1

SAFETY

SAFETY ALERTS

The safety alert symbol is used in decals on the unit

and with proper operation procedures in this

manual.

Understand the safety message. It contains

important information about personal safety on or

near the unit.

NOTATIONS

NOTE: General reference information for proper

operation and maintenance practices.

IMPORTANT: Specific procedures or information

required to prevent damage to unit or

attachment.

PRACTICES AND LAWS

Practice usual and customary safe working

precautions for the benefit of yourself and others.

Be alert to unsafe conditions and the possibility of

minor, moderate, or serious injury or death. Learn

applicable rules and laws in your area.

REQUIRED OPERATOR TRAINING

Original purchaser of this unit was instructed by the

seller on safe and proper operation. If unit is to be

used by someone other than original purchaser;

loaned, rented or sold, ALWAYS provide this

manual and any needed safety training before

operation.

ALWAYS read and understand the documentation

for any machine to be controlled by radio remote

control.

POSSIBLE SOURCES OF DANGER

This device is part of a system that makes remote

control via radio signals possible. However, the

transmission of control commands can take place

around obstacles and out of the operator’s direct

sight. Take the following precautions to prevent

accidental start-up and possible injury or damage:

1. Switch "OFF" the transmitter when it is not in

use. If equipped, remove the key if the unit is

placed any distance away from the operator.

2. Disconnect the power supply from the receiver

before any assembly, maintenance or repair

work is done.

IMPORTANT: AVOID SYSTEM DAMAGE -

ALWAYS disconnect receiver power

supply and control wiring before

welding on any part of the machine

3. Never remove or alter any of the safety

features.

4. ALWAYS confirm that the machine and radio

remote control Stop functions work properly

BEFORE beginning any machine operation.

PROTECTIVE FEATURES

This system is equipped with electronic and

mechanical safety features. Control signals from

other transmitters cannot be processed because

transmission coding is unique to each system

TOSTOP INANEMERGENCY

1. Press the red STOP pushbutton.

2. If equipped, turn the key to "OFF".

3. Wait for all moving machine parts to stop.

4. Refer to machine’s operator manual for further

instructions.

MAINTENANCE

Always shut off power to the machine, transmitter

and receiver before any assembly, maintenance or

repair.

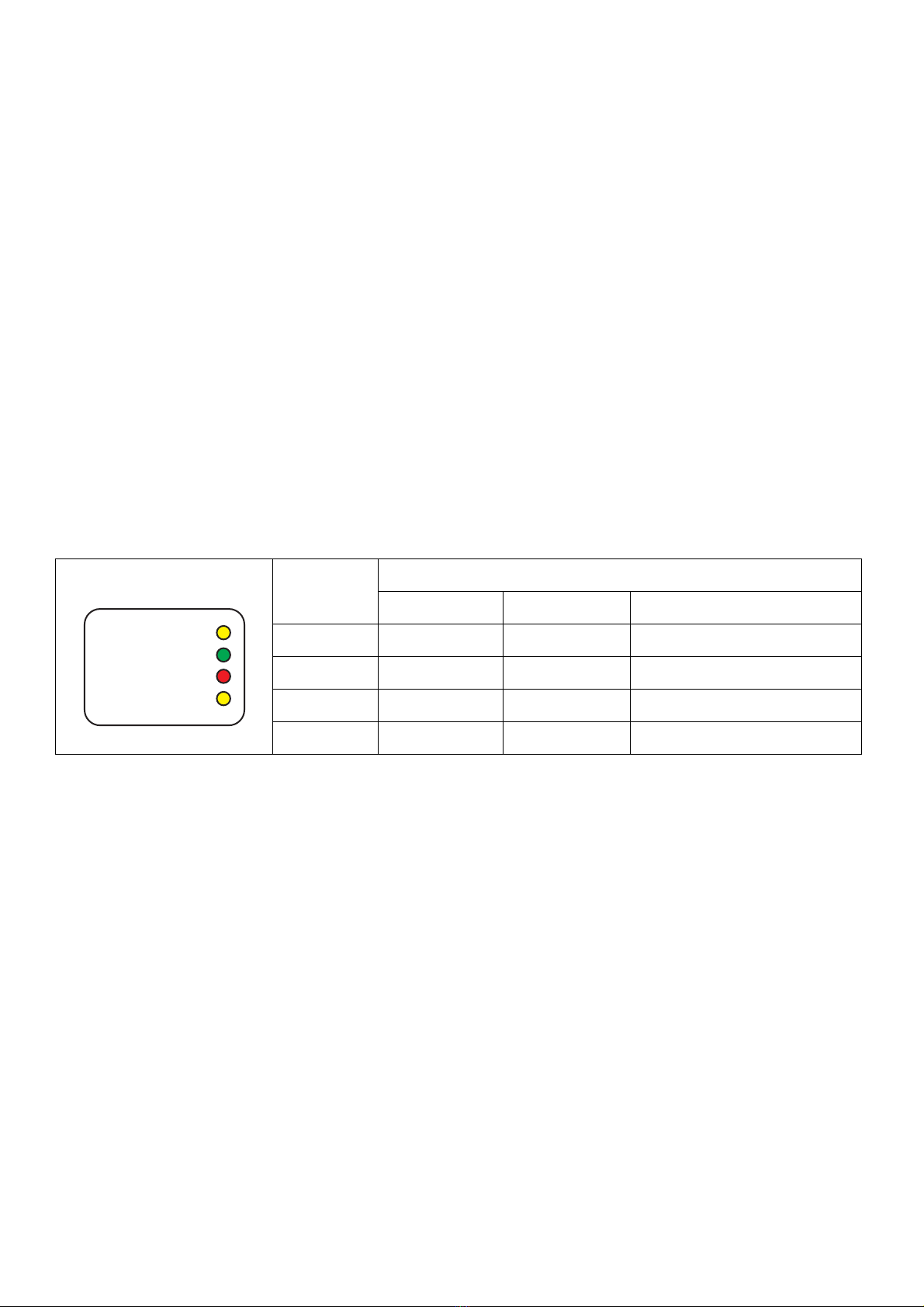

DANGER:IMMINENTLY HAZARDOUS

SITUATION! If not avoided, WILL

RESULT in death or serious injury.

WARNING: POTENTIALLY HAZARDOUS

SITUATION! If not avoided, COULD

RESULT in death or serious injury.

CAUTION: POTENTIALLY HAZARDOUS

SITUATION! If not avoided, MAY RESULT

in minor or moderate injury. It may also be

used to alert against unsafe practices.

!

!

!