3

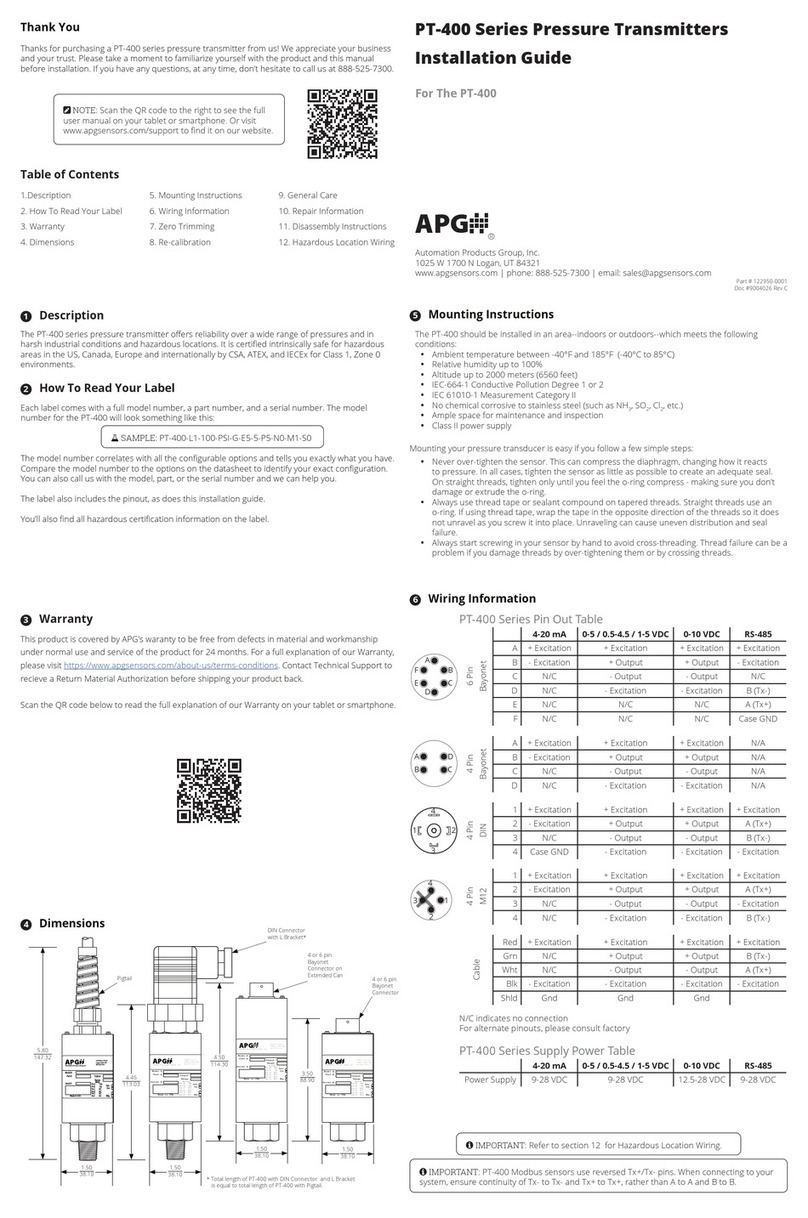

• Model Number Congurator

Model Number: PT-400 - _____ - _____ - _____ - _____ - _____ - _____ - _____ - _____ - _____ - _____

A B C D E F G H I J

A. Operation / Output

□L1▲4 - 20 mA output

□L3 0 - 5 VDC output

□L10 0 - 10 VDC output

Modbus

□L5 RS-485 (Modbus/RTU), 4-wire

Pressure reading only

(Approvals Pending)

□L31 RS-485 (Modbus/RTU), 4-wire

Level calculations, tank volume

(Approvals Pending)

B. Common Pressure Ranges - PSI*

□5 □50 □200 □1000 □5000

□15 □60 □300 □2000 □10000

□30 □100 □500 □3000 □30000

*Other ranges available. Please consult factory.

C. Units of Measure

□psi▲□bar □kPa □inH2O□inWC

□fH2O□fWC □mmH2O□inHG

D. Pressure Type

□A Absolute ( ≤ 200 psi)

□S▲ Sealed (200 psi - 30,000 psi)

□G Gauge ( ≤ 1,000 psi)

□CG Compound Gauge ( ≤ 15 psi)

□V VAC

E. Electrical Connection

(Mating connector sold separately)

□E3 4 pin bayonet (PT 1H-8-4P or equiv.)

□E4 4 pin M12 micro connector.

□E5▲ Pigtail with cable (specify cable length below)

□E6 4 pin per DIN 43650, short can

(mating connector included)

□E17 6 pin bayonet (PT02E-10-6P)

□E19 1/2 in NPTM with cable, short can

□E36 1/2 in NPTM with 6 in ying leads, long can

□E40 3 pin bayonet

□E41 Blue Junction Box

□E45 4 pin minifast Turck

▲This option is standard

F. Electrical Cable Length

□__ Number represents cable length, in 5-ft increments,

included on E5 and E19 options.

(ex. E5-10 equals pigtail, 10 ft cable)

G. Process Connection

□P0▲ 1/4 - 18 NPTM ( ≤ 10,000 psi)

□P1 1/2 - 14 NPTM ( ≤ 10,000 psi)

□P5 1/4 - 18 NPTF ( ≤ 15,000 psi)

□P6 1/2 NPTF ( ≤ 10,000 psi)

□P38 1 1/2 in. tri-clover with 3/4 in. diaphragm ( ≤ 1,000 psi)

□P52 1 1/2 in. NPTM ( ≤ 1,000 psi)

□P54 7/16 - 20 UNJF-3A Male w/ Cone ( ≤ 1,000 psi)

□P56 F250C High Pressure (10,000 psi - 30,000 psi)

□P57 F560C40 High Pressure (10,000 psi - 30,000 psi)

H. Accuracy

1-5,000 PSI

□N0*▲±0.25% (1% for pressure ≤ 1 psi)

□N1* ±0.25% with NIST certication

□N2 ±0.1% with NIST certication

*Note: ±0.25% available at 10,000 psi for 4-20 mA output only.

10,000 PSI

□N12 ±0.5%

□N13 ±0.5% with NIST certication

I. Materials

□M1▲316L SS ( ≤ 1,000 psi)

□M2 17-4 SS ( > 1000 psi)

□M7 Incoloy (10,000 psi - 30,000 psi; P56/P57 only)

J. Temperature

□S0▲Standard: 0º - 130ºF (-17º - 54ºC)

□S1 Extended: -40º - 180ºF (-40º - 82ºC) ( ≥ 1,000 psi)

□S2 Extended: -40º - 250ºF (-40º - 121ºC) ( ≥ 1,000 psi)

□S3 Extended: -30º - 170ºF (-34º - 77ºC) ( ≥ 1,000 psi)

□S4 Extended: 0º - 185ºF (-17º - 85ºC)