Hewland NMT User guide

PAGE 1

© Copyright Hewland Engineering Limited

SERVICING INSTRUCTIONS AND ILLUSTRATED

PARTS LIST FOR HEWLAND NMT GEARBOXES

HEWLAND ENGINEERING LTD

WALTHAM ROAD, WHITE WALTHAM,

Last Update 10th July 2012

MAIDENHEAD, BERKSHIRE,

SL6 3LR, ENGLAND

PAGE 2

© Copyright Hewland Engineering Limited

CONTENTS :-

page page

Technical specification 4 Changing gear ratios 13

General notes 5 Powerflow differential 14

Differential bearing preload 6 Differential Options 15

Pinion shaft mounting 7 Illustrated Parts List 22

Pinion shaft bearing preload 8 Gearbox Tooling 35

Crownwheel backlash setting 9 General Technical Bulletins 36

Sequential barrel setting 10 Oil system layout 38

Gearbox assembly 11 Recommended Tightening 39

Torques

PAGE 3

© Copyright Hewland Engineering Limited

ILLUSTRATIONS :-

page page

fig.1 Differential bearing preload 6 fig.12 Casings & Associated Parts 25

fig.2 Pinion shaft setting 7 fig.13 Layshaft Assembly 27

fig.3 Pinion shaft bearing preload 8 fig.14 Pinion Shaft Assembly 29

fig.4 Crownwheel setting 9 fig.15 Selector Assembly 31

fig.5 Sequential barrel setting 10 fig.16 NLT-218-Tripod Assembly 33

fig.6 Powerflow diff assembly 14 fig.17 Gearbox Tooling 35

fig.7-10 Differential Assemblies 15-21 fig.18 Oil system layout 38

fig.11 Differential Subsidiary Parts 23

PAGE 4

© Copyright Hewland Engineering Limited

TECHNICAL SPECIFICATION

The NMT gearbox is a transaxle unit, designed for mid-engined, rear wheel drive cars. The unit is produced with six

forward gears, reverse, and a powerflow differential.

The gear selection mechanism is sequential, with a separate, mechanically interlocked reverse engagement mechanism.

The drive is taken from the engine via the clutch shaft, which turns input and pinion gears to drive the final transmission

assembly.

Gear changing is effected through non-synchronising face dogs. An extensive range of gear ratios provides a wide

range of gearing requirements. The gear ratios and differential assembly can easily be changed without removing the

gearbox from the vehicle.

Heat treated nickel chrome steel is used to manufacture all gears and shafts. The selector forks are also steel.

Lubrication is by splash or optional internal pump with distribution circuit, and the oil is retained by lipped oil seals.

In general configuration, the NMT-200 is a high tech racing transaxle unit which achieves the maximum effective use of

power, in conjunction with extremely stiff integral rear suspension mountings.

weight (AL) 128 lbs (58 Kg) 1st to 6th gear ratios from 3.31:1 to .89:1

oil type SAE 80 or 90 final drive ratio 11/31, 10/31, 9/31

oil quantity 7 pints (4 litres) clutch shaft made to customer's requirements

max. torque 320 lbs.ft (430 Nm) Pinion shaft nut tightening torque = 120 lbs.ft (163 Nm)

Crownwheelbolts=75lbs.ft(100Nm)

PAGE 5

© Copyright Hewland Engineering Limited

GENERAL NOTES :-

a/ Read these instructions carefully and with reference to the illustrations.

b/ Before dismantling the gearbox, see that a clean tray is available, in which to place the parts.

c/ Thoroughly clean and inspect all parts before reassembly. Discard any worn or damaged components and replace with new

ones.

d/ Use only genuine Hewland parts as replacements. These are manufactured in our workshops to the fine tolerances necessary and

are rigorously inspected.

e/ Always ensure that locknuts, and oil seals are in good condition when reassembling.

f/ All studs and screws must be Loctited or wirelocked in position, unless stated otherwise

g/ Bearing Replacement :-

Bearings can only be removed or renewed if the casings have been warmed in an oven, or with a blowlamp. In the latter case,

keep the blowlamp moving while heating the casing.

Note: Do not overheat. Test with a spot of water which will bounce off at the correct temperature.

Once a casing is heated, all bearings should be pressed into their respective seatings without delay, thus eliminating the need to

reheat. At the correct temperature, fitting the bearings should present no difficulty.

During cooling, or when the casings have cooled, it is advisable to once more lightly press the bearings to ensure that they are

correctly seated.

h/ Oil:

Fill the gearbox through the plug hole on top of the maincase. The oil will find it's own level within the gearbox.

Note: Too much oil will not directly cause any harm, but is undesirable as it may induce power loss and overheating of internals.

