HESHBON HO-250A Instruction manual

Installation/Operation & Maintenance Manual

Please read this manual carefullybefore operation.

You must read and understand the precautions for safety

and avoid any damages and injury.

Fully Automatic A.T.F Changer

HO-250A

Installation/Operation & Maintenance Manual

1. Introduction

1-1. Features and characteristics

1-2. Names of each part

1-3. Description

1-4. Specification

1

1

2

3

4

2. Safety

2-1. Danger/Warning/Caution

5

5

3. Operation

3-1. Check points before operation

3-2. Calibration

3-3. Operation

7

7

7

8

4. Maintenance

4-1. Trouble-Shooting

5. Sparepart List

11

11

TABLE OF CONTENTS

▶This manual was prepared in January 2017 the product specifications

contained in this manual are subject to change without notice.

1

1-1.

Features and characteristics

DIGITAL

DIGITAL

DIGITAL

Possible to work for 4-10 shift

transmission

Exchanging level gauge Mode

Possible to work for car type without

level gauge

Voice guidance Mode

One-touch oil line

change Mode

Input car data

Etc.

•Equiped electronic digital scale

•Oil saving Mode

(Some of car type are excluded)

•Installed oil exchange program on cooler line

•Display oil temperature

•Possible transmission flushing by chemical

•Used oil sampling function (Application of selected model)

•Installed 40L used oil tank

•Installed anti-overflowing sensor of used oil

Introduction

2

Introduction

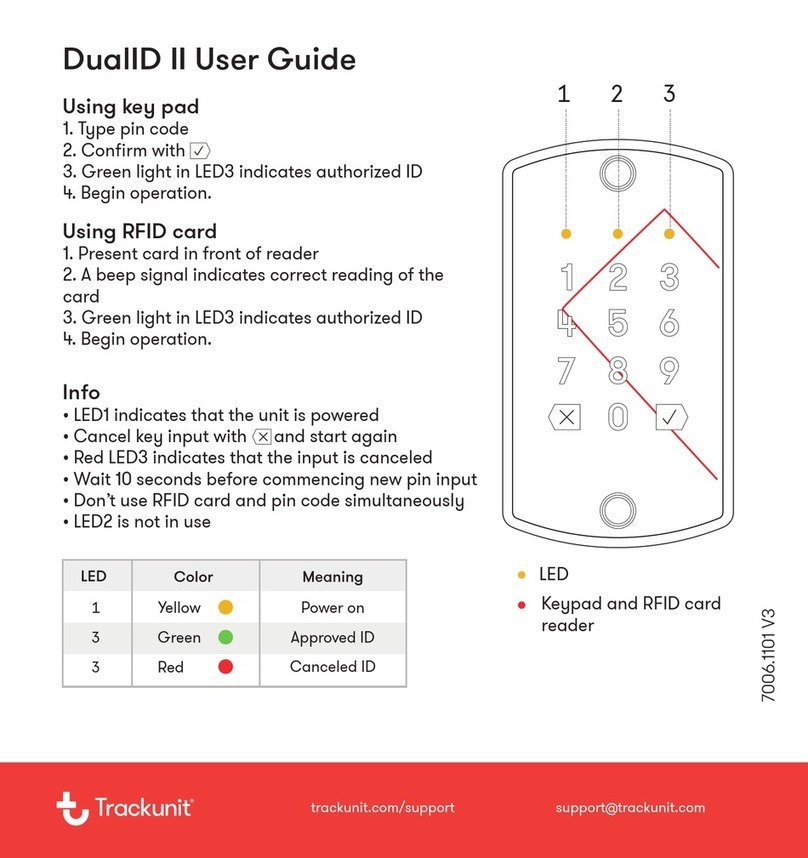

1-2.

Description

① Exchanging level gauge Mode ⑩ Up button

④ Recovery used oil In the vehicle

set amount ⑬ Pause button

⑦ Possible transmission flushing

by chemical ⑯ Menu button

② Exchanging IN/OUT Cooler line ⑪ Down button

⑤ inject new oil In the vehicle set

amount ⑭ Stop button

⑧ Recovery : Recovery of waste oil into the

device in a vehicle.

