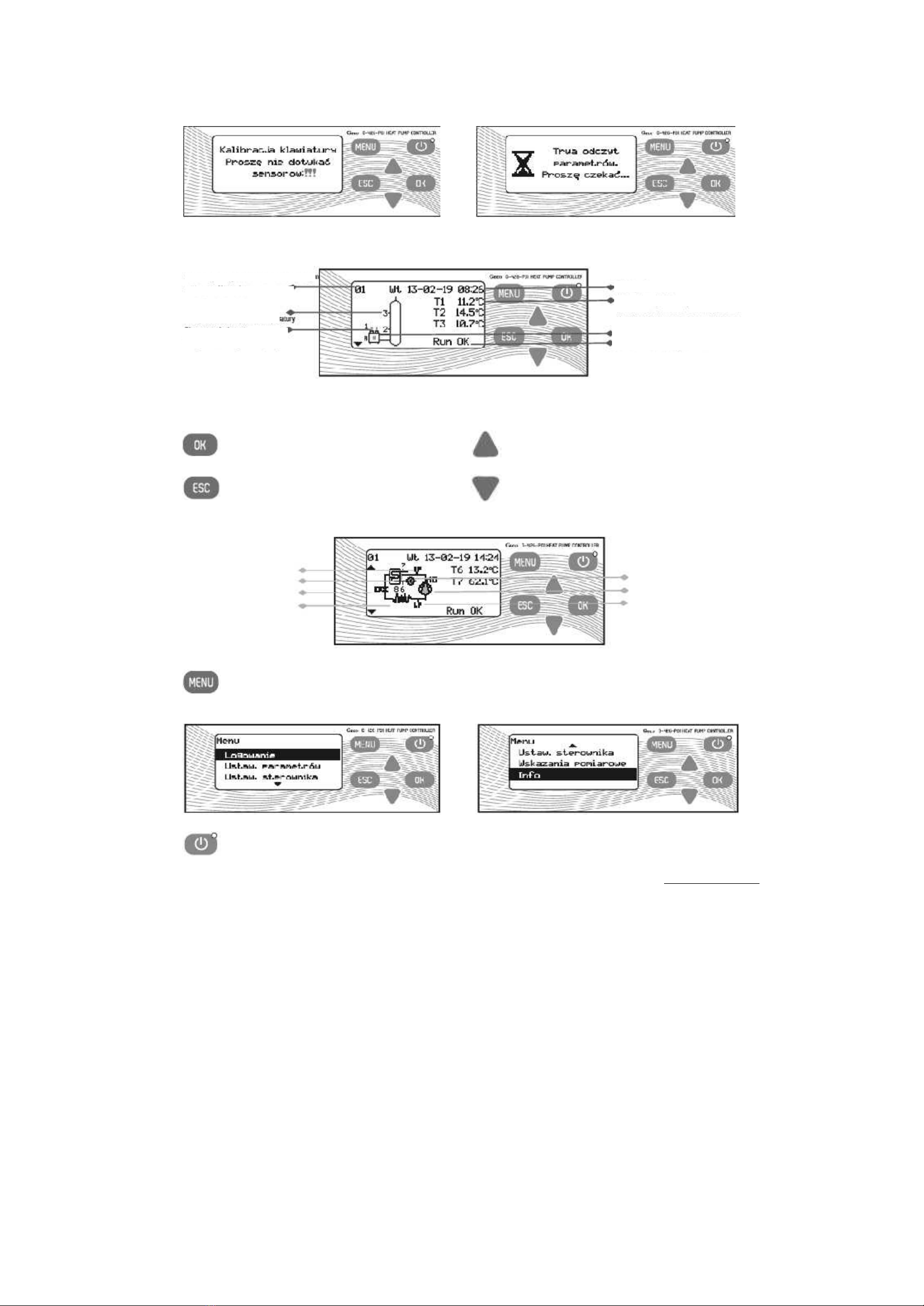

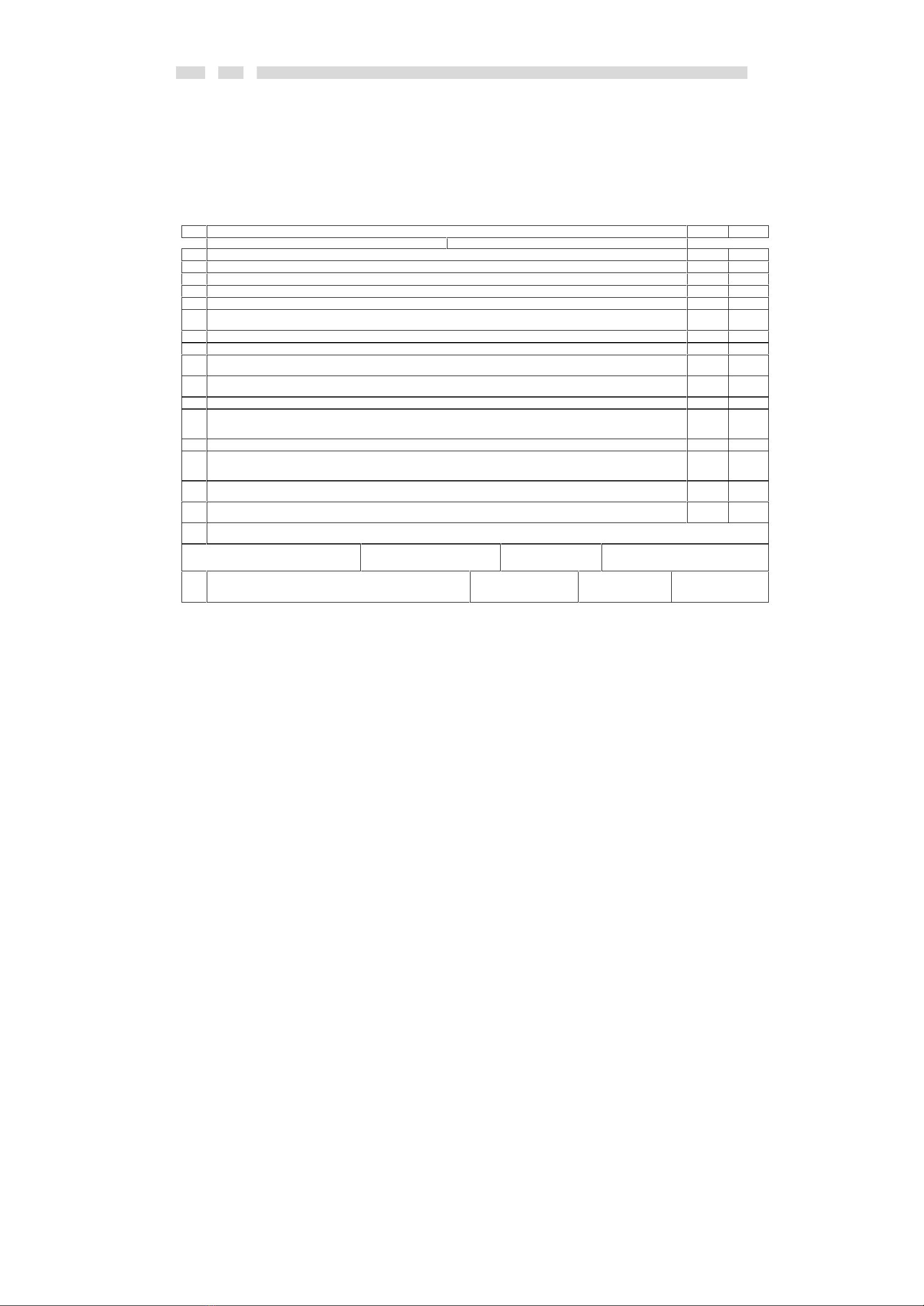

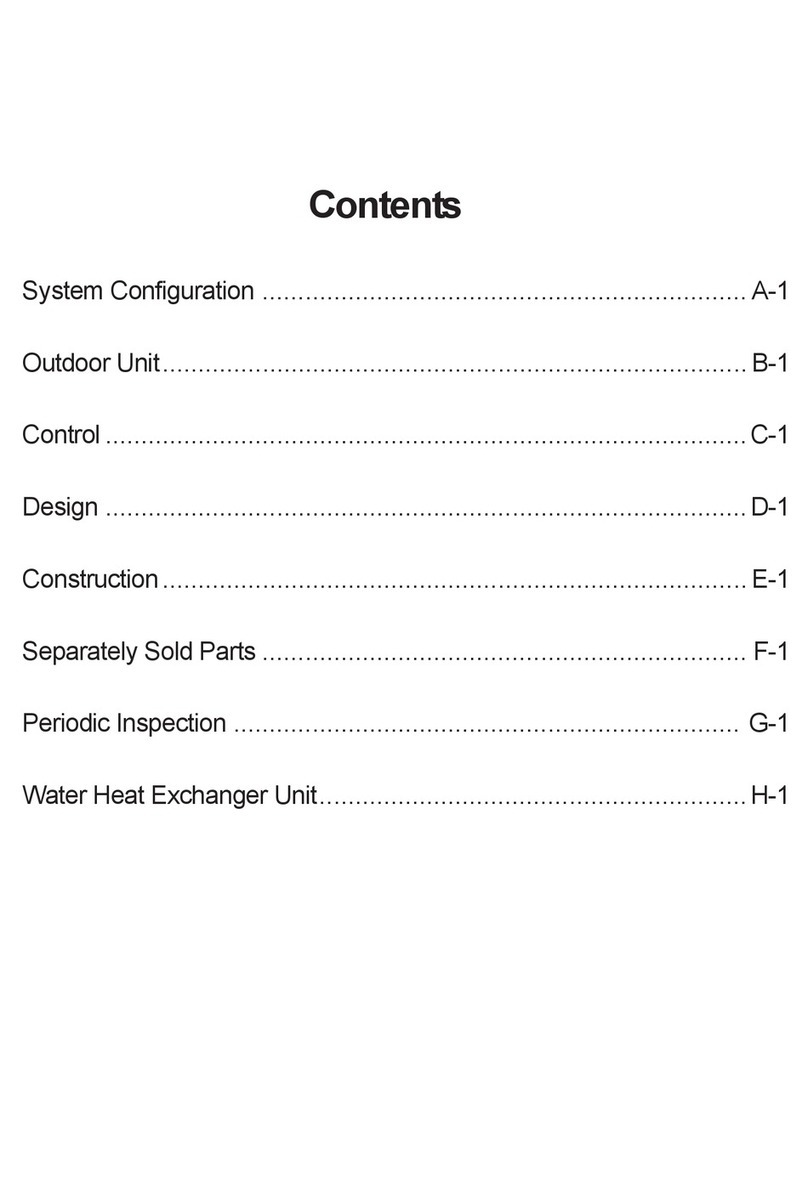

Controller map

MENU Login [default 0000]

Parameter settings

Heat pump operation parameters

Heat pump activation [YES/NO, factory setting YES]

HUW temperature for heat pump [10-60°C, factory setting 50°C]

Minimum ambient temperature (T1) [-5-10°C]

Parameters of accessory equipment

Heater E [shown in diagrams no. 3,4,5,6,7,8,9]

Heater activation [YES/NO, factory setting YES]

HUW temperature for heater - heat pump on [30-60°C, factory setting 45°C]

HUW temperature for heater - heat pump off [30-60°C, factory setting 55°C]

Heater stoppage during heat pump operation [YES/NO, factory setting YES]

Heater stoppage during gas-fired boiler operation [YES/NO, factory setting YES -

shown in diagrams no. 4,7,9]

Heater P [shown in diagrams no. 4,5,6,7,8,9]

Heater activation [YES/NO, factory setting YES]

HUW temperature for heater - heat pump on [30-60°C, factory setting 45°C]

HUW temperature for heater - heat pump off [30-60°C, factory setting 55°C]

Heater stoppage during heat pump operation [YES/NO, factory setting YES]

Heater stoppage during gas-fired boiler operation [YES/NO, factory setting YES -

shown in diagrams no. 4,7,9]

Circulating pump [shown in diagrams no. 2,3,4,6,7,8,9]

Minimum circulating pump activation temperature [20-60°C, factory setting 35°C]

Circulating pump operation mode [INTERMITTENT/CONTINUOUS, factory

setting INTERM.]