PAGE 6

© Copyright Hewland Engineering Limited

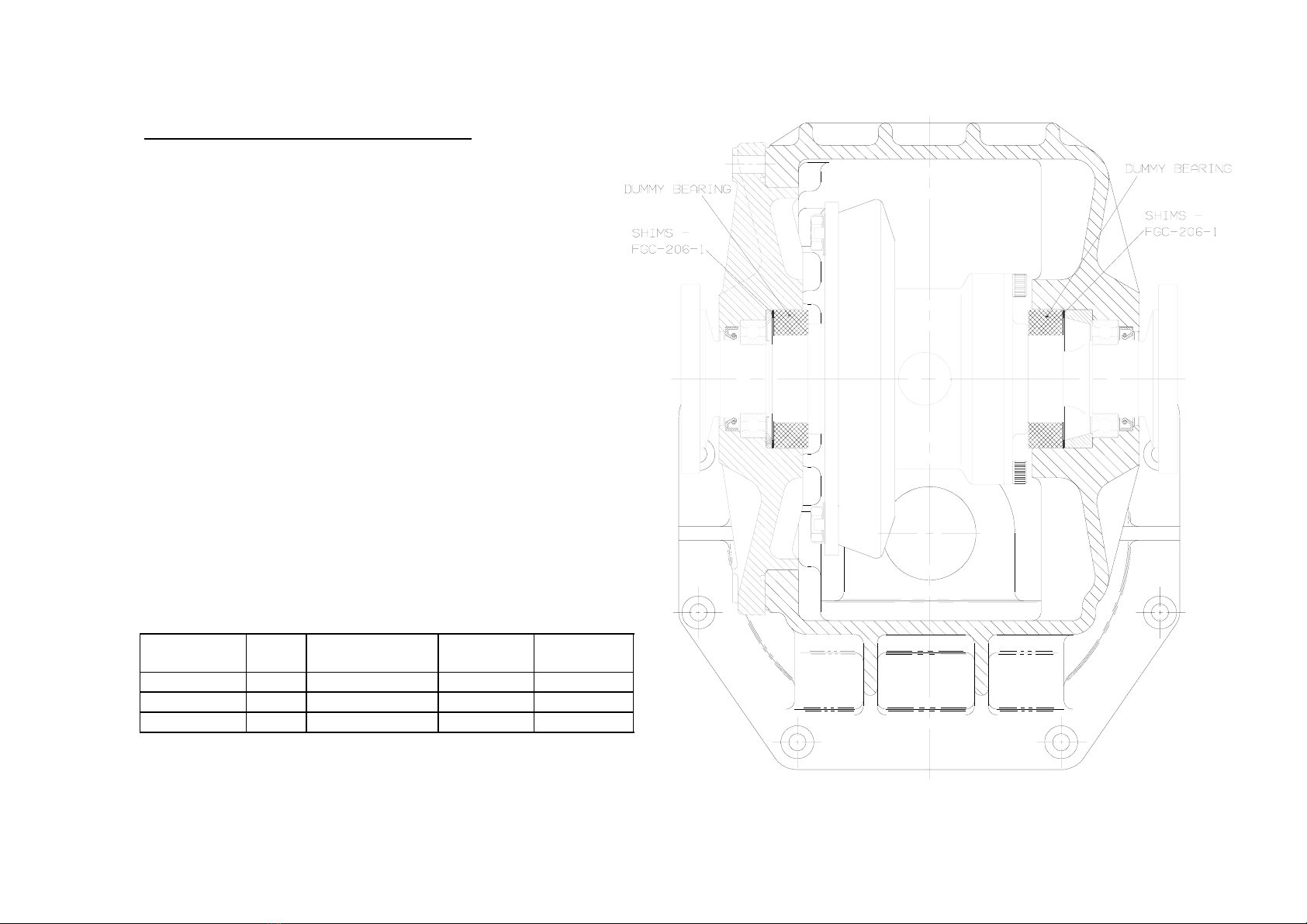

DIFFERENTIAL BEARING PRELOAD

Requires special tool No. SK-119-FGC

Assemble the differential case (57) and end cap (58),

and bolt the crownwheel (56) to it. Fit the differential

unit into the maincase (1) using dummy bearings SK-

119-FGC, and fit the sideplate (3). Adjust the shims

(103) if necessary, to achieve 4 – 6 lbs.ft of bearing

preload torque (to turn the diff assembly in it’s bearings

when oiled.).

The table below is to inform you of which sideplate

spacers should be used with which crownwheel when

mounted on a TPT differential. The reason that there are

two sets of spacers, is that the crownwheels have

different mounting distances.

FIGURE 1

PART No. RATIO MOUNTING

DIST

ITEM (90) ITEM (91)

