5

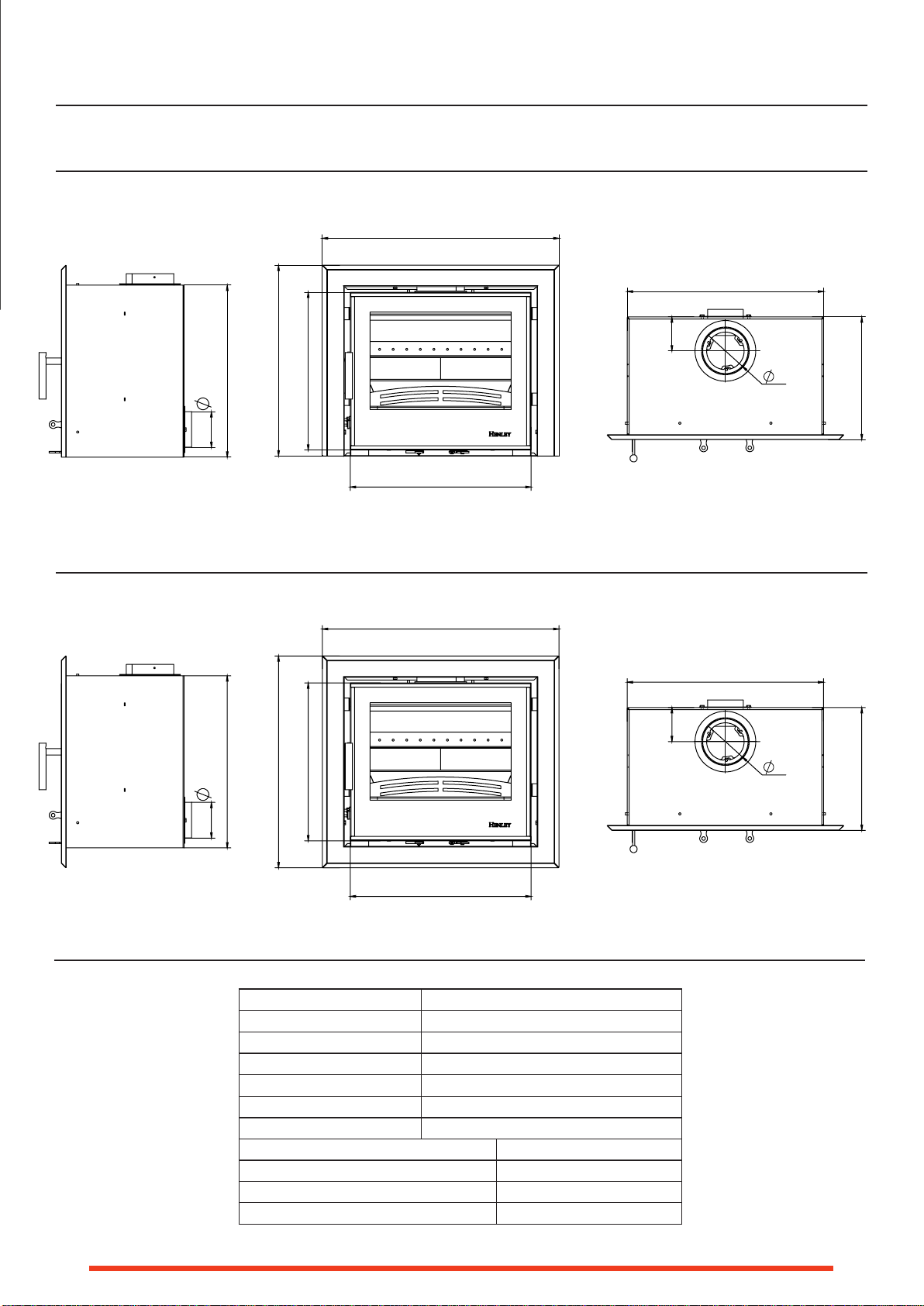

Installation Instructions

Installation

Before installation and/or use of this appliance

please read these instructions carefully to ensure

that all requirements are fully understood. The

appliancemustbettedbyaregisteredinstaller*,

orapprovedbyyourlocalbuildingcontrolocer.

Regulations

Please refer to the current issue of

British Standard BS 8303, Code of Practice

for Installation of domesting heating

appliances burning solid fuel, Building

Regulations, Local Authority Bylaws and other

specicationsorregulationsincludingIreland,

UKorEUstandardsreferredtoastheyaectthe

installation of the stove.

Building regulations available on www.environ.ie

& www.planningportal.gov.uk.

Domestic Heating

Only use for domestic heating in accordance with

these operating instructions.

Fuel

Only approved fuels must be burned.

Do not use liquid fuels or as an incinerator.

Fireguard

Appliance surfaces become very hot when in

use.AreguardconformingtoBS8423:2010

should be used in the presence of children, the

elderlyorinrm.

Please note, this appliance should be used with

theredoorclosedatalltimesexceptwhen

fueling, cleaning ash or initial lighting.

Combustible Materials

Do not place photographs, TV’s, paintings,

porcelain or other combustible items on the

wall or near the appliance. Exposure to hot

temperatures will cause damage. Do not place

furniture, or other items such as drying clothing,

closer than 1 metre from the front of this

appliance. Do not use aerosol sprays or any other

ammablematerialsneartheapplianceunderre.

Asbestos

This stove contains no asbestos. If there is a

possibility of disturbing asbestos in the course of

installation then please seek specialist guidance

& use appropriate protective equipment.

Fire Cement

Sometypesofrecementarecausticand

should not be allowed to come into contact

with the skin. In case of skin contact, wash

immediately with plenty of water.

Extractor Fan

It is possible to install this appliance in a kitchen

or open plan room which uses an extractor fan.

Adequate provisions must be made, as the

extractor will draw air from the room. A draught

test needs to be carried out on the appliance

with the extractor fan running on full power.

Based on results from the draught test, extra

ventilation should be added where necessary.

Ventilation:

Do not obstruct inside or outside ventilation

required for the safe use of this appliance.

Alterations

Do not make unauthorized changes to the

appliance.

Chimney

The chimney must be swept at least once a

year.

Flue System

Donotconnect,orshare,thesameueor

chimney system with another appliance.

Serial Number

The serial number is required when ordering

spare parts or making warranty claims. It is

found on the appliance data plate.

Manual Handling

Before continuing any further with the

installation of this appliance please read the

following guide to manual handling.

• Always obtain assistance when lifting

• When lifting always keep your back straight

• Avoid twisting at the waist. It is better to

reposition your feet.

• Avoid upper body/top heavy bending. Do not

lean forwards or sideways

• Always grip with the palms of your hands do not

useyourngertipsforsupport,useglovesfora

better grip

• Always keep the stove close to the body as this

will minimize the cantilever action.