INSTRUCTION MANUAL:

Model Series: MHP100 –MHP1000 inclusive

Hi-Force Limited –Prospect Way –Daventry –Northants NN11 8PL –United Kingdom

Tel: +44(0) 1327 301000: Fax: +44(0) 1327 706555: Website: www.hi-force.com

The operating lever must be stationary during

any pressure changeover.

Ensure fluid level in the reservoir does not drop

below minimum operating level. Air may be

pumped into the system if this occurs. Never

jerk the handle during use as this makes the

pump inefficient and can cause unexpected

pressure range change over. A smooth steady

action gives best results.

Each pump is fitted with an adjustable pressure

relief valve. This valve is set at the factory to the

maximum working pressure of the pump model

specified. This valve can be customer adjusted

to any desired pressure within the rating of the

pump. Details for the method of adjustment for

this valve are available on request.

2. Pressure is released by turning the Pressure

Release Valve anti-clockwise.

3. Never stand in a direct line with the

application of force or allow personnel under

loads that are not securely supported by

mechanical means.

After Operation:

1. Fully return hydraulic fluid to pump. Check

hydraulic fluid level in reservoir to prevent over

filling of the tank.

2. Keep hydraulic fluid clean. Change as

necessary and frequently if using water.

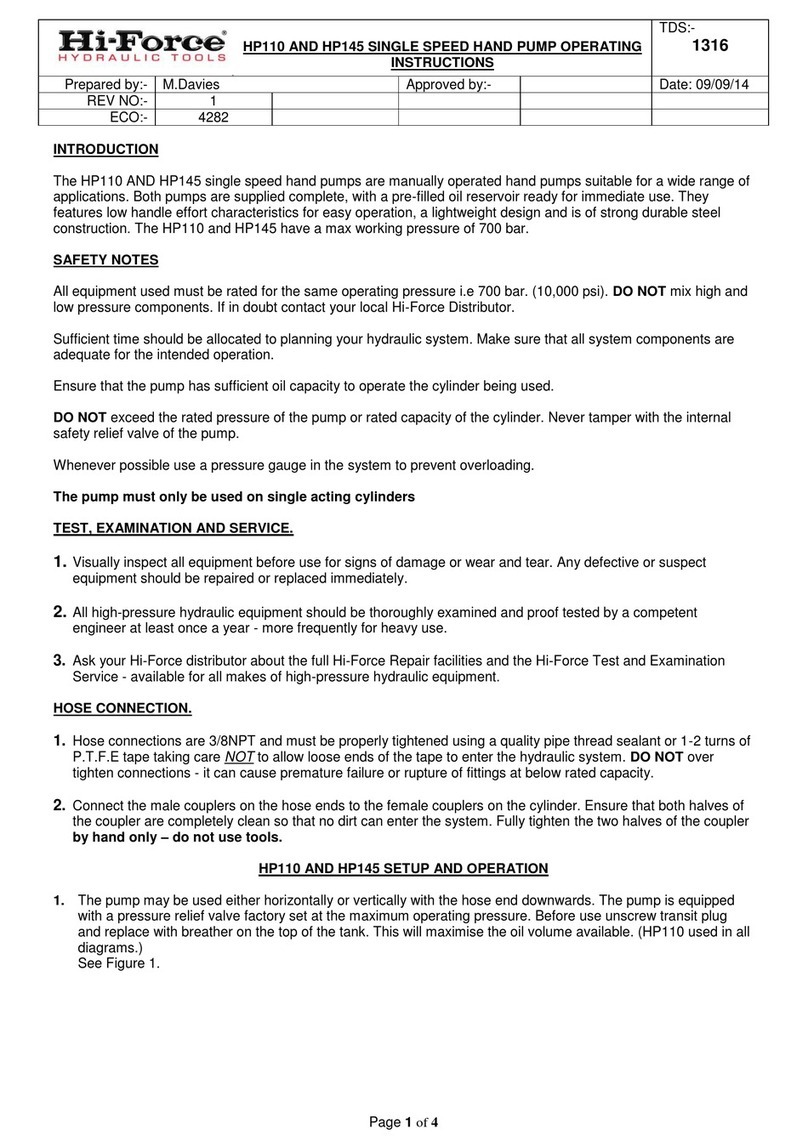

3. After heavy use, it may be necessary to

clean the filter. Before removing the filter

element from the pump, ensure that the system

is depressurised. Unscrew the filter retainer

screw shown on the pump diagram above.

Remove the filter, clean and replace.