NMT-221-AW 11/31 2.316” FGC-206-2A NMT-205-2

NMT-221-BW 10/31 2.316” FGC-206-2A NMT-205-2

NLT-221-CW 9/35 2.200” FGC-205-2A NMT-205-2A

PAGE 7

© Copyright Hewland Engineering Limited

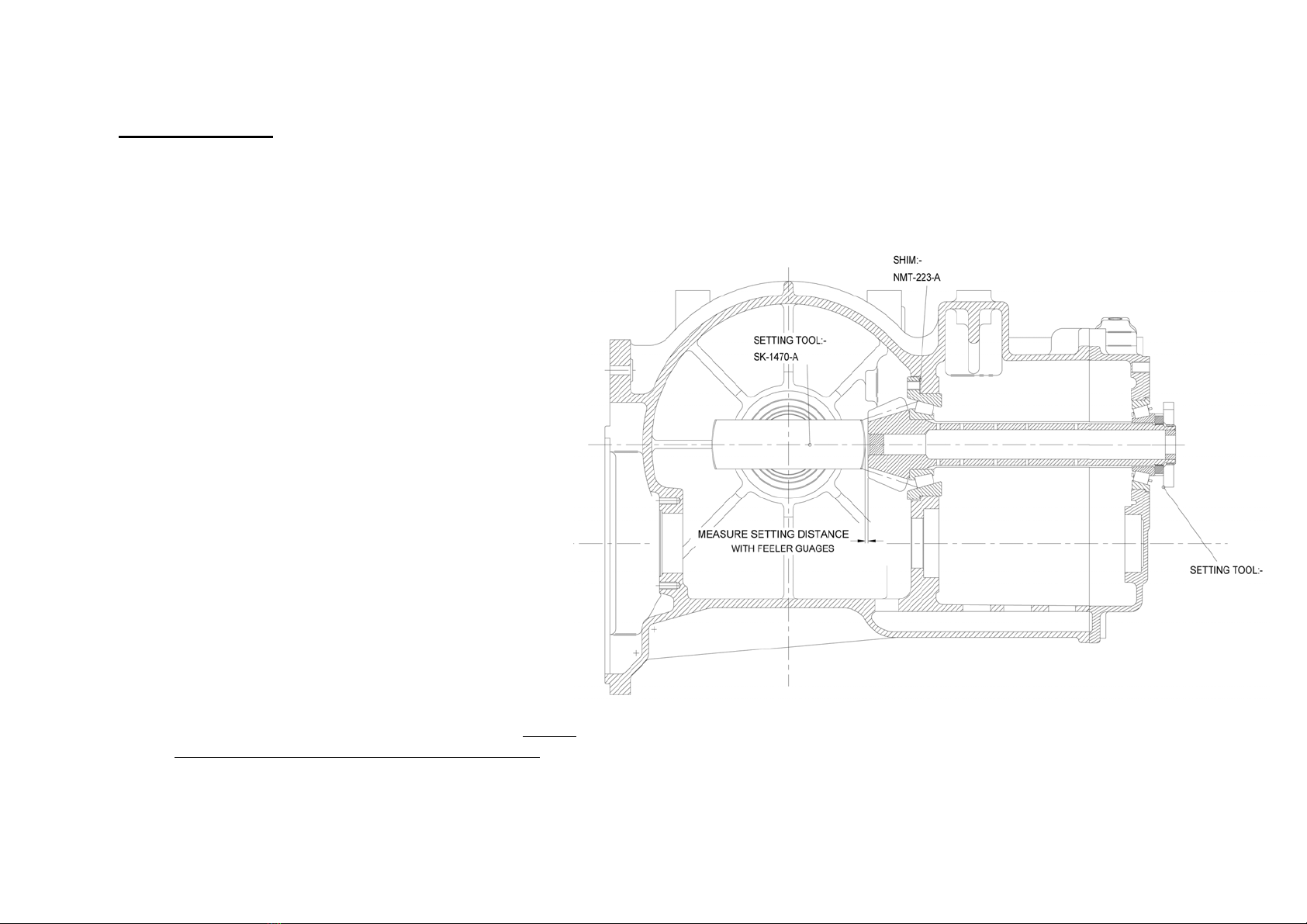

FIGURE 2

PINION SETTING

Requires special tool No.SK-1470-A & SK-1913

Press the pinion head bearing inner (37) onto the

pinion shaft (4). Fit the bearing housing (37) and

shims (40) into the maincase. Assemble the pinion

shaft into the maincase (1) and fit the bearing carrier

(2). Tighten the pinion shaft nut (111) onto the

pinion shaft until the pinion shaft requires 20-25

lbs.ins to turn it in it's bearings (equivalent to a

tangential force of 16-20 lbs at the outside diameter

of tool SK-1913)

Fit tool SK-1470-A into the maincase diff bearing

bore, and use feeler gauges to measure the gap

between the tool and the pinion front face. This

clearance should comply with the dimension

indicated on the pinion shaft label (also stamped on

the front face of the pinion shaft), and can be

adjusted by adding or removing shims (40) from

behind the pinion head bearing housing (37).

Alternatively, the pinion mounting distance can be

measured with a height gauge, and set to the

dimension on the pinion shaft label.

Note: It is not correct practice to replace a pinion

shaft without measuring the setting distance, even if

the old and new shafts have the same calibration.

SK-1913

PAGE 8

© Copyright Hewland Engineering Limited

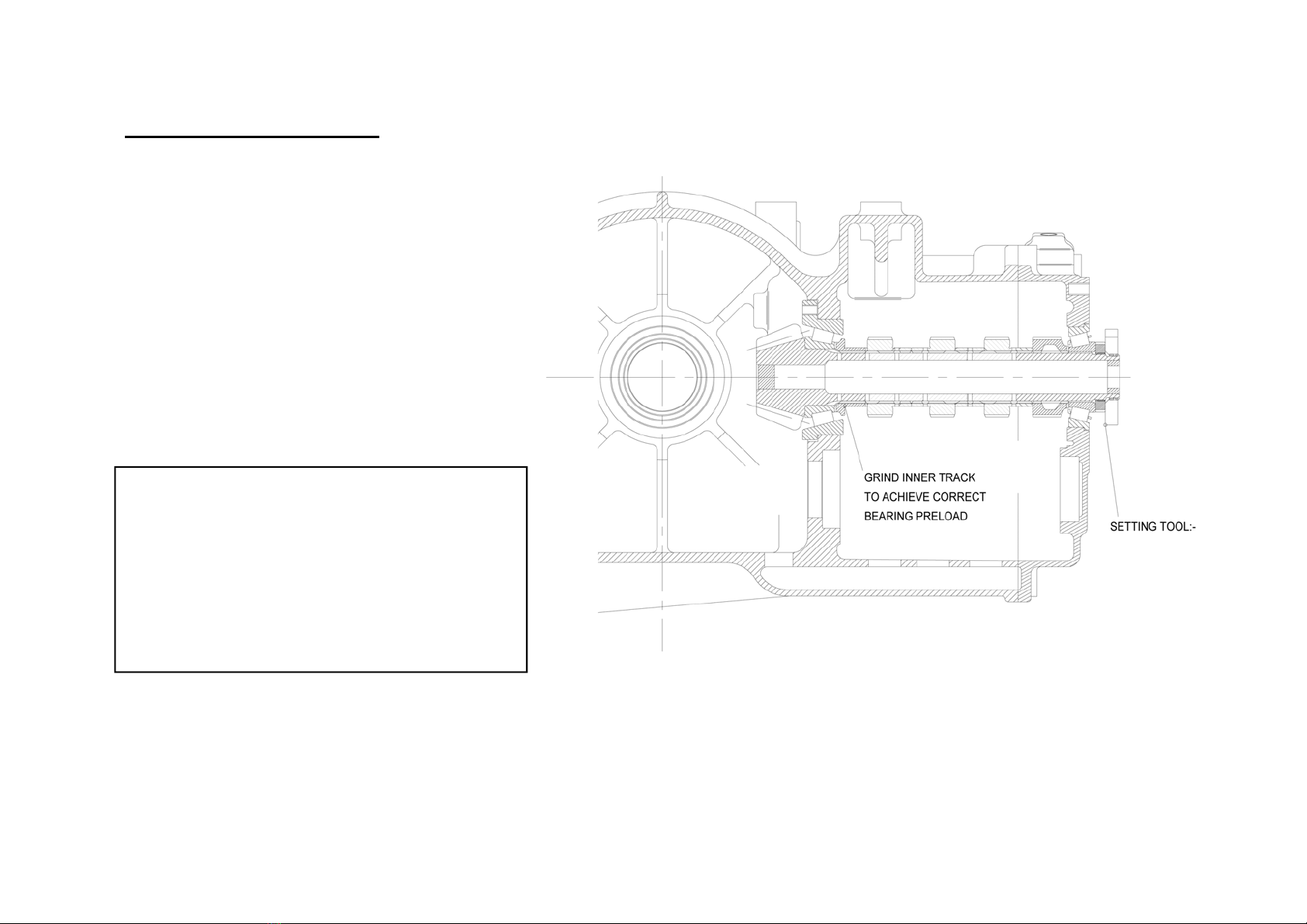

PINION BEARING PRELOAD

Requires special tool No.SK-1913

Having installed the correct pinion shaft

bearing shims, remove the bearing carrier

(2). Add the spacer (14) and hubs (20,33) to

the pinion shaft, and replace the bearing

carrier. The thickness of the spacer (14)

should be adjusted, by grinding, to give a

bearing preload torque of 20-25 lbs.ins with

oiled bearings (measure torque as when

setting pinion shaft, using tool SK-1913).