(It works only when pressing the start button)

⑰ Line change(option) : Change

Injection and recovery hose lines.

③ Oil saving Mode : 0.1 liters of used oil

recovery and inject new oil, so you let

healing the least. (Except for some models) ⑫ Start button

⑥ Drain the used oil. ⑮ Calibration the scale.

⑨

Inject : Inject of new oil into the device in

a vehicle.

(It works only when pressing the start button)

⑱ FUNC : System settings

⑲ ENTER button

Only trained personnel may

operate the equipment.

Inexperience can cause

accidents.

Work only on the horizontal

place for safety purpose.

3

Safety

2-1.

Danger / Warning / Caution

Danger / Warning/ Caution

Make sure you follow the instructions, otherwise critical injury or death can occur.

Make sure you follow the instructions, otherwise critical injury or damage can occur.

Make sure you follow the instructions; otherwise, injury or damage can occur

The terms are described to enhance the understanding of the equipment.

Danger / Warning / Caution

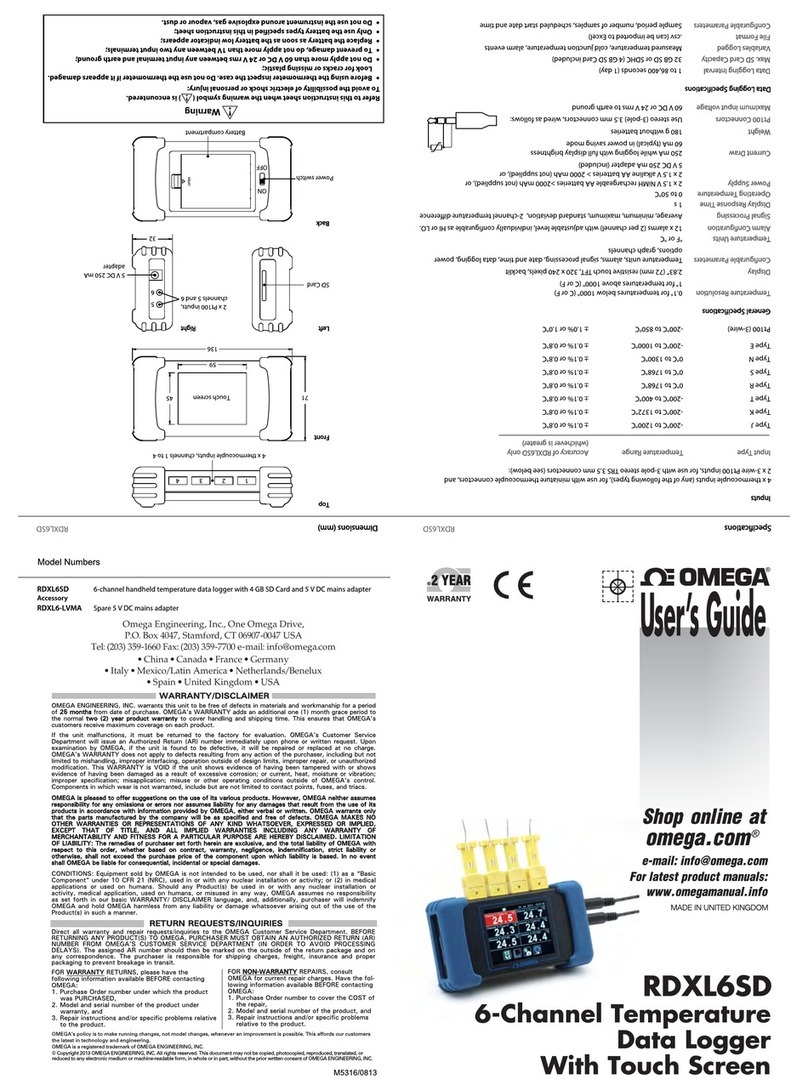

Model No. HO-250A

Control type Computer control

Measurement Digital scale control

Motor 0.2kw 1PH 220V

Pump Type TRO CHOID Relief Auto

New oil tank 20ℓ

Used oil tank 40ℓ

Net weight Approx. 50kg

Dimension 530(W) x 595(L) x 900(H)mm

1-3. Specification

Do not touch power cord with

wet hands.