4. It is advisable that if the system has been

used on water and the unit is to be stored for a

period of time, that the system is drained and

the pump unit flushed through prior to storage.

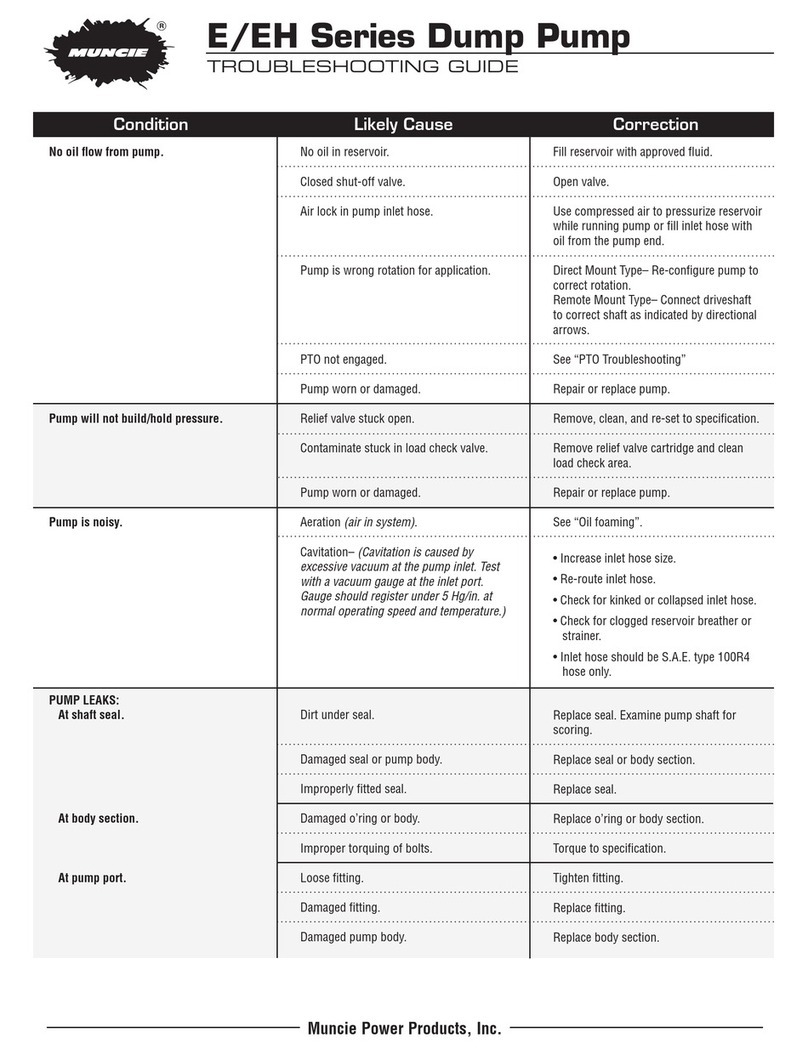

Troubleshooting:

No delivery:

Pump handle when operated does not

operate plunger. Incorrect assembly.

Suction valves not sealing. Remove

contaminant or replace the seals.

Relief valve seal sticking or

contaminant not enabling it to seal.

Seal failure on delivery valve

Handle drops on its own:

Suction ball is not sealing completely.

With the release valve open pump fluid

around the pump, this may dislodge

the dirt. Failing this, remove and

clean/replace both high and low

pressure suction balls

Handle rises when left:

Delivery valve is not sealing correctly.

With the release valve open pump fluid

around the pump, this may dislodge

the dirt. If this does not work remove

the optional pressure gauge if fitted or

the bolt which is in the outlet port on

the top of the pump, remove outlet

seal spacer, spring and outlet seal.

Inspect o-ring on seal and replace if

damaged. Also check the sealing face

on the pump body for damage or dirt.

Trapped air in the pump

Air in the pump will cause loss of

effective pumping stroke and will also

permit high pressure to be raised even

when the pressure selection button is in

the low pressure position.

Some possible areas where air is being

drawn into the pump are:-

1. Release valve joint washer

2. Release valve spindle seal

3. The suction pipe connection

4. Low/High Pressure changeover

valve

Under normal circumstances should any of the

above cause air to be drawn into the pump

unit it will be visible by the leakage of the fluid

medium from that area.

Service & Maintenance:

Only genuine Hi-Force spare parts should be

used in the repair or servicing of these units.

We recommend that any servicing or repair of

this equipment is only carried out by an

authorised Hi-Force repair centre.