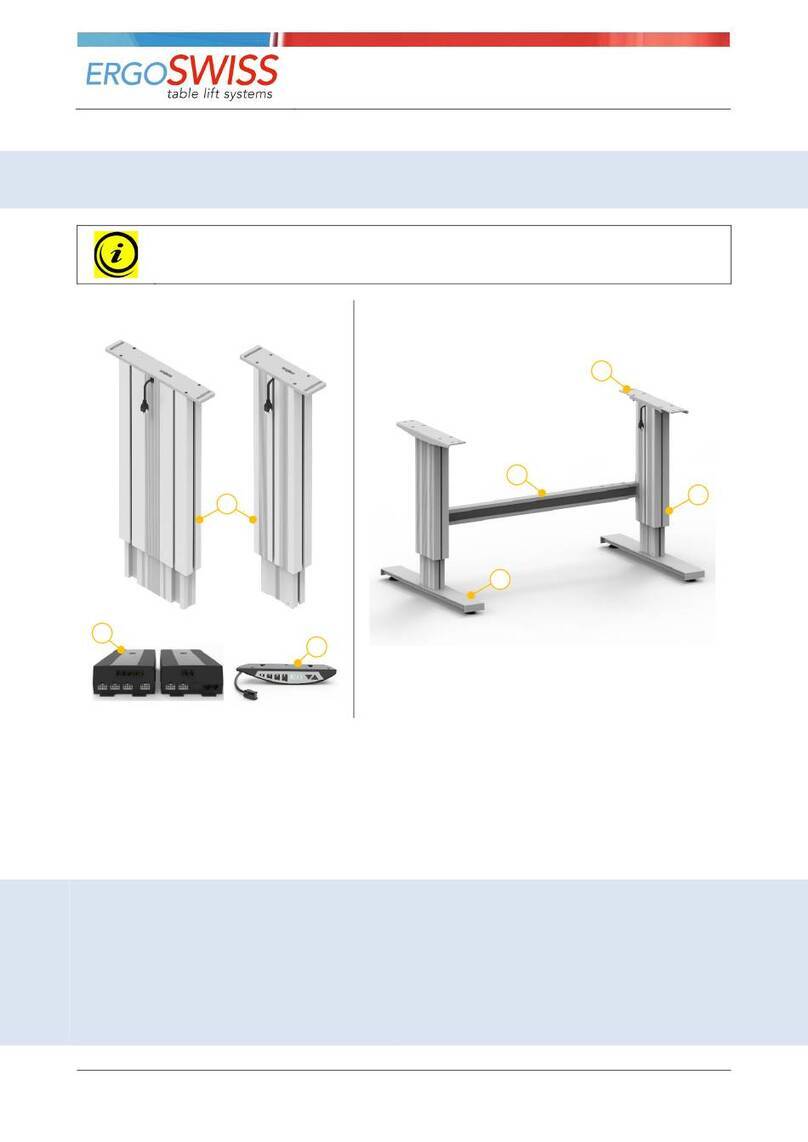

3.1 Mounting the control box and connecting the cables ................................................................................8

