hexinverter mutant User manual

Mutant Bassdrum

7.2.2014 Mutant Bassdrum assembly tips v1.05 PG1

hexinverter.net electronics, 2014

eurorack analogue bassdrum DIY assembly tips v1.05 hexinverter.net

This guide should help you on the quest to build yourself a hexinverter Mutant Bassdrum eurorack module

from a PCB/faceplate set. It is not a full blown step-by-step guide like with hexinverter full kit products and

assumes you have successfully built some easier projects before from full kits (such as Orbitals, Galilean

Moons, etc.)

FINDING PARTS

As with all hexinverter DIY projects, you should NOT blindly trust the Mouser Project Cart provided. It is

meant to save you the pain of searching for every common part on Mouser, but, that doesn’t mean you don’t

still have to go through the BoM line by line and make sure you’ve sourced each part for your build! I promise

you will not be happy if you blindly order the cart, expecting to receive 100% of the components you need for

the build –you cannot acquire all the pieces you need from Mouser alone! So make sure to read the Google

Docs hosted bill of materials for the project. I suggest printing it out and checking each item off line by line

to make sure you’ve accounted for it in your parts orders. I list sources in the BoM when available and even

provide handy comments to help you find parts easier. And if you can’t find something, pop by the

Muffwiggler Music Tech DIY Forum thread for the project and someone (perhaps myself) will help you out

there so others can benefit from the answer to your problem as well.

STEP 1: Board-level components

7.2.2014 Mutant Bassdrum assembly tips v1.05 PG2

hexinverter.net electronics, 2014

Let’s get started! I recommend stuffing all the PCBs with everything except the control surface components

and headers that connect the boards together. Once all the board level stuff (resistors, capacitors, ICs, etc.)

are installed, we’ll do the parts that stick through the panel (pots, switches, jacks, LEDs, etc).

Stuff the two PCBs with their components from shortest to tallest standing off the circuit boards. That’s so

you can flip the board over for soldering and the parts will hold themselves in. I recommend something like

this order…

1. Diodes

2. Resistors

3. IC Sockets

4. Small Capacitors

5. Vactrols (polarity sensitive! be careful)

6. Power header/large capacitors

STEP 2: Assemble the PCB stack

Once all the small parts are soldered into the board and you’re certain you haven’t made any mistakes, I

recommend putting the PCB stack together with the headers. Don’t solder anything until you’re certain that

the headers are all correct and your stack matches the way it is supposed to be assembled. I like to put the

boards together with the headers fitted but not soldered. I then tack one leg of each header so I can adjust

them until it all sits straight before soldering all the pins. Only once I know for sure everything is lined up

right do I solder all the pins of the headers. If you’re having trouble, installing the screws/standoffs to hold

the stack together will help hold it all in place while you solder.