FIGURE 3

It is essential that the pinion bearing preload

is checked and adjusted if any of the pinion

shaft components are replaced, with the ex-

ception of the locknut and locking ring.

Fitting a longer six gear spacer (14) will de-

crease the pinion bearing

preload, whereas shortening the six gear

spacer (14) will increase the pinion bearing

preload.

SK-1913

PAGE 9

© Copyright Hewland Engineering Limited

CROWNWHEEL & PINION BACKLASH SETTING

Requires special tool No. SK-1913

With the pinion shaft correctly fitted, and the correct diff

bearing shims ascertained, the actual backlash can be

measured by means of a dial test indicator against the

notch in the outside diameter of tool SK-1913. Be sure to

take at least 6 backlash readings, turning the crownwheel

30-45 degrees between each reading (this is to ensure

that any variation due to manufacturing tolerances are

taken account of.

The correct backlash figure should be taken from the

card supplied with the gears. If the measured backlash is

incorrect, rectify it by removing some shims (103) from

behind one diff bearing, and inserting them behind the

other, thus moving the diff across in the maincase. Do

not add or discard any shims at this stage, as to do so

would affect the diff bearing preload.

Once the correct backlash has been achieved, replace the

dummy bearings with bearings (83) and confirm that the

backlash is correct.

Note: Dummy are used so that it is easy to change the shims

during the setting procedures. Before fitting the actual diff

bearings, it is important compare thier width with that of the

dummy bearings and compensate the shims accordingly for any

difference.

FIGURE 4

PAGE 10

© Copyright Hewland Engineering Limited

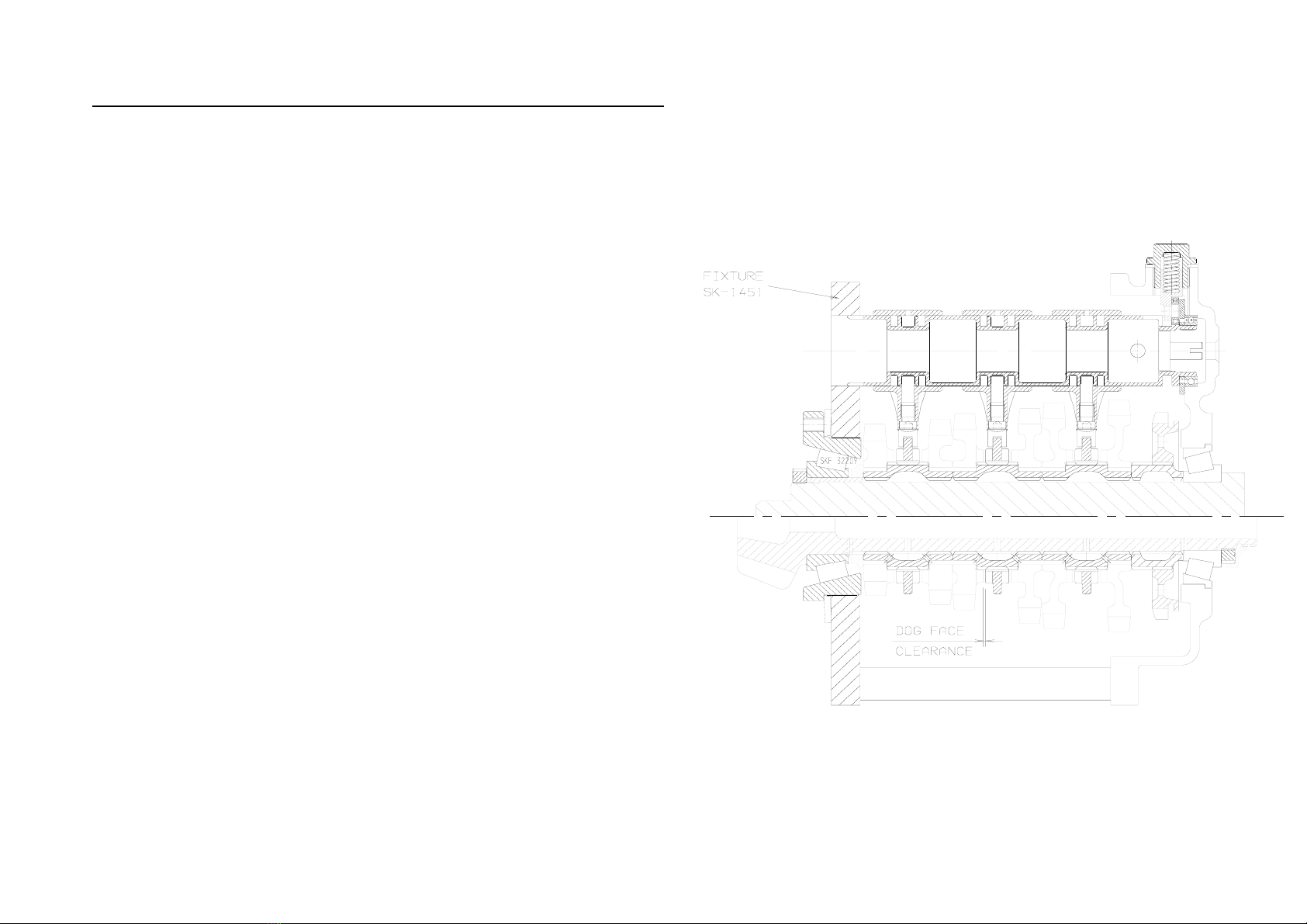

FIGURE 5

SEQUENTIAL BARREL SETTING - Requires special tool No.SK-1451

a/ Assemble the barrel (15), spacer (26), bearing retaining plate (25),

bearing (27), and nut (29). Heat the bearing carrier (2), slide the barrel

assembly into the bearing carrier, and secure using screws (12).

b/ Place the roller (24) onto the detent plunger (21), and insert them into

the bearing carrier (2). Add the detent spring (22), bonded seal (115),

and detent plug (23).

c/ Slide the selector forks (17) over the barrel (15), and secure using

selector pins (18). For final assembly, Loctite the pins (18) into the forks

(17).

d/ Stack the pinion gears (16), hubs (19,20), clutch rings (19) and spacer

(14) in place in the bearing carrier, and slide the whole thing onto the

dummy shaft of fixture SK-1451.

e/ Tighten the pinion shaft nut (111) onto the end of the dummy shaft,

ensuring that the disc spring on the fixture preloads the bearings.

f/ Rotate the barrel to engage first gear. Measure and record the gap

between the dogfaces of third through sixth gears. Engage third gear and

repeat the measurement for first and second dogfaces. It is important

that these dimensions are not taken when the barrel is in the neutral

position.

