4

Chimney fires

In the event of a chimney fire – which often re-

sults from incorrect operation or protracted fi-

ring with moist wood – close the door and shut

off the secondary/start-up air supply to smother

the fire. Call the fire department.

Lighting and combustion

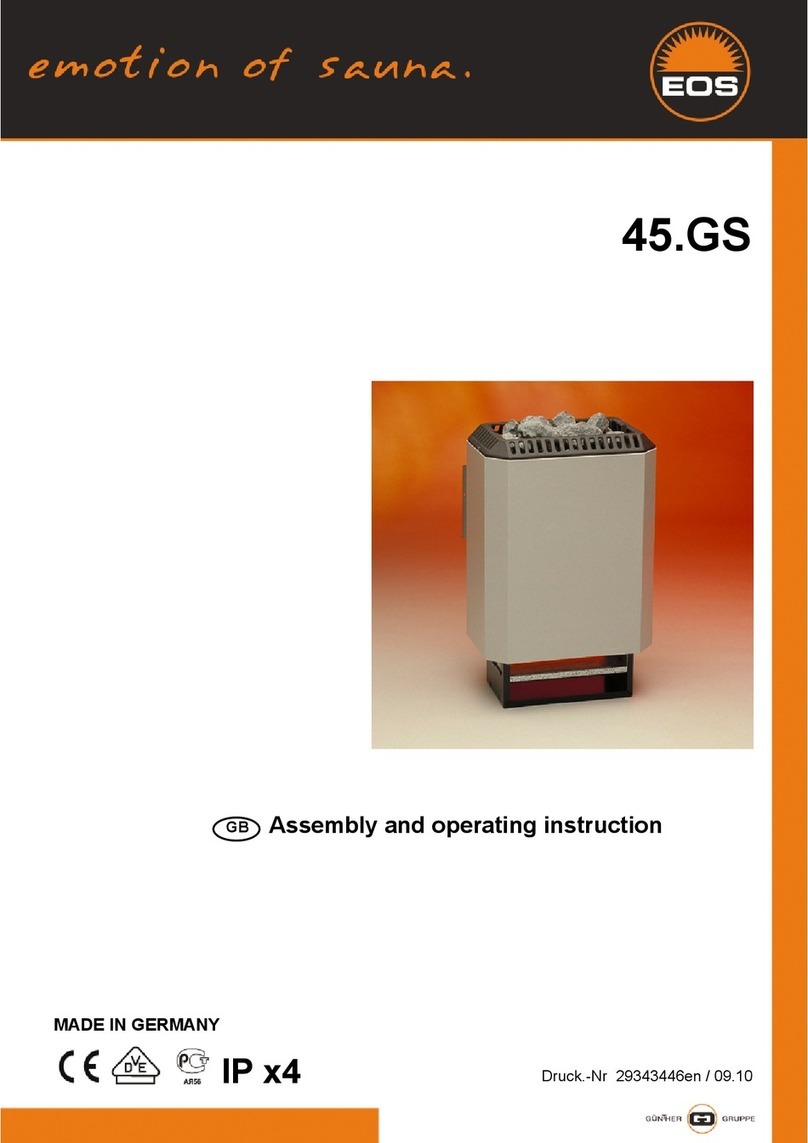

To open the flow of secondary air, use the ope-

rating handle at the front of the stove. The se-

condary airflow is completely open when the

handle is to the left side position, fig. 1. Shut

off the secondary airflow gradually by moving

the handle to the right. The supply is completely

shut off when the handle is to the right side po-

sition, fig. 2.

Lighting

To ignite the fuel, use fire lighters, small paraffin ig-

nition bags or small pieces of wood placed on the

bottom grate. Place larger pieces of wood on top

of this kindling material, at right angles to the firing,

doors. Completely open the secondary air supply

and leave the firing door ajar – i.e. approx. 1 cm

open. Once the fire has taken a good hold of the

fuel and the chimney has heated up (after about

10 min) close the firing door. We recommend that

you burn the entire first firing with the secondary air

supply fully open to make sure that the chimney is

thoroughly heated.

Refiring

You should normally refire the stove

while there

is still a good layer of embers

. Distribute the em-

bers across the bottom grate, place pieces of

fuel (max. 2 kg) on the embers in a single layer

perpendicular to the firing opening. Close the fi-

ring door and fully open the start-up mechanism.

The wood will then ignite very quickly – i.e. in

30 seconds or 1 minute. When the wood is bur-

ning with a steady flame, close the start-up me-

chanism. Then adjust the secondary airflow to

the level required. For nominal operation

(6,1kW),

the secondary air supply should be 38% open.

When firing, take care not to place the pieces

of fuel too close-ly together, as this will result in

poor combustion and insufficient exploitation of

the fuel.

Reduced burning

The stove is well-suited to intermittent use. If

you wish to operate the stove with reduced out-

put, simply insert smaller volumes of wood at

each firing, and apply a lower airflow. However,

remember that the secondary combustion air

supply must never be shut off completely du-

ring firing. It is important to keep a good bed of

embers. Gentle heat is released when the fire

settles - i.e. when the wood no longer genera-

tes flames and has been converted to glowing

embers.

Optimal firing

To achieve optimal firing and the highest pos-

sible effect, it is important to make sure that the

air supply is used correctly. As a general rule,

the secondary air is to be used to control the

fire to ignite the flue gases. This produces a

high effect and keeps the glass panel complet-

ely clear of soot as the secondary air “washes”

down over it. Please note that the stove will,

naturally, produce soot if both the start-up me-

chanism and secondary air intakes are closed

completely. This will prevent oxygen from being

drawn into the stove, and the viewing window

and other parts will become covered with soot.

If this situation is combined with firing with wet

wood, the build-up of soot can become so

thick and sticky that the sealing rope can, for

example, become detached when the door is

opened the next day.

Risk of explosion

After you add new fuel, it is very

important that you do not leave the

stove unattended until the wood is

burning constantly. This will normal-

ly occur within 30 to 60 seconds.

A risk of explosion can possibly arise if too

much wood is placed in the stove. This may re-

sult in the production of large volumes of gas,

and this gas can explode if the intake of primary

and secondary air is insufficient.

It is an advantage always to leave some ash ly-

ing in the bottom of the comb-

stion chamber.

Take care when emptying the ash pan, as

cinders can continue to burn in the ash for

long periods of time.

Open Closed

Fig. 1 Fig. 2