▶ It may cause injuries or even

death.

Do not use damaged

power plug or loosened

outlet.

▶ It may cause injuries or

even death.

Do not expose this product

directly to rain and moisture.

▶It may cause injuries or even

death.

Do not work with this product

close to heating source.

▶It may cause injuries or even

death.

Do not apply excessive

force to unplug power

cord.

▶ It may cause an electric

shock or a fire.

Make sure to install

it indoors only and protect it

from rain or snow.

Do not insert multiple plugs

on the socket.

▶ It may cause an electric

shock or a fire.

Make sure that electric oulet/

pins must be

maintained clean.

▶ It may cause an electric

shock or a fire.

Do not apply any impact

on the body frame[housing]

or expose it to dust.

▶It may cause unexpected

malfunction.

Do not expose this product

to direct sun light.

▶ It may cause unexpected

malfunction.

Do not attempt to push any

incorrect button during

operation.

▶ It may cause unexpected

malfunction

Do not modify the control

panel and structure volun-

tarily.

▶ It may cause unexpected

malfunction.

Make sure to install

it indoors only and protect

it from rain or snow.

Read this manual carefully

before use.

▶ Serious accidents may

happen due to negligence of

danger & warning information.

Do not use unprescribed

oil.

▶ It can cause damage to

the machine.

Do not bend the power

cord or place any heavy

article on it.

4

Safety

Make sure that you read and understand them.

Operation

3-1. Preparing to work

3-2. How to calibration new oil Scale

(1) Fill up new oil in the new oil tank.

(2) Connect power supply and turn on the power switch.

(3) FWD vehicle shift the gear into N and RWD vehicle shift the gear

into P.

(4) Connect coupler to recovery hose and injection hose.

(5) Make sure oil flow direction is upward(⇡) in the sight glass.

(6) If oil flow direction is downward(), switch line change lever.

Then oil flow direction will be changed to upward.

1-1) Put 20 liter empty oil tank on the electronic scale.

1-2) Connect the oil inlet hose.

1-3) Press the calibration button.

1-4) Press DOWN button and hold (3sec) until COMPLETE message

shown on the screen.

1-5) Make sure the process is completed.

2-1) Put 20 liter full oil tank on the electronic scale.

2-2) Connect the oil inlet hose.

2-3) Press the calibration button.

2-4) Press UP button and hold (3sec) until COMPLETE message shown

on the screen.

2-5) Make sure the process is completed.

1) Calibration with 20 liter empty oil tank

2) Calibration with 20 liter full oil tank.

▶ Park vehicle on the flat floor and make sure the vehicle is securely

braked.

(*If necessary, prop up wheels to prevent rolling the wheel.)

▶ Operator should wear safety glasses and protective equipment.

▶ Precise electronic scale equipped in the product, so pay attention to

prevent damage from impact or shock.

CALIBRATION

UP = 20 liter

DOWN = 0 liter

5

6

Operation

3-3. How to Use

1) Insert the hose to the oil check gauge of the vehicle.

2) Connect the appropriate accessories in the vehicle.

(Accessories for level gauge)

3) Connect a hose on any device orientation.

4) Select the level gauge mode(AUTO1).

5) Use the ▲ ▼ buttons to set the amount of oil changes. (Initial value 8.0 liters)

6) Press the Start button.

7) If necessary after checking whether the end-of-job message comes up oil

level is potent using a setting recovery, setting injection and align the oil level.

8) Finish the work.

1) Remove the cooling line of the vehicle.

2) Connect the appropriate accessories in the vehicle.

3) Connect a hose on any device orientation.

4) Check the oil flow direction. (The normal flow is flowing over, under it.) ⇡

5) Switch the direction lever to replace the line if the oil flow direction does not

match.

6) AUTO2 Select the exchanging cooler line mode.

7) Use ▲ ▼ to set the amount of oil changes. (Initial value 8.0 liters)

8) Press the Start button.

9) If necessary after checking whether the end-of-job message comes up oil

level is potent using a setting recovery, setting injection and align the oil level.

10) Finish the work.