First, third and fifth gear dog gap measurements will be similar (as will

second, fourth and sixth). Any difference between the odd & even gear

measurements must be corrected by replacing the barrel spacer (26) with

one of the correct thickness.

Note: It is not possible (or necessary) to individually adjust each fork.

PAGE 11

© Copyright Hewland Engineering Limited

GEARBOX - ASSEMBLY

a/ It is assumed that all bearings, oil seals, studs, oil jets, and dowels are already fitted into casing. (see page 5).

b/ Assemble the oil pump components (if required). Heat the maincase, and drop the pump into position. Secure with screws , and add the drive

gear and circlip.

c/ Place the reverse idler gear (104), bearing (106), and thrust washers (107) in position in the bearing carrier, and slide the spigot (105) into

position. Secure with screw (12).

d/ Assemble the selector rack (75), washers (76), spring (77), and circlip (78), and slide into the maincase. Secure with the selector rack stop

(80). Note: Check the gear linkage return spring length regularly (item 77). This spring has a finite life and will weaken with use. A new

spring has a free height of 1.450”. It is also adviseable never to re-use the circlip (78).

e/ Assemble the drum (8), bearing (28), pin (10), retaining plate (11), barrel driver (13), and shifter spindle (7). Assemble the drum shifter (6),

guide plate (9), pawls (64), springs (63), and plungers (62), and slide into engagement with the drum assembly. Push the complete assembly

into it's location in the maincase, ensuring correct location with the selector rack teeth.

f/ Assemble the selector input shaft (70), bearing (68), seal (71), spacer (72), quadrant gear (73) and circlip (112) into their housing (66). Slide

the whole assembly into the maincase, ensuring correct engagement with the selector rack (75).

g/ Build the selector barrel parts into the bearing carrier as described in the section 'Sequential Barrel Setting'.

h/ Fit the pinion shaft as described previously.

i/ Hold the reverse selector fork (31), with reverse pinion gear (121), in position in the bearing carrier (2). Slide the reverse selector shaft (110)

into place and secure with screw (122).

PAGE 12

© Copyright Hewland Engineering Limited

j/ With the bearing carrier face up, add the layshaft (50), input gears (46), spacers (45), disc spring (44), and bearing inner track

(43). Stack the reverse hub (33), hubs (20), pinion gears (16), bearings (120), clutch rings (19), and spacer (14) into position in

the bearing carrier (2), and slide the dummy shaft through from the bearing carrier end.

k/ Locating the tip of the dummy shaft into the end of the pinion shaft, slide the completed gear cluster assembly into the maincase

to engage the pinion shaft and layshaft bearing, allowing the dummy shaft to slide out of the gear cluster. Whilst locating the

gear cluster, lightly operate the selector rack (75) to ensure correct location of the barrel and driver.

Tighten the pinion shaft nut using tool No. SK-1452

l/ Fit the rear cover (36) using nuts (49). and dowels (139).

m/ Fit the clutch spigot bearing (97) and seal (98) into their housing (99) and secure with circlip (101). Slide the housing assembly

onto the clutch shaft (96) and secure with circlip (102). Fit the o'ring seal (100) onto the housing and slide the assembly into the

maincase to engage the layshaft (50). Fix the housing in place using screws (124).

Note : If the oil pump is fitted, the diff assembly must be removed from the maincase to allow the clutch shaft to be fitted (or

removed).

n/ Fit magnetic plug (114) and washer (115) to maincase.

PAGE 13

© Copyright Hewland Engineering Limited

CHANGING GEAR RATIOS

a/ With a drip tray placed beneath the gearbox, remove the drain plug (114) and drain the oil.

b/ Disconnect the reverse gear linkage from the gearbox.

c/ Remove the rear cover (36).

c/ Remove the M8 nuts (48) securing the bearing carrier (2), and slide it out of the maincase, complete with the gear cluster. It may

be necessary to tap lightly on the lugs provided to break the seal. Use a soft hammer for this purpose, never use a screwdriver to

lever between joint faces as this may damage the faces and impair the seal efficiency when reassembled. Take care not to drop

any of the pinion shaft components as they won't be fully supported at this time. The dummy shaft from SK-1451 can be used to

prevent the pinion shaft components from falling by inserting it into the rear end of the pinion shaft and sliding the loose parts

onto it.

d/ Remove the pinion gears (16), hubs (20), and clutch rings (19). Slide the input gears (46), and spacers (45) from the layshaft

(50), then withdraw the layshaft from the bearing carrier.

e/ Replace the gears with the required ratios. Gears are supplied in matched pairs, one for the mainshaft and one for the layshaft.

Each gear is marked with two sets of numbers. The first of these indicates the number of teeth on the layshaft gear, while the

second figure signifies the number of teeth on the mainshaft gear which mates with it. Both gears of each pair are marked in an

identical manner. It is essential that gears are correctly paired to these numbers.

Note: On all first gears, and some second gears, the gear teeth are machined integral with the layshaft. In such cases, therefore, if

a first (or second) gear ratio change is required, the layshaft itself must be changed.

f/ Whilst changing ratios it is advisable, as a matter of course, to wash and inspect all components which are to be used again

before refitting. Check for wear and cracks, particularly to the clutch rings. Also examine the selector forks for heavy or uneven

wear.

g/ Reassembly is the reverse of disassembly. Take care, when refitting the gear cluster into the maincase, to ensure location of the

layshaft into it's bearing, and of the selector barrel (15) it's driver (13). Assembly of the pinion shaft components is made easier

by use of the dummy shaft as described previously. [Some mechanics find assembly easier if the layshaft bearing inner track is

pre-fitted in the casing, rather than onto the end of the layshaft.]