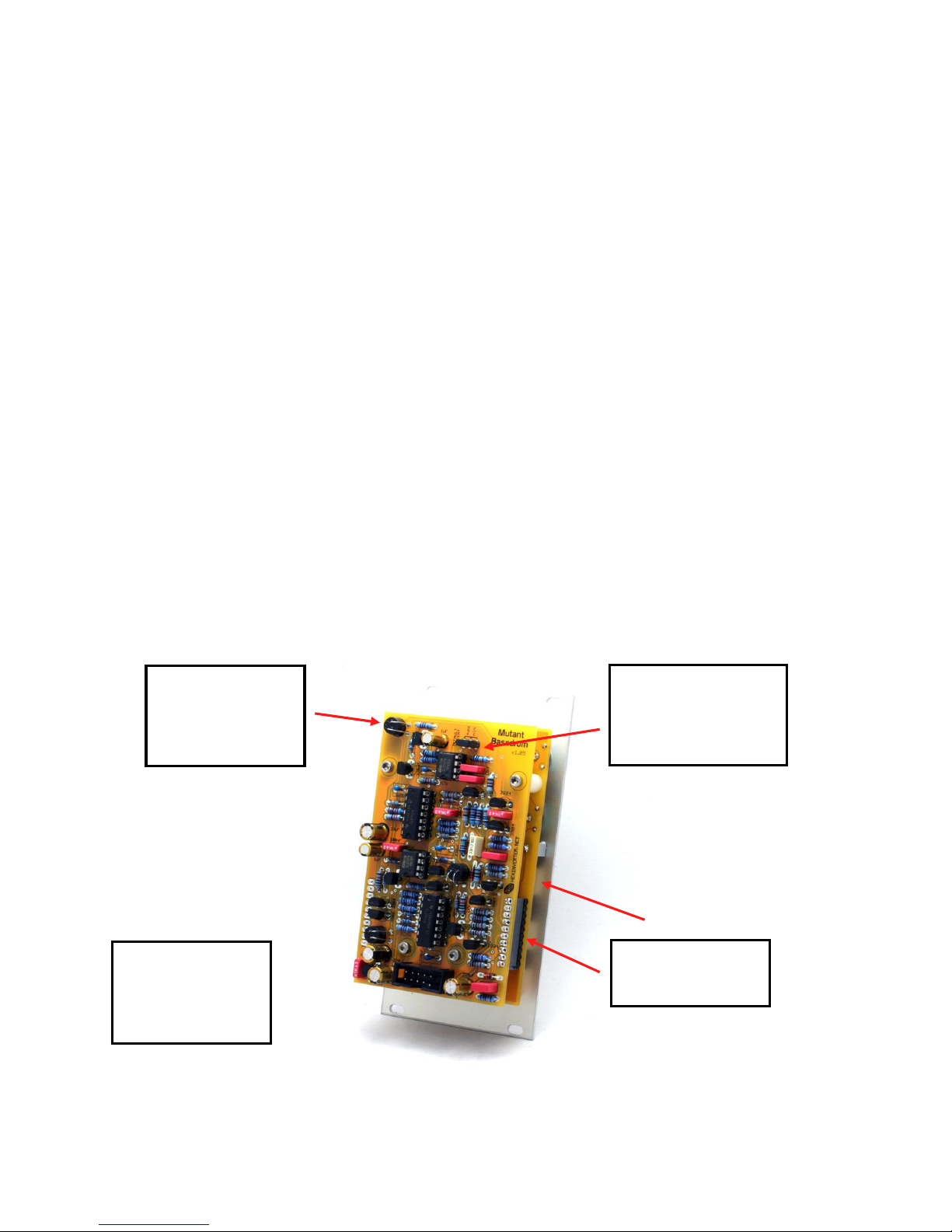

There are only two

10pin header pairs to

install on this build

The bottom header is

stacked only one PCB

layer deep –it lies

between the top and

middle PCB

This jumper selects the

DEFAULT ACCENT level. It

must be jumpered one way

or the other or the module

won’t work at all!

Make sure to install the

vactrols the right way

by lining up their dot

with the shaded area on

the PCB legend!

7.2.2014 Mutant Bassdrum assembly tips v1.05 PG3

hexinverter.net electronics, 2014

STEP 3: Control surface assembly

Putting together the control surface is arguably the most challenging part of this project so I recommend

taking your time. If you have been working for awhile, put down the soldering iron and go take a break and

clear your mind. I recommend this order of assembly:

1. Take the control PCB off of the PCB stack in order to work on it alone

2. Cut the little metal tab off each potentiometer (this depends on the type of pot you use)

3. Put everything loosely in place on the control PCB (don’t solder yet)

4. Place some washers/spacers on the pots to match the panel height

5. Remove the protective film on the panel and place it on the components

6. Finger tighten all of the nuts onto the panel. The jacks should be flat against the panel so they raise

off the PCB a bit.

7. Solder one leg of each pot and then reheat, pushing the pots flat against the PCB

8. Solder one leg of each jack and then reheat, pushing the jack flat against the panel

9. Solder one leg of each part and reheat, adjusting them to their final position on the panel

10. Once you are happy with the position of everything, solder everything!

11. Take a piece of component leg and use it to make a ground lead for each of the 3.5mm jacks.

Solder them in place.

The 3.5mm jacks should be

raised off of the PCB

surface a bit

I used a washer or two on

each pot to help match the

height of everything else

DON’T FORGET TO MAKE

THE GROUND LEADS

FOR THE JACKS!

This LED isn’t part of the

panel components so

instead it sits on the PCB. It

should be the same as the

purple DIST indicator LED

on the panel, but I’ve used

a different colour (clear)

here instead of purple since

it’s what I had laying

around.

Lay the tall electrolytic

capacitors on their sides,

otherwise they won’t fit

under the panel!

7.2.2014 Mutant Bassdrum assembly tips v1.05 PG4

hexinverter.net electronics, 2014

STEP 4: Test, then put it all together

I recommend testing the module before putting it all together. It takes awhile to take everything apart so you

want to correct any mistakes now before finalizing the whole build by putting on knobs and screwing the

PCB stack together. Plug the top PCB into the control PCB for testing but don’t install the screws and

spacers yet. You should be able to test everything with it just loosely assembled.

Once you’re confident everything works properly, assemble the PCB stack with the screws and spacers. Then

install the panel onto the PCB stack and tighten down all the control surface parts! This is what the finished

product looks like…

This screw adjusts the

maximum decay amount

the control/CV input adjust

to. See the USER MANUAL

for more information!