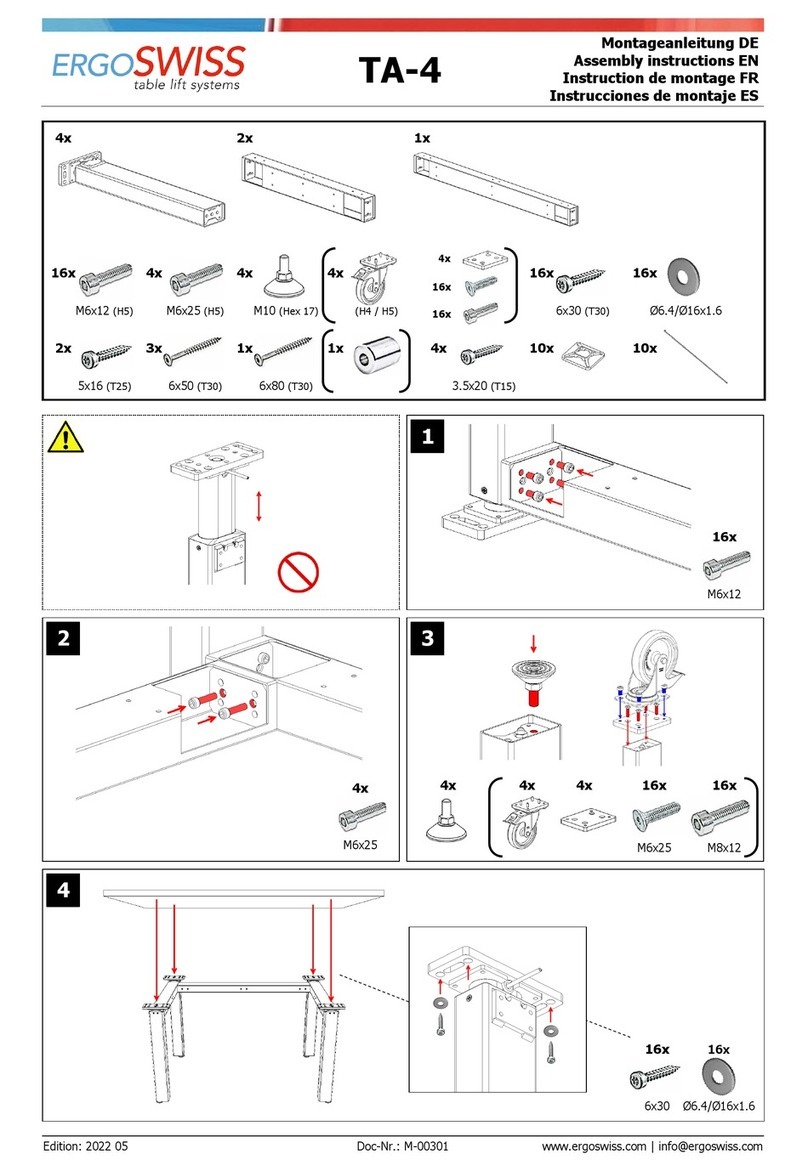

3.2 Mounting of the manual control switch ................................................................................................. 10

3.2.1 Manual control switch VD Up / Down ............................................................................................... 10

3.2.2 Manual control switch VD / Memory ................................................................................................. 10

3.2.3 Manual control switch VD Memory T6............................................................................................... 11