PAGE 14

© Copyright Hewland Engineering Limited

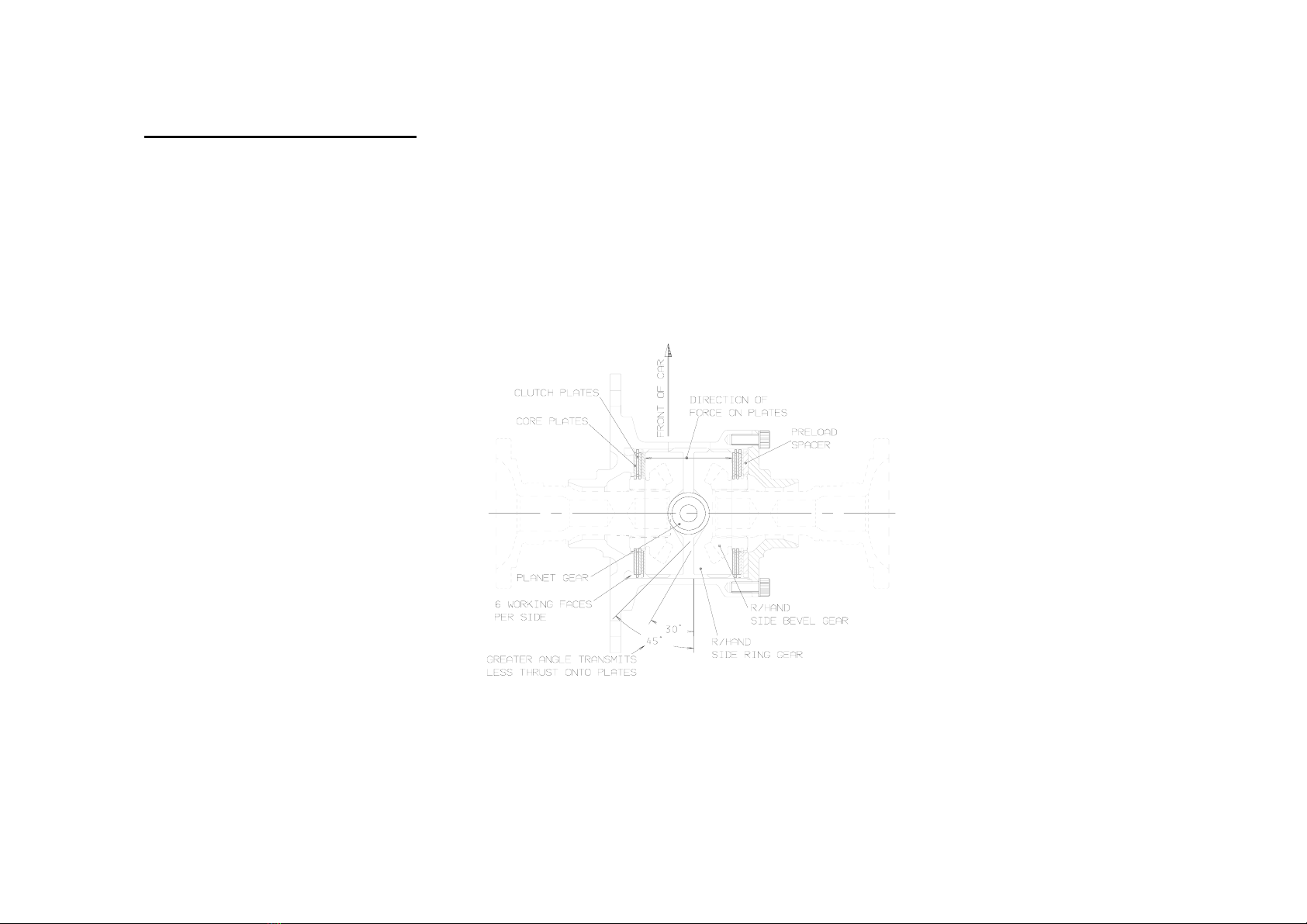

POWERFLOW DIFFERENTIAL

This powerflow differential unit is designed with versatility as it's major asset. Many factors will contribute to the settings required. A car with

good traction and low power, may require a completely different arrangement to that of a car with poor traction and high power.

There are 10 friction plates within the unit (4 (87) splined to the diff casing (57), and 6 (88) splined to the side bevel gears(84). Slip limiting is

dependant on the friction resistance between these plates, and is affected by clamping the plates together.. Four factors contribute to the total

friction torque between the plates :-

3/ The second adjustable factor is

how tightly the plate stack is

compressed on assembly (known

as static preload). Included in the

plate stack is a preload spacer

(89). The preload torque is

measured between the side bevel

gears, by holding one side bevel

gear (84) stationary, and

measuring the torque required to

turn the other using tool SK-____.

When the diff is assembled, the

preload torque must be at least 10

lbs.ft, but can be much greater if

required. New plates ‘run in’ so a

higher preload is advised than

with used plates.

4/ The final adjustment is simply to

re-order the plate stack so as to

change the number of relatively

rotating faces. The diagram shows

the stack setup with the maximum

12 working faces. Standard stack

may be shuffled to give as few as

2 working faces.

1/ The side bevel gears (84) thrust

apart to clamp the plates as they

transmit the driving power. This

is a feature of the gear geometry,

and is not adjustable.

2/ The ramp angles cut on the side

ring gears (85) have an effect on

how much of the transmitted

torque is converted into sideways

(clamping) force onto the plates.

For example, on the drive side

ramp, 45 degrees transmits less

sideways force than 30 degrees.

Likewise on the coast side ramp,

an 80 degree angle will transmit

little or no clamping force onto

the plates, whereas a 45 degree

angle will transmit a much

greater force. Side ring gears

(85) are available with many

different drive/coast ramp angle

combinations.