AUTO_1

volume: 8.0 0.0

0.0

(1) Exchanging level gauge mode

(2) Exchanging cooler line mode

AUTO_2

volume: 8.0 0.0

0.0

7

Operation

1) Select

Setting recovery or Setting injection

.

2) Use the ▲ ▼ buttons to set.

3) Press Start button.

RECOVERY

volume: 1.0 0.0

0.0

CHARGE

volume: 1.0 0.0

0.0

(4)

Setting recovery / Setting injection

1) Remove the cooling line of the vehicle.

2) Connect the appropriate accessories in the vehicle.

3) Connect a hose on any device orientation.

4) Check the oil flow direction. (The normal flow is flowing over, under it.) ⇡

5) Switch the direction lever to replace the line if the oil flow direction does not match.

6) AUTO3 Select the oil saving mode.

7) Use ▲ ▼ to set the amount of oil changes. (Initial value 8.0 liters)

8) Press the Start button.

9) If necessary after checking whether the end-of-job message comes up oil

level is potent using a setting recovery, setting injection and align the oil level.

10) Finish the work.

(3) Oil saving Mode

AUTO_3

volume: 8.0 0.0

0.0

8

Operation

1) Standby : Display oil temperature, new oil and

used oil.

2) Manual Recovery : Only works if press the

START button

3) Manual Injection : Only works if press the

START button

4) Cleaning mode : After chemical Injection,

setting UP/DOWN buttons and

START button to begin

1) Pull the exchange lever forward.

2) Connect the hose accessories at the end of Injection hose (red).

3) Press the discharge used oil button.

4) Press the Start button.

5) Check that the discharge through an Injection hose.

DISCHARGE

volume: 5.4 0.0

CLEANING

5 minute

CHARGE

volume: 0.0

RECOVERY

volume: 0.0

(5) Discharge used oil

(6) Other information Description

NEW : 0.0 L

USED : 0.0 L

TEMPERATURE

: 00℃

9

정지 시킵니다.

5) 연결용 검정호스에 게이지구멍 삽입호스를 연결한 후 레벨게이지

삽입합니다.

6) 장비 전원 스위치를 ON 합니다.

7) [LEVEL AUTO1]을 두번 누릅니다. → "CVT_오일교환" 확인 후 →

[시작]키를 누릅니다.

8) 밋션의 폐오일을 장비로 흡입 후, 흡입된 폐오일량과 동일한 양의 새 오일이

밋션으로 주입됩니다.

9) 엔진을 시동시키고, 3~5분 동안 엔진을 워밍업 시킵니다.

10) 엔진을 정지 시키고, 필요한 경우에는 다시 8번에서 10번의 과정을 반복

합니다.

<주의> 장비가 오일흡입 또는 오일주입 시에는 차량의 주행테스트를 금지합니다.

11) 오일교환 완료 후에는 차량과 오일교환기를 분리하고 변속 레버를 각

위치별로 2~3초간 2회씩 동작 한 후에, 레벨게이지로 오일량을 점검합니다.

(정비지침서 참조).

▶ 밋션 내부의 오일을 흡입한 후에, 흡입량 만큼의 새 오일을 주입할 경우 사용

▶ 한쪽호스 커플러에 커플러 마게를 연결하여 공기가 유입되지 않도록 막습니다.

▶ 오일팬에 닿을 때까지 삽입하며, 삽입호스의 끝부분이 휘어지지 않도록 주의합니다.

▶ 교환작업 중에 게이지 구멍 삽입호스가 빠지지 않도록 고정 합니다.

CVT

Volume : 0.0

Operation

(7) CVT exchange the Mission oil

1) Park the vehicle in a flat position or lift.

2) Set the selection lever to the “P” position and fill the parking brake.

3) Start the engine of the vehicle and check the amount of oil in the oil level

gauge check range.

4) Stop the engine.

5) Insert the gauge hole into the black hose for connection to the cooler. After

connecting the hose, insert it into the level gauge hole.

6) Turn on the power switch.

7) Press [LEVEL AUTO1] twice. → Check "CVT_ Oil Change" → Press [Start] key.