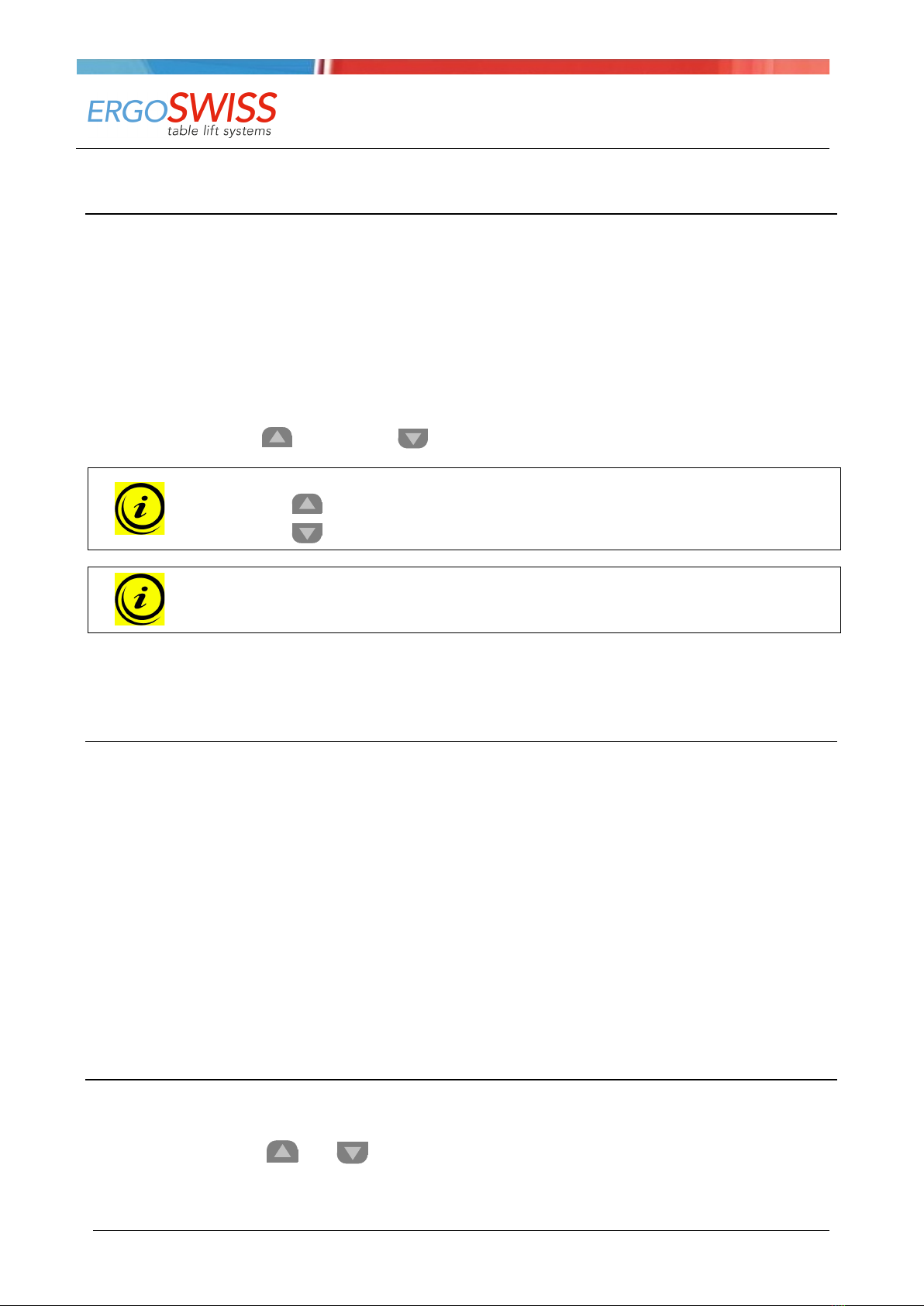

4Initial operation ....................................................................................................................................... 12

5Operation ................................................................................................................................................. 13

5.1 Drive up / down ................................................................................................................................. 13

5.2 Duty cycle monitoring ......................................................................................................................... 13

5.3 Saving a memory position (Only with manual control switch type Memory!) ............................................. 13

5.4 Approaching a stored position (Only with manual control switch type Memory!) ....................................... 13

5.5 Container-Stop and Shelf-Stop-positions (Only with manual control switch type Memory!)......................... 14

5.5.1 Child-proof lock (Only with manual control switch type Memory!) ....................................................... 14

5.6 Reset of the control box ...................................................................................................................... 14

6Synchronous operation of 2 control boxes ............................................................................................. 15

6.1 Cable connections............................................................................................................................... 15

6.2 Commissioning the synchronized system............................................................................................... 15

7Safety strip - Squeezing protection......................................................................................................... 16

7.1 Technical Data ................................................................................................................................... 16

8Maintenance and disposal ....................................................................................................................... 17

8.1 Maintenance and cleaning ................................................................................................................... 17

8.2 Repairs and spare parts ...................................................................................................................... 17

8.3 Disassembly and disposal .................................................................................................................... 17

8.4 Electrical and Electronic Equipment Act................................................................................................. 17

8.5 Error messages on the display (Only with manual control switch type Memory!)....................................... 18

8.6 Trouble-shooting ................................................................................................................................ 19

9Declaration of Incorporation ................................................................................................................... 20