FIG URE 6

PAGE 15

© Copyright Hewland Engineering Limited

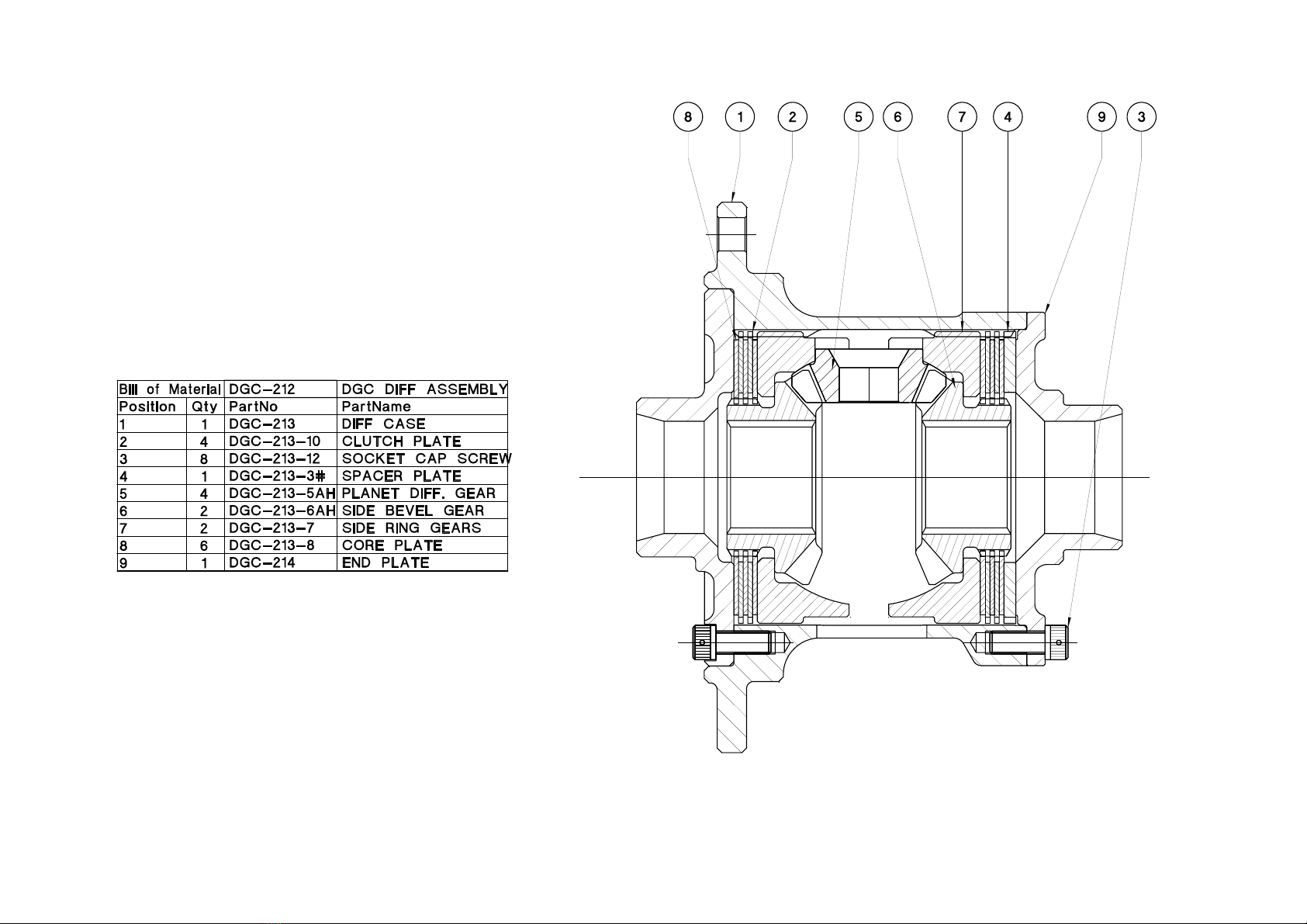

FIGURE 7

DGC-212 Diff Assembly (superseded March 2010)