8) After suctioning the waste oil from the transmission, the same amount of new

oil as the amount of the inhaled waste oil is injected into the transmission.

9) Start the engine and warm up the engine for 3 to 5 minutes.

10) Stop the engine and if necessary repeat steps No.8 to No.10 again.

<Caution>

Driving test of the vehicle is prohibited when the equipment is inhaled or oiled.

11) After completing the oil change, separate the vehicle and oil changer, operate

the shift lever twice for 2 to 3 seconds at each position, and check the oil level

with the level gauge. (Please refer to Maintenance Manual).

▶ It is used when injecting new amount of oil after inhalation of oil inside the

transmission

▶ Connect coupler mage to one hose coupler to prevent air from entering.

▶ Insert it until it touches the oil pan and be careful not to bend the tip of

the insertion hose.

▶ Insert the gauge hole during replacement.

10

3 STAGE MODE

1sta > 3.0L 5M

2sta 3.0L 5M

3sta 8.0L 5M

3 STAGE MODE

1sta 3.0L > 5M

2sta 3.0L 5M

3sta 8.0L 5M

3 STAGE MODE

1sta 3.0L 5M

2sta > 3.0L 5M

3sta 8.0L 5M

3 STAGE MODE

1sta 3.0L 5M

2sta 3.0L > 5M

3sta 8.0L 5M

3 STAGE MODE

1sta 3.0L 5M

2sta 3.0L 5M

3sta > 8.0L 5M

3 STAGE MODE

1sta 3.0L 5M

2sta 3.0L 5M

3sta 8.0L > 5M

Operation

(8) AUTO 3_Exchange : Flushing exchange 3stages

Step 3 : Change the Flushing: Press the AUTO3 button to enter this function.

Move the arrow with the ENTER button, and change the data with the

UP / DOWN buttons

5-1) Set the 1st stage oil level.

5-2) Set the 1st step waiting time.

5-3) Set the 2nd stage oil level.

5-4) Set the 2nd step waiting time.

5-5) Set the oil level in 3 steps.

5-6) Set the 3 step waiting time

11

Maintenance

4-1. Troubleshooting

Symptom Solution

0.1 liter for 20 seconds

When used oil is not recovered

1. Check the amount of oil of vehicle

2. The vehicle shift lever P-> as N, N-> P

After the conversion starts

0.1 liter for 20 seconds

When new oil is not recovered

1. Ensure that the new oil tank is in-

stalled correctly

2. Check that the inlet connection is cor-

rect of new oil

3. Check connect the inlet hose is new

oil container Press or apply pressure to

ensure that

4. Make sure that new oil is not lacking

The used oil overflow

Discard used oil equipment.

Insufficient new oil Supplements new oil.

CAR

IN 1

S2-0

S0

S1

Pressure S/W

S2-1

S3

IN 2

Used oil load cell

Sample

window Check valve

Used oil

Used oil

window

New oil

window

Pressure

gauge

New oil

New oil load cell

P

Used oil load cell

Temperature sensor

New oil load cell

20

5

5

3

9

S0

S1

S2-0

S2-1

~

Main Board

Key Board

LCD Display Speaker

2

2

3

2

2

2

Pressure S/W

Motor

Part list

Feature Description Code

Electric

valve (1) 880101

Electric

valve (2) 880102

Pressure

switch 880103

Motor 880104

Oil pump 880105

Rear

wheel 880106

Front

caster 880107

Hose

coupler 880108

Hose

hanger 880109

Feature

Hose

holder 880110

Hose

(2.5M) 880111

Speaker 880112

Trans-

former 880113

Key pad 880114

Display

panel 880115

LCD dis-

play 880116

Main PCB 880117

Load cell 880118

Description Code

Part list

Feature Description Code

Oil tank 880119

Power

S/W 880120

Power ca-

ble socket 880121

Pressure

gauge 880122

Sight glass 880123

HESHBON CO.,LTD.

673-52, GYEONGSEO-DONG, SEO-GU, INCHEON, 404-170 KOREA

TEL:+82-32-585-3570(Int’l trading) / FAX: +82-32-585-3535

http://www.heshbon.com / e-mail:[email protected]

Table of contents