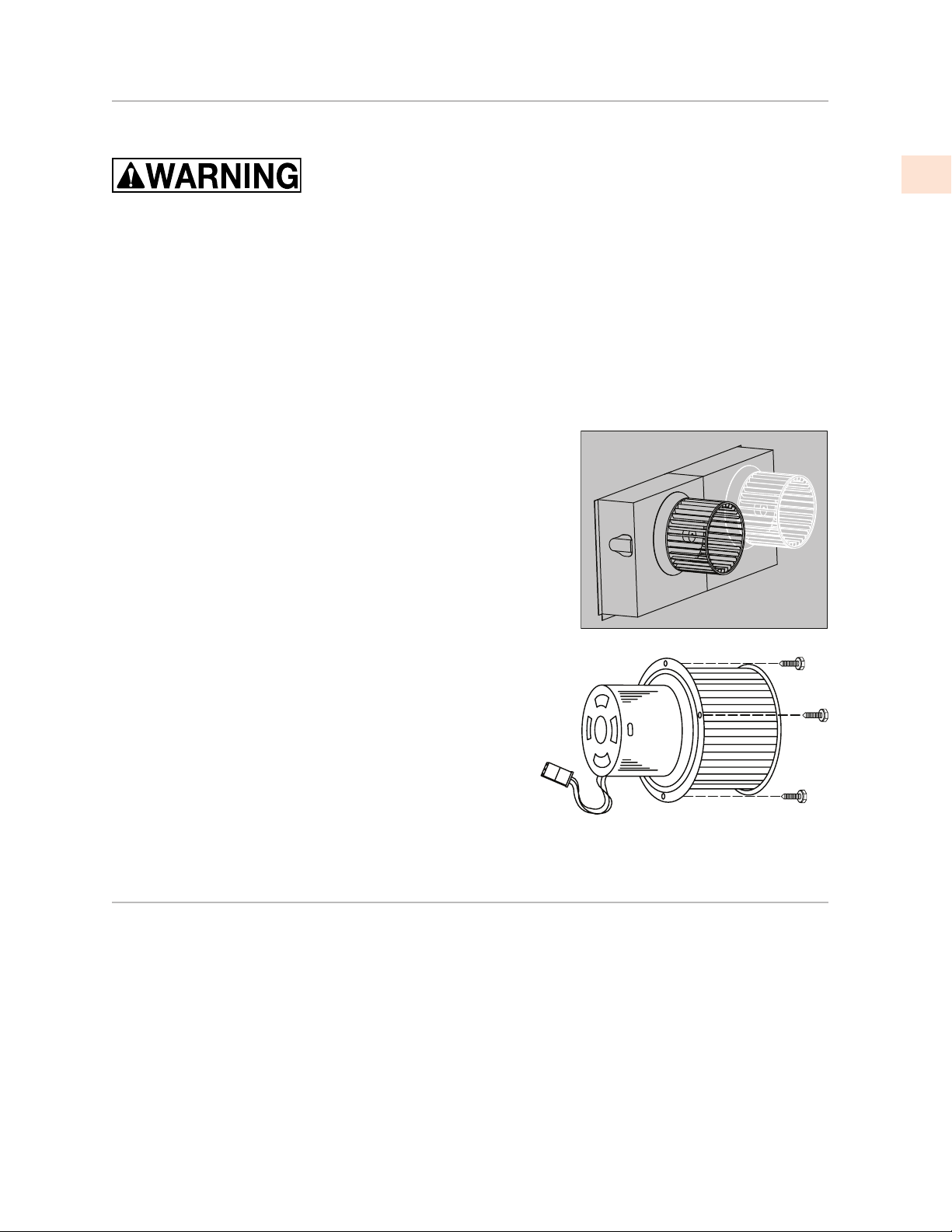

INSTALLATION

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO

PERSONS, OBSERVE THE FOLLOWING:

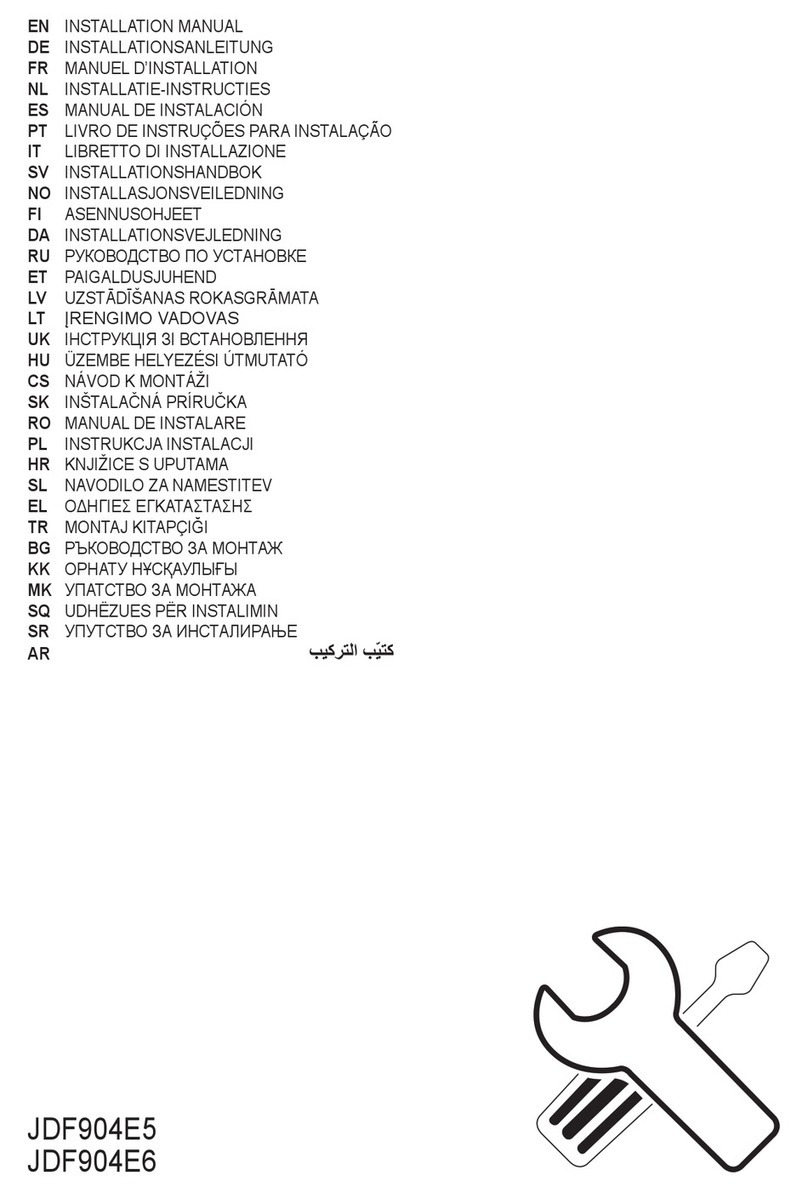

a) Load-bearing framework in the ceiling is necessary for the installation of an island hood.

Additional framework construction may be required. Do not attach an island hood to a structure

that cannot support twice the weight of the hood and (optional) duct covers. For weights of

hoods, see the Dimensions table on page13, and “Duct Covers” on page16.

b) Installation work and electrical wiring must be done by qualified person(s) in accordance with all

applicable codes and standards, including fire-rated construction.

c) Sufficient air is needed for proper combustion and exhausting of gases through the flue

(chimney) of fuel burning equipment to prevent back drafting. Follow the heating equipment

manufacturer’s guideline and safety standards such as those published by the National Fire

Protection Association (NFPA), and the American Society for Heating, Refrigeration, and Air

Conditioning Engineers (ASHRAE) and the local code authorities.

d) When cutting or drilling into ceiling, do not damage electrical wiring and other hidden utilities.

e) Ducted fans must always be vented to the outdoors.

TO REDUCE THE RISK OF FIRE, USE ONLY METAL DUCTWORK.

TO REDUCE THE RISK OF FIRE OR ELECTRICAL SHOCK, DO NOT USE THIS BLOWER WITH

ANY SOLID-STATE SPEED CONTROL DEVICE.

INSTALLATION DETAILSINSTALLATION DETAILS

1. Read all instructions thoroughly before beginning installation. Note: These instructions apply to

Hestan’s hoods only.

• See “DUCTING DO’S AND DON’TS” on page10.

• Weight and size: For safe installation, at least two people should be present to lift and hold the

hood. For larger hoods and installations with duct covers, it is advisable to have a third person

present to assist. For weights of hoods, see the Dimensions table on page13, and “Duct Covers”

on page16.

2. When installing an island hood, it is recommended that the bottom edge of the hood be located

no more than 30” above the cooking surface for optimum performance.

3. If using a duct cover:

a) Remove the duct cover from its packaging and remove the

hood-mounting screws from the base of the duct cover.

b) Install the duct cover to the load-bearing framework in the

ceiling using appropriate hardware through the four inside

corner mounting flanges on the top of the duct cover.

4. Install the duct from outside the home, down to the location of

the exhaust outlet on the top of the included transition of the

hood, plus 1”. This will allow the transition to engage 1” inside

of the duct. Consult the connection diagrams (on next page) for

further details on exhaust outlet placement.

• Use foil HVAC tape (not grey cloth duct tape) to seal all joints.

See “VENT ACCESSORIES” on page15 for a listing of available

Hestan ducting materials.

Optional duct

cover

30”

[76.2 cm]

18”

[45.7 cm]

36”

[91.4 cm]

©2020 Hestan Commercial Corporation

11

EN