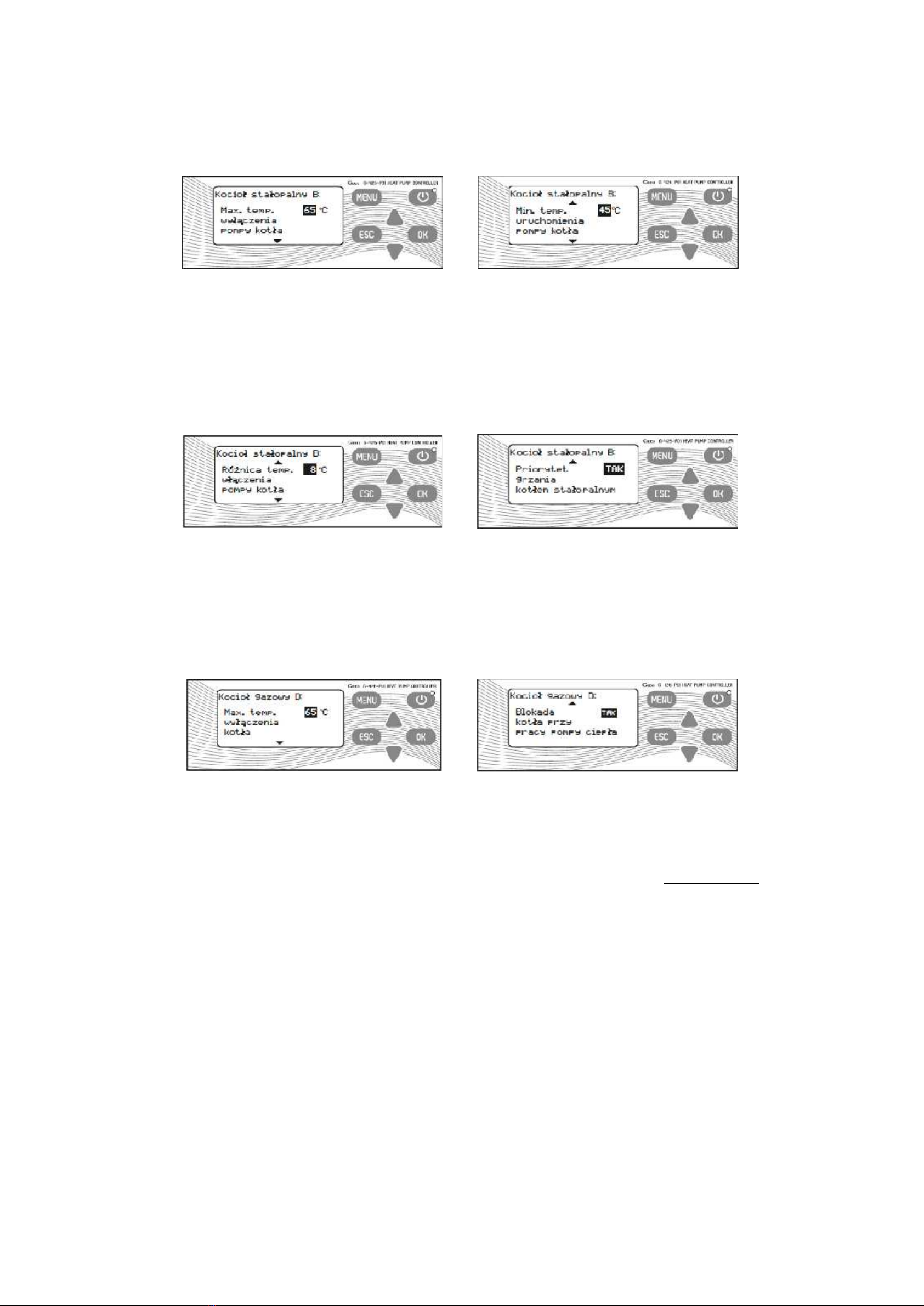

Solid fuel fired boiler B [shown in diagrams no. 5,7,9]

Max. boiler pump deactivation temperature [10-85°C, factory setting 65°C]

Min. boiler pump activation temperature [30-60°C, factory setting 45°C]

Temperature difference for boiler pump activation [5-15°C, factory setting 8°C]

Solid fuel fired boiler heating priority [YES/NO, factory setting YES]

Gas-fired boiler D [shown in diagrams no. 6,7,8]

Max. boiler pump deactivation temperature [10-85°C, factory setting 65°C]

Boiler stoppage during heat pump operation [YES/NO, factory setting YES]

Time programmes

Heat pump

Heater E

Circulating pump [shown in diagrams no. 2,3,4,6,7,8,9]

Gas-fired boiler D [shown in diagrams no. 6,7,8]

Anti-Legionella [shown in diagrams no. 3-9]

Anti-Legionella function activation [YES/NO, factory setting YES]

Protection carried out by heater E [YES/NO, factory setting YES]

Protection carried out by heater P [YES/NO, factory setting YES]

Protection carried out by gas-fired boiler [YES/NO, factory setting YES, shown in diagrams

no. 6,7,8]

Passwords

User

Controller settings

Date and time

Display Backlight brightness [1-10, fab.10]

Inactivity time until backlight switching off [1-10min., factory setting 10min.]

Sounds Sound of keys [YES/NO, factory setting YES]

Sound of alarms [YES/NO, factory setting YES]

Port RS485

Transmission rate [by default 115200]

Physical address [by default 255]

Logic address [by default 65535]

Language

Polish

English

German

Manual control

Measured indications

Info

Software replacement [only for manufacturer]