PAGE 16

© Copyright Hewland Engineering Limited

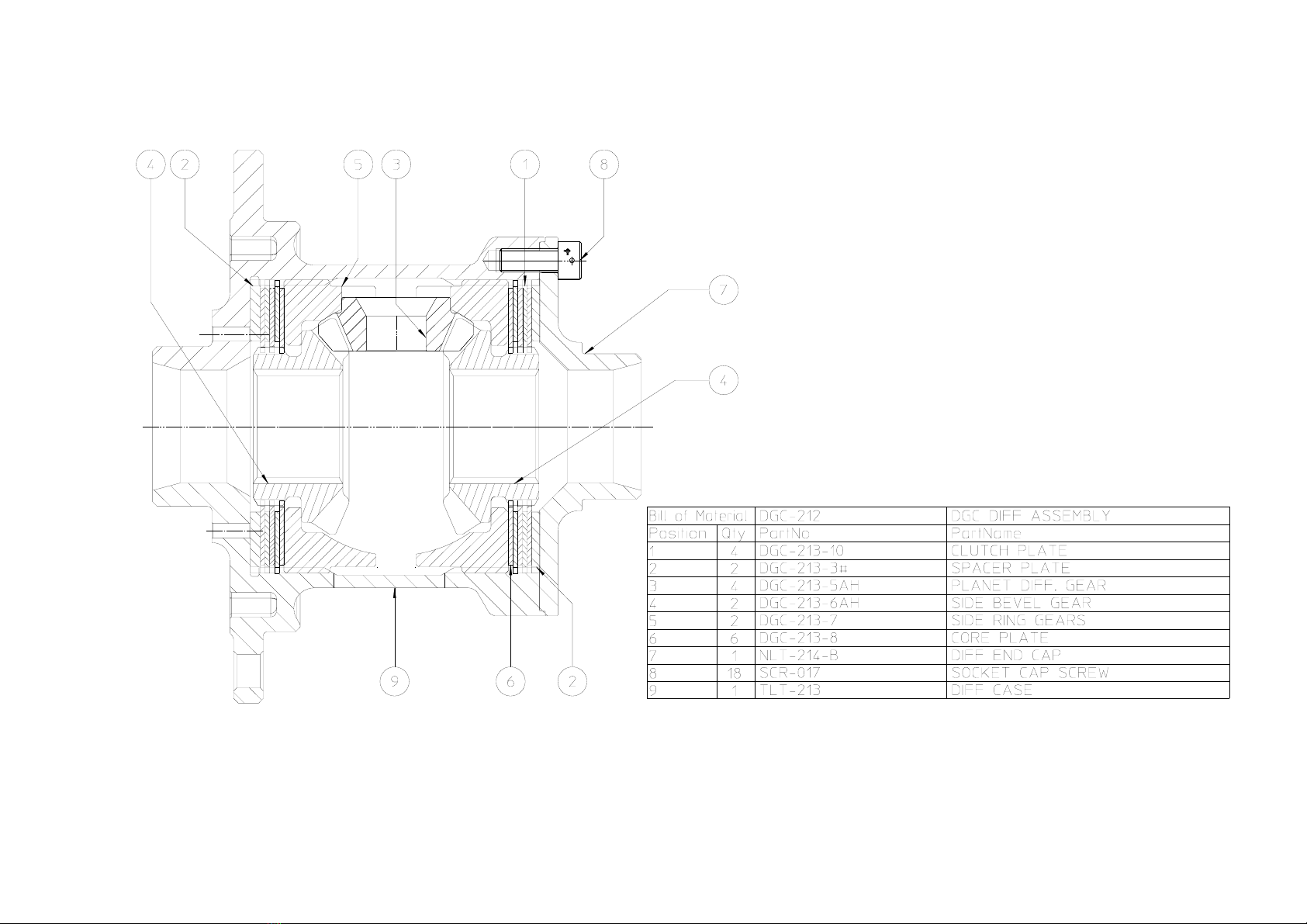

DGC-212 Diff Assembly (March 2010 onwards)

FIGURE 7a

PAGE 17

© Copyright Hewland Engineering Limited

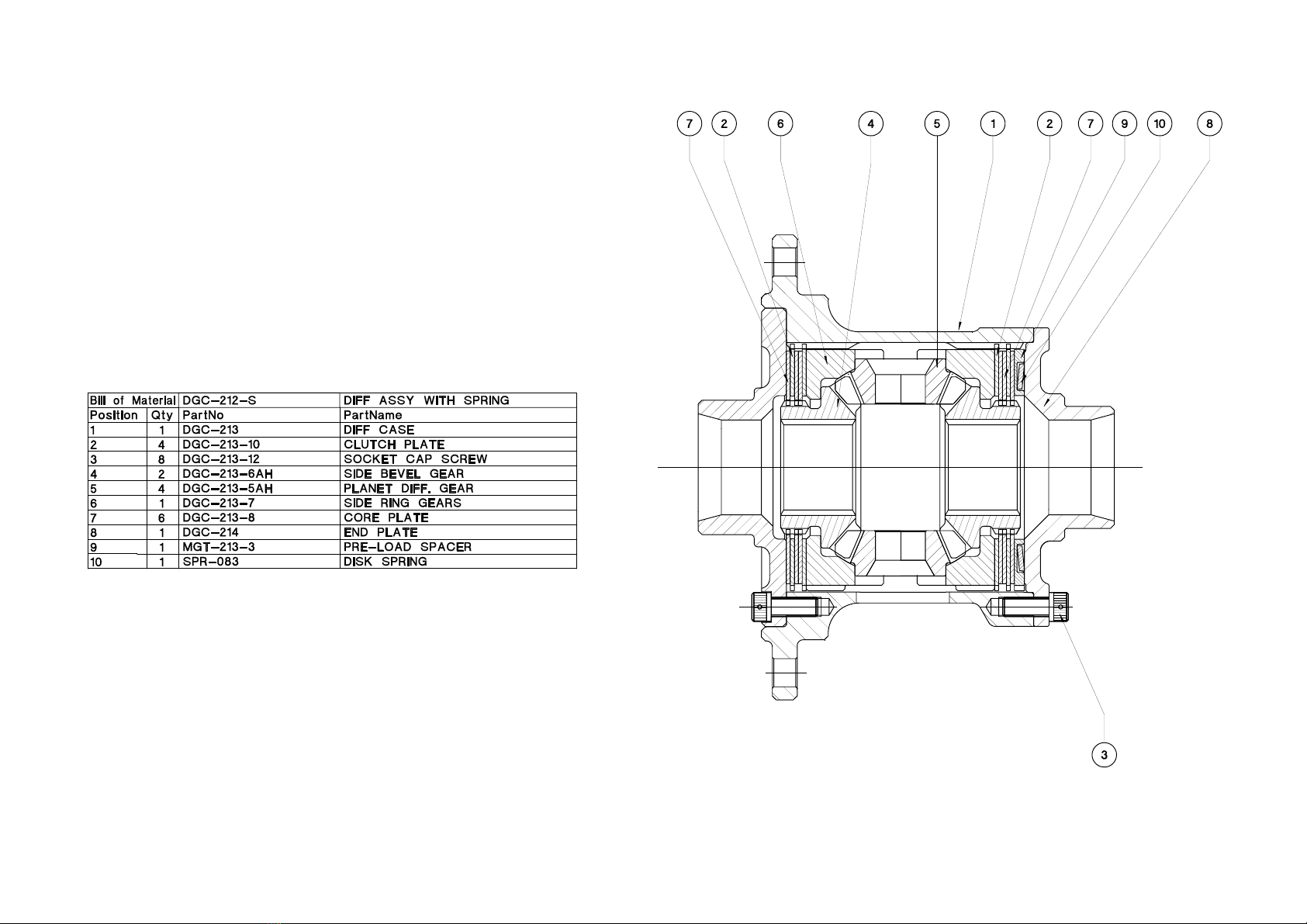

FIGURE 8

DGC-212-S Diff Assembly (superseded March 2010)

PAGE 18

© Copyright Hewland Engineering Limited

DGC-212-S Diff Assembly (March 2010 onwards)

FIGURE 8a

PAGE 19

© Copyright Hewland Engineering Limited

TPT-212 Diff Assembly

FIGURE 9

PAGE 20

© Copyright Hewland Engineering Limited

IN ORDER TO FIT THE NLT DIFFERNETIAL

IN THE NMT BOX, THE NLT SIDE PLATE

(NLT-205) WILL NEED TO BE FITTED

FIGURE 10

NLT-212 Diff Assembly (superseded March 2009)

This differential was superseded

by the differential shown on the

next page.

Table of contents